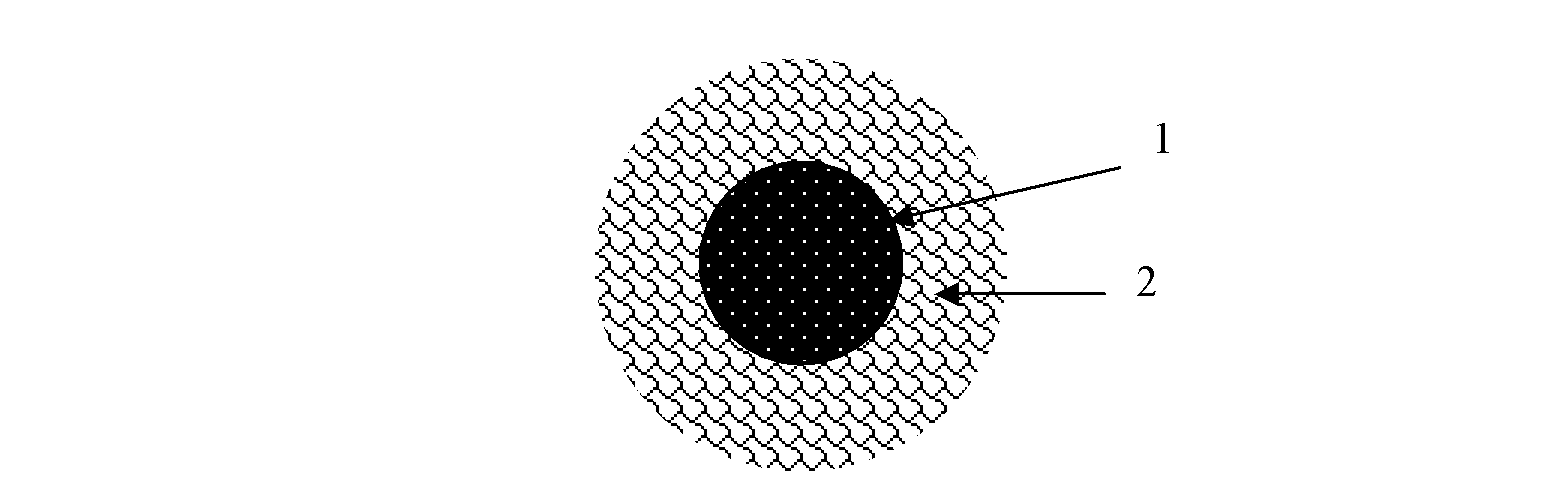

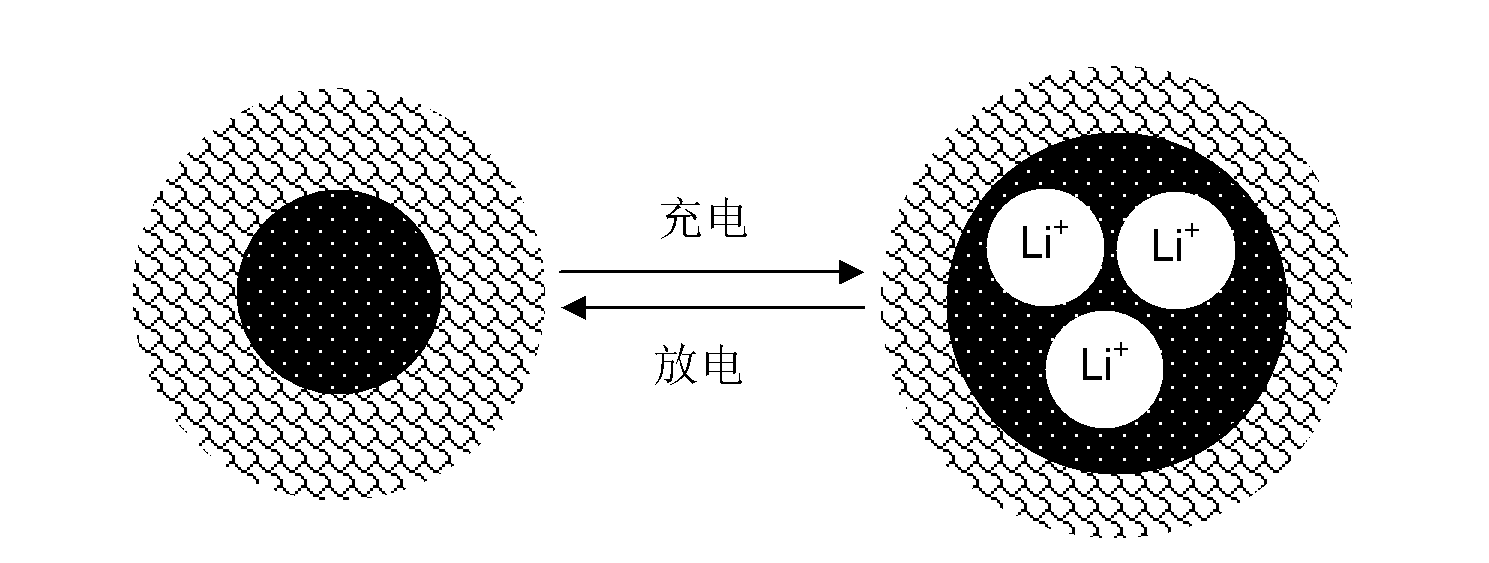

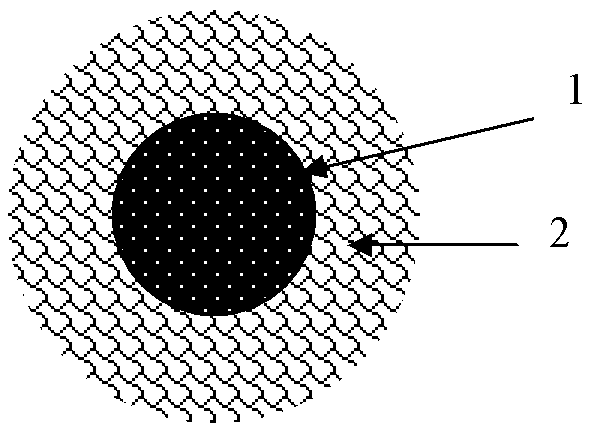

Anode material used for lithium ion battery and preparation methods thereof

A technology for lithium-ion batteries and negative electrode materials, applied to battery electrodes, circuits, electrical components, etc., can solve problems such as weak binding force, reduced battery life, carbon layer separation, and peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) dissolving the organic precursor polyacrylonitrile in tetrahydrofuran to form a homogeneous solution with a mass concentration of 10%;

[0035] (2) adding a certain amount of silicon into the above solution, and mixing the silicon with the solution evenly to form a spinning stock solution; the amount of silicon added is 5wt.% of the organic precursor;

[0036] (3) Prepare the organic fiber felt containing silicon by the above spinning stock solution by electrospinning; wherein the spinning stock solution propulsion speed is 1mL / h, the voltage is 15KV, and the receiving distance is 10cm;

[0037] (4) Carbonize the organic fiber felt in an argon atmosphere, and heat up at a heating rate of 10°C / min until the temperature of the furnace body is 900°C; after 4 hours of heat preservation, all the organic fibers are pyrolyzed and carbonized to form carbon fibers ;

[0038] (5) Pulverize the material obtained in the previous step to obtain the anode material for lithium-io...

Embodiment 2

[0042] (1) dissolving the organic precursor polyacrylonitrile in dimethyl sulfoxide to form a homogeneous solution with a mass concentration of 30%;

[0043] (2) adding a certain amount of silicon monoxide into the above solution, and mixing the silicon monoxide with the solution evenly to form a spinning stock solution; the amount of silicon monoxide added is 5wt.% of the organic precursor;

[0044] (3) Prepare the organic fiber mat containing silicon monoxide by electrospinning the above spinning stock solution; wherein the spinning stock solution advance speed is 1.5mL / h, the voltage is 25KV, and the receiving distance is 15cm;

[0045] (4) Carbonize the organic fiber mat in a mixed gas of 5% hydrogen and 95% argon, and heat up at a heating rate of 5°C / min until the temperature of the furnace body is 900°C; All organic fibers are pyrolyzed and carbonized to form carbon fibers;

[0046] (5) Pulverizing the material obtained in the previous step to obtain the anode material ...

Embodiment 3

[0050] (1) dissolving the organic precursor polyacrylonitrile in dimethylamide to form a homogeneous solution with a mass concentration of 15%;

[0051] (2) adding a certain amount of silicon dioxide to the above solution, and mixing the silicon dioxide with the solution evenly to form a spinning stock solution; the amount of silicon dioxide added is 10wt.% of the organic precursor;

[0052] (3) Prepare the organic fiber felt containing silicon dioxide by electrospinning the above spinning stock solution; wherein the spinning stock solution propulsion speed is 1.2mL / h, the voltage is 18KV, and the receiving distance is 11.5cm;

[0053] (4) Carbonize the organic fiber mat in an argon atmosphere, and heat up at a heating rate of 5°C until the temperature of the furnace body is 800°C; after 4 hours of heat preservation, all the organic fibers are pyrolyzed and carbonized to form carbon fibers;

[0054] (5) Pulverizing the material obtained in the previous step to obtain the anode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com