Lithium ion battery negative electrode MOF material and application thereof

A lithium-ion battery, MOF technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, circuits, etc., can solve the problem of low capacity, achieve high lithium storage capacity, increase diffusion rate, and good solvent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

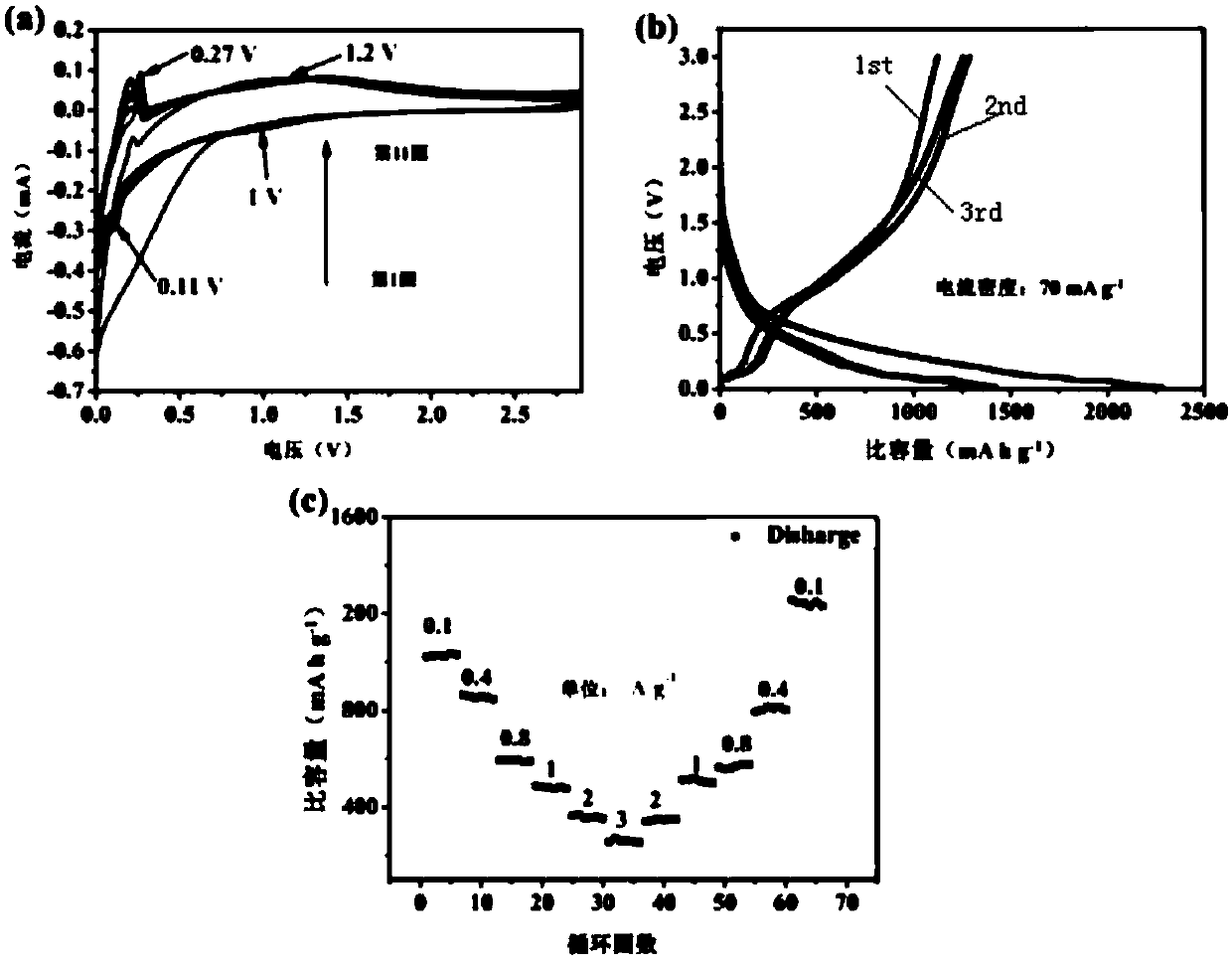

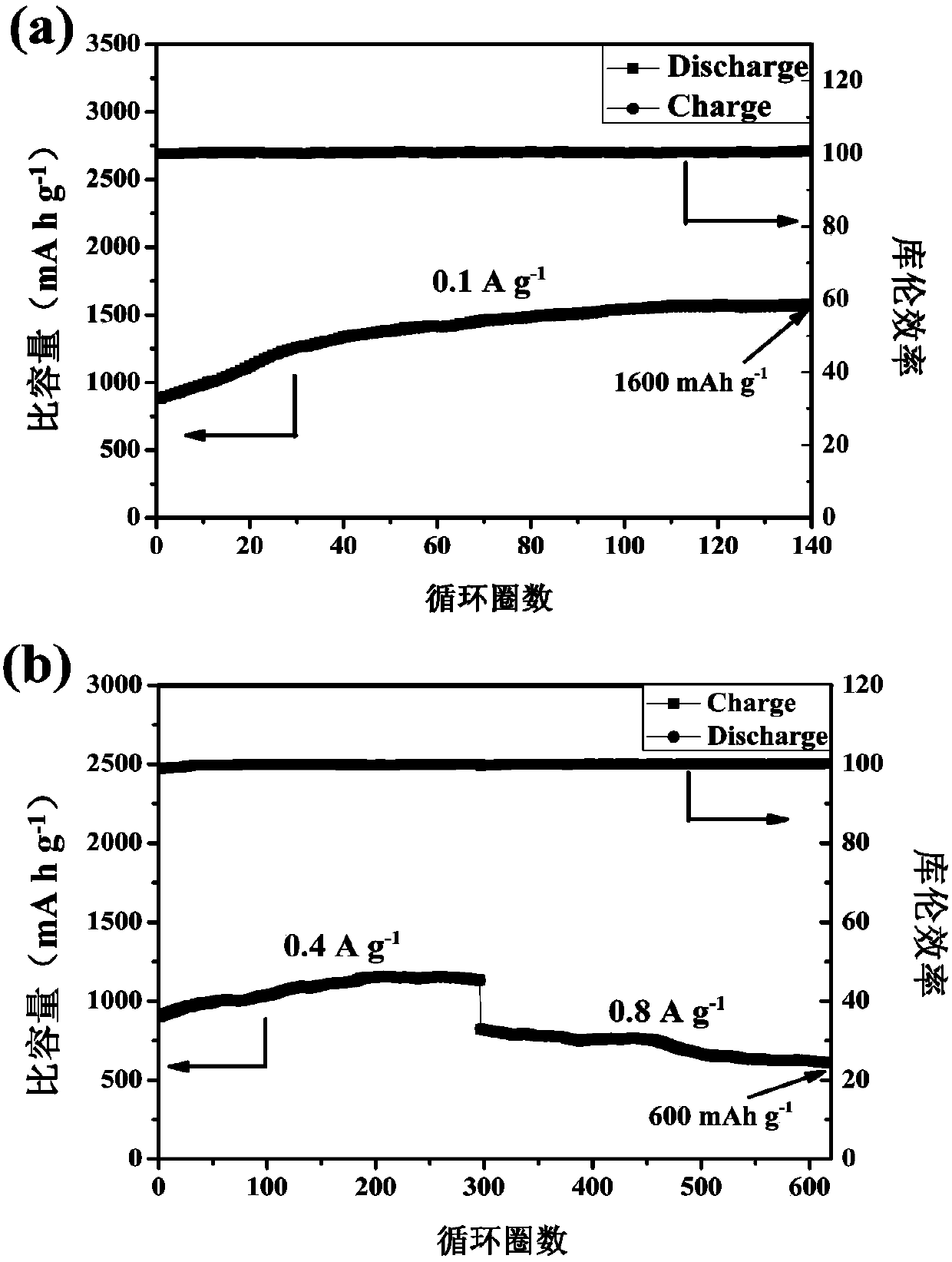

Examples

Embodiment 1

[0023] The specific steps for the preparation of PCN-600(Fe) lithium battery negative electrode material are:

[0024] (1) Synthesis of PCN-600(Fe):

[0025] a: [Fe 3 O(OOCCH 3 ) 6 OH]2H 2 For the synthesis of O clusters, 8 g of ferric nitrate nonahydrate and 11 g of sodium acetate trihydrate were dissolved in 9 ml of deionized water, stirred overnight at room temperature, the obtained precipitate was filtered and washed once with cold deionized water, and dried at 100 ° C. The product was obtained by recrystallization at 150°C in N,N-dimethylformamide;

[0026] b: Synthesis of PCN-600(Fe), 80 mg of [Fe 3 O(OOCCH 3 ) 6 OH]2H 2 O clusters, 80 mg of tetrakis(4-carboxyphenyl)porphyrin (TCPP) and 2.4 mL of trifluoroacetic acid were sonicated in 16 mL of N,N-dimethylformamide, and the resulting homogeneous solution was transferred to a stainless steel reaction vessel , 150 ° C solvent heat treatment for 12 hours, cooled to room temperature to obtain needle-shaped single cr...

Embodiment 2

[0031] (1) Synthesis of Ni-TCPP:

[0032] 80 mg of nickel nitrate hexahydrate, 80 mg of tetrakis(4-carboxyphenyl)porphyrin (TCPP) and 2.4 mL of trifluoroacetic acid were ultrasonically dissolved in 16 mL of N,N-dimethylformamide, and the resulting homogeneous solution was Transfer to a stainless steel reactor, heat-treat with a solvent at 150°C for 12 hours, and cool to room temperature to obtain a needle-shaped single crystal;

[0033] (2) The assembly of the simulated button lithium battery is the same as the preferred example, Ni-TCPP is used as the negative electrode of the lithium battery, the cycle performance is equivalent to that of PCN-600(Fe), and the reversible capacity is ~800mA h g -1 .

Embodiment 3

[0035] Synthesis of Co-TCPP and its performance as a lithium battery negative electrode: the nickel nitrate hexahydrate in Example 2 was replaced by cobalt nitrate hexahydrate, the others were the same as in Example 2, and the performance of the assembled lithium battery was equivalent to that of Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com