Method for preparing diantimony trioxide lithium battery anode material with hollow prism structure

A technology of antimony trioxide and negative electrode materials, which is applied in battery electrodes, chemical instruments and methods, structural parts, etc., and can solve problems such as lithium storage capacity limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

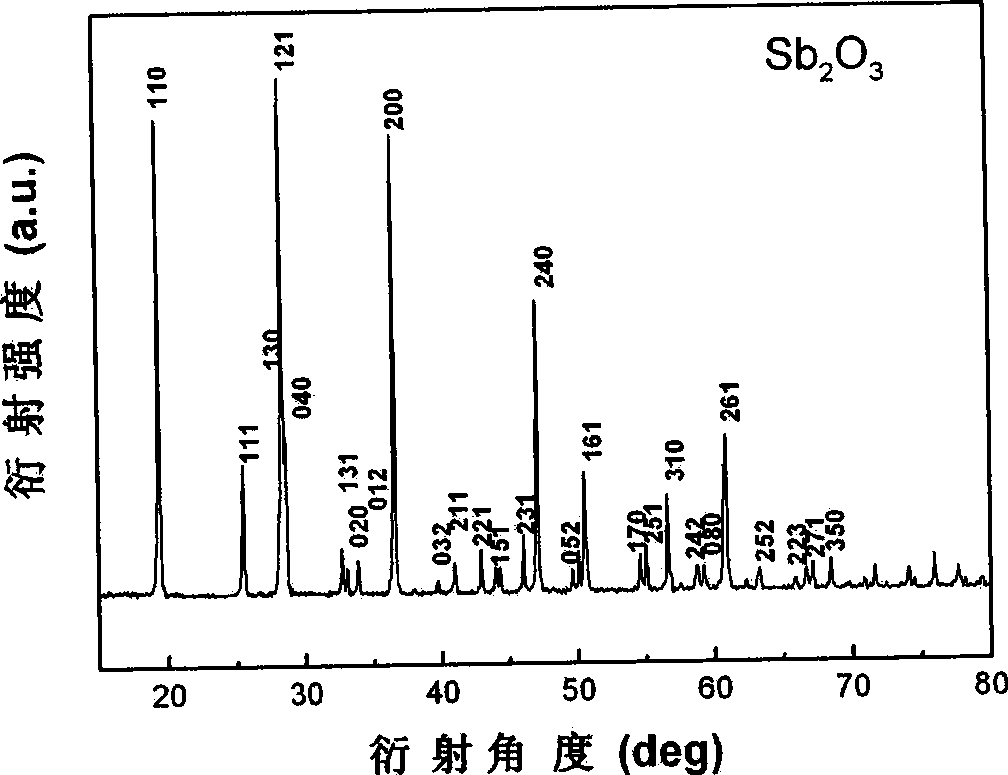

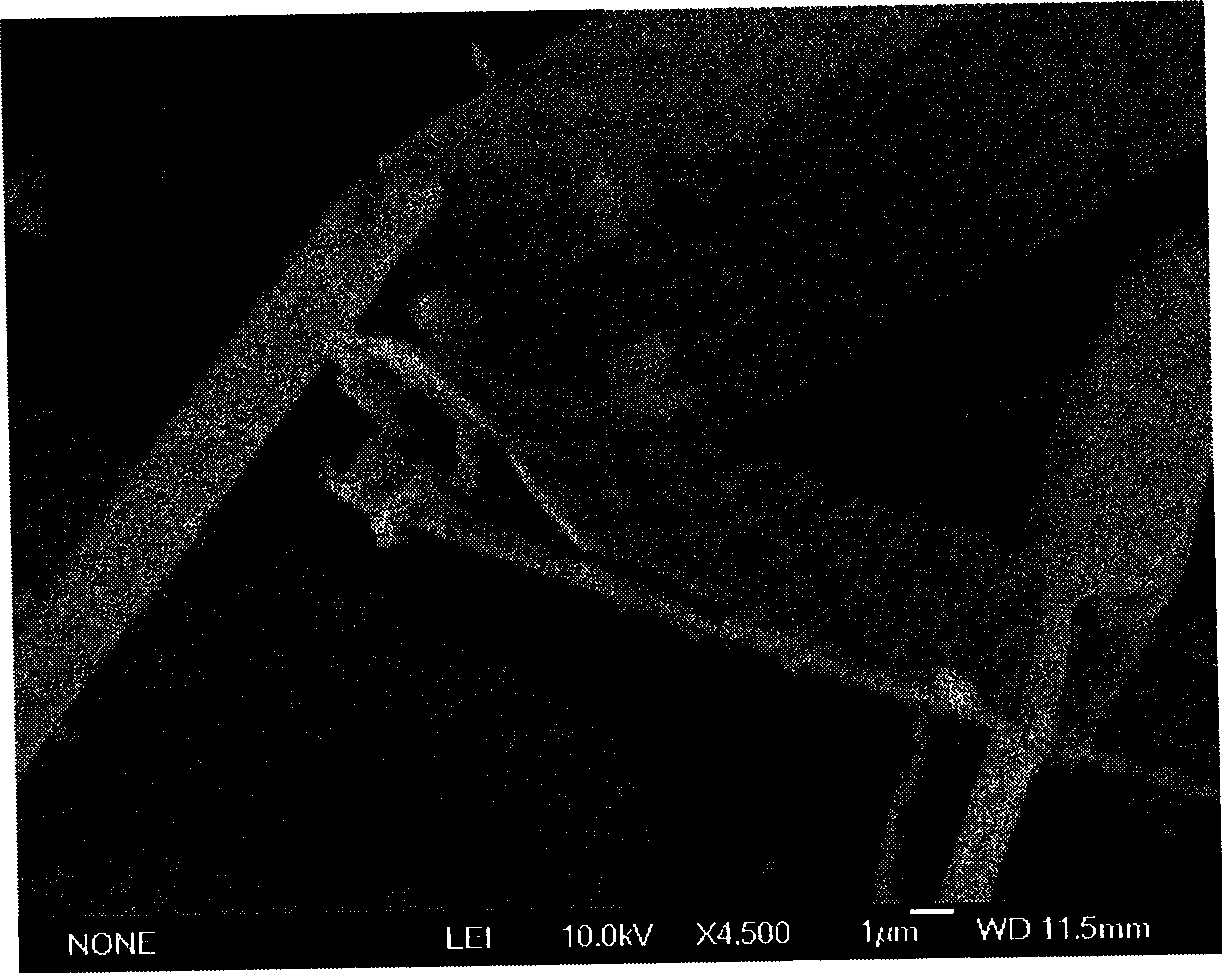

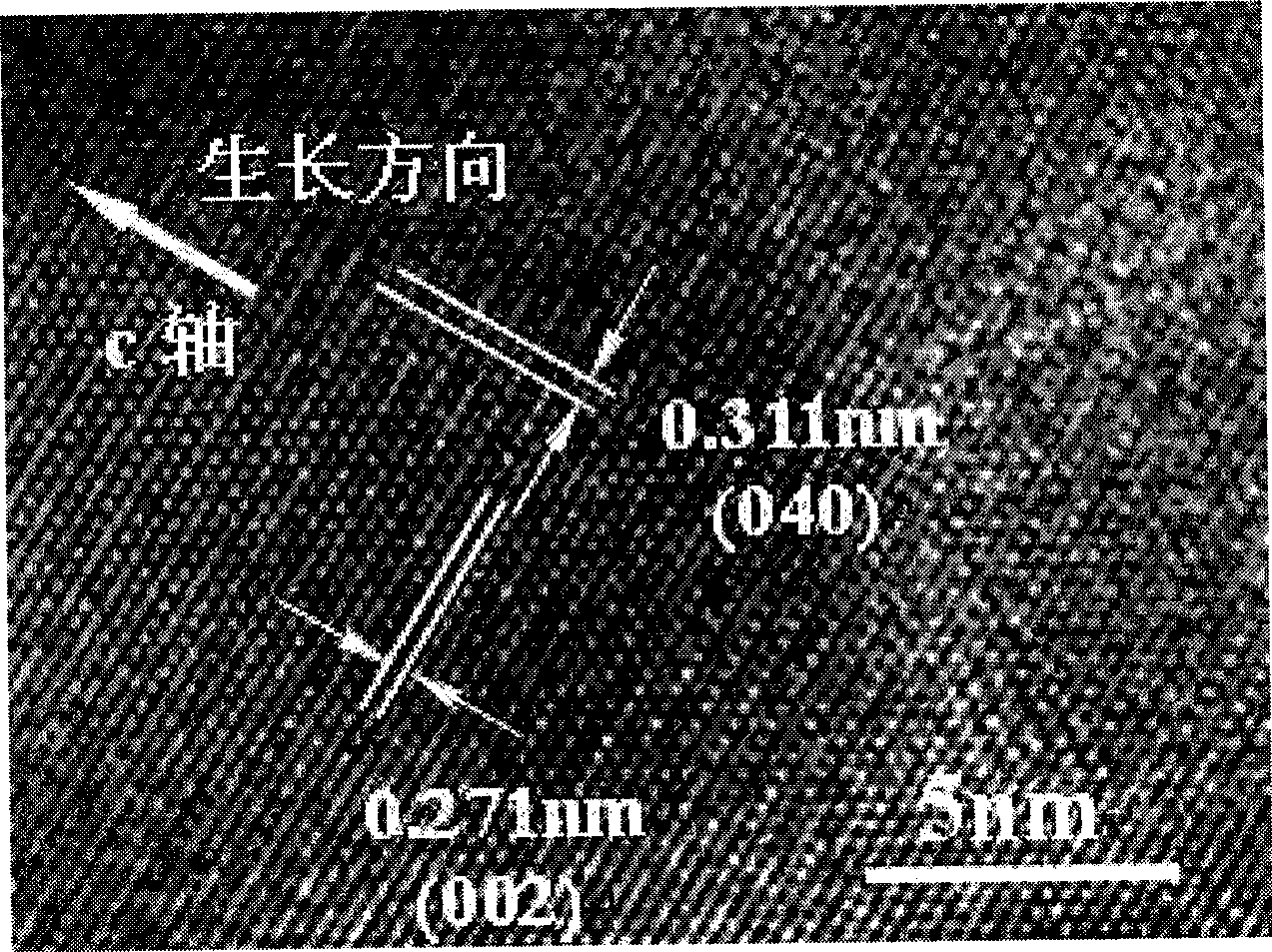

[0015] Take by weighing 0.45mmol of antimony trichloride, dissolve it in 15ml of absolute ethanol to obtain a colorless transparent solution, take by weighing 4.5mmol of urea and dissolve it in 30ml of deionized water to obtain a colorless and transparent solution, in the case of stirring Next, the urea aqueous solution is added dropwise in the ethanolic solution of antimony trichloride, and after the dropwise addition, the stirring is continued for 0.5 hour, and the obtained milky white mixed solution is transferred to a stainless steel hydrothermal reaction kettle lined with polytetrafluoroethylene ( The filling degree of the hydrothermal reaction kettle is: 75-85%), sealed. The reaction kettle was placed in an electric furnace, and reacted at 180°C for 20 hours. After the reaction, the obtained white precipitate was washed with alcohol and deionized water several times, and dried at 80°C to obtain antimony trioxide material with a hollow prism structure. The XRD pattern is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com