Carbon-coated antimony-zinc alloy material of cathode for lithium-ion battery and method for preparing same

A carbon-coated antimony-zinc, lithium-ion battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of poor cycle performance and low lithium storage capacity, achieve low cost, avoid agglomeration, and improve lithium storage capacity and cycle life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Accurately weigh 14.57g Sb with electronic balance 2 o 3 , 8.138g ZnO and 32g glucose were put into a planetary ball mill and fully milled with stainless steel balls for 40 hours. Heating in the furnace to 850° C. at a speed of 10° C. / min, keeping the temperature for 2 hours, and then slowly cooling to room temperature to obtain a carbon-coated antimony-zinc alloy negative electrode material for lithium ion batteries.

[0024] The obtained material was subjected to particle size analysis, and the average particle size was 110 nm. The content of carbon in the material was 3.5% by weight. The molar ratio of antimony and zinc in the material is 1:1.

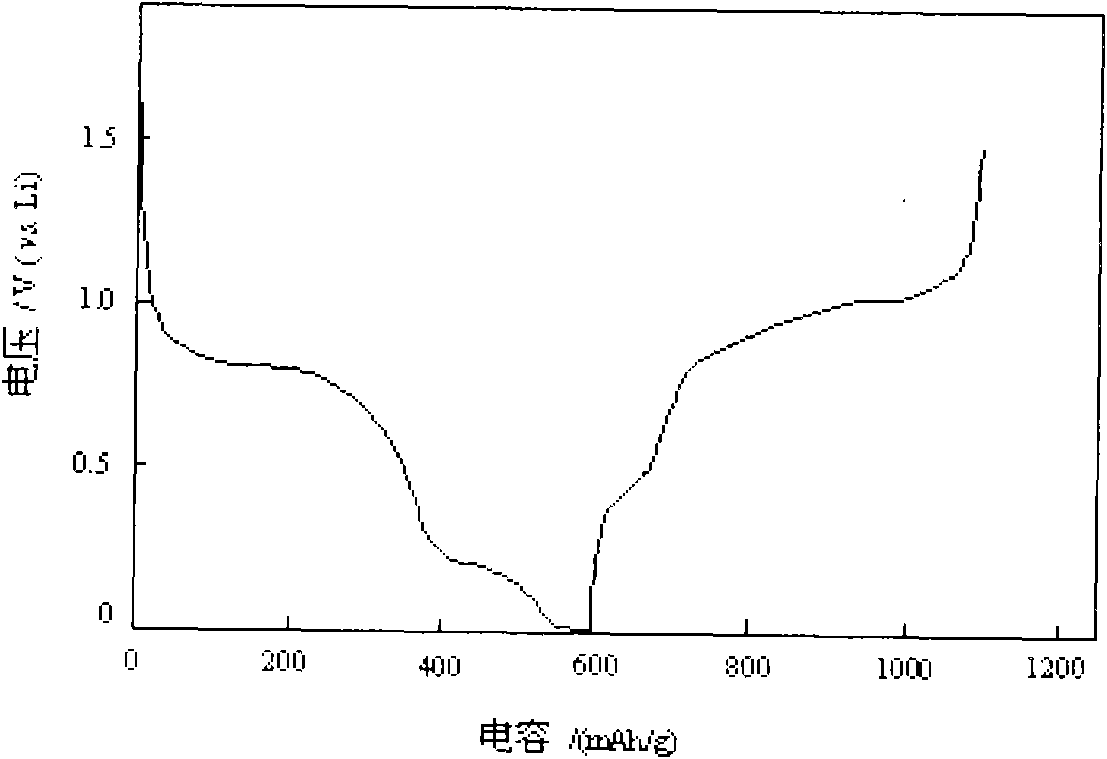

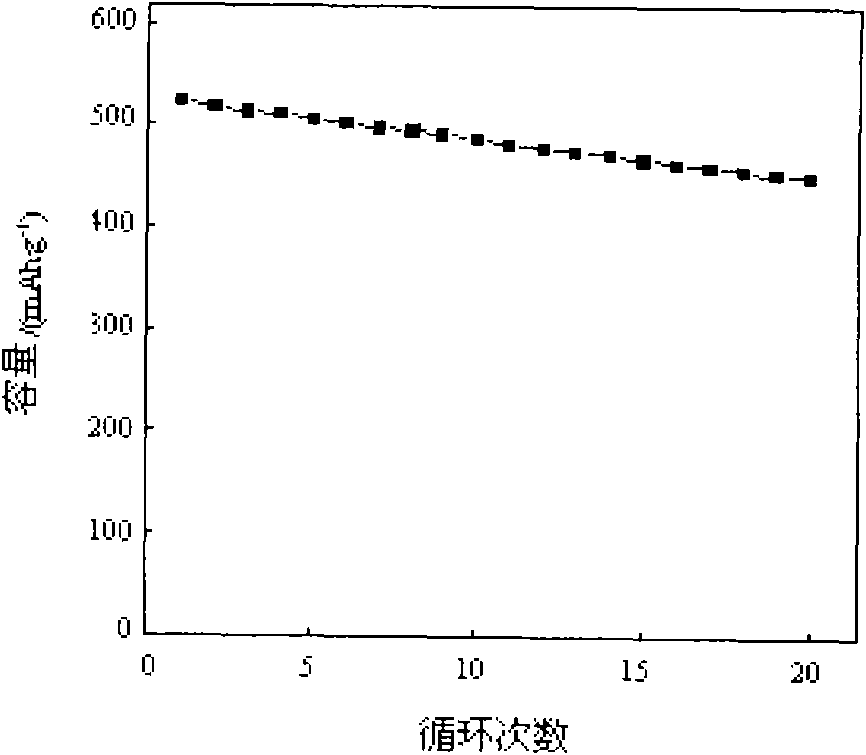

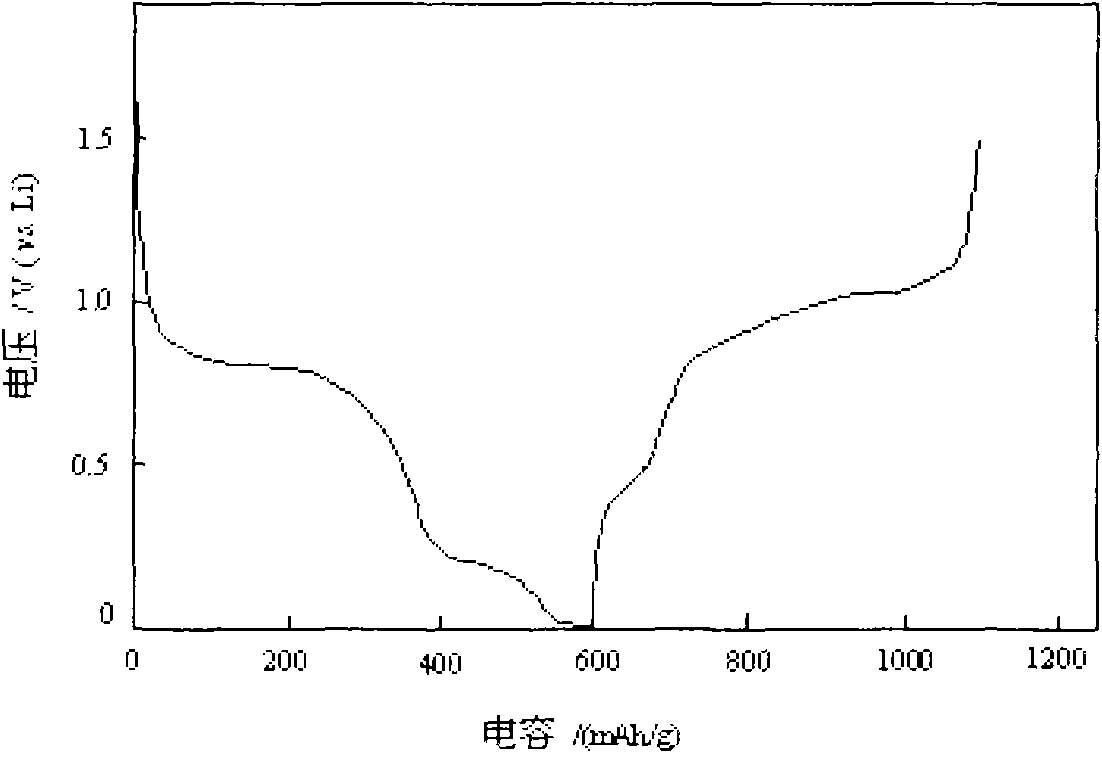

[0025] Mix the synthesized material with acetylene black and polytetrafluoroethylene at a mass ratio of about 80:10:10, press it into a film with a thickness of about 1 mm, place it in an oven at 120°C and dry it fully, and intercept Surface area is 1cm 2 A circular membrane, pressed on a stainless steel mesh, made into ...

Embodiment 2

[0027] Accurately weigh 14.57g Sb with electronic balance 2 o 3 , 10.851g ZnO and 24g polyethylene glycol, put them into a planetary ball mill, fully ball mill them with stainless steel balls for 48 hours, put the ball-milled mixture in a crucible and put it into a program-controlled tube furnace, under the protection of high-purity argon Heating to 750°C at a speed of 5°C / min in a tube furnace, holding the temperature for 3 hours, and then slowly cooling to room temperature to obtain a carbon-coated antimony-zinc alloy negative electrode material for a lithium-ion battery.

[0028] The obtained material was subjected to particle size analysis, and the average particle size was 86 nm. The content of carbon in the material was 4.7% by weight. The molar ratio of antimony and zinc in the material is 3:4.

[0029] Mix the synthesized material with acetylene black and polytetrafluoroethylene at a mass ratio of about 80:10:10, press it into a film with a thickness of about 1 mm, ...

Embodiment 3

[0031] Accurately weigh 14.57g Sb with electronic balance 2 o 3 , 12.207g ZnO and 28g sucrose were put into a planetary ball mill and fully milled with stainless steel balls for 36 hours. Heating to 950°C at a speed of 10°C / min in the furnace, holding the temperature for 4 hours, and then slowly cooling to room temperature to obtain the carbon-coated antimony-zinc alloy negative electrode material for lithium-ion batteries

[0032] The obtained material was subjected to particle size analysis, and the average particle size was 138 nm. The content of carbon in the material was 2.6% by weight. The molar ratio of antimony and zinc in the material is 2:3.

[0033] Mix the synthesized material with acetylene black and polytetrafluoroethylene at a mass ratio of about 80:10:10, press it into a film with a thickness of about 1 mm, place it in an oven at 120°C and dry it fully, and intercept A circular membrane with a surface area of 1 cm2, pressed onto a stainless steel mesh, wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com