Lithium-ion battery graphitized mesoporous carbon/silicon composite anode materials and preparation method thereof

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, circuits, electrical components, etc., to achieve high lithium storage capacity, long cycle life, and good safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

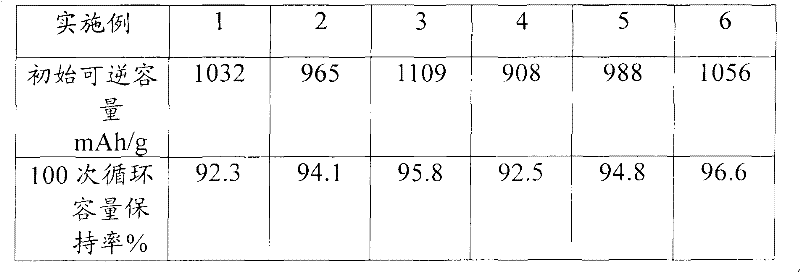

Examples

Embodiment 1

[0014] Weigh 3.0 grams of SBA-15 of two-dimensional hexagonal p6m and impregnate it into 28.5ml of Ni(NO 3 ) 2 ethanol aqueous solution, and stirred at 35-85°C for 10 hours until the solvent was completely evaporated and dried. The above Ni / SBA-15 was impregnated into a solution containing 3.75g of sucrose, 0.42g of sulfuric acid and 15.0g of water, dried at 100°C for 6 hours after thorough stirring, then heat-treated at 160°C for 6 hours, cooled and then dipped again But the amount of sucrose and sulfuric acid is 50-60% of the original. Then, the composite was carbonized and catalyzed graphitized at 900°C under a nitrogen atmosphere for 6 hours, and the silicon oxide was etched and removed with 2 mol / L NaOH to obtain a partially graphitized and Ni-containing ordered mesoporous carbon CMK-3.

[0015] Weigh 2 grams of the above-mentioned partially graphitized and Ni-containing ordered mesoporous carbon CMK-3, spread it in a quartz boat and place it in a vacuum tube furnace, a...

Embodiment 2

[0017] Take by weighing 3.0 grams of SBA-15 of two-dimensional hexagonal p6m and impregnate it into 28.5ml of Fe(NO 3 ) 3 ethanol aqueous solution, and stirred at 35-85°C for 10 hours until the solvent was completely evaporated and dried. Immerse the above-mentioned Fe / SBA-15 into a solution containing 3.75 grams of sucrose, 0.42 grams of sulfuric acid and 15.0 grams of water, dry at 100°C for 6 hours after thorough stirring, then heat-treat at 160°C for 6 hours, and repeat the dipping once after cooling But the amount of sucrose and sulfuric acid is 50-60% of the original. Then the composite was carbonized and catalyzed graphitized at 950°C for 4 hours under a nitrogen atmosphere, and the silicon oxide was etched and removed with 2 mol / L NaOH to obtain a partially graphitized and Fe-containing ordered mesoporous carbon CMK-3.

[0018] Weigh 2 grams of the above-mentioned partially graphitized and Fe-containing ordered mesoporous carbon CMK-3, spread it in a quartz boat and ...

Embodiment 3

[0020] Weigh 3.0 grams of SBA-15 of two-dimensional hexagonal p6m and impregnate it into 28.5ml of Co(NO 3 ) 2 ethanol aqueous solution, and stirred at 35-85°C for 10 hours until the solvent was completely evaporated and dried. Immerse the above Co / SBA-15 into a solution containing 3.75g of sucrose, 0.42g of sulfuric acid and 15.0g of water, stir well and dry at 100°C for 6 hours, then heat-treat at 160°C for 6 hours, then repeat the impregnation once after cooling But the amount of sucrose and sulfuric acid is 50-60% of the original. Then the composite was carbonized and catalyzed graphitized at 900°C for 4 hours under a nitrogen atmosphere, and the silicon oxide was etched and removed with 2 mol / L NaOH to obtain a partially graphitized and Co-containing ordered mesoporous carbon CMK-3.

[0021] Weigh 2 grams of the above-mentioned partially graphitized and Co-containing ordered mesoporous carbon CMK-3, spread it in a quartz boat and place it in a vacuum tube furnace, and h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com