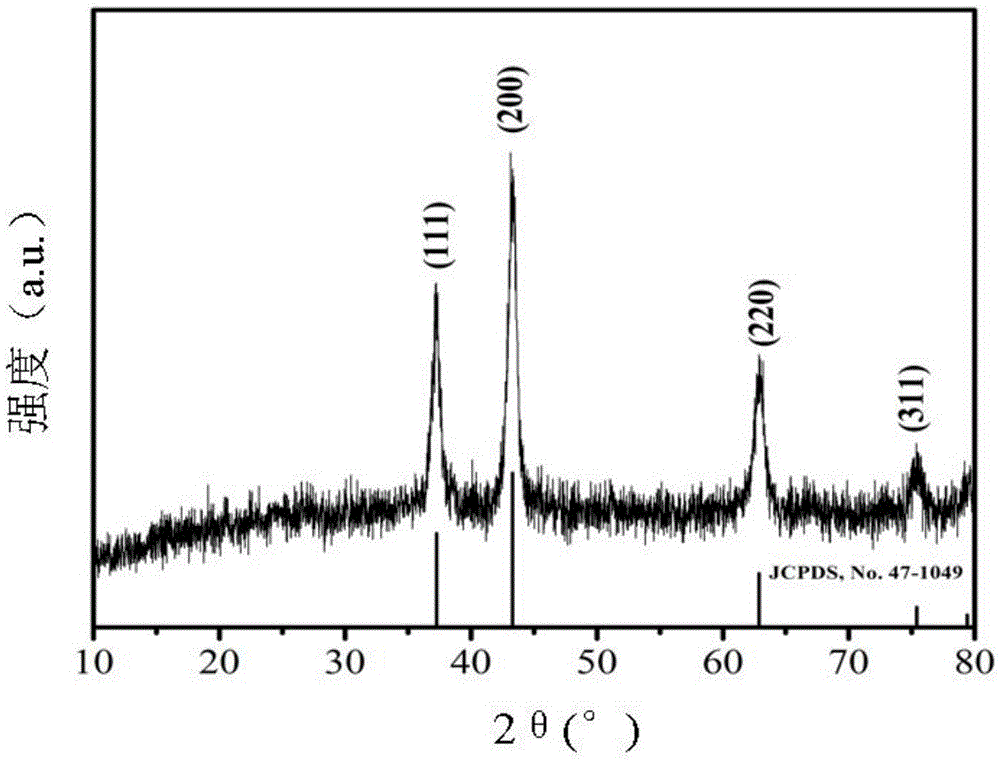

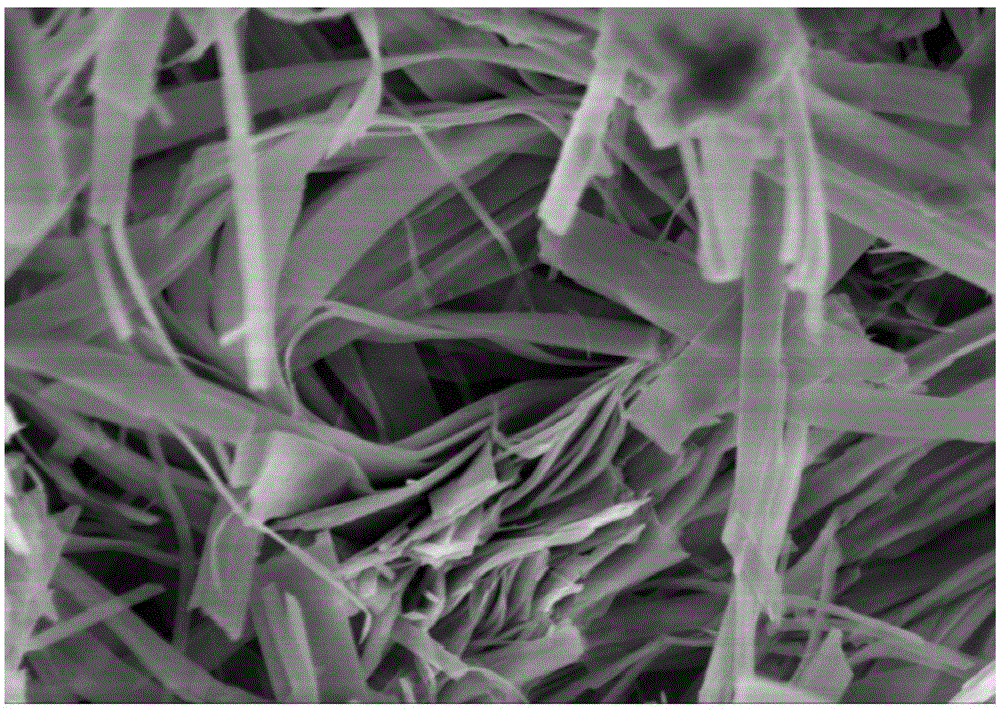

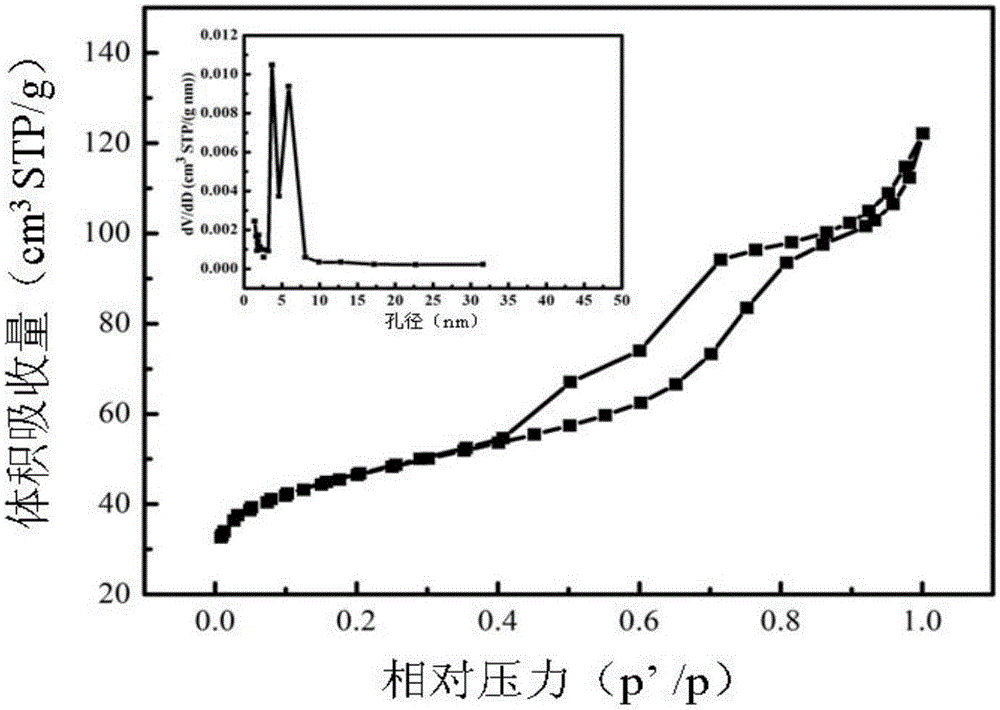

A preparation method of a ribbon-shaped hierarchical mesoporous nickel oxide high specific capacitance electrode material

A technology for high specific capacitance and electrode materials, which is applied in the preparation of nickel oxide electrode materials and the preparation of ribbon-shaped graded mesoporous nickel oxide high specific capacitance electrode materials. problem, to achieve the effect of simple process, low cost, and reduced diffusion path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In this example, nickel sulfate, guanidine hydrochloride and sodium chloride were used as raw materials, and mesoporous carbon was used as a template to prepare a ribbon-shaped graded mesoporous nickel oxide high specific capacitance electrode material through the template method. The specific steps are as follows:

[0029] (1) The preparation of nickel sulfate solution: be nickel sulfate according to the mass ratio of each substance: sodium chloride: water=0.0016: 0.00036: 1, be mixed with mixed solution, stir 30min, prepare the nickel sulfate solution containing sodium chloride;

[0030] (2) Preparation of guanidine hydrochloride solution: according to the mass ratio of each substance, it is guanidine hydrochloride: water=0.0024: 1, mixed into a mixed solution, stirred for 30min, and prepared into guanidine hydrochloride solution;

[0031] (3) Preparation of nickel hydroxide precursor and mesoporous carbon composite: Slowly add the guanidine hydrochloride solution prep...

Embodiment 2

[0041] In this example, nickel sulfate, guanidine hydrochloride and sodium chloride were used as raw materials, and mesoporous carbon was used as a template to prepare a ribbon-shaped graded mesoporous nickel oxide high specific capacitance electrode material through the template method. The specific steps are as follows:

[0042] (1) The preparation of nickel sulfate solution: be nickel sulfate according to the mass ratio of each substance: sodium chloride: water=0.0033: 0.00073: 1, be mixed with mixed solution, stir 30min, prepare the nickel sulfate solution containing sodium chloride;

[0043] (2) Preparation of guanidine hydrochloride solution: according to the mass ratio of each substance, it is guanidine hydrochloride: water=0.0048: 1, mixed into a mixed solution, stirred for 30min, and prepared into guanidine hydrochloride solution;

[0044] (3) Preparation of nickel hydroxide precursor and mesoporous carbon composite: Slowly add the guanidine hydrochloride solution prep...

Embodiment 3

[0048] In this example, nickel sulfate, guanidine hydrochloride and sodium chloride were used as raw materials, and mesoporous carbon was used as a template to prepare a ribbon-shaped graded mesoporous nickel oxide high specific capacitance electrode material through the template method. The specific steps are as follows:

[0049] (1) The preparation of nickel sulfate solution: be nickel sulfate according to the mass ratio of each substance: sodium chloride: water=0.0066: 0.0015: 1, be mixed with mixed solution, stir 30min, prepare the nickel sulfate solution containing sodium chloride;

[0050] (2) Preparation of guanidine hydrochloride solution: according to the mass ratio of each substance, it is guanidine hydrochloride: water=0.0096: 1, mixed into a mixed solution, stirred for 30min, and prepared into guanidine hydrochloride solution;

[0051] (3) Preparation of nickel hydroxide precursor and mesoporous carbon composite: Slowly add the guanidine hydrochloride solution prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com