Method for synthesizing nano-silicon powder by using silicon tetrachloride as raw material and application of nano-silicon powder

A silicon nanopowder, silicon tetrachloride technology, applied in chemical instruments and methods, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problems of expensive raw materials, lower reaction temperature, harsh reaction conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

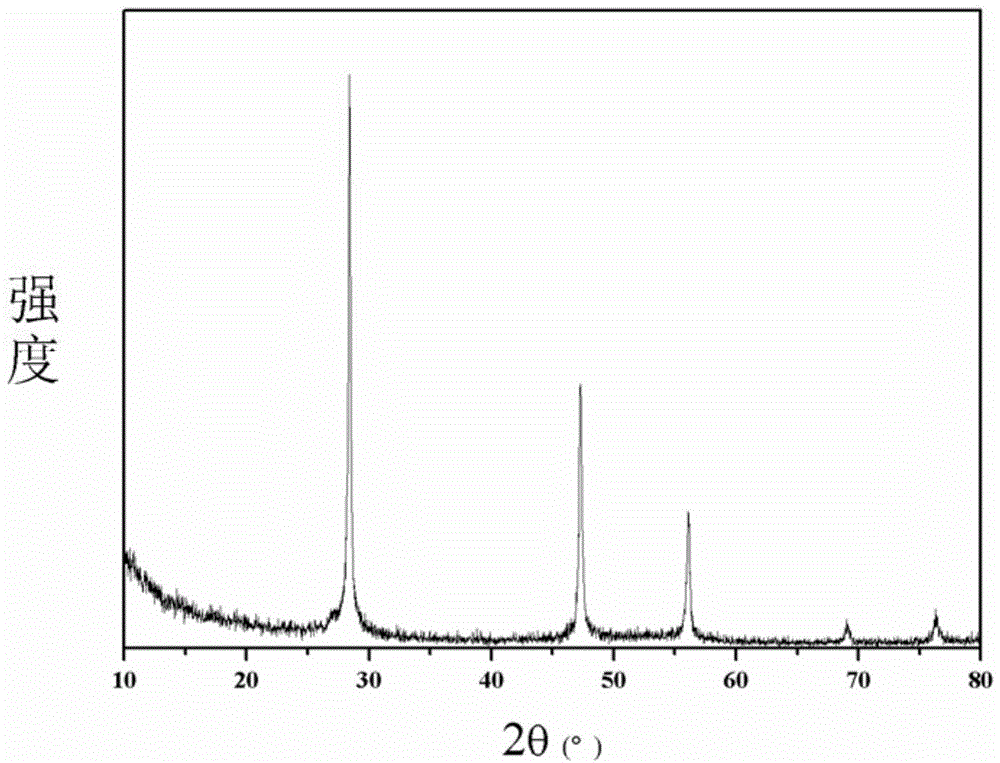

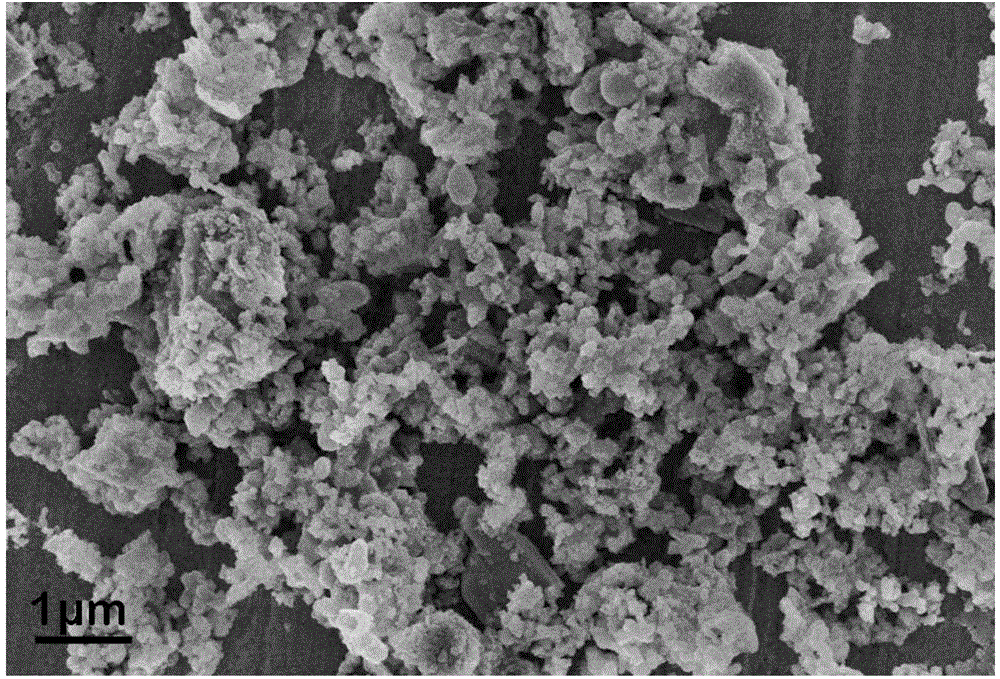

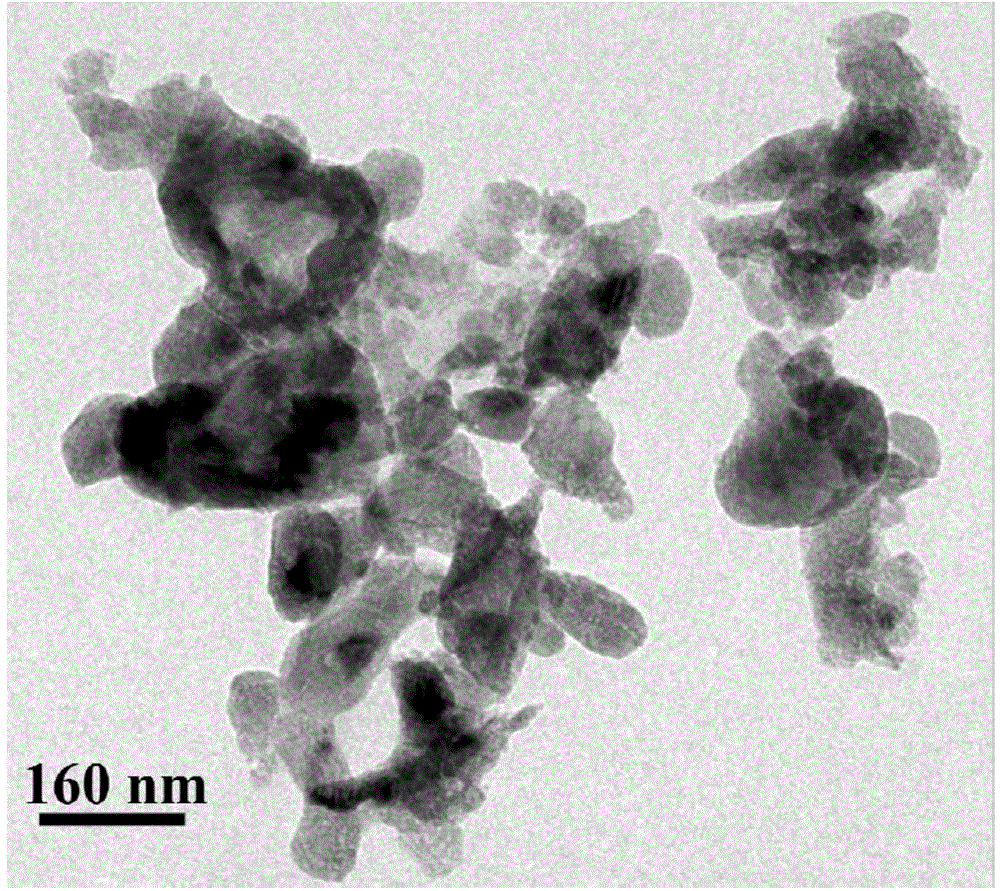

[0016] The first aspect of the present invention provides a method for preparing silicon nano-powder by molten salt reaction. Under the condition of low-temperature molten salt, the silicon nano-powder is synthesized by reducing cheap silicon source with metal. The method adopts the reduction reaction participated by the molten salt to realize the macro-preparation of the silicon material.

[0017] In a preferred embodiment, the silicon source is industrial grade silicon tetrachloride.

[0018] In a preferred embodiment, the metal is selected from one or more of sodium metal, magnesium powder, aluminum powder, or their corresponding metal alloys.

[0019] In a preferred embodiment, the molten salt is selected from one or more of anhydrous aluminum chloride, anhydrous zinc chloride, anhydrous magnesium chloride, and anhydrous sodium chloride.

[0020] In a preferred embodiment, the reduction reaction temperature is 200°C-500°C; the reaction time is 5h-3 days, preferably 5-20h....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com