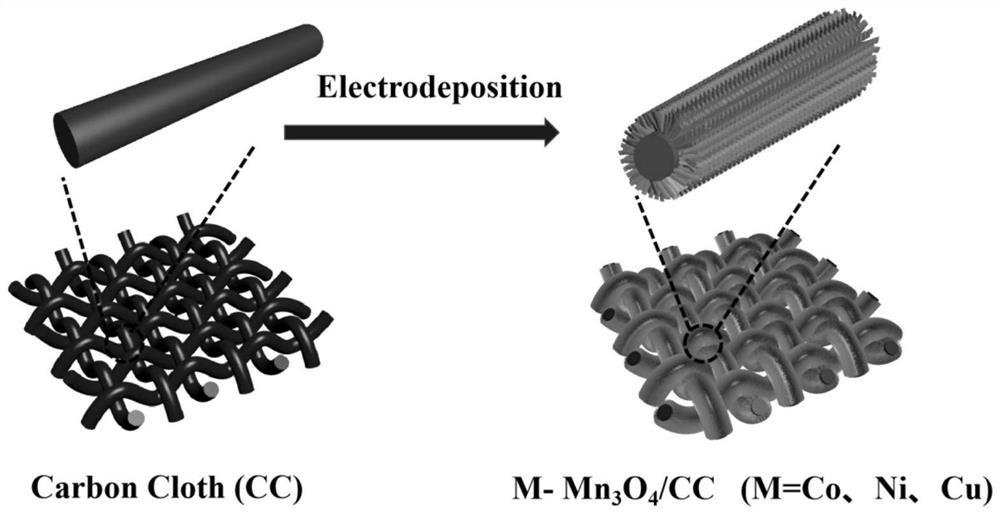

Transition metal ion doped manganous-manganic oxide nanosheet array based on carbon cloth growth as well as preparation method and application thereof

A transition metal ion, manganese tetroxide technology, applied in nanotechnology for materials and surface science, manganese oxide/hydroxide, nanotechnology, etc. , structural instability and other problems, to achieve the effect of low preparation cost, simple method and improved electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

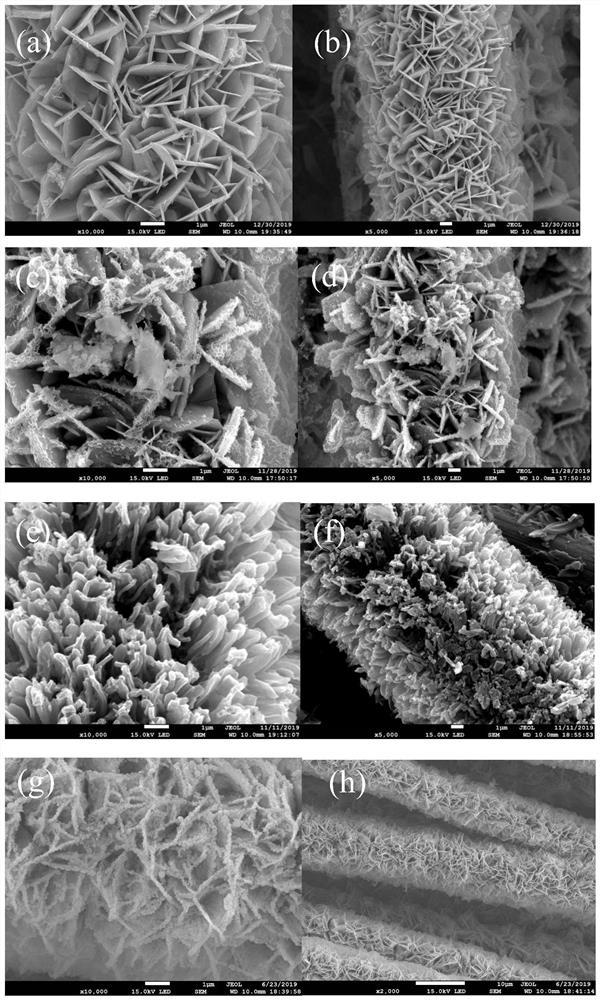

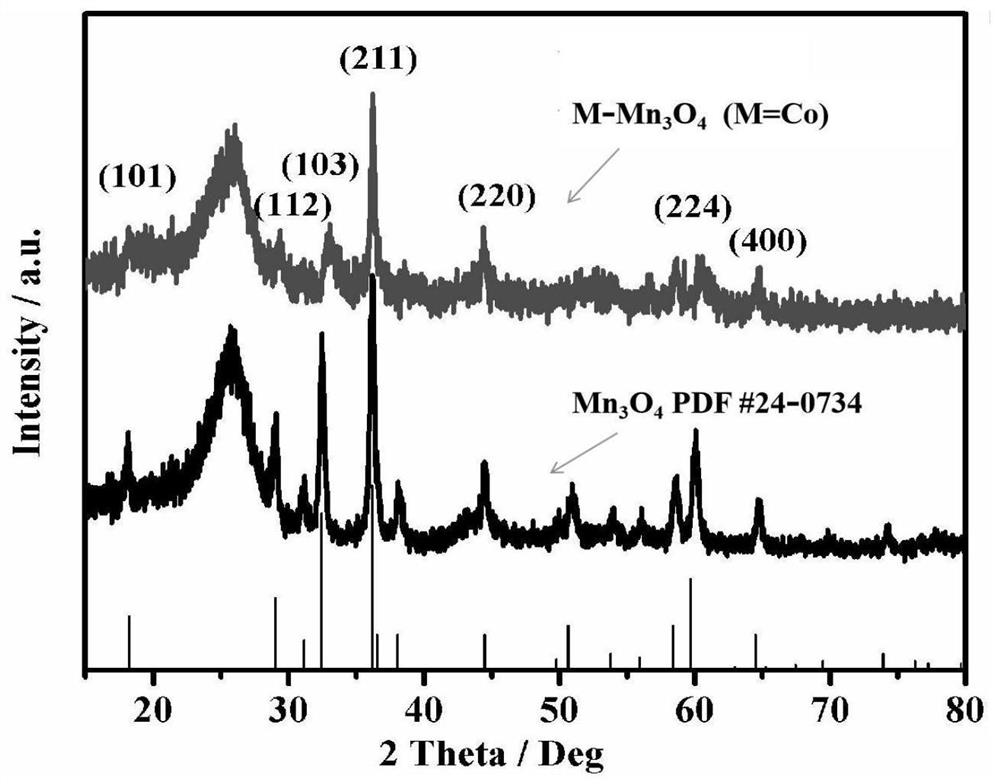

[0050] A cobalt ion-doped trimanganese tetraoxide (Co-Mn) based on carbon cloth growth in this embodiment 3 o 4 / CC) the preparation method of nanosheet array, the steps are as follows:

[0051] (1) Carbon cloth pretreatment

[0052] First make a 3×3cm 2 The standard empty carbon cloth is soaked in concentrated nitric acid with a concentration of 12mol / L, heated in a water bath at a constant temperature of 80°C for 1 to 2 hours, then the empty carbon cloth is ultrasonically cleaned several times with absolute ethanol and deionized water, and finally dried Boxes are also left to dry overnight.

[0053] (2) material preparation

[0054] Electrolyte preparation: prepare 100mL containing 0.1mol / L manganese acetate tetrahydrate (Mn(CH 3 COO) 2 4H 2 O), 0.1mol / L sodium sulfate (Na 2 SO 4 ) and 0.005mol / L cobalt acetate tetrahydrate (Co(CH 3 COO) 2 4H 2 O) mixed aqueous solutions.

[0055] (3) Constant potential electrodeposition

[0056] The treated empty carbon cloth ...

Embodiment 2

[0060] A kind of nickel ion doped manganese tetraoxide (Ni-Mn 3 o 4 / CC) the preparation method of nanosheet array, the steps are as follows:

[0061] (1) Carbon cloth pretreatment

[0062] First make a 3×3cm 2 The standard empty carbon cloth is soaked in concentrated nitric acid with a concentration of 12mol / L, heated in a water bath at a constant temperature of 80°C for 1 to 2 hours, then the empty carbon cloth is ultrasonically cleaned several times with absolute ethanol and deionized water, and finally dried Boxes are also left to dry overnight.

[0063] (2) material preparation

[0064] Electrolyte preparation: prepare 100mL containing 0.1mol / L manganese acetate tetrahydrate (Mn(CH 3 COO) 2 4H 2 O), 0.1mol / L sodium sulfate (Na 2 SO 4 ) and 0.005mol / L nickel acetate tetrahydrate (Ni(CH 3 COO) 2 4H 2 O) mixed solution.

[0065] (3) Constant potential electrodeposition

[0066] The treated empty carbon cloth was used as the working electrode for constant potent...

Embodiment 3

[0070] A copper ion-doped trimanganese tetraoxide (Cu-Mn) based on carbon cloth growth in this embodiment 3 o 4 / CC) the preparation method of nanosheet array, the steps are as follows:

[0071] (1) Carbon cloth pretreatment

[0072] First make a 3×3cm 2 The standard empty carbon cloth is soaked in concentrated nitric acid with a concentration of 12mol / L, heated in a water bath at a constant temperature of 80°C for 1 to 2 hours, then the empty carbon cloth is ultrasonically cleaned several times with absolute ethanol and deionized water, and finally dried Boxes are also left to dry overnight.

[0073] (2) material preparation

[0074] Electrolyte preparation: prepare 100mL containing 0.1mol / L manganese acetate tetrahydrate (Mn(CH 3 COO) 2 4H 2 O), 0.1mol / L sodium sulfate (Na 2 SO 4 ) and 0.005mol / L copper acetate monohydrate (Cu(CH 3 COO) 2 ·H 2 O) mixed aqueous solution.

[0075] (3) Electrodeposition by CV scanning method

[0076] The treated empty carbon cloth w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com