Pumped vacuum system and die casting method of magnesium alloy vacuum high-pressure die casting mould

A vacuum system and die-casting mold technology, which is applied to the vacuum system of the mold and its die-casting field, can solve problems such as ineffective design of the vacuum system and influence on the method of die-casting products, and achieve improved metal utilization, good economy, and smooth surface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

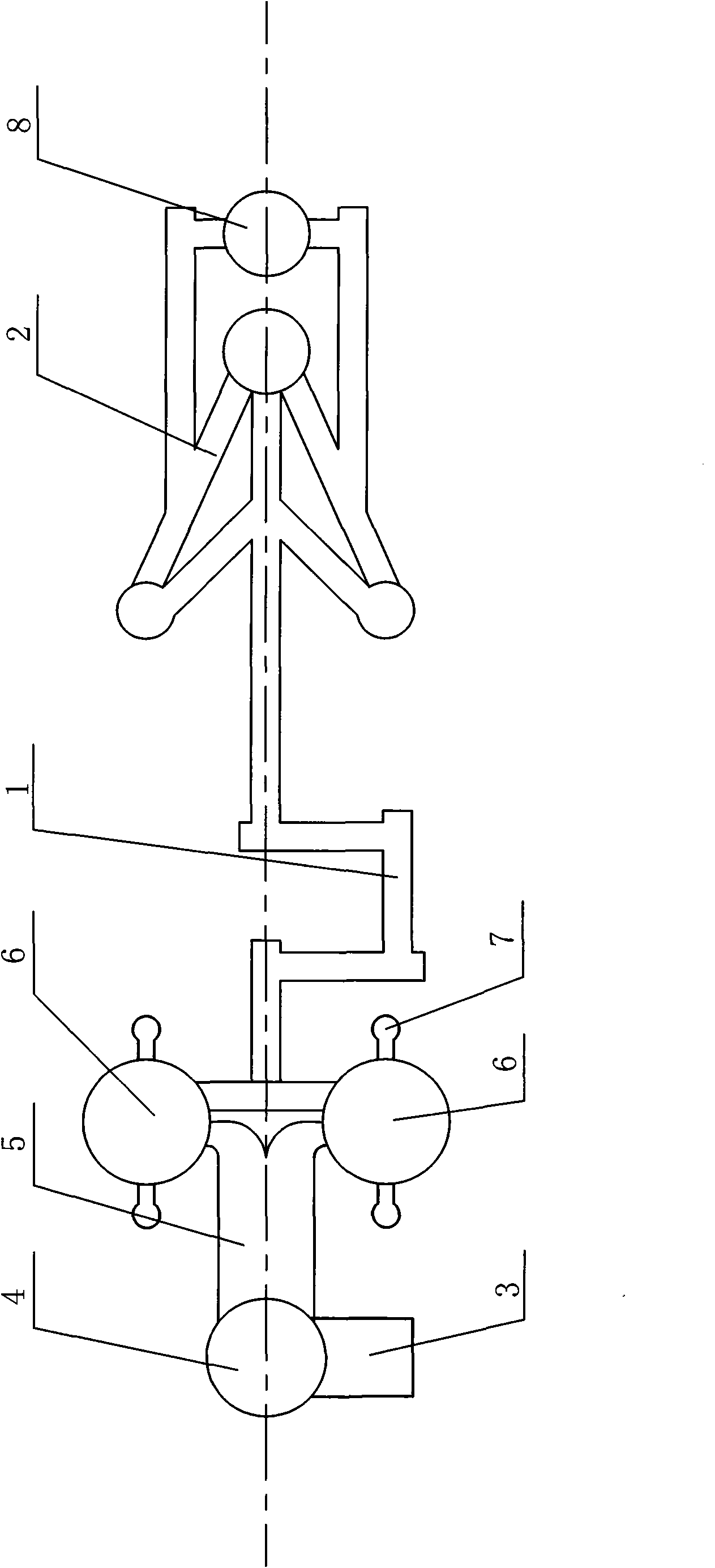

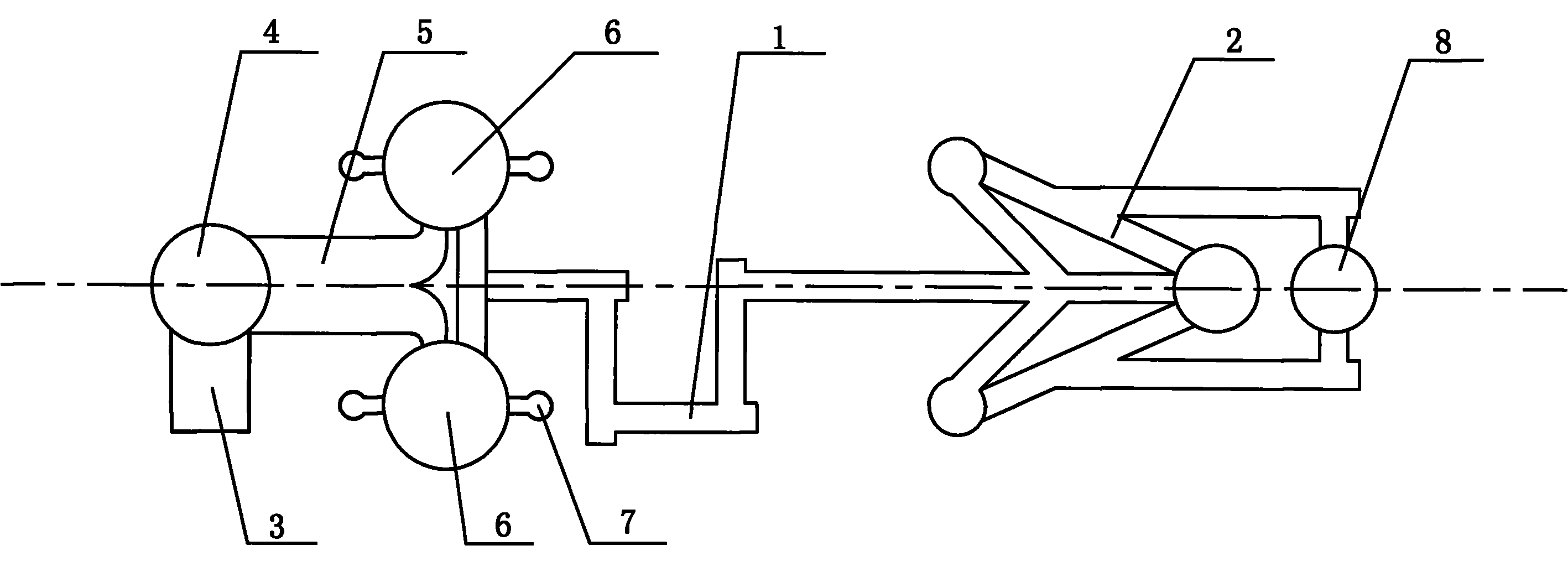

[0025] Magnesium alloy vacuum high-pressure die-casting mold vacuum system, which consists of: a gating system, the gating system is connected to the labyrinth system 2 through the exhaust pipe 1, the gating system includes a pressure chamber 3, and the pressure chamber is connected to the direct pouring system. Road 4, the sprue is connected to the runner 5, the runner is connected to the ingate 6, the ingate is connected to the exhaust pipe, and the ingate includes an overflow System 7, the labyrinth system is connected with vacuum valve 8.

[0026] In the vacuum pumping system for magnesium alloy vacuum high-pressure die-casting molds, the pressure chamber is cylindrical, with an inner diameter of 50mm and a thickness of 10mm.

[0027] In the magnesium alloy vacuum high-pressure die-casting mold vacuum system, the sprue is an equal-width channel with a width of 25-50mm and a thickness of 10mm.

[0028] In the magnesium alloy vacuum high pressure die casting mold vacuum sys...

Embodiment 2

[0032] Magnesium alloy vacuum high-pressure die-casting mold vacuum system, which consists of: a gating system, the gating system is connected to the labyrinth system 2 through the exhaust pipe 1, the gating system includes a pressure chamber 3, and the pressure chamber is connected to the direct pouring system. Road 4, the sprue is connected to the runner 5, the runner is connected to the ingate 6, the ingate is connected to the exhaust pipe, and the ingate includes an overflow System 7, the labyrinth system is connected with vacuum valve 8.

[0033] In the vacuum pumping system for magnesium alloy vacuum high-pressure die-casting molds, the pressure chamber is cylindrical, with an inner diameter of 100 mm and a thickness of 10 mm.

[0034] In the magnesium alloy vacuum high-pressure die-casting mold vacuum system, the sprue is an equal-width channel with a width of 50mm and a thickness of 1.6mm.

[0035] In the magnesium alloy vacuum high-pressure die-casting mold vacuuming...

Embodiment 3

[0039] Magnesium alloy vacuum high-pressure die-casting mold vacuum system, which consists of: a gating system, the gating system is connected to the labyrinth system 2 through the exhaust pipe 1, the gating system includes a pressure chamber 3, and the pressure chamber is connected to the direct pouring system. Road 4, the sprue is connected to the runner 5, the runner is connected to the ingate 6, the ingate is connected to the exhaust pipe, and the ingate includes an overflow System 7, the labyrinth system is connected with vacuum valve 8.

[0040] In the magnesium alloy vacuum high-pressure die-casting mold vacuum system, the pressure chamber is cylindrical, with an inner diameter of 60mm or 70mm or 80mm or 90mm, and a thickness of 10mm.

[0041] In the magnesium alloy vacuum high-pressure die-casting mold vacuum system, the sprue is rectangular, its inner diameter is 30mm or 35mm or 40mm, and its thickness is 9mm or 8mm or 7mm or 6mm or 2mm.

[0042] In the vacuum pumpin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com