A highly stable three-dimensional mxene-cof-li composite metal lithium anode material and its preparation method and application

A mxene-cof-li and composite metal technology, applied in the field of electrode material preparation, can solve the problems of low charge and discharge capacity, poor electrode cycle stability, etc., and achieve the effects of high safety, small polarization phenomenon, and controllable deposition amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

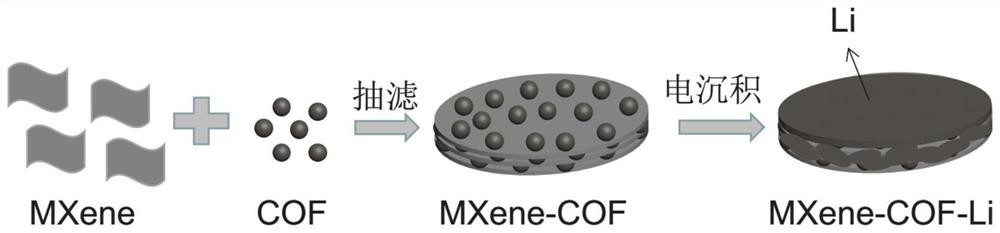

[0044] In a second aspect of the present invention, a method for preparing a highly stable three-dimensional MXene-COF-Li composite metal lithium negative electrode material is provided, comprising:

[0045] After mixing MXene and COF nanoparticles, a three-dimensional flexible MXene-COF self-supporting film was formed by suction filtration, and then metal lithium was deposited on the three-dimensional flexible MXene-COF self-supporting film.

[0046] In one or more embodiments of the present invention, the mixing of MXene and COF nanoparticles is as follows: adding COF nanoparticles into an aqueous solution of MXene, stirring or ultrasonically treating;

[0047] Preferably, the suction filtration adopts vacuum suction filtration;

[0048] Preferably, the stirring or ultrasonic treatment time is 5-20min, preferably 10min;

[0049] Preferably, after the suction filtration, the drying process of the three-dimensional flexible MXene-COF self-supporting film is further included, ...

Embodiment 1

[0073] The preparation and application of a highly stable three-dimensional MXene-COF-Li composite metal lithium anode material, comprising the following steps ( figure 1 ):

[0074] (1) Etch Ti by acid etching 3 AlC 2 MAX phase powder to obtain Ti 3 C 2 T x MXene aqueous solution with a concentration of 1 mg / mL.

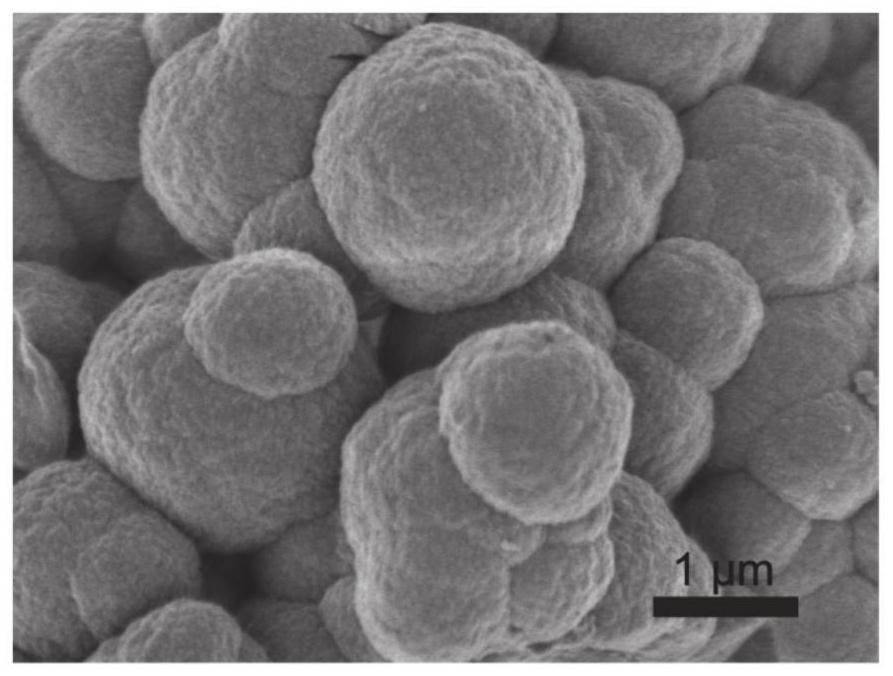

[0075] (2) Using trimesicaldehyde and p-phenylenediamine as raw materials and dioxane as solvent to synthesize COF-LZU1 nanoparticles ( figure 2 ).

[0076] (3) Add COF-LZU1 nanoparticles with a mass of 1.5 mg to 30 mL of Ti 3 C 2 T x The MXene aqueous solution was sonicated for 10 minutes to obtain a uniform mixed solution.

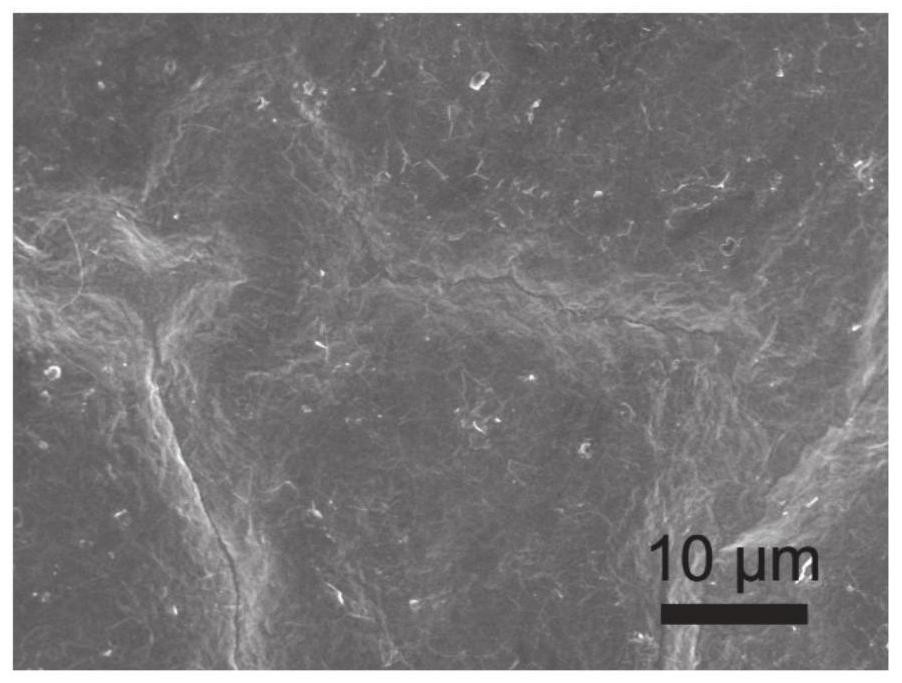

[0077] (4) The mixed solution in step (3) was filtered into MXene-COF self-supporting film by vacuum filtration device, and dried at 60°C for 12h ( Figure 4 ).

[0078] (5) The MXene-COF-Li composite metal lithium anode material was obtained by electrochemically depositing lithium in a 1M LiTFSI-DOL / DME (volume ratio 1:1) liqu...

Embodiment 2

[0081] The preparation and application of a highly stable three-dimensional MXene-COF-Li composite metal lithium anode material, comprising the following steps ( figure 1 ):

[0082] (1) Etch V by acid etching2 AlC MAX phase powder gives V 2 CT x MXene aqueous solution with a concentration of 1 mg / mL.

[0083] (2) COF-LZU1 nanoparticles were synthesized by using trimesicaldehyde and p-phenylenediamine as raw materials and dioxane as solvent.

[0084] (3) Add COF-LZU1 nanoparticles with a mass of 1.5 mg to 30 mL of V 2 CT x The MXene aqueous solution was sonicated for 10 minutes to obtain a uniform mixed solution.

[0085] (4) Using a vacuum filtration device, the mixed solution in step (3) was suction-filtered into an MXene-COF self-supporting film, and dried at 60° C. for 12 h.

[0086] (5) The MXene-COF-Li composite metal lithium anode material was obtained by electrochemically depositing lithium in 1M LiTFSI-DOL / DME (volume ratio 1:1) liquid electrolyte with a CR203...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com