Method for preparing Fe2O3 and expanded graphite composite material of lithium ion battery

A lithium-ion battery and expanded graphite technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as difficult to meet the application conditions of lithium-ion batteries, achieve superior cycle and rate performance, convenient operation, and low production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

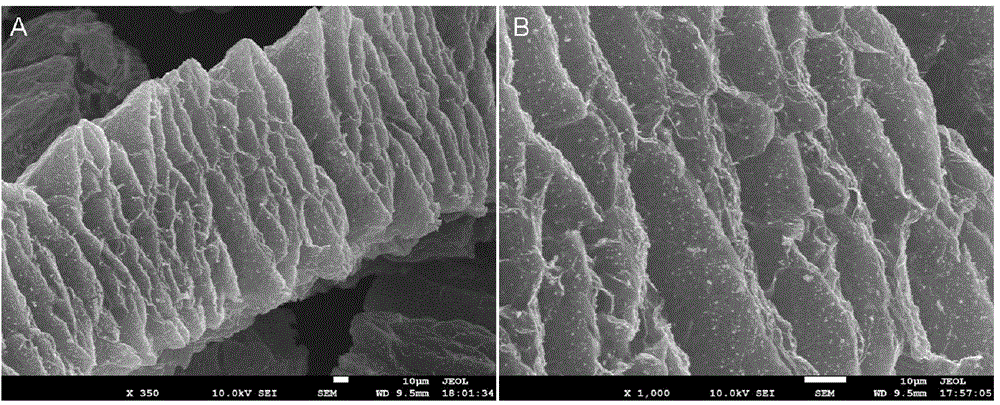

[0042] Mix expanded graphite with an expansion volume of 350 mL / g and a purity of 95% with ferrocene at a mass ratio of 1:8. Then put it in an autoclave, keep the temperature at 500°C for 4 hours, and take it out after cooling to prepare Fe 2 o 3 Nanoparticles well dispersed Fe 2 o 3 / expanded graphite composites, see figure 1 , B in the figure is an enlargement of A.

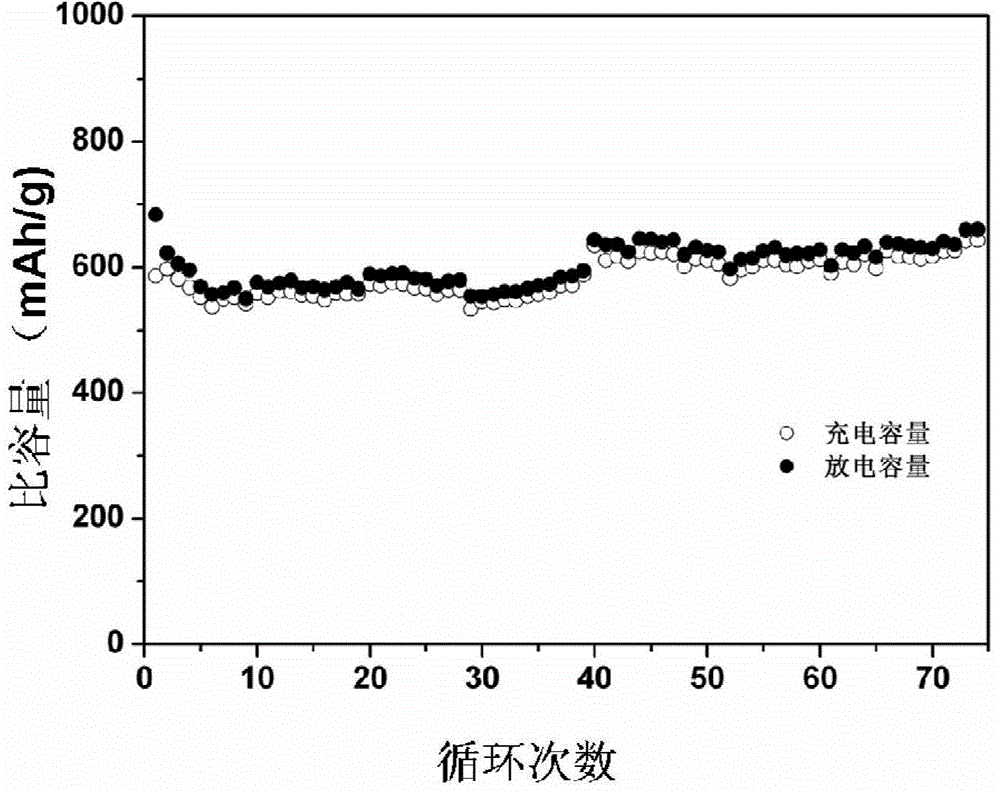

[0043] The material's initial charge capacity can reach 685mAh / g at a current density of 50mA / g, and it still maintains a reversible capacity of 653mAh / g after 70 cycles, see figure 2 .

Embodiment 2

[0045] Mix expanded graphite with an expansion volume of 428 mL / g and a purity of 98% with ferrocene at a mass ratio of 1:12. Then put it in an autoclave, keep the temperature at 400°C for 8 hours, and take it out after cooling to prepare Fe 2 o 3 Nanoparticles well dispersed Fe 2 o 3 / Expanded graphite composite.

[0046] The material has an initial charge capacity of 692mAh / g at a current density of 50mA / g, and still maintains a reversible capacity of 658mAh / g after 70 cycles.

Embodiment 3

[0048] Mix expanded graphite with an expansion volume of 560 mL / g and a purity of 98% with ferrocene at a mass ratio of 1:10. Then put it in a closed reaction kettle, preferably at a temperature of 180° C. for 12 hours, and take it out after cooling. Put the product in a microwave oven and heat it for 15s at the preferred power of 700W to produce Fe 2 o 3 Nanoparticles well dispersed Fe 2 o 3 / Expanded graphite composite.

[0049] The material has an initial charge capacity of 672mAh / g at a current density of 50mA / g, and still maintains a reversible capacity of 651mAh / g after 70 cycles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com