A kind of preparation method of lithium nickel manganese oxide lithium battery cathode material

A cathode material, lithium nickel manganese oxide technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of material specific capacity decline, prolonged experimental period, poor high-rate charge and discharge performance, etc., to improve the initial discharge. Effects of specific capacity, improved electrochemical kinetics, and easy control of experimental conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

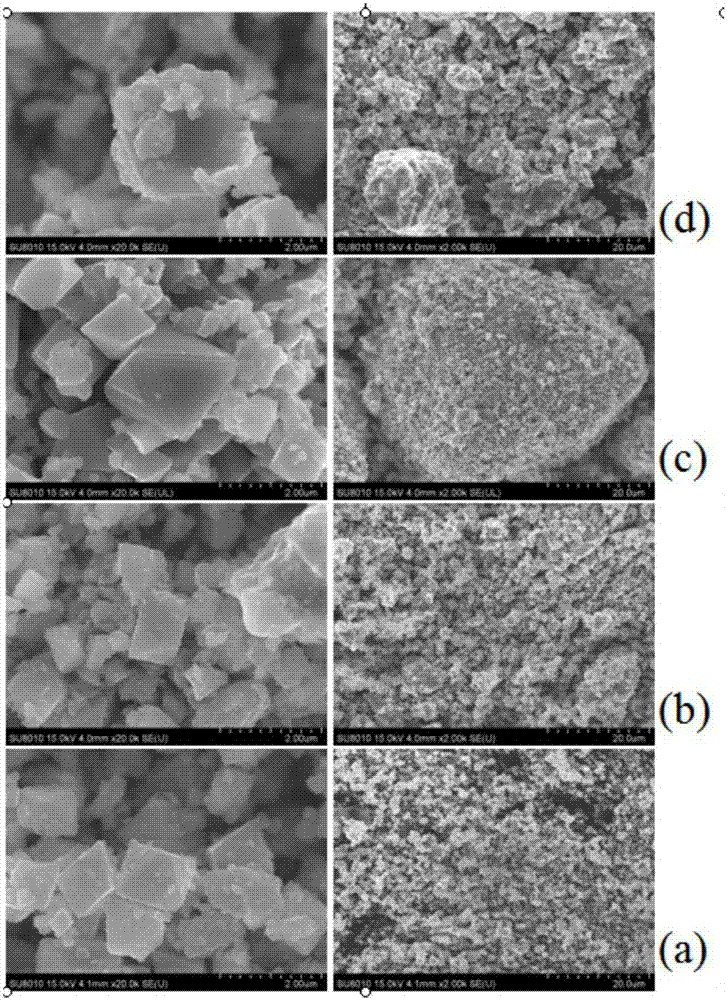

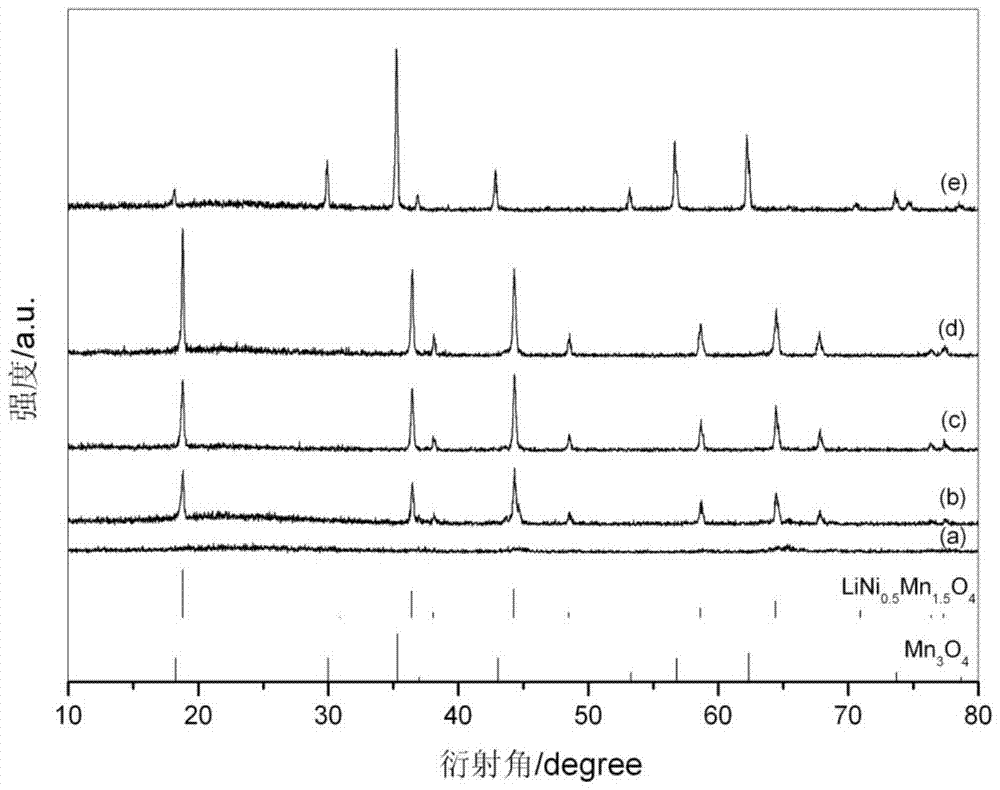

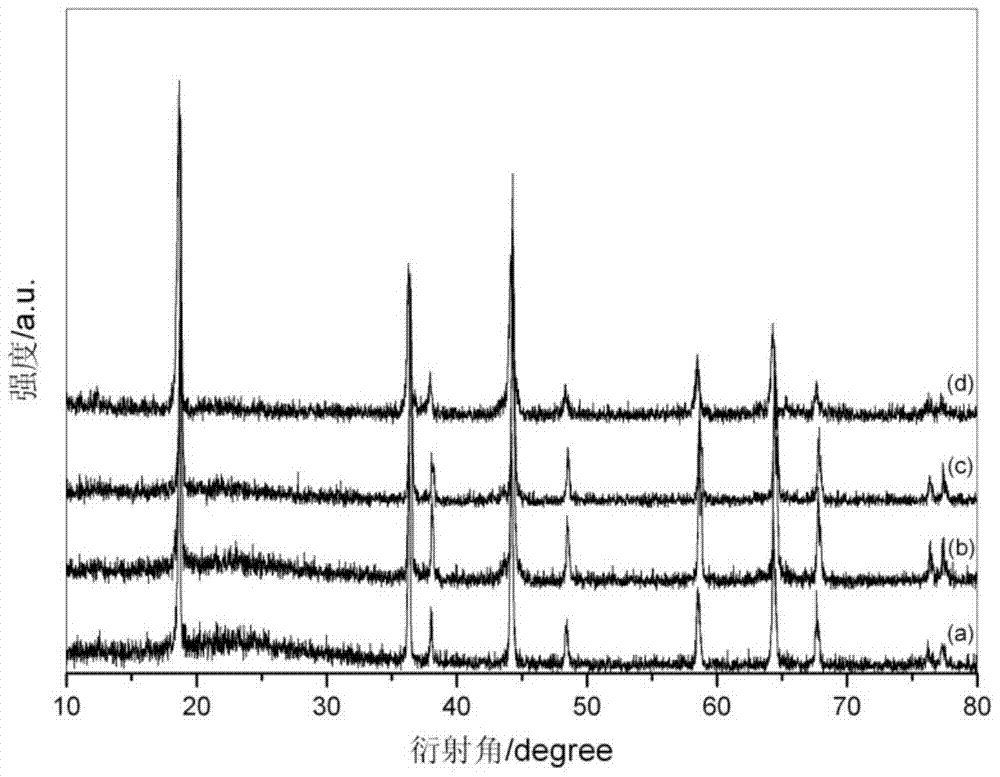

[0027] The preparation method of lithium nickel manganese oxide lithium battery anode material of the present invention comprises the following steps: (a) adding lithium source, nickel source and manganese source into a solvent to dissolve and mix to obtain a first mixed solution, the lithium source, nickel source The molar ratio of manganese source and manganese source is 10:5:9; (b) Add oxidant and mineralizer to the first mixed solution, then transfer it to an autoclave, and react at 150~230°C for 48~72 hours ; (c) Grinding the product in step (b) into powder, pressing it into a sheet, and then heating it at 800-950°C for 12-24 hours in an air atmosphere; the mineralizer includes the main mineralizer; The main mineralizer is KOH or / and NaOH, and its molar ratio to the nickel source is 60-180:5; the molar ratio of the oxidizing agent to the nickel source is 6:5, and the oxidizing agent is potassium permanganate or / and potassium manganate. By adding the main mineralizer an...

Embodiment 1

[0031] This embodiment provides a kind of preparation method of lithium nickel manganese oxide lithium battery cathode material, it comprises the following steps:

[0032] (a) Add 0.01mol of lithium acetate, 0.005mol of nickel acetate and 0.009mol of manganese acetate into the solvent to dissolve and mix to obtain the first mixed solution;

[0033] (b) Add 0.006 mol oxidant and mineralizer (composed of 0.01 mol lithium acetate and 0.06 mol KOH) to the first mixed solution, then transfer it to an autoclave, and react at 150°C for 72 hours;

[0034] (c) Grinding the product in step (b) into powder, pressing into flakes, and then heating at 800° C. for 24 hours in an air atmosphere.

Embodiment 2

[0036] This embodiment provides a method for preparing lithium nickel manganese oxide, the positive electrode material of lithium batteries. The preparation process is basically the same as that in Example 1, except that the composition of the mineralizer is different. It consists of 0.01mol lithium acetate and 0.12 mol KOH composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com