Method for preparation of ferric oxide/graphene/carbon fiber composite material

A technology for ferric oxide and composite materials, which is applied in the field of preparing new ferric oxide/graphene/carbon fiber composite materials, can solve the problems of pulverization and shedding, the reduction of lithium storage capacity of negative electrode materials, and the increase of internal resistance. , to achieve the effect of small environmental impact, improved lithium storage capacity and electron mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

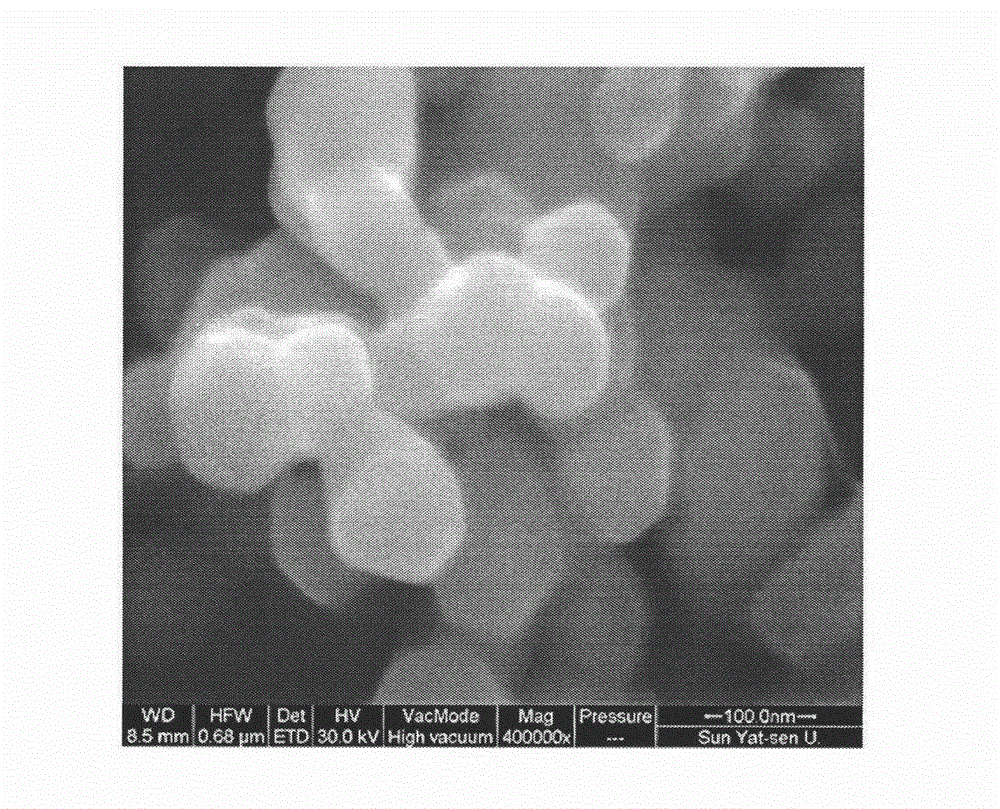

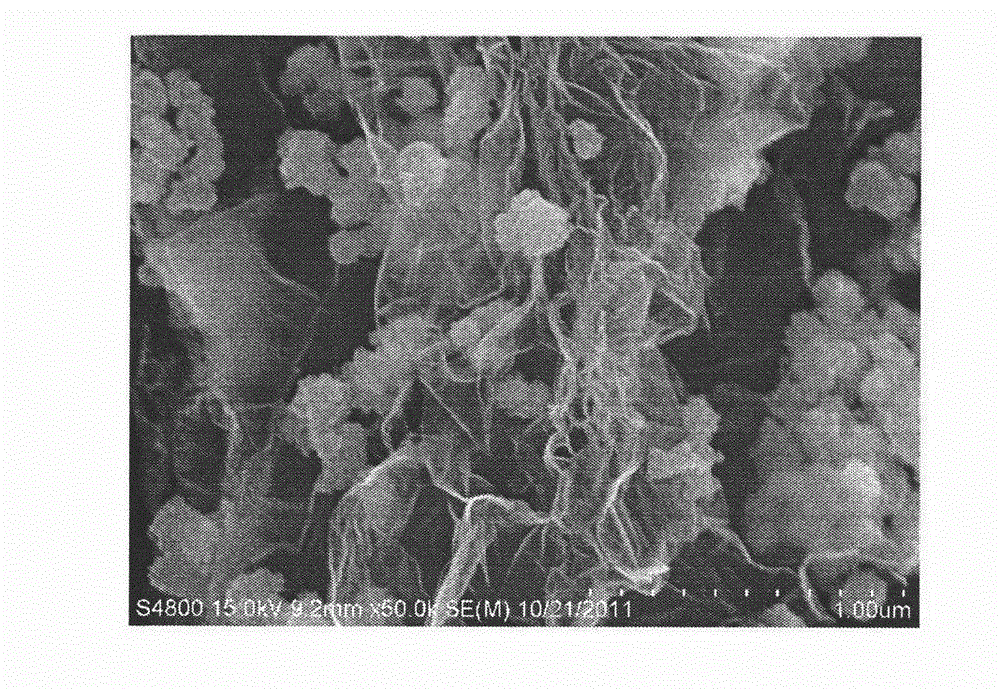

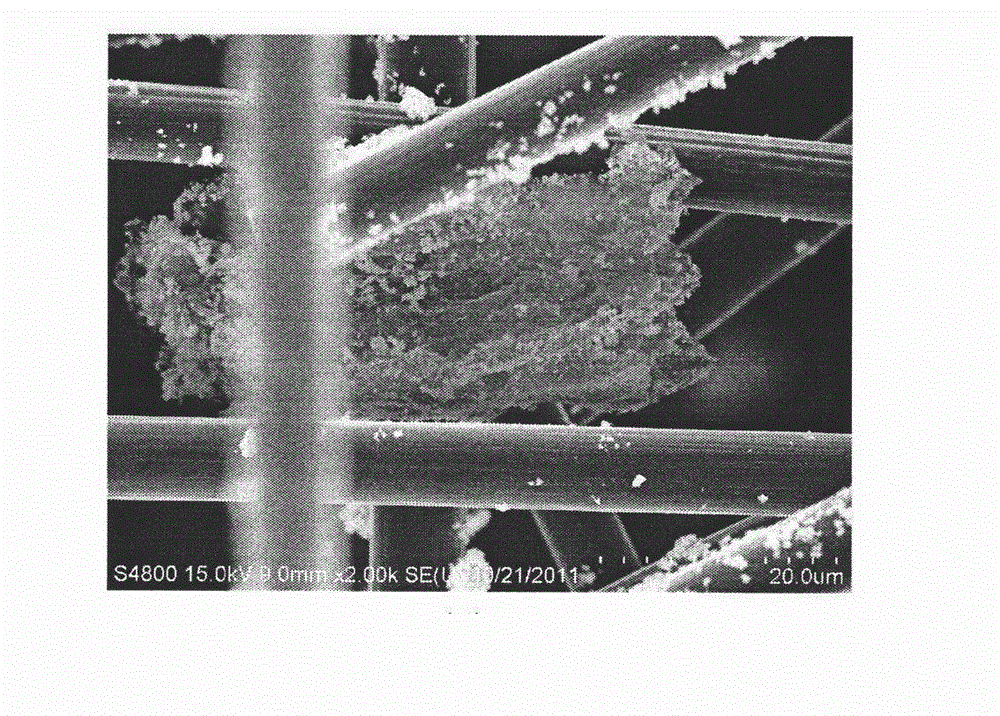

[0022] Example 1: Take 9g of ferric oxide and 0.1g of graphene oxide in 300ml of absolute ethanol, stir for 3h, and then ultrasonically disperse for 5h. The above mixture was added to 0.9 g of carbon fiber in anhydrous ethanol solvent, stirring was continued for 3 h, followed by ultrasonic dispersion at 1.5 K Hz power for 5 h. The mixture is then washed with water and the composite material is isolated by suction filtration. Finally, the ferric oxide / graphene / carbon fiber composite material was obtained after air drying at a temperature of 40°C.

Embodiment 2

[0023] Example 2: Take 8.5g of ferric oxide and 0.15g of graphene oxide in 300ml of absolute ethanol, stir for 3h, and then ultrasonically disperse for 2h. The above mixture was added to 1.35 g of carbon fiber in ethylene glycol solvent, stirring was continued for 3 h, followed by ultrasonic dispersion at 3K Hz power for 5 h. The mixture is then washed with water and the composite material is separated by centrifugation. Finally, the ferric oxide / graphene / carbon fiber composite material was obtained after air drying at a temperature of 40°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com