Pre-sodium-modified positive pole piece, application of pre-sodium-modified positive pole piece, sodium-ion battery and preparation method of sodium-ion battery

A technology of sodium ion battery and positive pole piece, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of increasing the difficulty of industrialization and production efficiency, increasing polarization, and difficulty in high-performance sodium ion battery systems, etc. Achieve the effect of reducing material structure damage and side reactions, reducing polarization, and improving electrochemical kinetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] In the present invention, the preparation method of the high-voltage sodium ion positive electrode slurry preferably includes the following steps: mixing the raw materials to obtain the high-voltage sodium ion positive electrode slurry;

[0049] The mixing is preferably vacuum stirring, and the rotational speed of the vacuum stirring is preferably 1500-3000rpm, more preferably 1800-2700rpm, more preferably 2100-2400rpm; the time is preferably 4-6h, more preferably 4.5-5.5h, and more preferably Preferably it is 4.8~5.2h; the vacuum degree is preferably -0.05~-0.08MPa, more preferably -0.06~-0.07MPa, more preferably -0.063~-0.066MPa.

[0050] In the present invention, the high-capacity sodium ion positive electrode slurry preferably contains the following raw materials: a high-capacity layered oxide positive electrode material, a binder, a conductive agent, carbon nanotubes, and a solvent.

[0051] In the present invention, the high-capacity layered oxide cathode material...

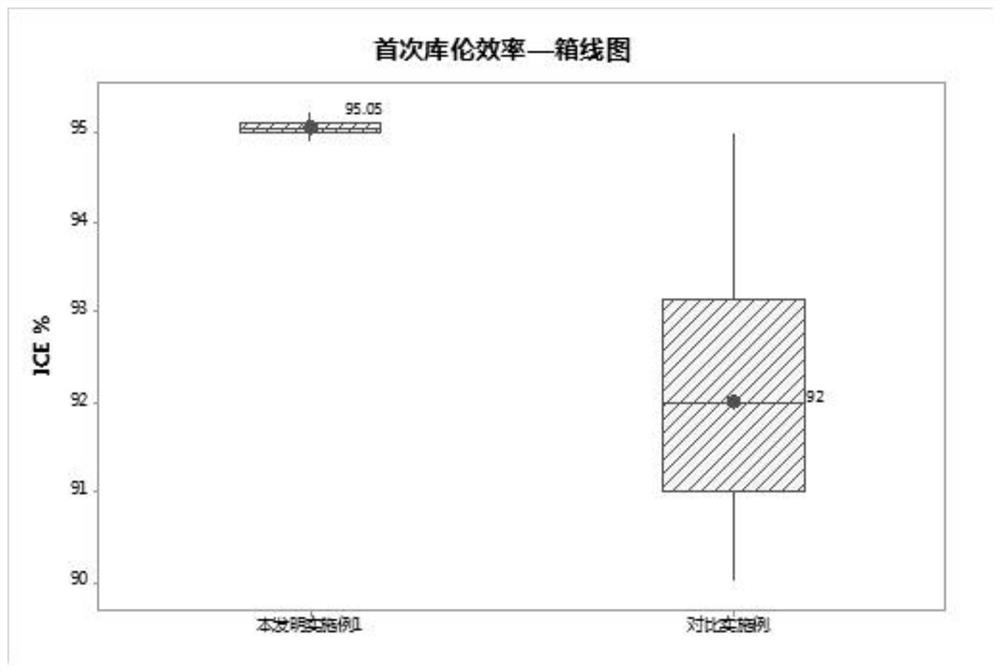

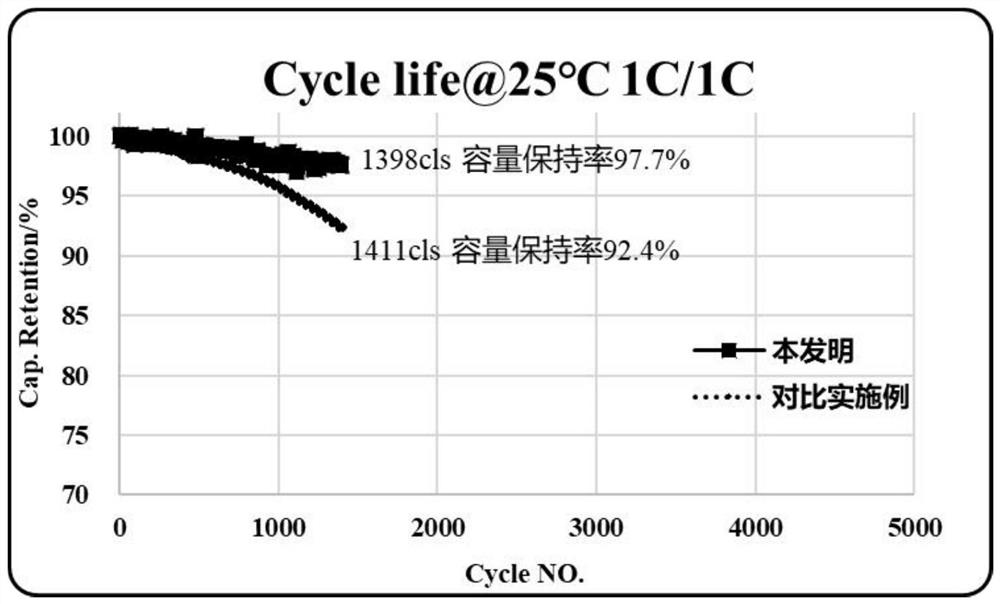

Embodiment 1

[0068] According to the mass ratio of 95:2.5:2:0.5, the high-capacity layered oxide cathode material O3-Na[Cu 1 / 9 Ni 2 / 9 Fe 1 / 3 Mn 1 / 3 ]O 2 , polyvinylidene fluoride, conductive agent-super-p, and carbon nanotubes were added to the stirring tank, N-methylpyrrolidone was added to control the solid content to be 60%, and stirred for 5h under the conditions of 2500rpm and -0.05MPa vacuum to obtain High-capacity sodium-ion cathode material.

[0069] According to the mass ratio of 96:2:1.5:0.5, the high-voltage layered oxide cathode material P2-Na 2 / 3 [Cu 1 / 3 Mn 2 / 3 ]O 2 , Na 2 C 2 O 4 , polypyrrole nanofibers and sodium carboxylate were added to the stirring tank, N-methylpyrrolidone was added to control the solid content to 70%, and stirred for 5h under the conditions of 2500rpm and -0.05MPa vacuum to obtain high-voltage sodium ion positive electrode slurry .

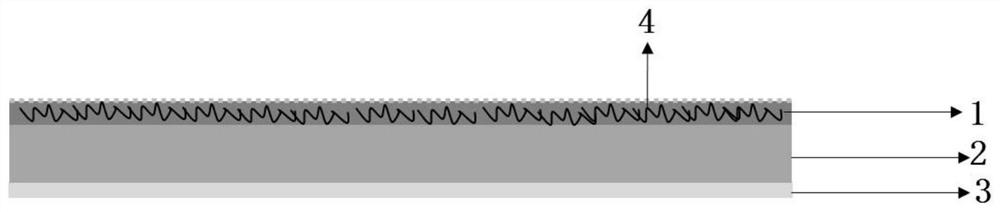

[0070] The first layer of high-capacity sodium ion positive electrode slurry and the second layer of high-...

Embodiment 2

[0083] According to the mass ratio of 94:3:1.5:0.8, the high-capacity layered oxide cathode material O3-Na[Cu 1 / 9 Ni 2 / 9 Fe 1 / 3 Mn 1 / 3 ]O 2 , polyvinylidene fluoride, conductive agent-super-p, and carbon nanotubes were added to the stirring tank, N-methylpyrrolidone was added to control the solid content to 62%, and stirred for 4h under the conditions of 1800rpm and -0.08MPa vacuum to obtain High-capacity sodium-ion cathode material.

[0084] According to the mass ratio of 97:1.9:1.9:0.4, the high-voltage layered oxide cathode material P2-Na 2 / 3 [Cu 1 / 3 Mn 2 / 3 ]O 2 , Na 2 C 2 O 4 , polypyrrole nanofibers and sodium dodecyl sulfate were added to the stirring tank, N-methylpyrrolidone was added to control the solid content to 73%, and stirred for 4.5h under the conditions of 2800rpm and -0.06MPa vacuum to obtain high-voltage sodium Ionic cathode slurry.

[0085] The first layer of high-capacity sodium ion positive electrode slurry and the second layer of high-vol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com