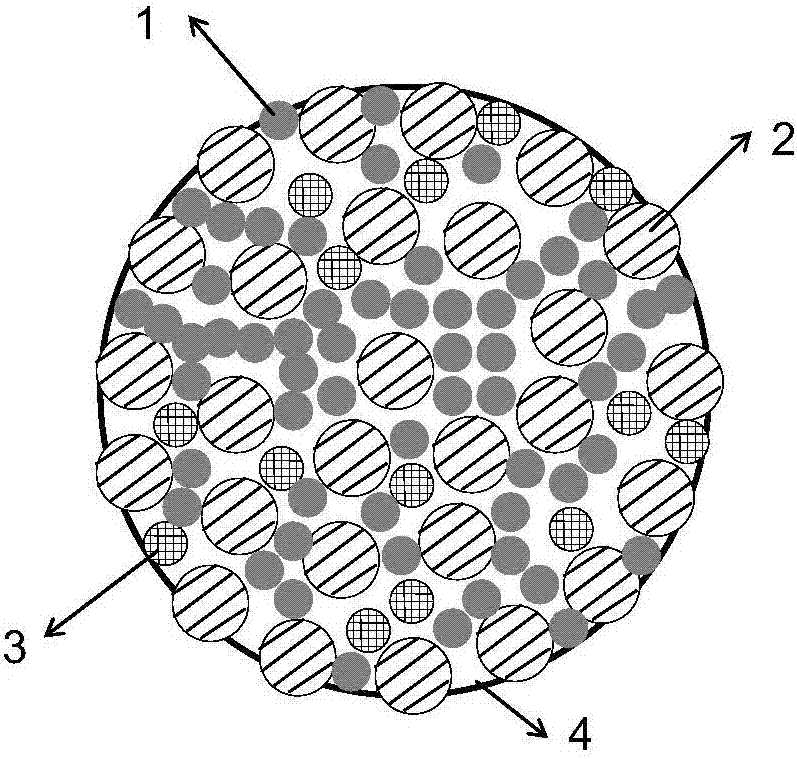

Porous silicon based composite anode material, preparation method and lithium ion battery

A negative electrode material, porous silicon-based technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor reversible capacity and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present invention provides a method for preparing the porous silicon-based composite negative electrode material described in the above technical solution, comprising the following steps:

[0041] Mixing silicon-containing nanoparticles with a solvent and ball milling to obtain a slurry;

[0042]mixing the slurry with metal particles, carbon sources and additives, spray drying and sintering to obtain a porous silicon-based composite negative electrode material;

[0043] The metal particles include one or more of Sn, Cu and Mn.

[0044] In the invention, the silicon-containing nano particles are mixed with a solvent and ball milled to obtain a slurry. In the present invention, the silicon-containing nanoparticles preferably include silicon, SiO 2 and SiO x One or more of them; the SiO x The value of x is preferably 0<x<2, more preferably x=1, x=0.5 or x=1.5. In the present invention, the particle diameter of the silicon-containing nanoparticles is preferably 5nm...

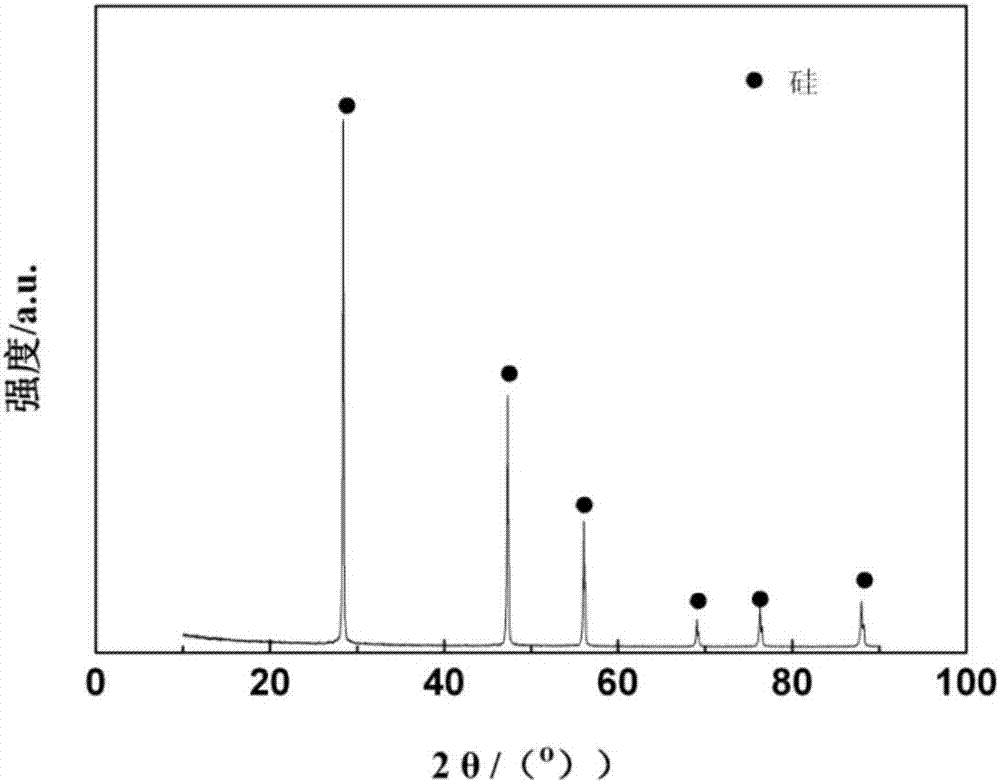

Embodiment 1

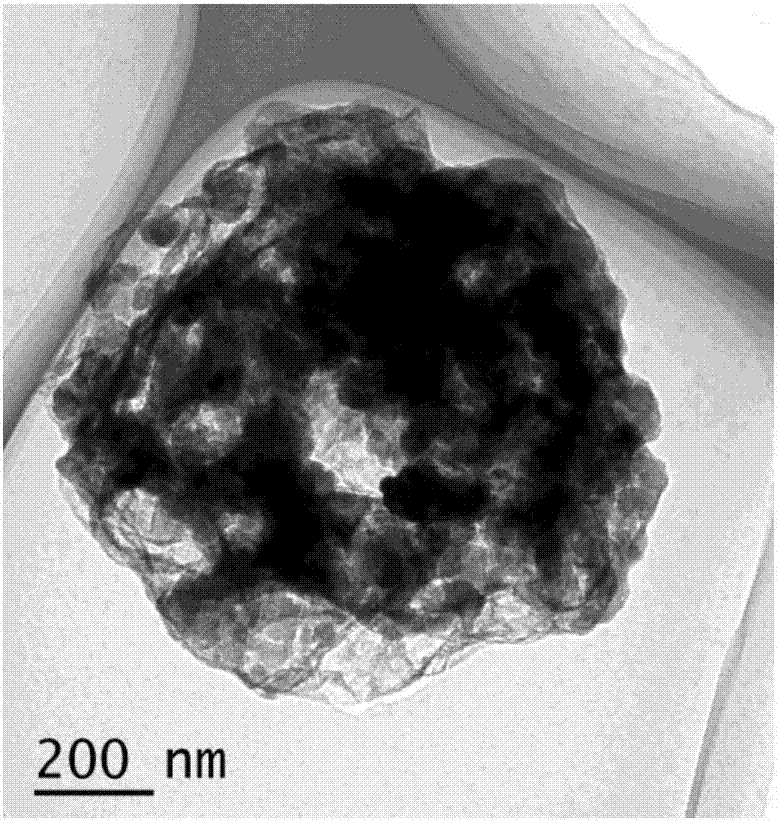

[0063] Put the silicon powder and 50mL aqueous solution under an inert atmosphere, 2000 rpm high-energy ball mill for 8 hours, and then transfer it to a sand mill for 4 hours at 1000 rpm ball mill; the obtained 2.5g of silicon with a particle size of 5-100nm Slurry, the mass ratio of silicon powder, glucose and Sn is 10:40:3, the mass ratio of silicon powder and sodium chloride is 1:1, after mixing, ultrasonically disperse for 5 hours, spray dry for granulation, atomizer speed 20000 In order to achieve the purpose of uniform particles, the temperature of the drying air inlet is 220°C, and the temperature of the air outlet is 110°C. The obtained spherical material is then placed in a resistance furnace for sintering at 800°C for 5 hours in an inert atmosphere, and the obtained spherical material is centrifugally washed with water. , dried, and sieved to obtain a porous spherical nanometer silicon-based negative electrode material for lithium ion batteries, that is, a porous sili...

Embodiment 2

[0067] Silicon powder and 50mL aqueous solution were milled by high-energy ball at 1800 rpm for 8 hours under an inert atmosphere, and then transferred to a sand mill for ball milling at 1500 rpm for 4 hours; Slurry, the mass ratio of silicon powder, phenolic resin and Sn is 70:90:10, silicon powder and (NH 4 ) 2 CO 3 The mass ratio of (ammonium carbonate) is 1:10, mixed ultrasonically for 5 hours, spray-dried for granulation, the atomizer speed is 20000 rpm to achieve uniform particles, the drying air inlet temperature is 220 °C, and the air outlet temperature It is 110°C. The obtained spherical material is then placed in a resistance furnace and sintered at 800°C for 10 hours in an inert atmosphere. The obtained spherical material is washed with centrifugal water, dried, and sieved to obtain a porous spherical nano-silicon-copper negative electrode material for lithium-ion batteries, that is, porous silicon-based Composite anode materials.

[0068] Electrochemical perfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com