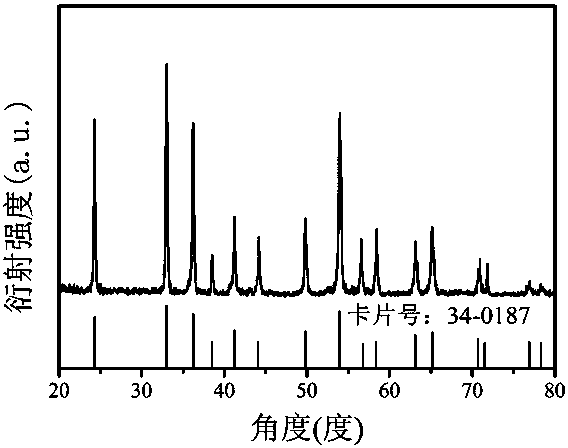

Preparation method of spherical lithium ion battery anode composite material

A technology for lithium-ion batteries and composite materials, which is applied in the preparation of negative spherical vanadium trioxide/carbon composite materials for lithium-ion batteries and the preparation of spherical lithium-ion battery negative electrodes V2O3/C composite materials, which can solve the problem of low specific surface area of materials, Unfavorable industrial application, poor electrochemical performance and other problems, to achieve the effects of high specific surface area, shortened diffusion path, and high tap density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment includes the following steps:

[0032] (1) First, weigh 1 mmol of glucose, add it to 50 mL of water and ethylene glycol mixed solution, wherein the volume ratio of water and ethylene glycol is 1:10, transfer it to a magnetic stirrer, continue stirring and heating until Dissolve, heat at 80°C, and stir at 400 rpm to obtain solution A;

[0033] (2) Then, weigh 5 mmol of ammonium metavanadate and add it into solution A, continue to stir and heat until dissolved, the heating temperature is 80°C, and the stirring rate is 450 rpm to obtain solution B;

[0034] (3) Next, transfer the solution B into the reaction kettle, and conduct a solvothermal reaction at a temperature of 190° C. for 18 hours to obtain a precursor;

[0035] (4) The obtained precursor was washed with alcohol three times, centrifuged, dried, and finally heat-treated under an inert atmosphere to obtain V 2 o 3 / C material. The centrifugal speed is 8000 r / min; the drying temperature is 80°C,...

Embodiment 2

[0046] This embodiment includes the following steps:

[0047] (1) First, weigh 0.5 mmol of glucose, add it to a mixed solution of 60 mL of water and ethylene glycol, wherein the volume ratio of water and ethylene glycol is 1:8, transfer it to a magnetic stirrer, keep stirring and Heat until dissolved, the heating temperature is 80°C, the stirring rate is 400 rpm, and solution A is obtained;

[0048] (2) Then, weigh 6 mmol of sodium vanadate and add it into solution A, continue to stir and heat until dissolved, the heating temperature is 80°C, and the stirring rate is 450 rpm to obtain solution B;

[0049] (3) Next, transfer the solution B into the reaction kettle, and conduct a solvothermal reaction at a temperature of 180° C. for 20 hours to obtain a precursor;

[0050] (4) The obtained precursor was washed with alcohol three times, centrifuged, dried, and finally heat-treated under an inert atmosphere to obtain V 2 o 3 / C material. The centrifugal speed is 8000 r / min; th...

Embodiment 3

[0058] This embodiment includes the following steps:

[0059] (1) First, weigh 0.1 mmol of glucose, add it to 20 mL of water and ethylene glycol mixed solution, wherein the volume ratio of water and ethylene glycol is 1:12, transfer it to a magnetic stirrer, continue to stir and heat Until it dissolves, the heating temperature is 80°C and the stirring rate is 400 rpm to obtain solution A;

[0060] (2) Then, weigh 7 mmol of sodium metavanadate and add it into solution A, continue to stir and heat until dissolved, the heating temperature is 80°C, and the stirring rate is 450 rpm to obtain solution B;

[0061] (3) Next, transfer the solution B into the reaction kettle, and conduct a solvothermal reaction at a temperature of 195° C. for 14 hours to obtain a precursor;

[0062] (4) Finally, wash 3 times with alcohol, centrifuge, dry, and finally heat-treat in an inert atmosphere to obtain V 2 o 3 / C material. The centrifugal speed is 8000 r / min; the drying temperature is 80°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com