Sponge loaded type organic solvent absorbent and preparation method thereof

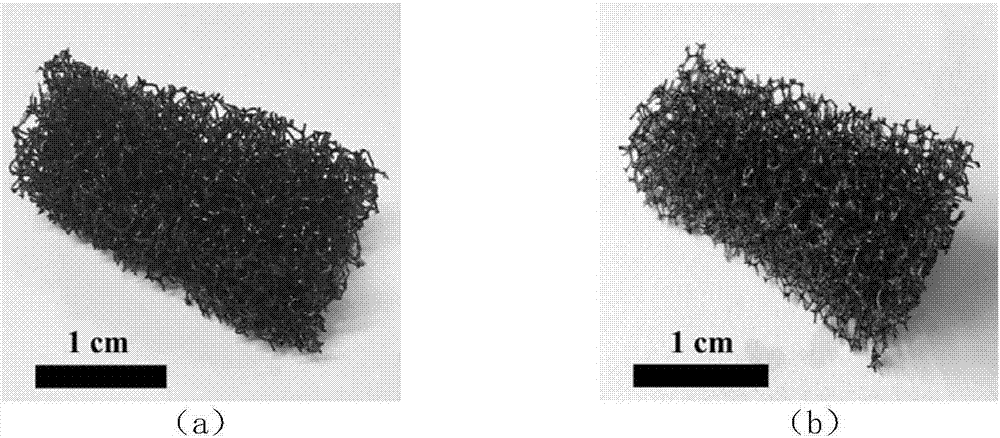

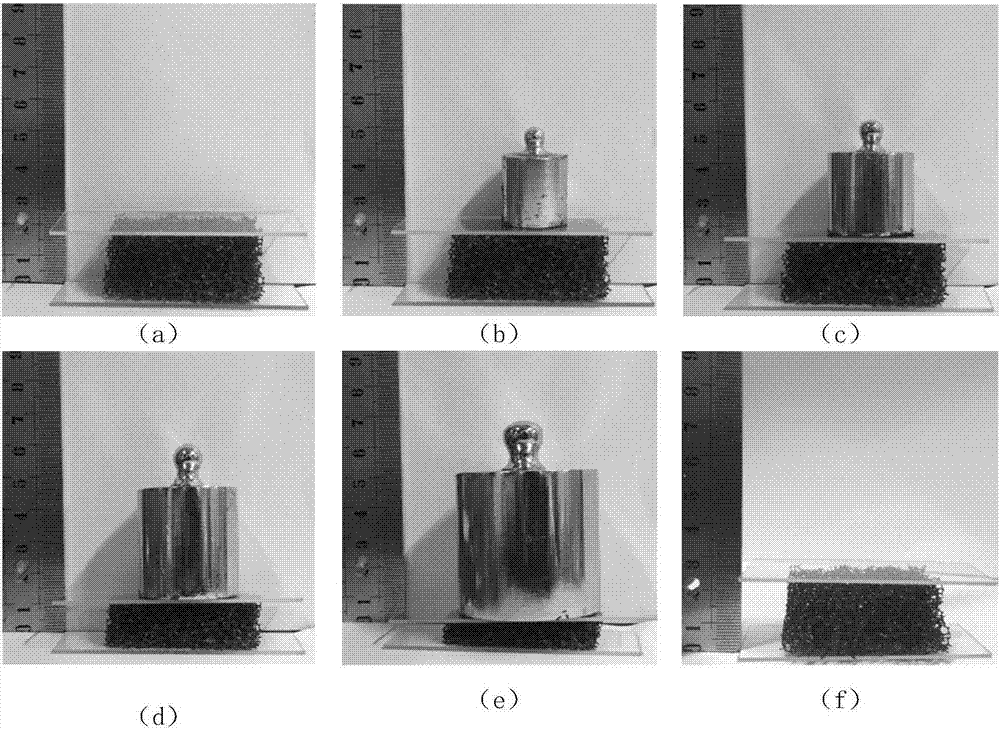

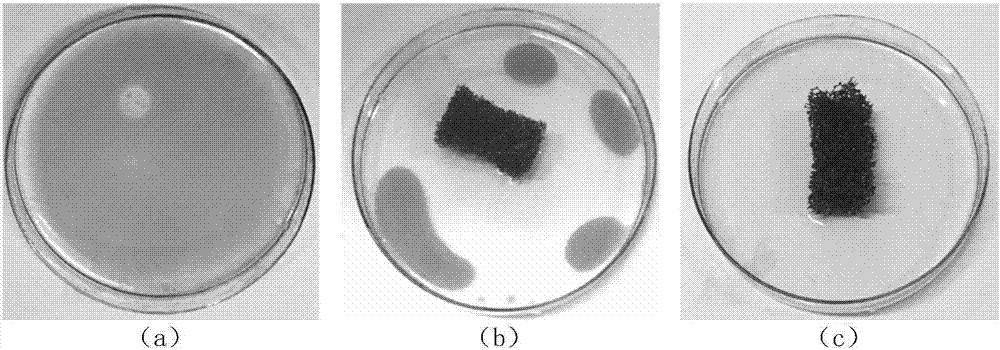

A technology of organic solvents and absorbents, applied in the field of environmental pollution control, sponge-loaded organic solvent absorbents and its preparation, can solve problems such as swelling and deformation, unfavorable filling and use, and easy breakage, and achieve low penetration resistance and industrial applicability Good, unbreakable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A preparation method of sponge-loaded organic solvent absorbent:

[0037] Put 1.5g of polyurethane sponge, 10g of hexamethylene diisocyanate and 100mL of toluene into a three-necked flask, react at 70°C for 1 hour, wash with toluene repeatedly three times, and filter with suction to obtain an activated sponge, then put the activated sponge, 10mL of hexadiene Add amine and 100mL toluene into a three-necked flask, react at 45°C for 24h, wash with toluene repeatedly three times, filter with suction, and dry in vacuum to obtain a modified sponge;

[0038]The compound emulsifier composed of 0.45g sodium lauryl sulfate and 0.15g octylphenol polyoxyethylene ether is ultrasonically dissolved in 5g distilled water, and the emulsifier aqueous solution is mixed with 3.6g styrene, 9.6g butyl acrylate, 1.5g Methyl methacrylate, 0.15 g of acrylic acid, 0.15 g of glycidyl methacrylate and 0.12 g of dimethyl glycol acrylate were ultrasonically emulsified in an ultrasonic cleaner to obt...

Embodiment 2

[0041] A kind of preparation method of sponge-loaded organic solvent absorbent

[0042] Add 3g of polyurethane sponge, 15g of diphenylmethane diisocyanate and 100mL of toluene into a three-necked flask, react at 80°C for 0.5h, wash with toluene repeatedly for three times, and filter with suction to obtain an activated sponge, then add the activated sponge, 15mL of hexadiene Add amine and 100mL toluene into a three-necked flask, react at 45°C for 18h, wash with toluene repeatedly three times, filter with suction, and dry in vacuum to obtain a modified sponge;

[0043] The compound emulsifier composed of 0.3g sodium dodecylsulfonate and 0.15g octylphenol polyoxyethylene ether was ultrasonically dissolved in 6.7g distilled water, and the emulsifier aqueous solution was mixed with 4.8g styrene, 12.8g butyl acrylate, 2g of lauryl methacrylate, 0.3g of glycidyl methacrylate and 0.16g of dimethyl glycol acrylate were ultrasonically emulsified in an ultrasonic cleaner to obtain a unif...

Embodiment 3

[0045] A kind of preparation method of sponge-loaded organic solvent absorbent

[0046] Add 2g of polyurethane sponge, 12g of diphenylmethane diisocyanate and 100mL of toluene into a three-necked flask, react at 60°C for 2h, wash with toluene repeatedly three times, and filter with suction to obtain an activated sponge, then add the activated sponge, 5mL of hexamethylenediamine and 100mL of toluene were added to a three-necked flask, reacted at 40°C for 36h, washed repeatedly with toluene three times, filtered with suction, and dried in vacuum to obtain a modified sponge;

[0047] The compound emulsifier composed of 0.15g sodium lauryl sulfate and 0.15g octylphenol polyoxyethylene ether is ultrasonically dissolved in 3.3g distilled water, and the emulsifier aqueous solution is mixed with 2.4g styrene, 6.4g butyl acrylate, 1g Lauryl methacrylate, 0.1 g acrylic acid, 0.1 g allyl glycidyl ether and 0.08 g divinyl benzene were ultrasonically emulsified in an ultrasonic cleaner to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com