Maltose-derived carbon/titanium niobium oxide composite material and preparation method and application thereof

A composite material and maltose technology, which are applied in the field of maltose-derived carbon/titanium niobium oxide composite materials and their preparation to achieve the effects of improving utilization, increasing specific surface area, and improving rate performance and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Wash the purchased glutinous rice and pour it into a pot to simmer and stir it with the chopped malt, let it ferment for 4-6 hours until the juice is transformed. Then the juice is filtered out and boiled at high temperature to form a paste, and after cooling, it becomes an amber-like candy. The titanium niobium oxide powder was poured into maltose and stirred ultrasonically for 30 minutes, the mass ratio of titanium niobium oxide powder and maltose was 1:4, and then freeze-dried with a freeze dryer for 24 hours. The precursor obtained by freeze-drying was preheated at 600°C in argon for 4h, then transferred to a tube furnace for sintering at 800°C for 3h, and the heating rate was 5°C / min. After cooling, maltose-derived carbon / titanium niobium was obtained Oxygen composites.

Embodiment 2

[0031] Wash the purchased glutinous rice and pour it into a pot to simmer and stir it with the chopped malt, let it ferment for 4-6 hours until the juice is transformed. Then the juice is filtered out and boiled at high temperature to form a paste, and after cooling, it becomes an amber-like candy. The titanium niobium oxide powder was poured into maltose and stirred ultrasonically for 30 minutes, the mass ratio of titanium niobium oxide powder and maltose was 1:4, and then freeze-dried with a freeze dryer for 24 hours. The precursor obtained by freeze-drying was preheated at 600°C in argon for 4h, then transferred to a tube furnace for sintering at 800°C for 5h, and the heating rate was 5°C / min. After cooling, maltose-derived carbon / titanium niobium was obtained Oxygen composites.

Embodiment 3

[0033] Wash the purchased glutinous rice and pour it into a pot to simmer and stir it with the chopped malt, let it ferment for 4-6 hours until the juice is transformed. Then the juice is filtered out and boiled at high temperature to form a paste, and after cooling, it becomes an amber-like candy. The titanium niobium oxide powder was poured into maltose and stirred ultrasonically for 30 minutes, the mass ratio of titanium niobium oxide powder and maltose was 1:4, and then freeze-dried with a freeze dryer for 24 hours. The precursor obtained by freeze-drying was preheated in argon at 600°C for 4h, then transferred to a tube furnace for sintering at 800°C for 4h, and the heating rate was 5°C / min. After cooling, maltose-derived carbon / titanium niobium was obtained Oxygen composites.

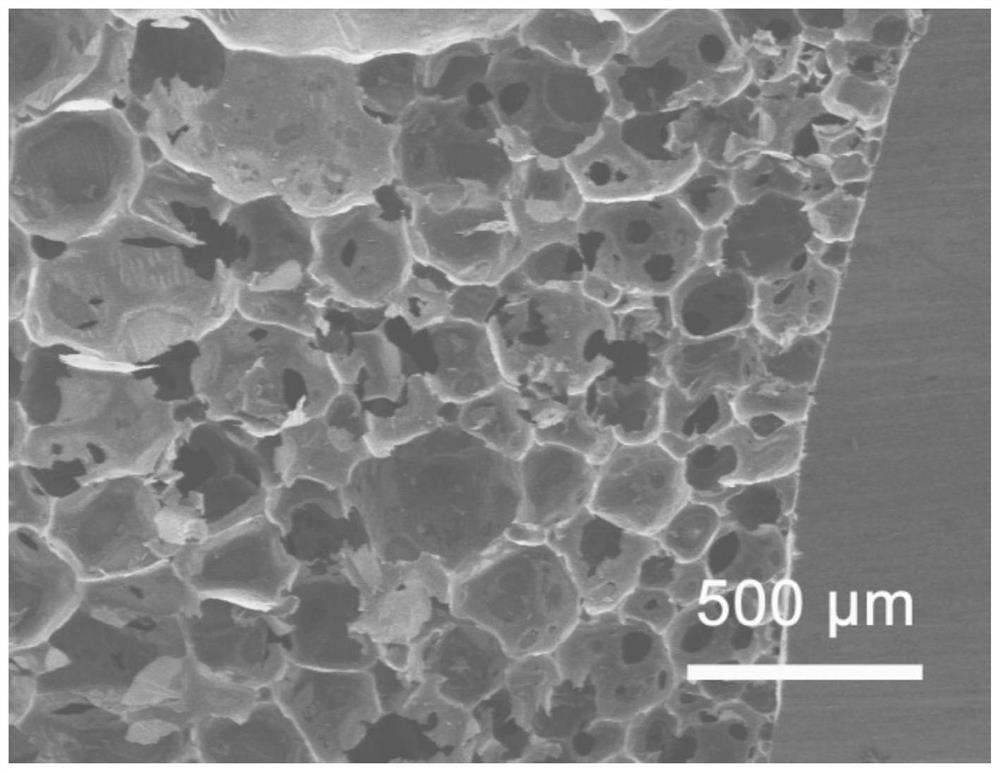

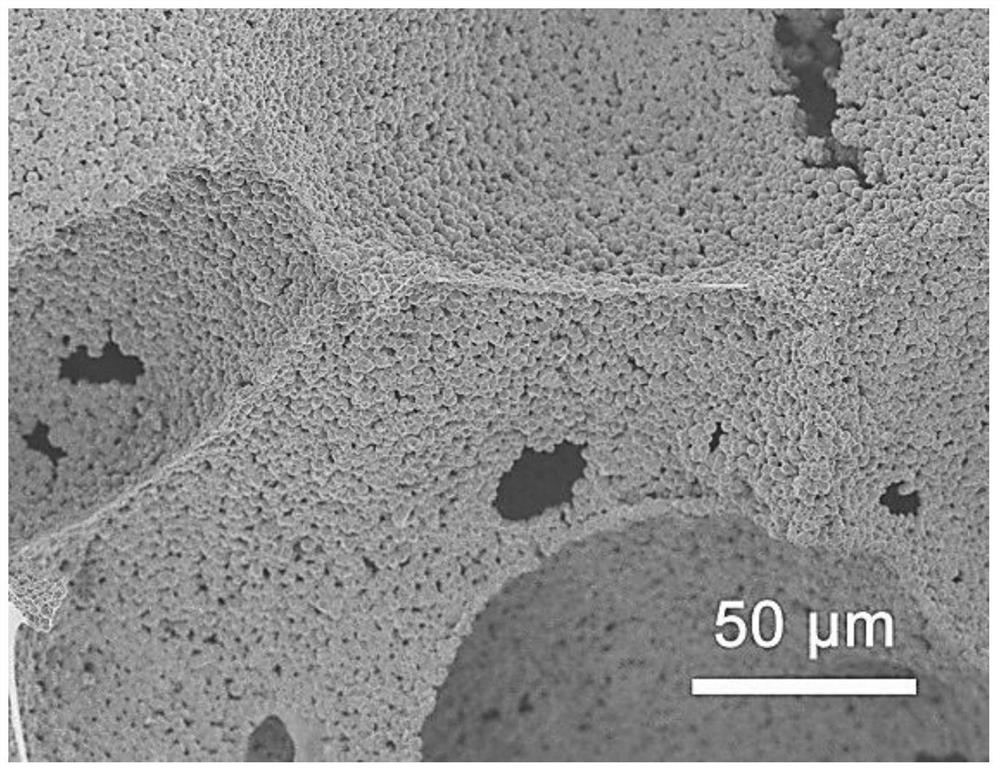

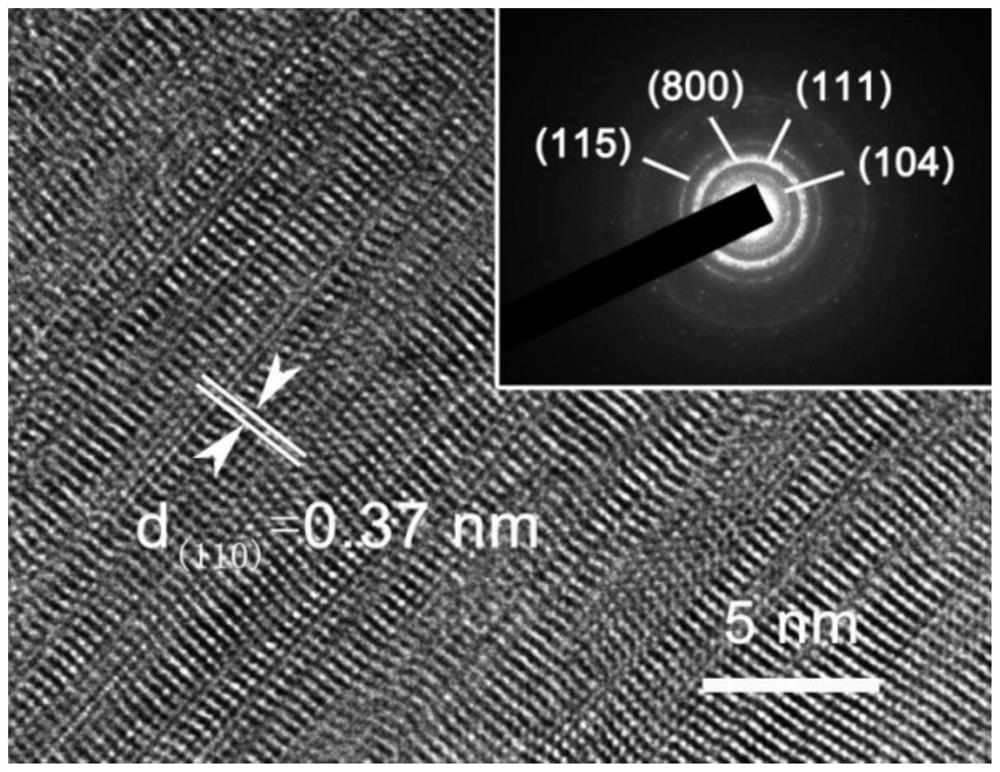

[0034] figure 1 , 2 It is a scanning electron micrograph of the maltose-derived carbon / titanium-niobium-oxygen composite material prepared in Example 3. image 3 It is a transmission electron ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com