Patents

Literature

31results about How to "No complex post-processing required" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Five-element transition metal oxide high-entropy material for lithium-ion battery

ActiveCN110600703ACustomized electrochemical performanceMeet the needs of useNegative electrodesSecondary cellsSynthesis methodsLithium-ion battery

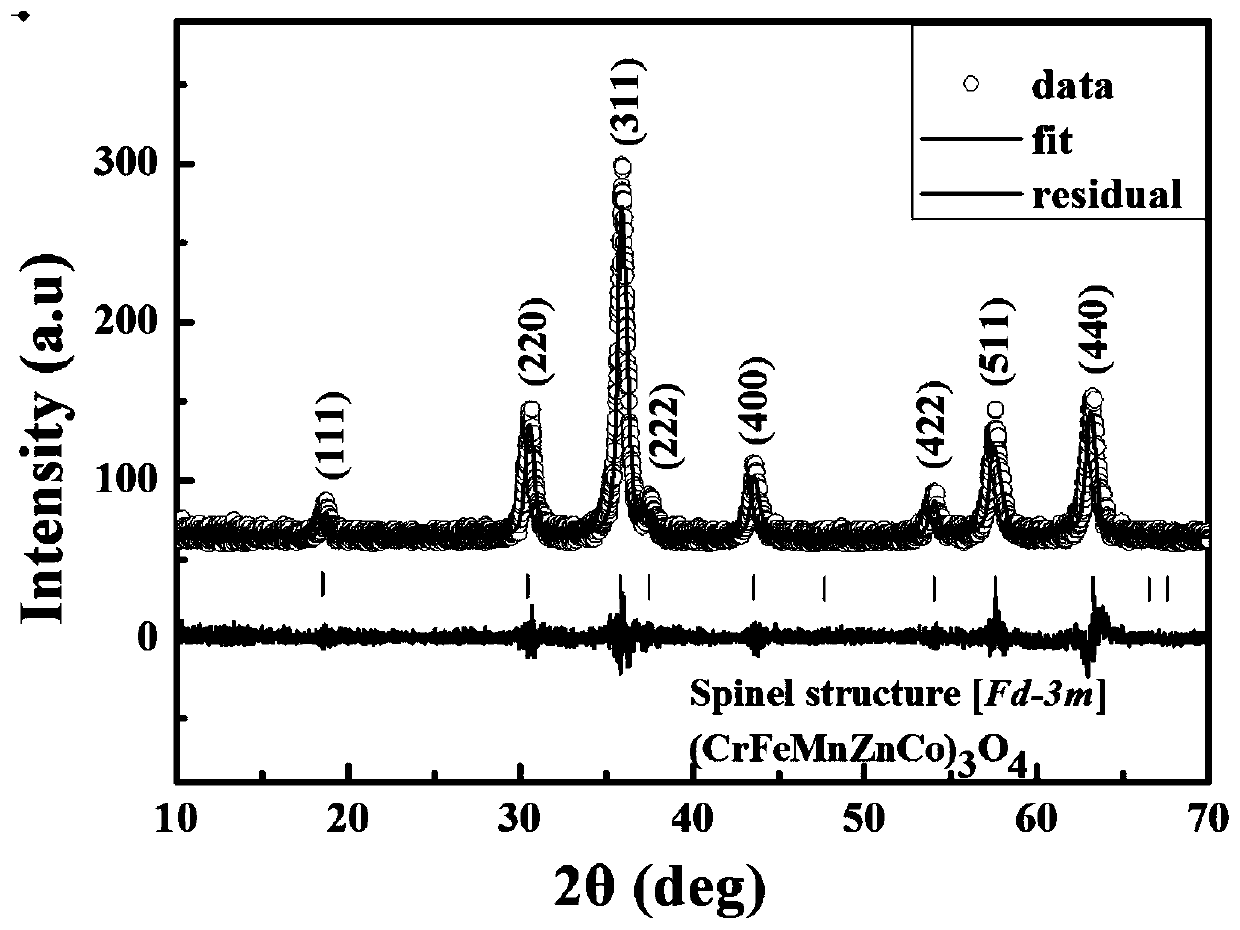

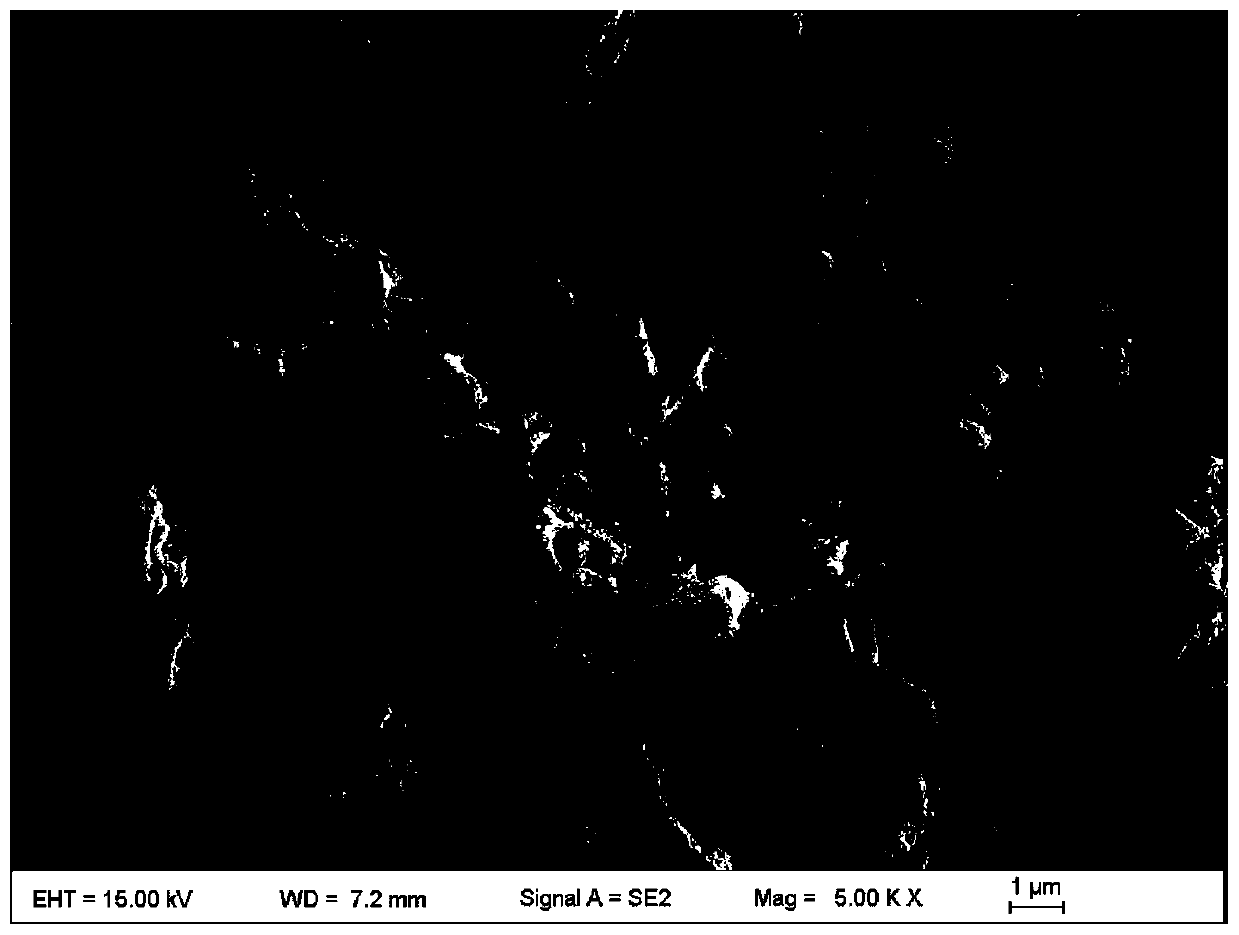

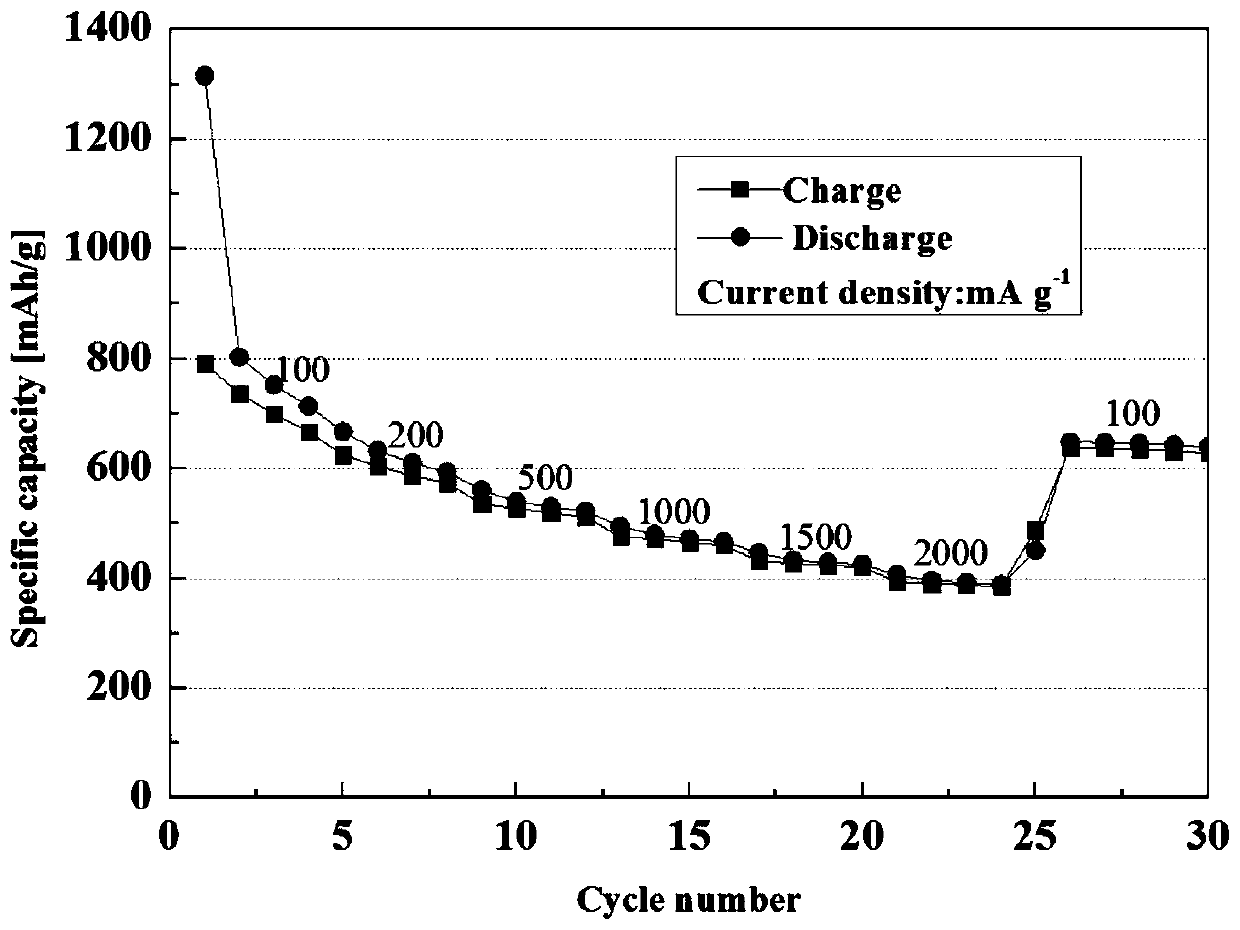

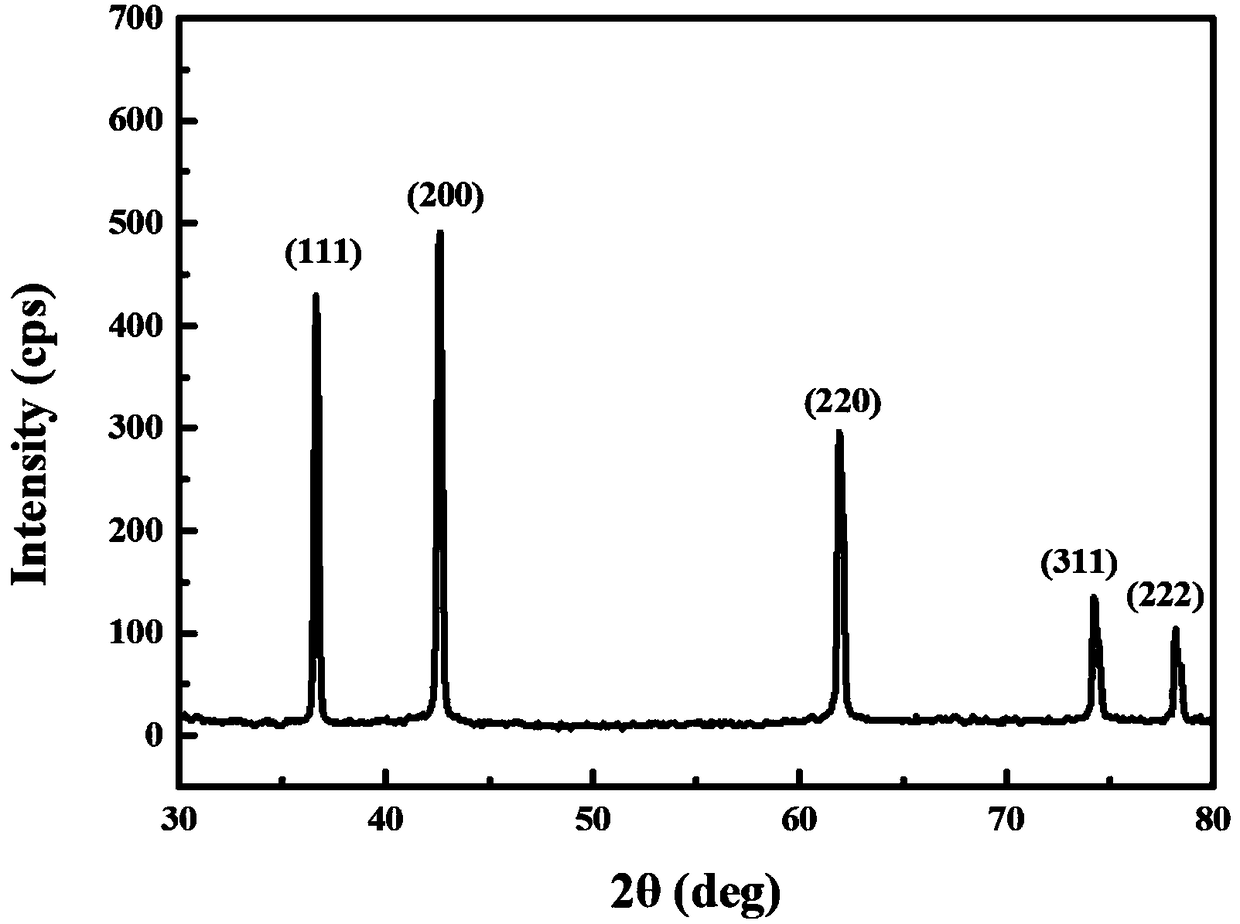

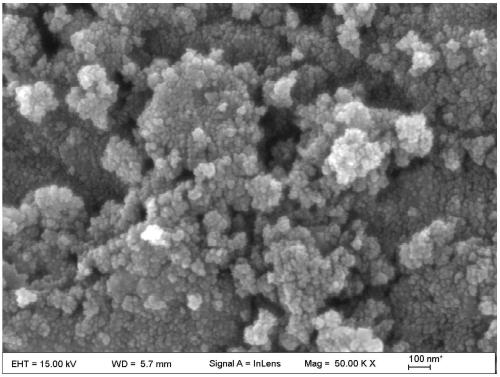

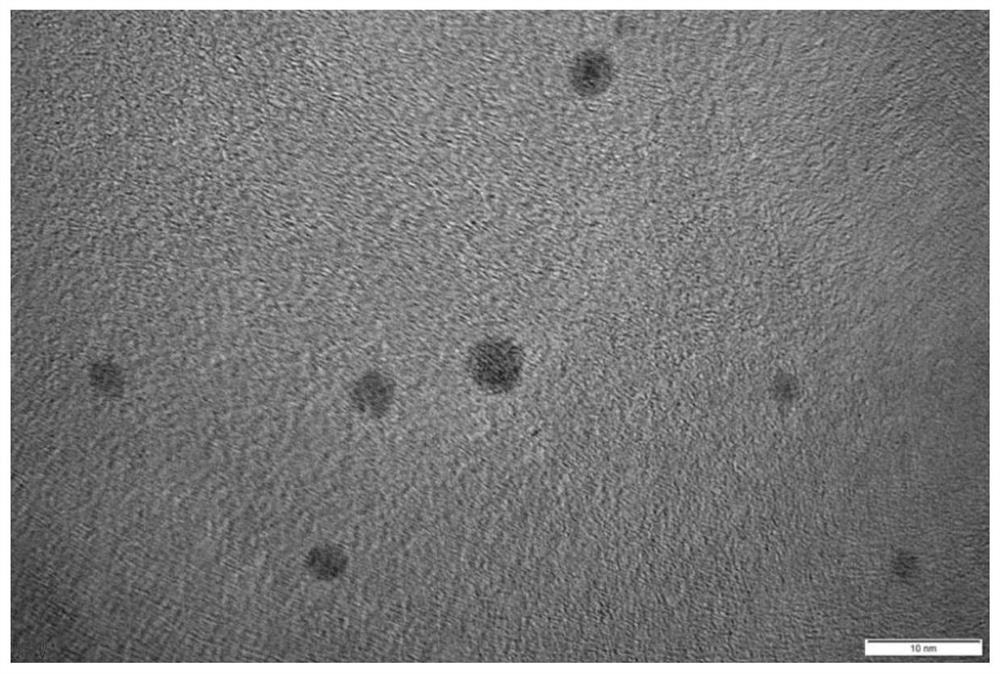

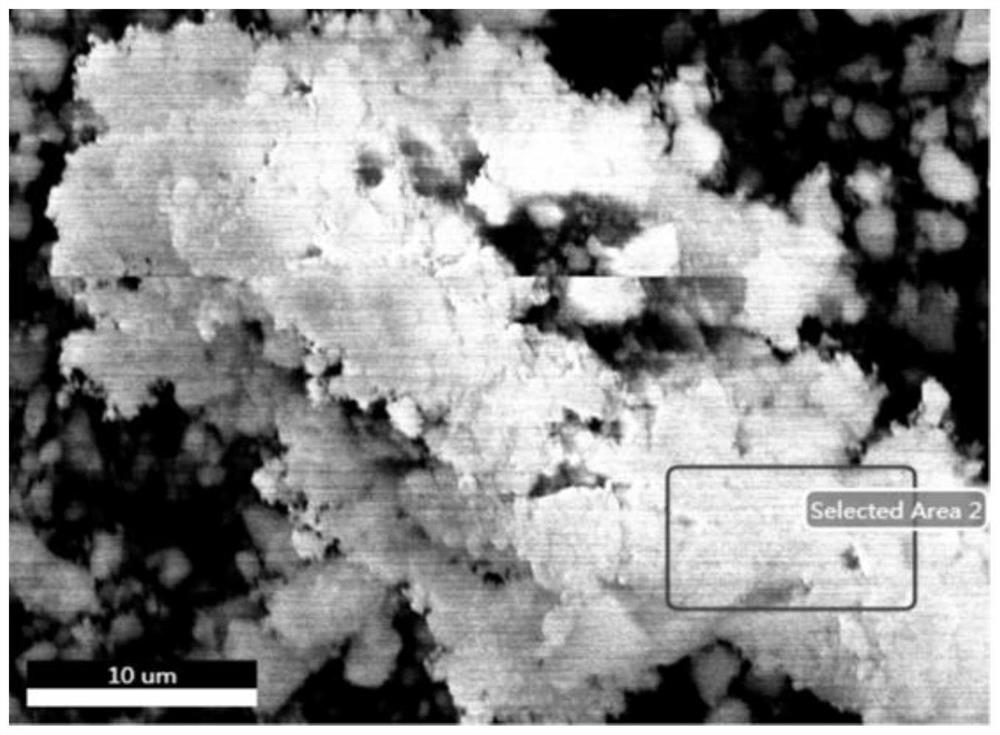

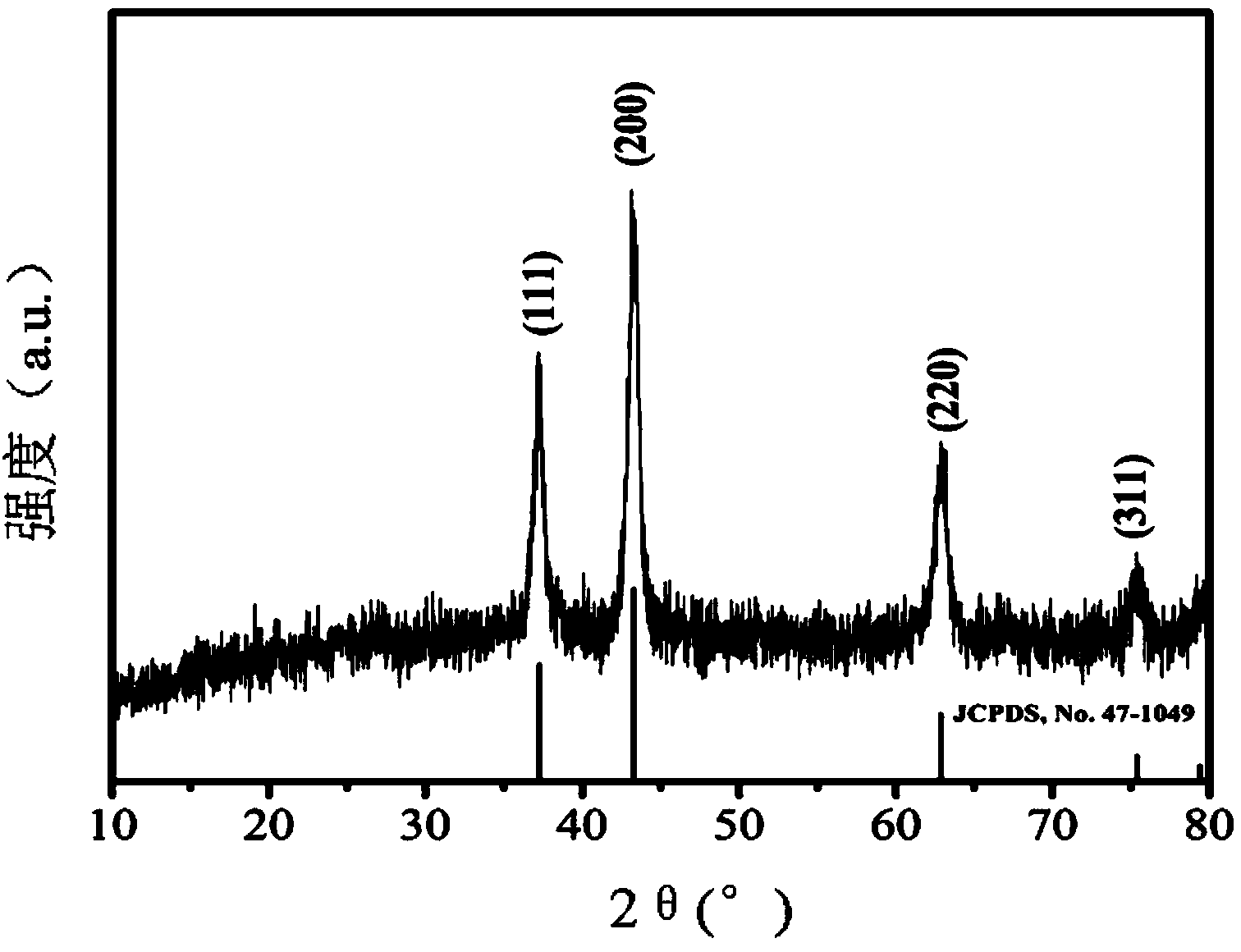

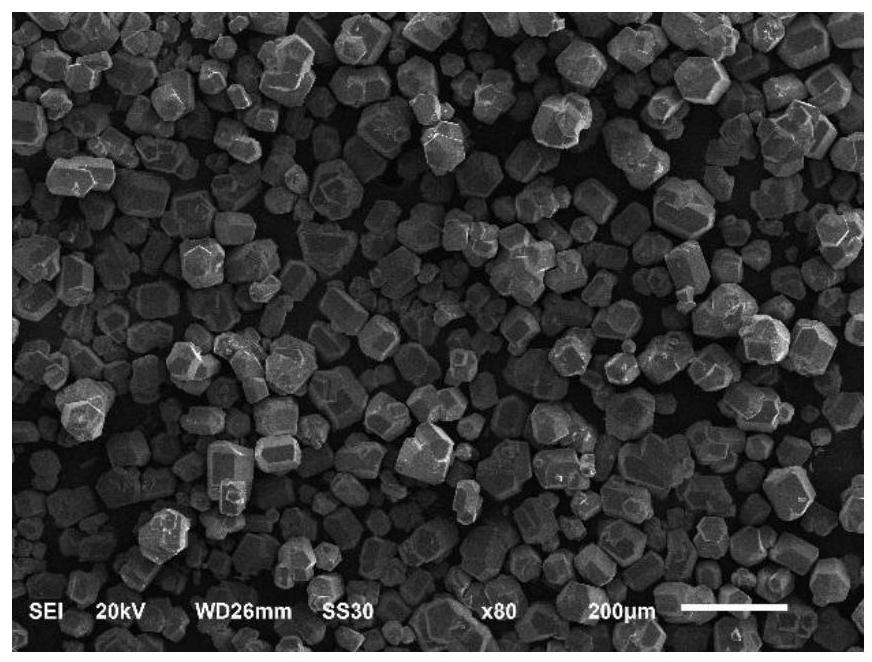

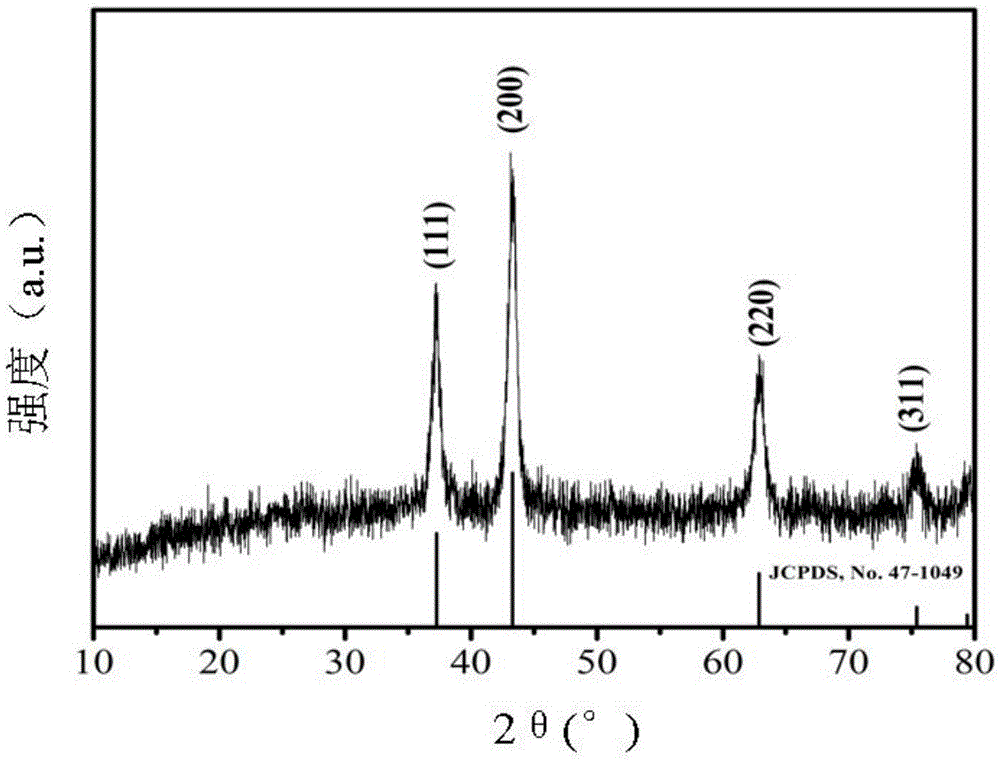

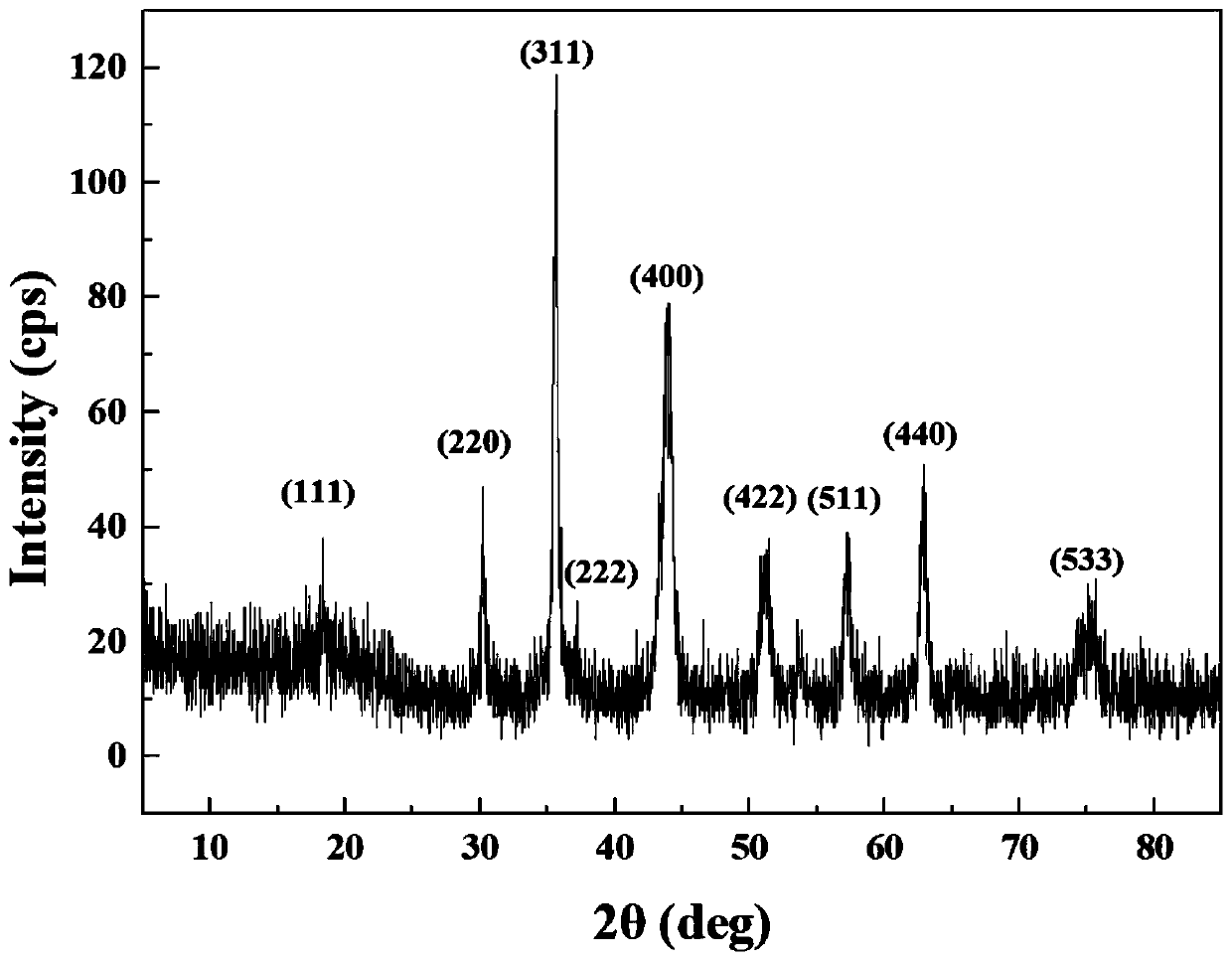

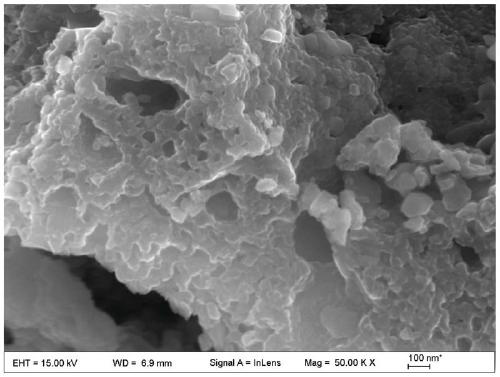

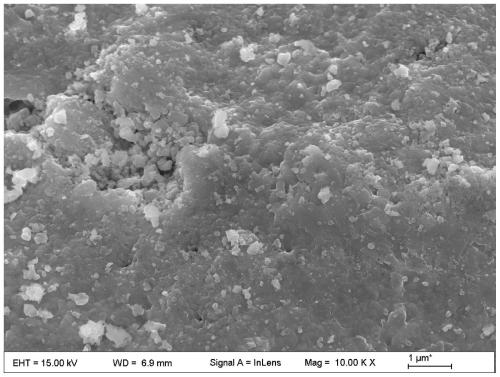

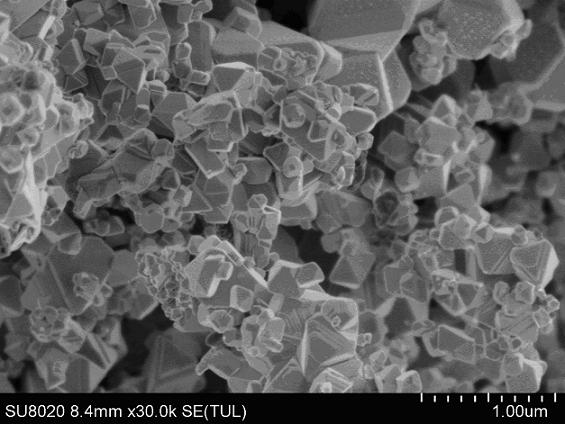

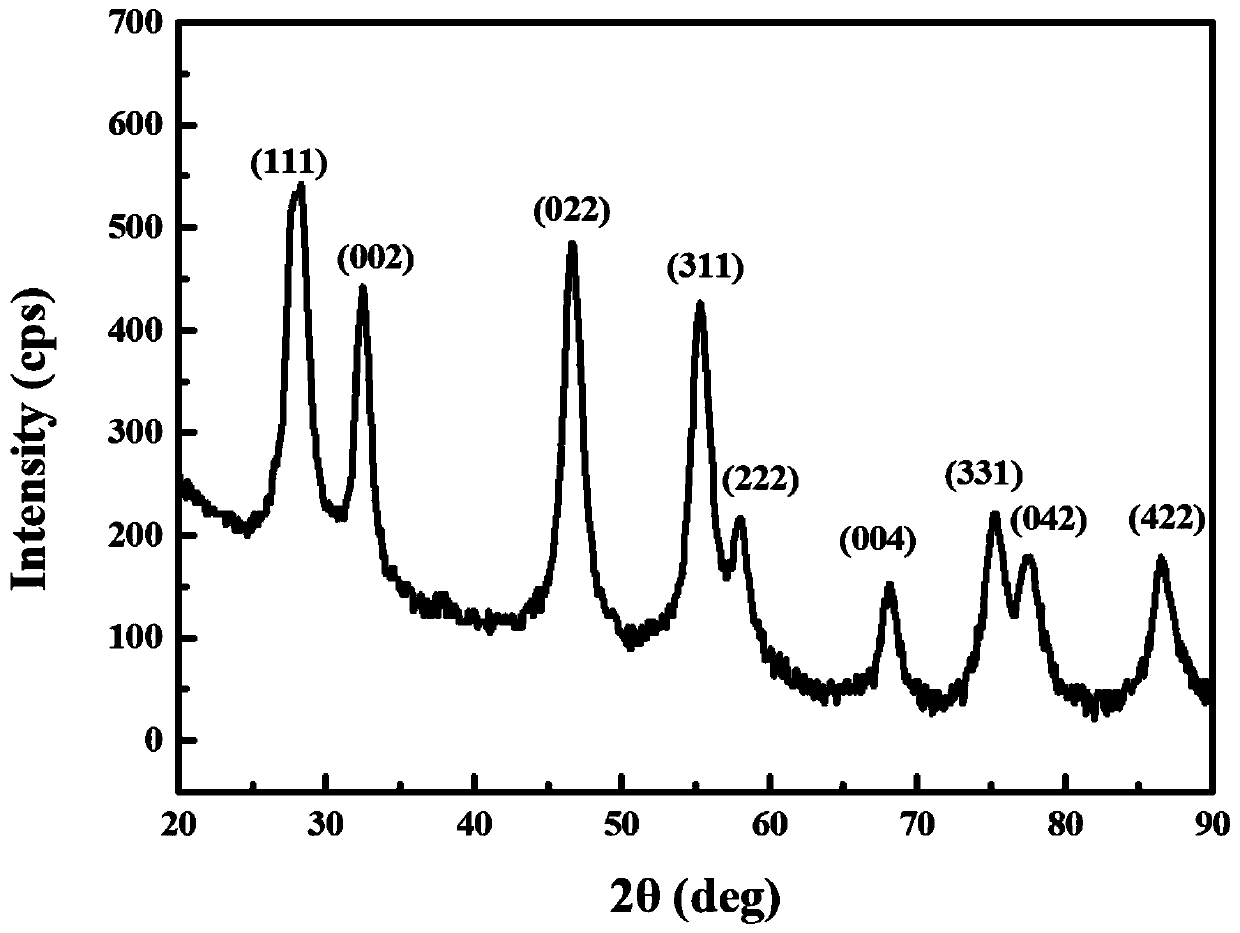

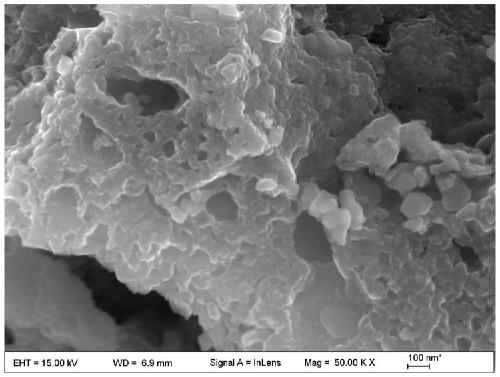

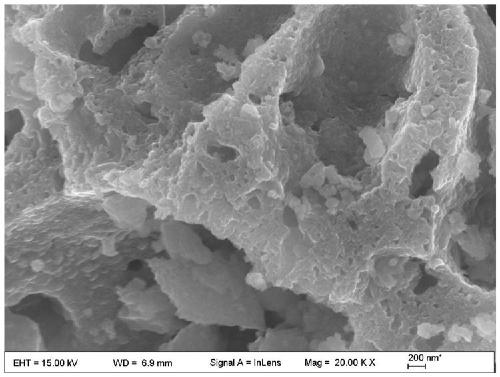

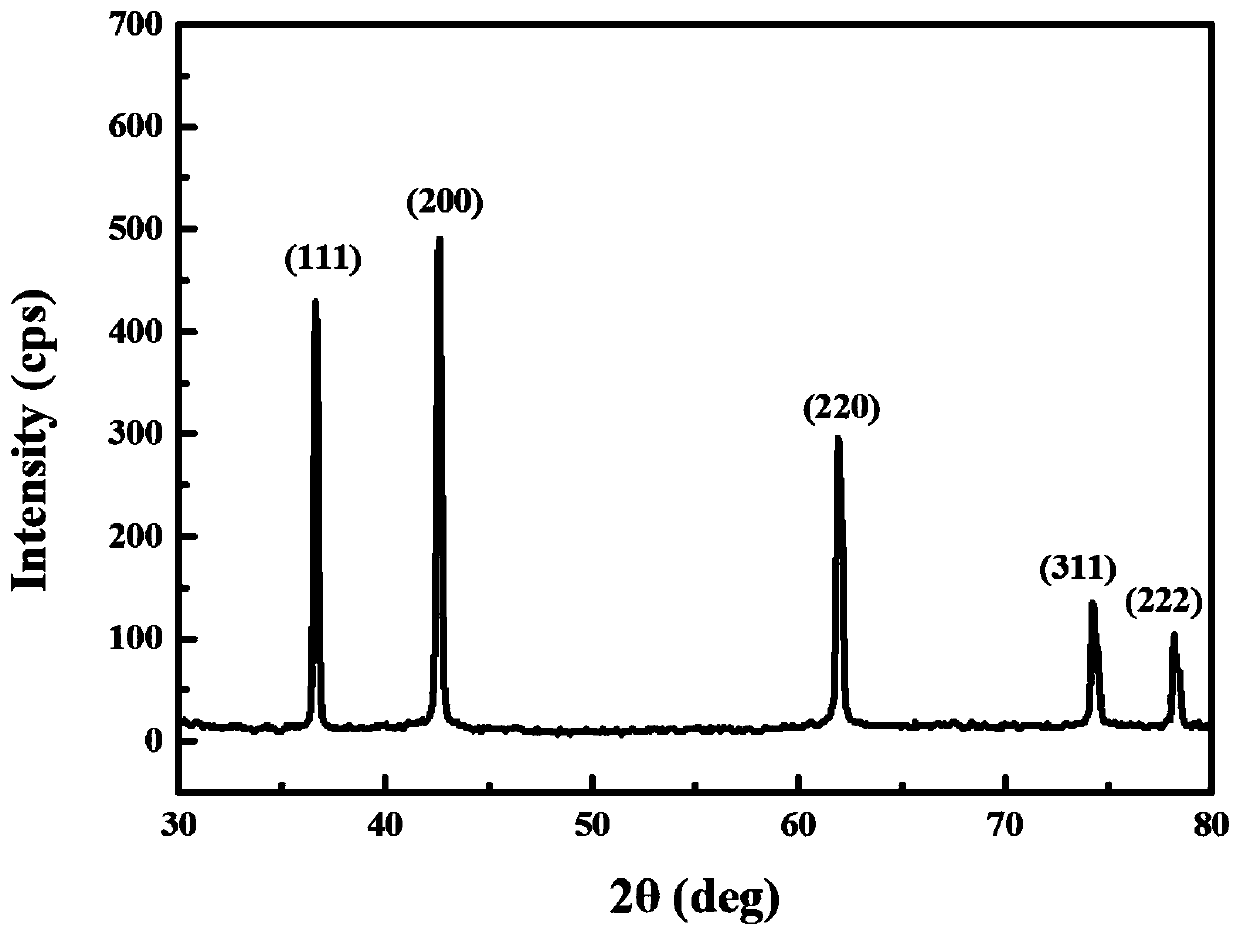

The invention discloses a five-element transition metal oxide high-entropy material for a lithium-ion battery. The high-entropy material is a five-element spinel type oxide high-entropy material formed by five transition metal positive ions, the chemical formula of the high-entropy material is (Cr0.2Fe0.2Mn0.2Zn0.2M0.2)3O4, wherein M is a divalent metal positive ion Co2+ or Ni2+. According to theinvention, a high-entropy oxide material with a spinel structure and different chemical compositions is regulated and controlled by changing the variety of divalent transition metal positive ions, sothat the electrochemical performance of the high-entropy oxide material is customized, and a nanocrystalline powder material with large specific surface area, small grain size and uniform chemical composition and microstructure is prepared through a combustion synthesis method. The five-element transition metal oxide high-entropy material for the lithium-ion battery has the advantages of large initial charge specific capacity, stable reversible specific capacity, good rate capability and good cycling stability.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

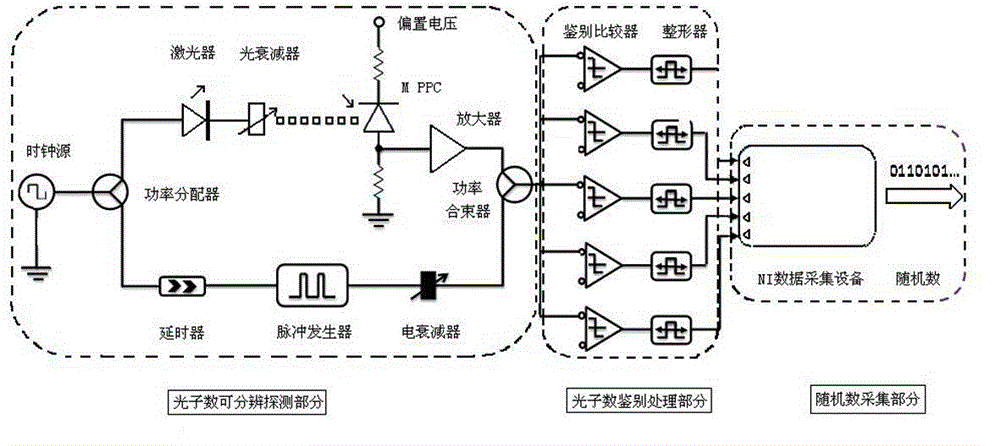

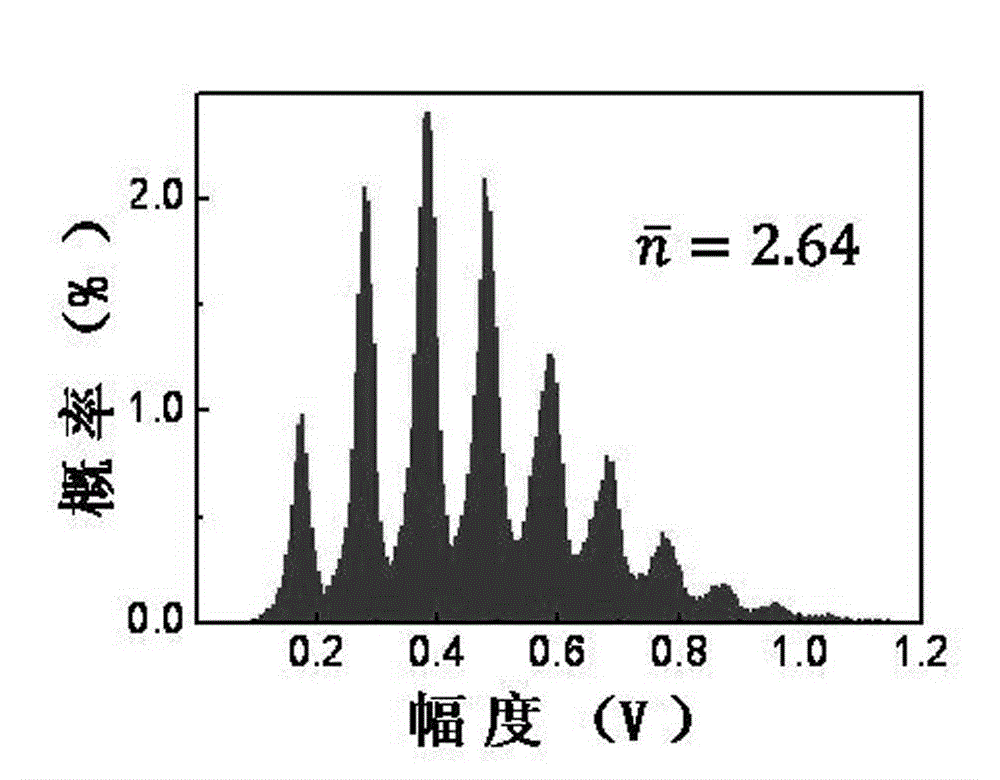

Photon-number distinguishable detection-based true random number generator

InactiveCN101980146ANo complex post-processing requiredRandom number generatorsSecure communicationProcess module

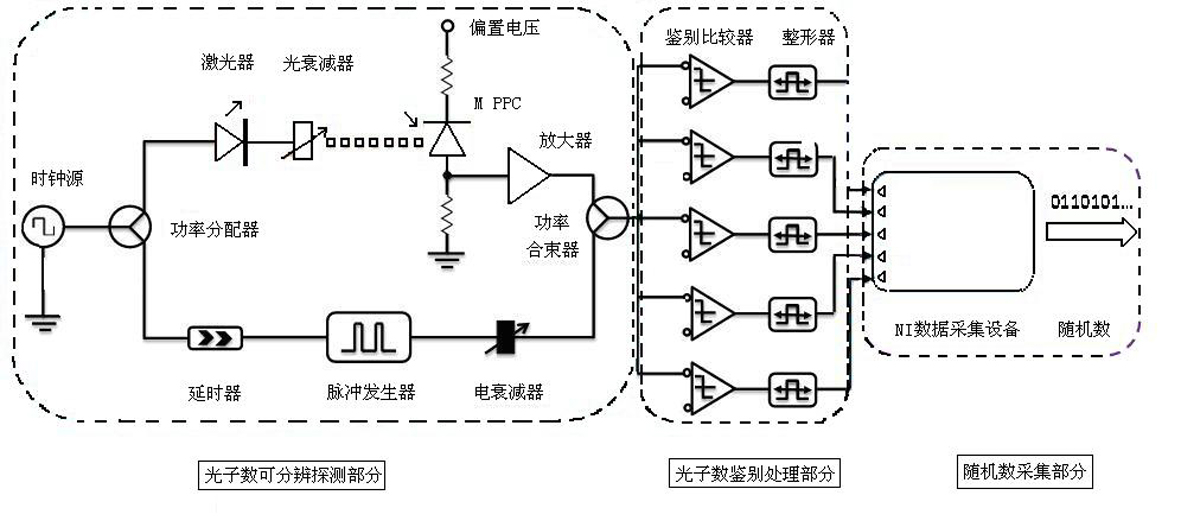

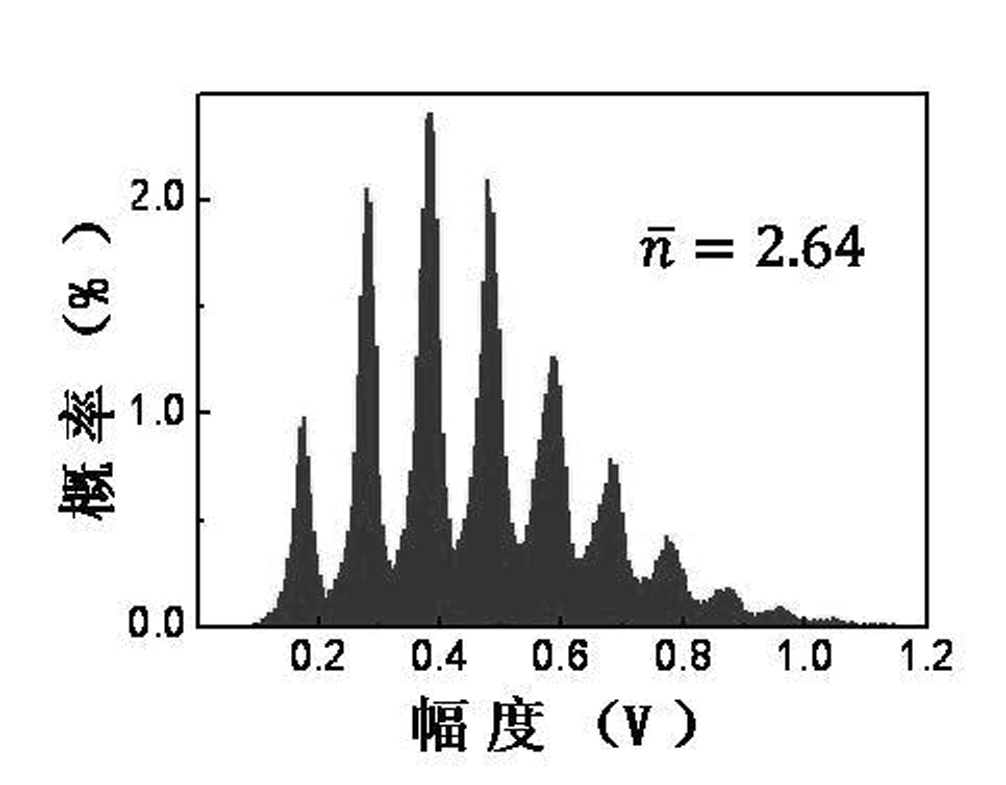

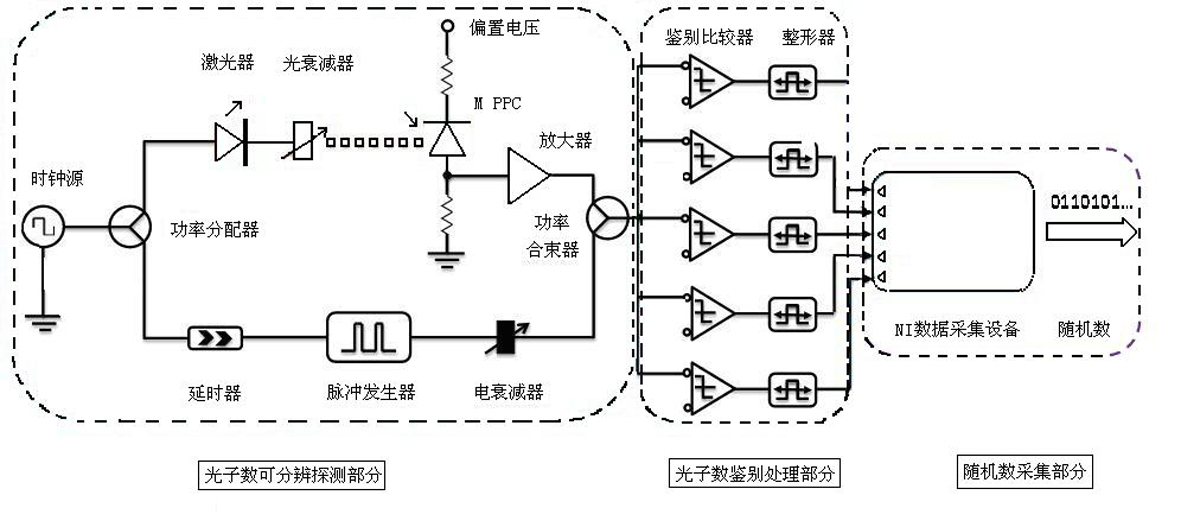

The invention discloses a photon-number distinguishable detection-based true random number generator and belongs to the class of quantum secure communication. Different photon-number incident events are combined into a 2-bit random number sequence according to the uncertainty principle of poisson distribution by using the characteristics of a photon-number distinguishable detector capable of distinguishing incident photon numbers. The true random number generator mainly comprises a photon-number distinguishable detection module, a photon-number identifying and processing module and a random number acquisition module and can generate high-speed random secret keys needed in the quantum secure communication. The true random number generator has stable and reliable random sources; the generated true random number cannot be repeated or deciphered by the random characteristics of light quanta; a complex post-processing procedure is not needed; and the true random number generator is convenient to use.

Owner:EAST CHINA NORMAL UNIV

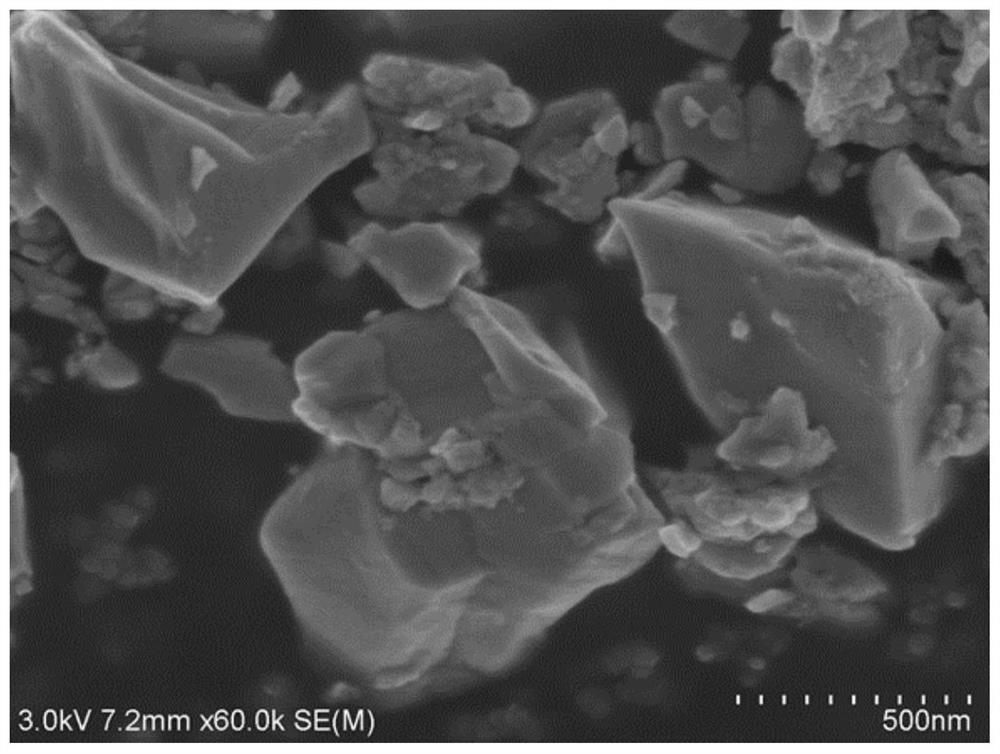

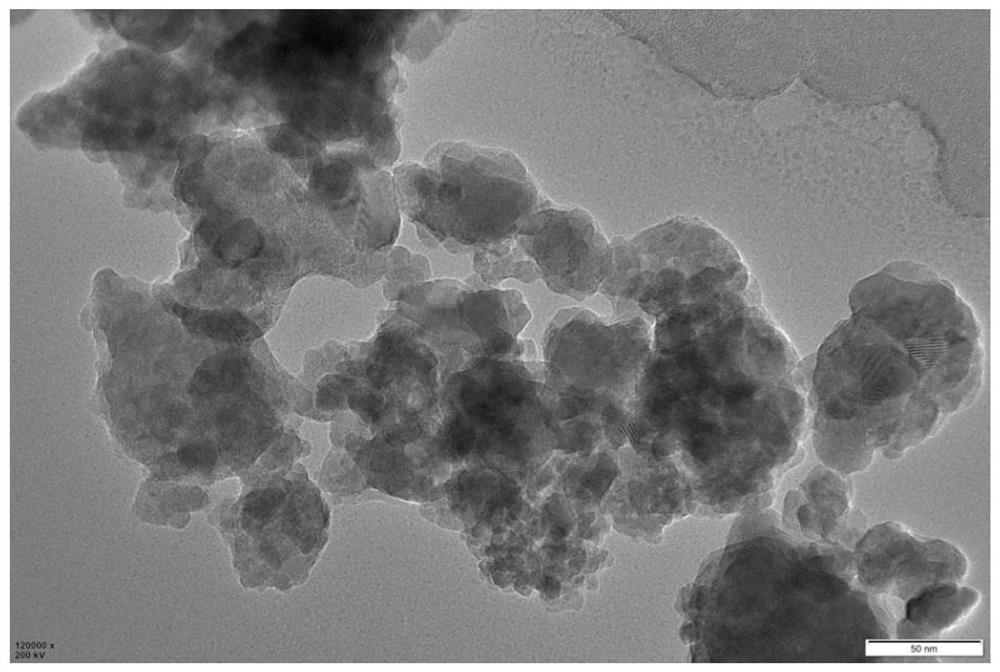

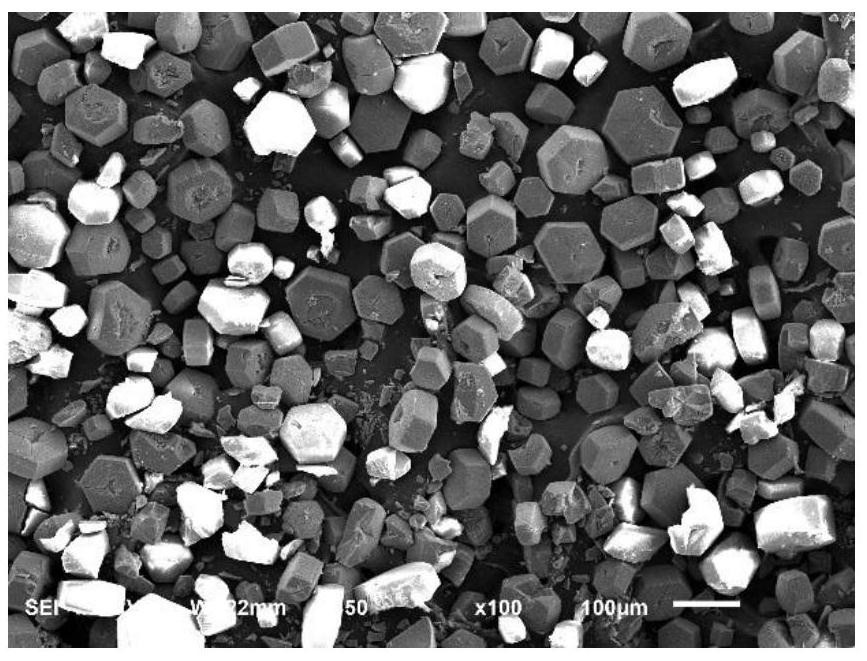

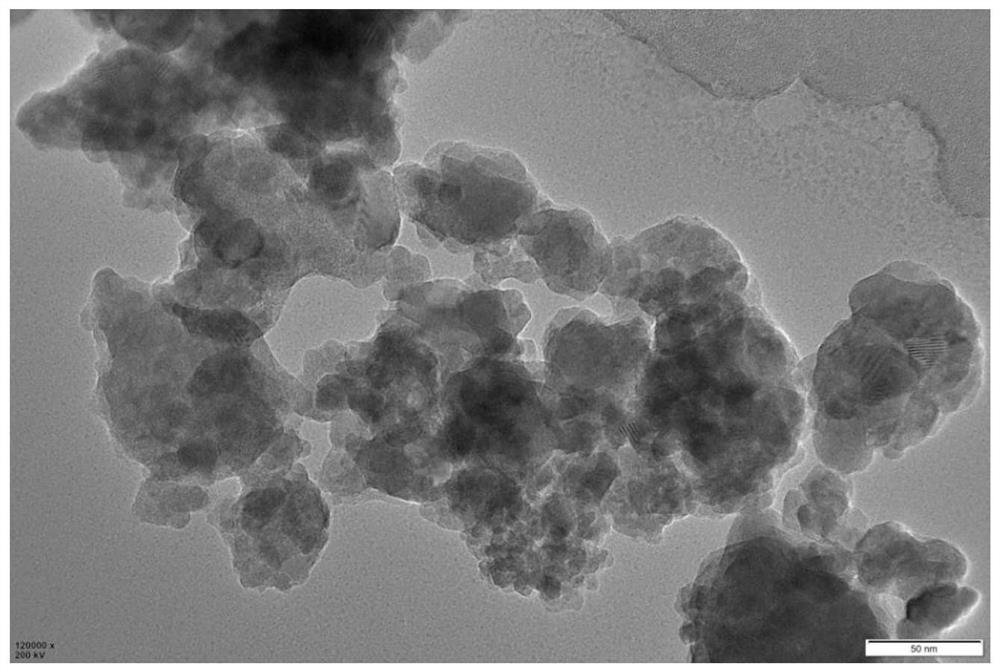

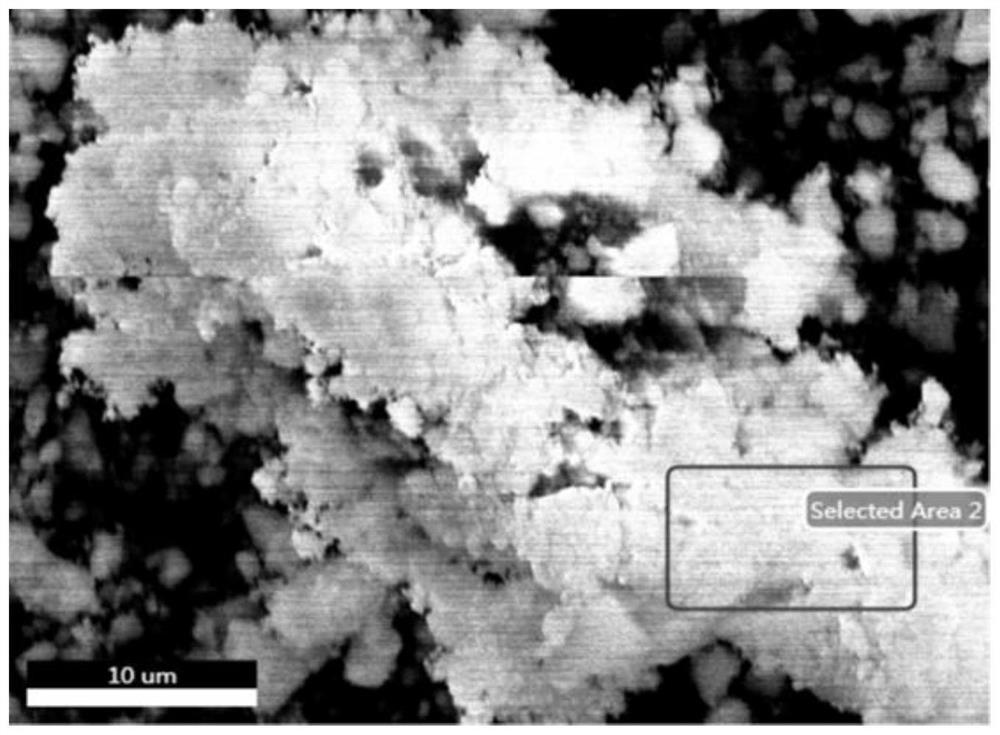

Preparation method of rock salt type (MgCoCuNiZn)O high entropy oxide powder material

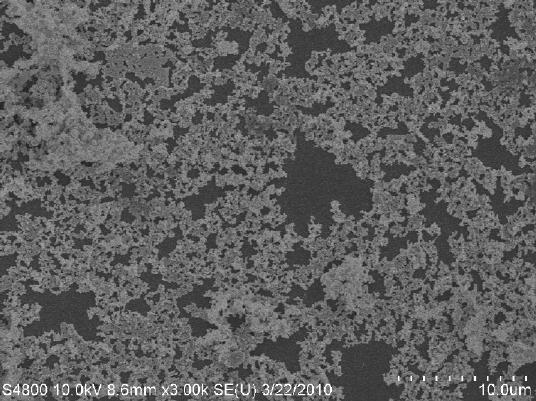

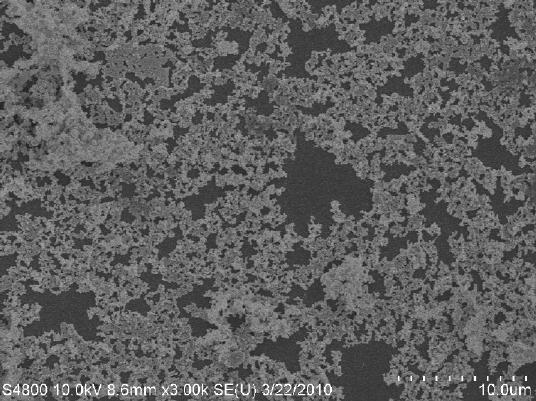

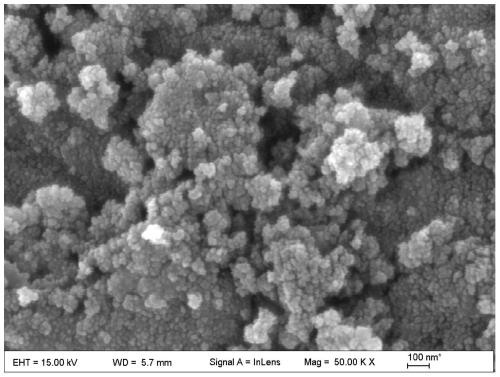

ActiveCN109019701AAchieving a stoichiometric ratioIncrease productivityCobalt compoundsSynthesis methodsMolecular level

Belonging to the field of high entropy oxide powder materials, the invention discloses a preparation method of a (MgCoCuNiZn)O high entropy oxide powder material with a rock salt type structure. The method is low-temperature combustion synthesis method, uses a metal nitrate as the metal source, and takes one or more of citric acid, tartaric acid and glucose with an appropriate carbon content as the fuel. The concentration of the metal salt raw material, the fuel variety and adding amount, the combustion improver variety and adding amount, and the ignition way are controlled to regulate the granularity, morphology and other characteristics of the high entropy oxide (MgCoCuNiZn)O nanopowder. According to the invention, the reactants exist in a solution, so that the raw materials in the solution can easily reach molecular level blending, and the product realizes a stoichiometric ratio. At the same time, the method provided by the invention has the advantages of energy saving, high production efficiency, simple and feasible process, green and environmental protection, no need for complex post-treatment, etc., and the prepared high entropy oxide powder has high purity and fine particlesize, and is uniformly distributed.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

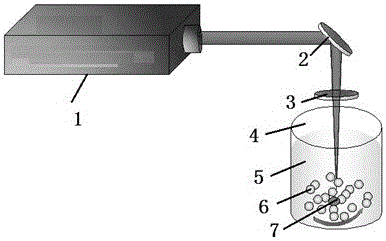

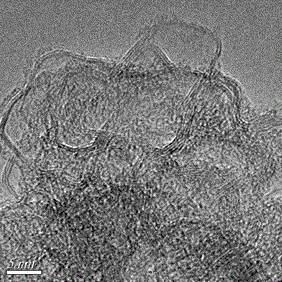

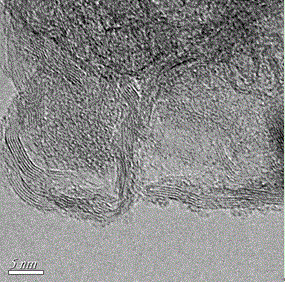

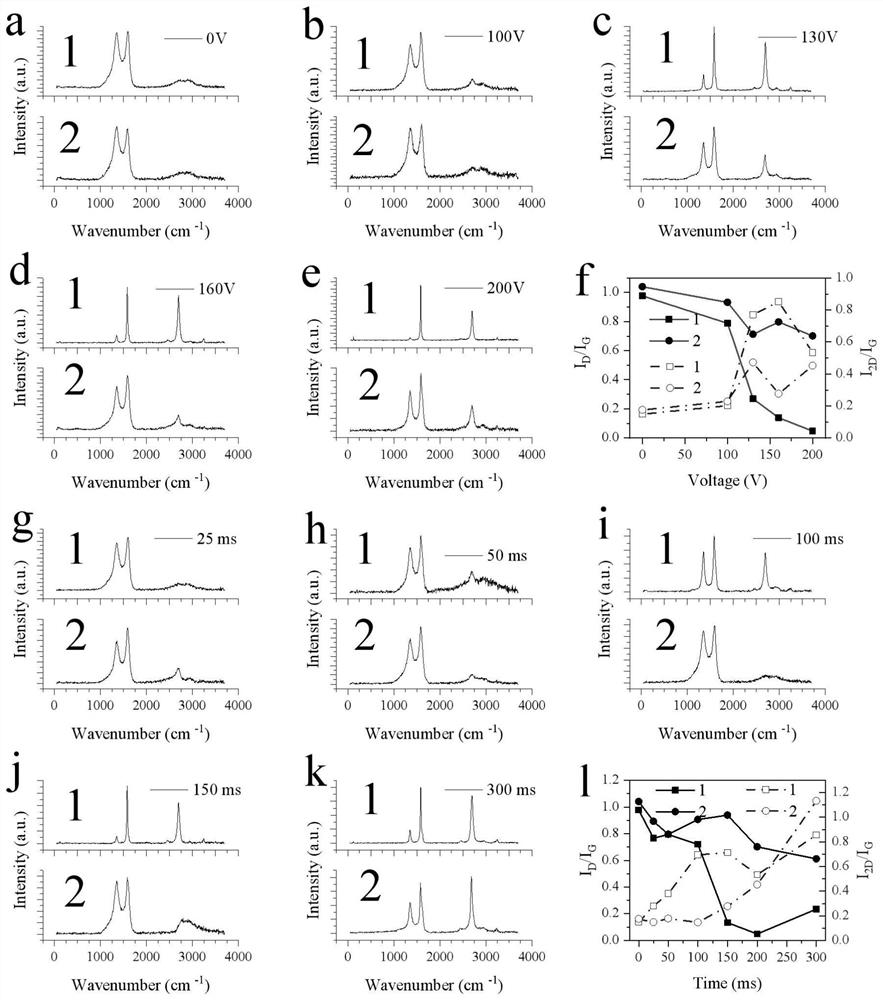

Controllable graphene nanolayer preparation method

The invention relates to a controllable graphene nanolayer preparation method. The method comprises the steps that graphite powder is put into a reaction container, a solvent is injected into the reaction container, ultrasonic vibration is conducted, and a stirrer is started, so that the raw material-graphite powder is fully and uniformly distributed in the solvent; a laser path is adjusted, so that laser beams sequentially pass through a total reflective mirror and a focus lens and then are focused at the position 3 mm below the liquid level; a pulse laser is started, different kinds of laser energy are adjusted to enable laser light to irradiate graphite particles in a liquid environment, after the reaction process lasts 1 h to 2 h, the laser is stopped, and finally graphene with the different layer numbers can be obtained. The method is easy to operate, controllable in layer number and free of toxins and pollution and has potential application in the fields of nanometer equipment and spintronics.

Owner:JIANGSU UNIV

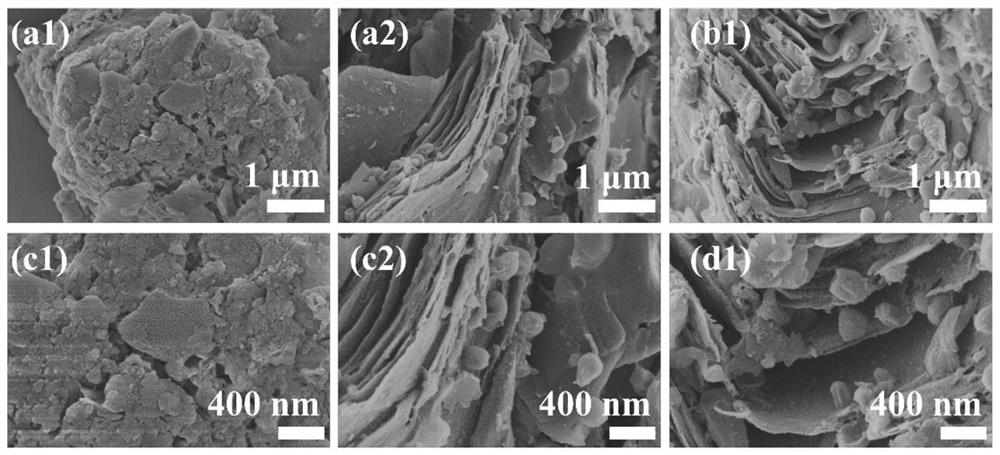

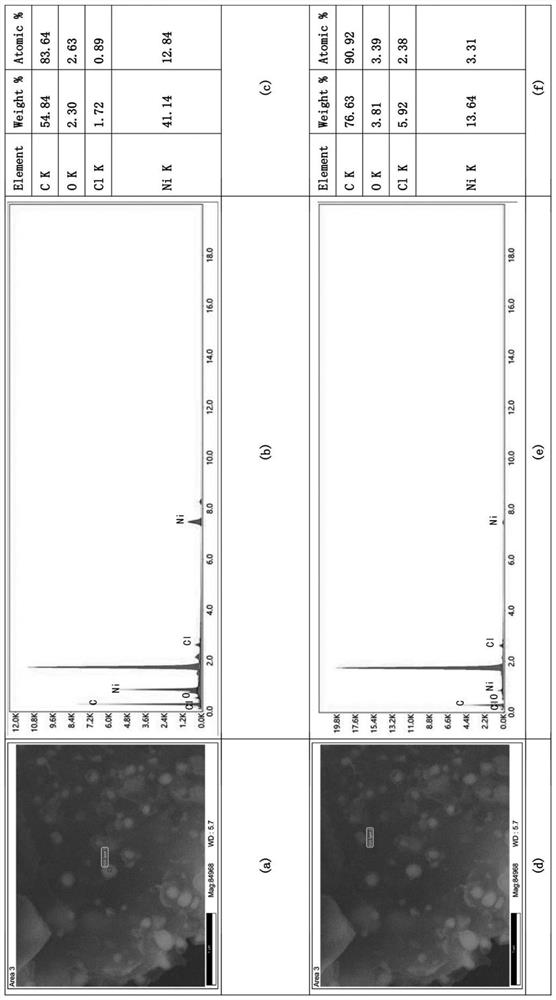

Method for preparing metal particle-loaded coal-based graphene through high-temperature thermal shock

ActiveCN113333773ASave raw materialsLow costMaterial nanotechnologyHybrid capacitor electrodesChemistryCarbon source

The invention provides a method for preparing metal particle-loaded coal-based graphene through high-temperature thermal shock. Nano metal particles are introduced into a carbon source through a dipping reduction method. According to the method, the carbon sources such as coal, coal pitch, coke and coal-based graphite are subjected to high-temperature thermal shock graphitization and metal salt thermal reduction by utilizing joule heat generated by capacitor discharge, and the coal-based graphene-loaded metal particles are generated in a short time. The metal used in the metal nano particle loading process is transition-state metal such as Fe, Co, Ni and Cu, and the metal salt is one of chloride or hydrate thereof, acetate or hydrate thereof. The preparation method is simple, low in cost, high in product graphitization degree, excellent in performance and suitable for large-scale production and has important application value.

Owner:CHINA UNIV OF MINING & TECH

Photon-number distinguishable detection-based true random number generator

InactiveCN101980146BNo complex post-processing requiredRandom number generatorsSecure communicationProcess module

The invention discloses a photon-number distinguishable detection-based true random number generator and belongs to the class of quantum secure communication. Different photon-number incident events are combined into a 2-bit random number sequence according to the uncertainty principle of poisson distribution by using the characteristics of a photon-number distinguishable detector capable of distinguishing incident photon numbers. The true random number generator mainly comprises a photon-number distinguishable detection module, a photon-number identifying and processing module and a random number acquisition module and can generate high-speed random secret keys needed in the quantum secure communication. The true random number generator has stable and reliable random sources; the generated true random number cannot be repeated or deciphered by the random characteristics of light quanta; a complex post-processing procedure is not needed; and the true random number generator is convenient to use.

Owner:EAST CHINA NORMAL UNIV

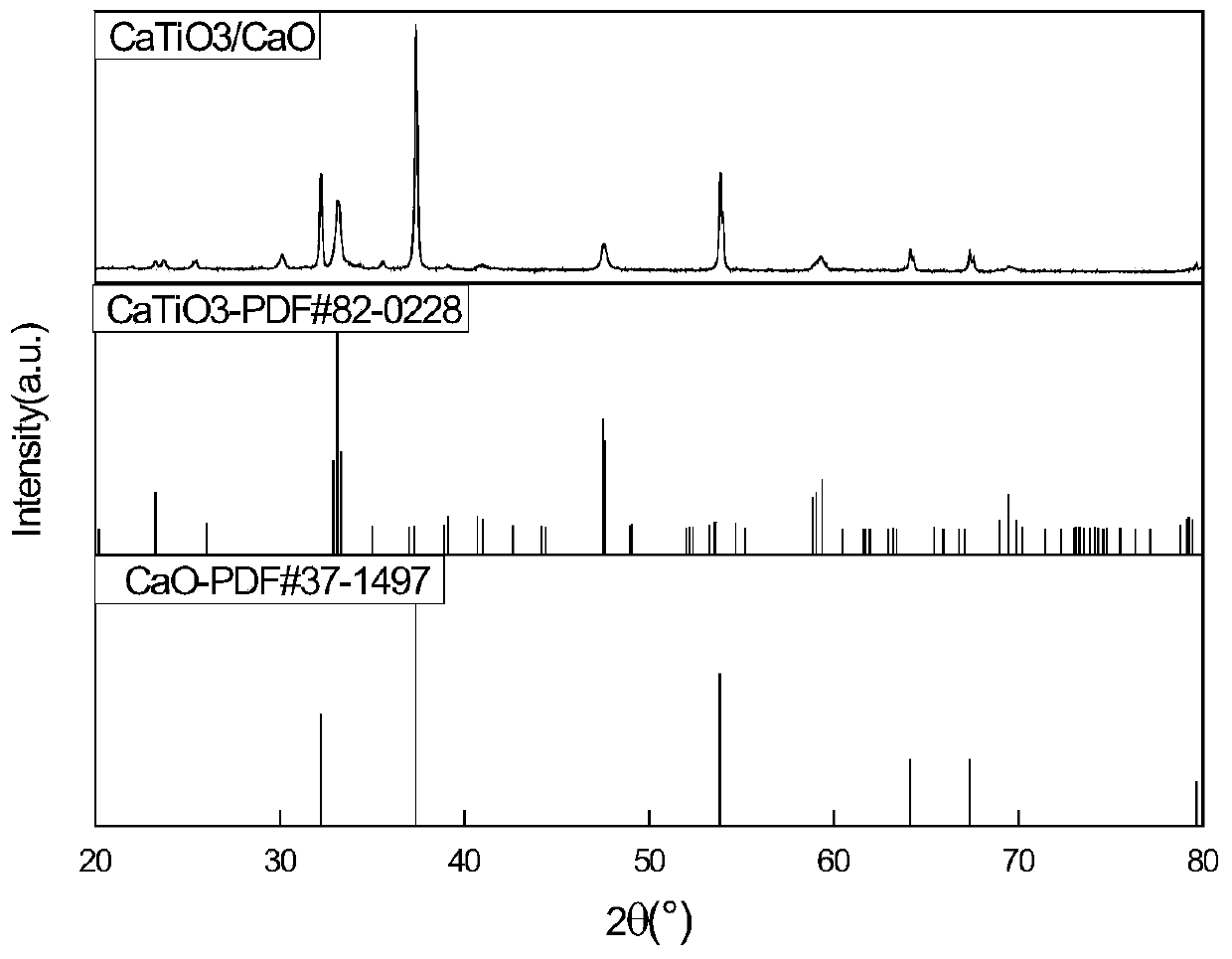

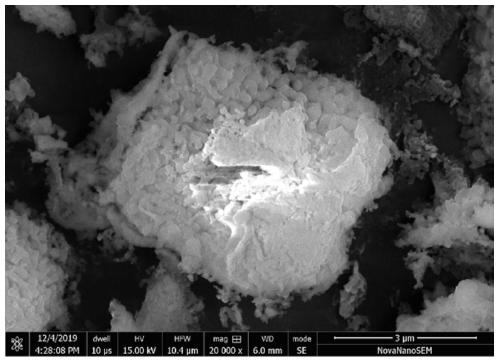

CaTiO3/CaO composite material as well as preparation method and application thereof

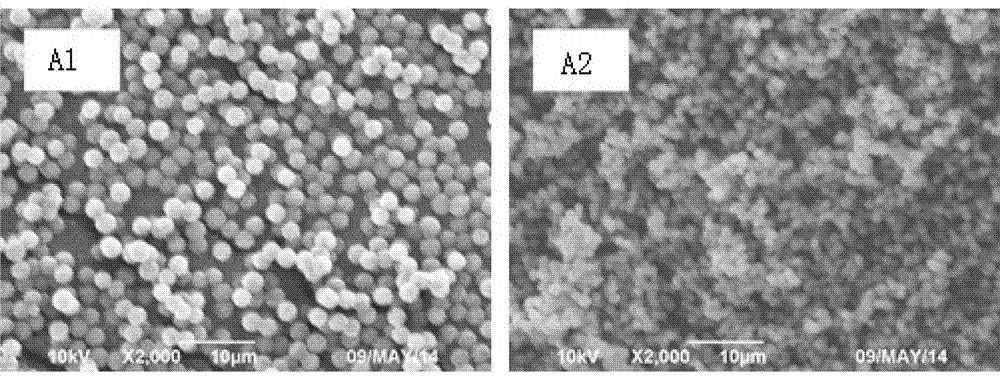

ActiveCN111468094AReduce manufacturing costAvoid Strong Alkaline PollutionGas treatmentWater/sewage treatment by irradiationStrong acidsPhysical chemistry

The invention relates to a CaTiO3 / CaO composite material as well as a preparation method and application thereof. The preparation method comprises the following steps: S1, slowly adding a CaCO3 suspension into a TiOSO4 solution which is continuously stirred under a first preset temperature condition, and uniformly stirring to obtain a mixed solution; S2, stirring the mixed solution obtained in thestep S1 under a second preset temperature condition at a constant temperature, dropwise adding a CO (NH2) 2 solution, and adjusting the pH value of the mixed solution to 5-7; and S3, carrying out hydrothermal reaction on the mixed solution obtained in the step S2, and calcining a product of the hydrothermal reaction to obtain the CaTiO3 / CaO composite material. According to the method, strong acidand strong alkali are prevented from being used, meanwhile, the cubic CaTiO3 and spherical CaO composite photocatalytic material with uniform particle size distribution is prepared through calcination under the low-temperature condition, and the method has the advantages of energy saving, high production efficiency, environmental friendliness, good product performance and the like.

Owner:ZHEJIANG UNIV OF TECH

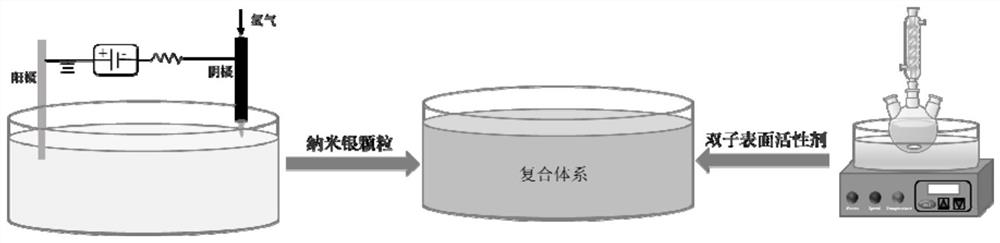

Method for preparing stable compound through gas-liquid plasma technology and application of method

PendingCN112846216AHigh purityUniform product particle sizeMaterial nanotechnologyBiocideSteel tubeActive agent

The invention discloses a method for preparing a stable compound through a gas-liquid plasma technology. The method comprises the following steps: (1) mixing a silver nitrate water solution and a stabilizer water solution to obtain a reaction solution; (2) placing the reaction solution obtained in the step (1) into a container, placing the container at a position below a stainless steel tube cathode of a plasma reactor, and inserting a platinum wire into the reaction solution to serve as an anode; (3) in an inert gas atmosphere, applying direct-current negative bias to the cathode of the plasma reactor, and treating the reaction solution for 10-30 minutes to obtain a colloidal solution containing silver nanoparticles; and (4) adding a cationic surfactant into the colloidal solution containing the silver nanoparticles, and carrying out uniform mixing to obtain the stable compound. According to the method, the colloidal solution containing the silver nanoparticles is prepared by utilizing a high-energy electron one-step method through the gas-liquid plasma technology. The method is simple, feasible, green and efficient, and the compound with stability, transparency and excellent antibacterial performance can be obtained by compounding the colloidal solution with the surfactant.

Owner:JIANGSU XINRI E VEHICLE

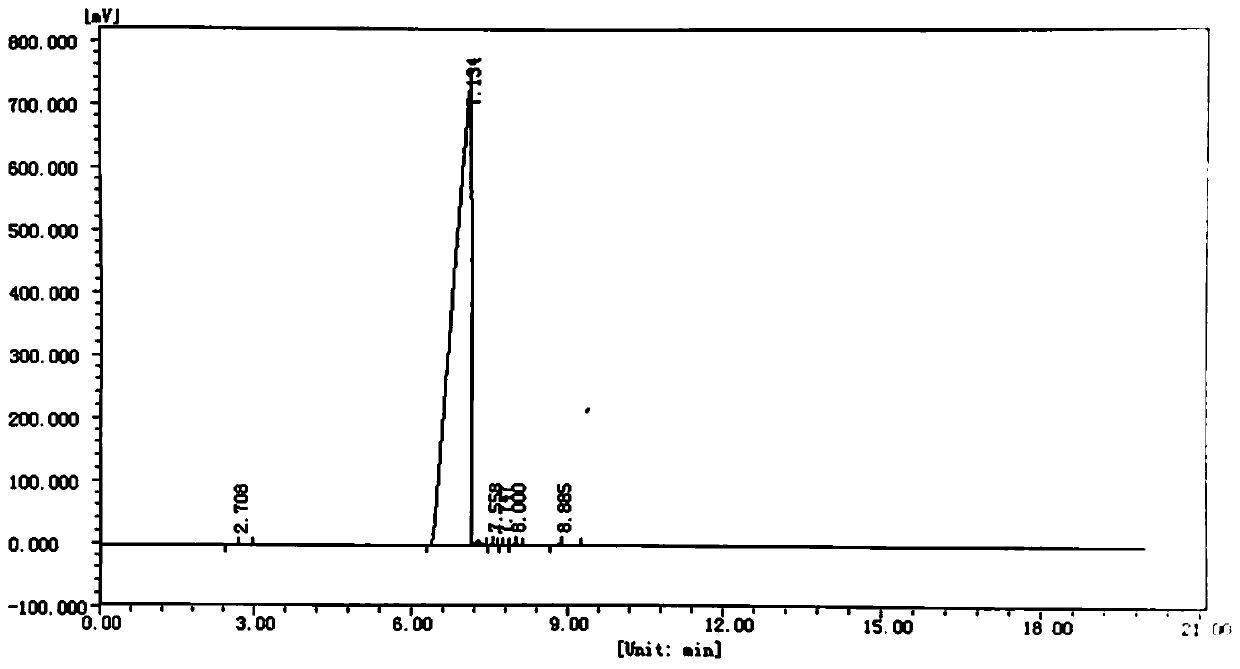

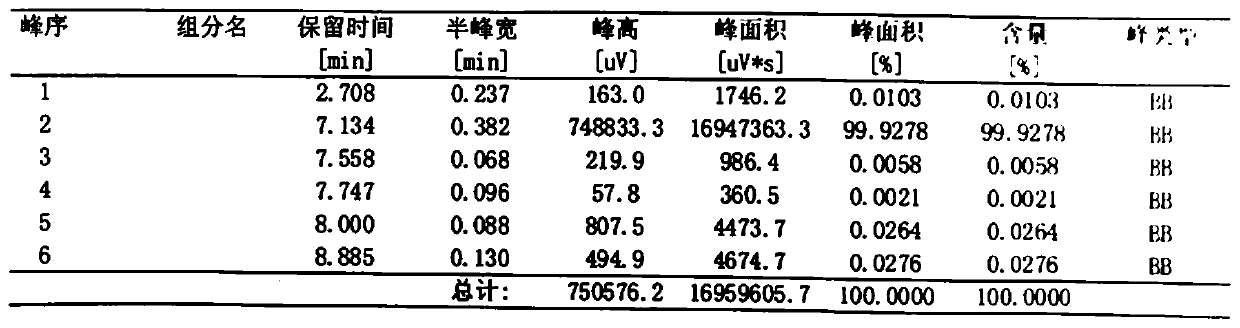

1,3-propane sultone preparation method

InactiveCN110105326AShort process routeNo complex post-processing requiredOrganic chemistrySulfite saltSodium sulfite

The invention relates to a 1,3-propane sultone preparation method, which comprises: S1, completely mixing in a reaction container by using 3-chloropropanol and sodium sulfite as raw materials and using water as a solvent, controlling the temperature at 25-120 DEG C, carrying out a reaction for 4-48 h, carrying out pressure reducing dewatering concentration, adding concentrated hydrochloric acid tothe concentrated liquid, carrying out acidification, controlling the temperature at 0-80 DEG C, stirring for 1-24 h, filtering, and concentrating the filtrate to obtain 3-hydroxypropanesulfonic acid;S2, controlling the temperature of the concentrated liquid obtained in the step S1 at 40-110 DEG C, and carrying out pressure reducing concentrating to carry out dewatering ring closure on the 3-hydroxypropanesulfonic acid in the concentrated liquid to obtain a crude product containing 1,3-propane sultone; and S3, rectifying the crude product containing 1,3-propane sultone to obtain 1,3-propane sultone. According to the present invention, the method has characteristics of short process route, less three-waste and simple post-treatment, wherein the total yield can achieve more than 90%, and the purity of the product can achieve more than 99.9%.

Owner:武汉松石科技股份有限公司

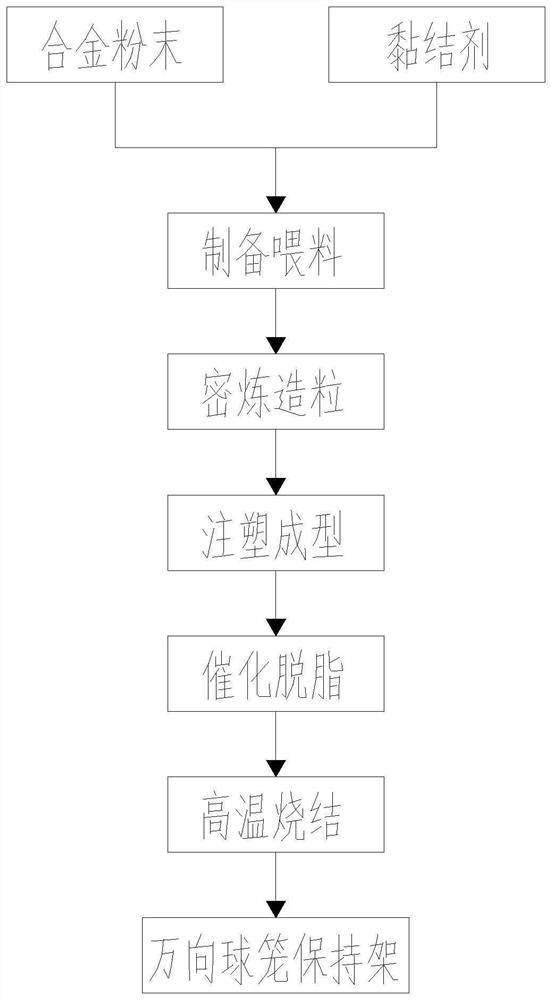

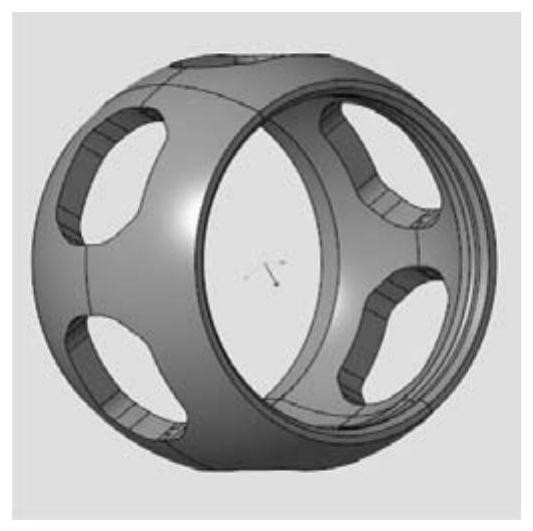

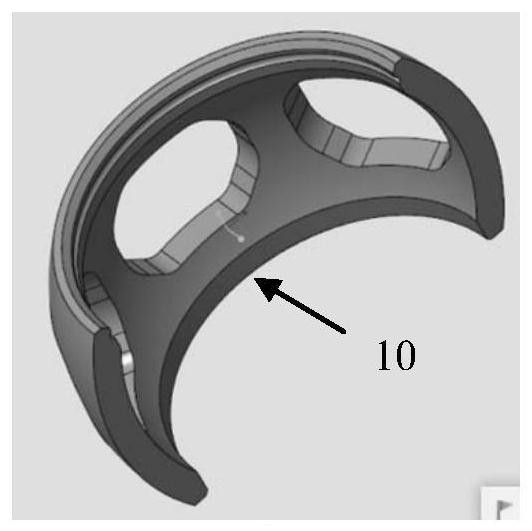

Manufacturing method of universal ball cage holder

PendingCN114453580AReduce the proportionEasy to buyTransportation and packagingMetal-working apparatusPolyoxymethyleneAdhesive

The manufacturing method of the universal ball cage holder comprises the following steps that A, alloy powder and an adhesive containing polyformaldehyde are mixed in proportion, and feed is obtained; b, the feed is subjected to banburying and granulation to be made into columnar particles with the diameter phi being 3 * 5 mm; c, preparing the columnar particles into a green body through an injection molding process; d, polyformaldehyde in the green body is removed through a catalytic degreasing technology, and then the universal ball cage holder is obtained through high-temperature sintering; wherein the alloy powder comprises ASTM 86 series low-alloy steel powder, ASTM 51 series low-alloy steel powder and 20CrMnTi alloy steel powder, the mass ratio of the alloy powder to the adhesive is (87.7-91.2)%: (8.8-12.3)%, the mass ratio of polyformaldehyde in the adhesive is 80-95%, the green body comprises a forming body, the size of the forming body is proportionally enlarged according to the size of the universal ball cage holder, and the size of the forming body is larger than that of the universal ball cage holder. According to the manufacturing method, metal material waste approaches to zero, the working procedures are simple, the number of steps is small, the production efficiency is high, the yield is high, stress residues do not exist, cost is low, and the manufacturing method is suitable for mass production of universal ball cage retainers.

Owner:KUNSHAN KADAM NEW MATERIAL TECH CO LTD

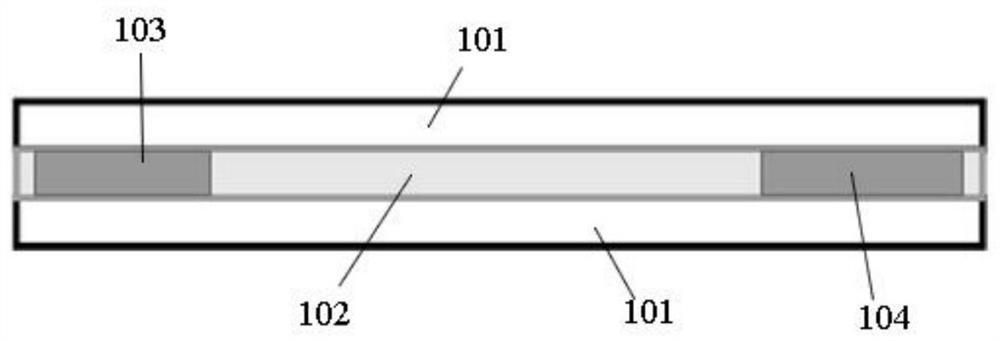

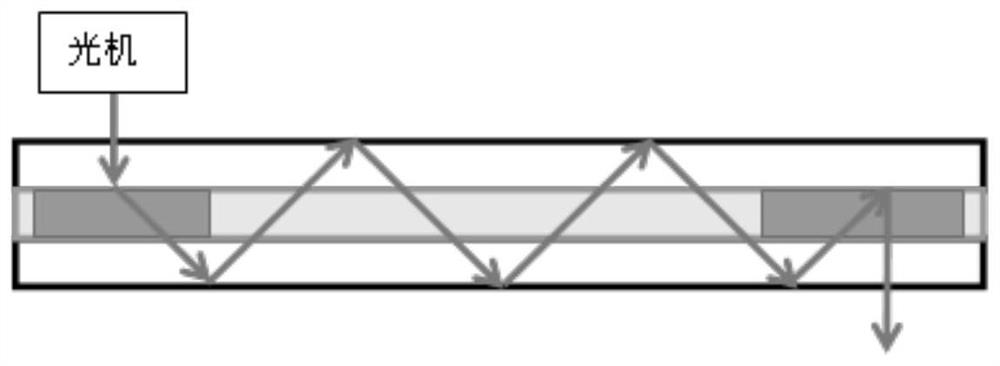

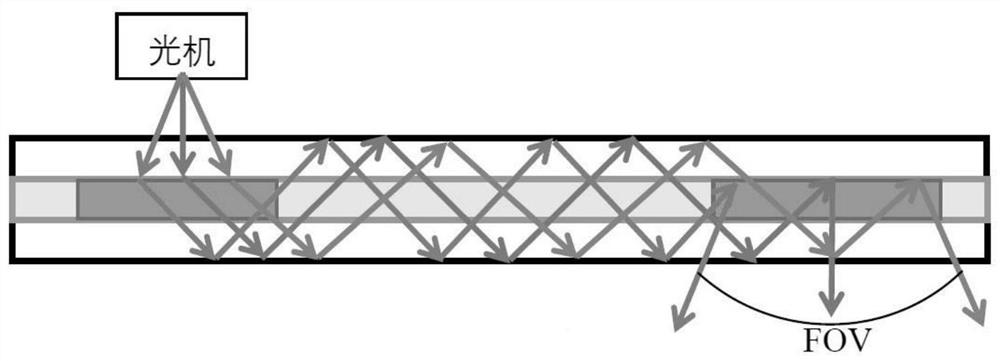

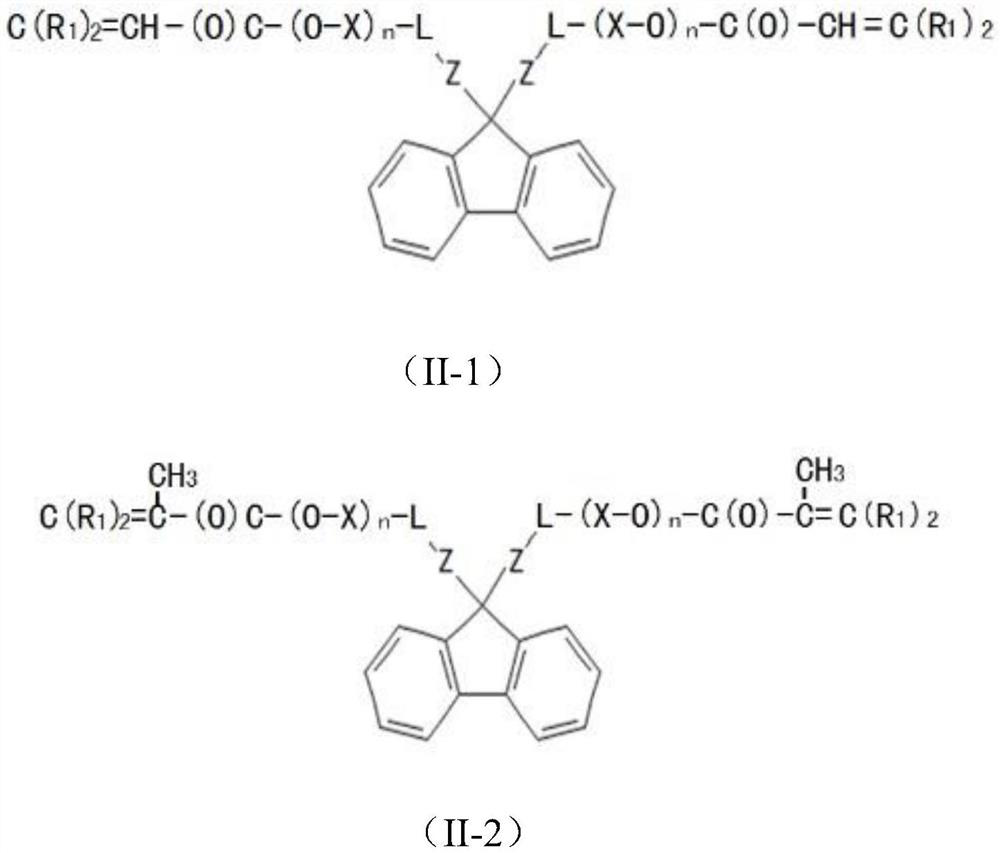

Optical waveguide element, preparation method thereof and holographic optical waveguide display equipment

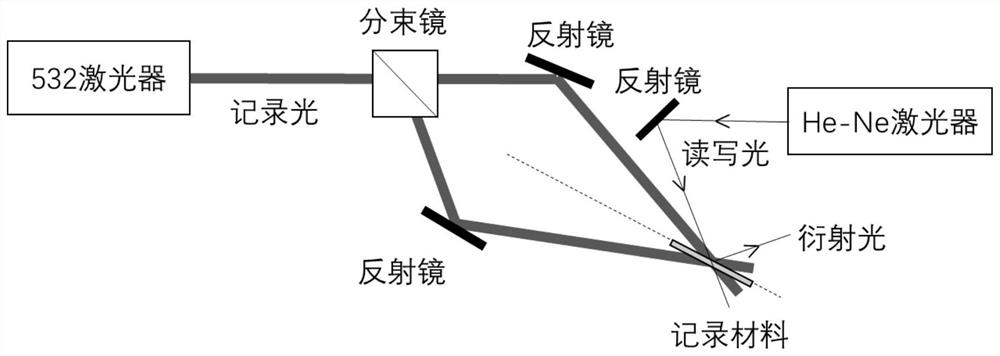

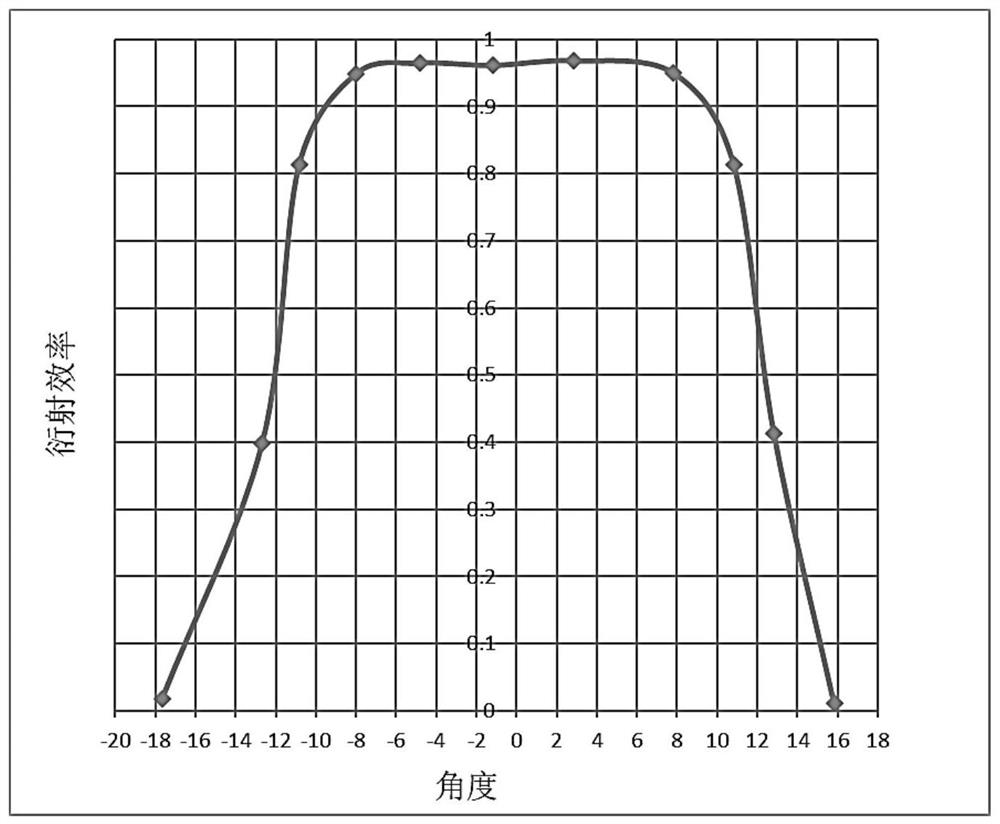

ActiveCN112764159AIncreased refractive index modulationHigh diffraction efficiencyOptical waveguide light guideOptical transmittancePhotopolymer

The invention relates to an optical waveguide element, a preparation method thereof and holographic optical waveguide display equipment. The optical waveguide element comprises a laminated body formed by at least two carriers and a photopolymer film, wherein the photopolymer film is positioned between the at least two carriers; the photopolymer film is provided with at least one light coupling-in area and at least one light coupling-out area; the optical coupling-in area is not connected with the optical coupling-out area; and the positions of the optical coupling-in area and the optical coupling-out area are respectively provided with a grating structure. The optical waveguide element has high refractive index modulation degree, diffraction efficiency, sensitivity and light transmittance, and has an excellent optical waveguide imaging effect.

Owner:LIGHTIN INC

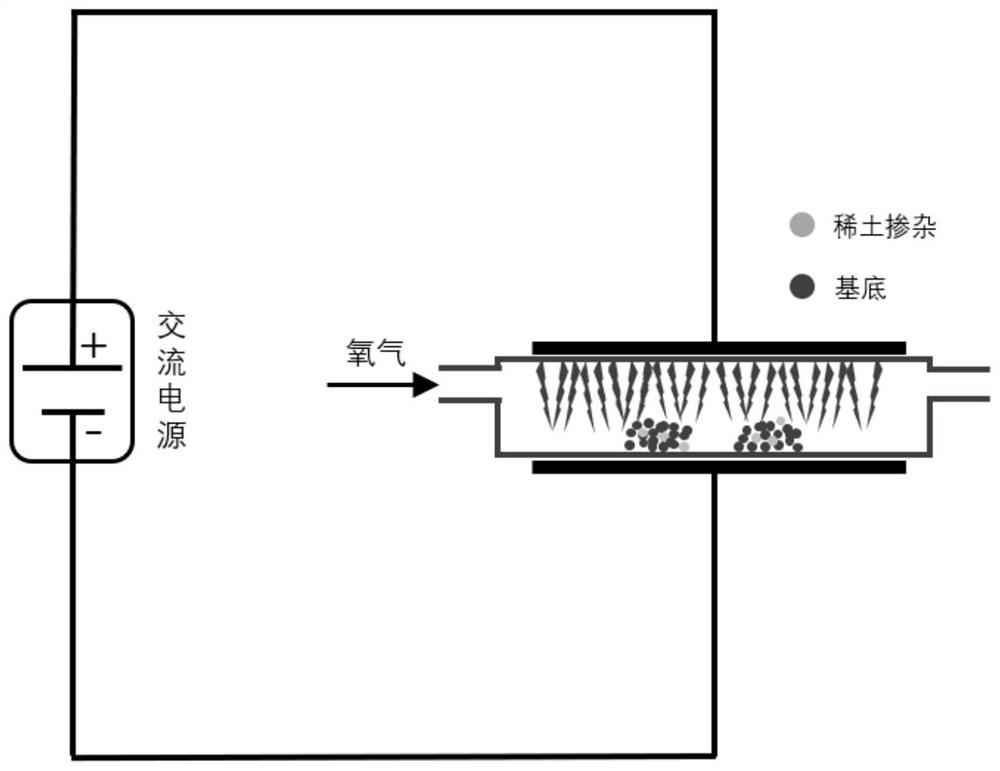

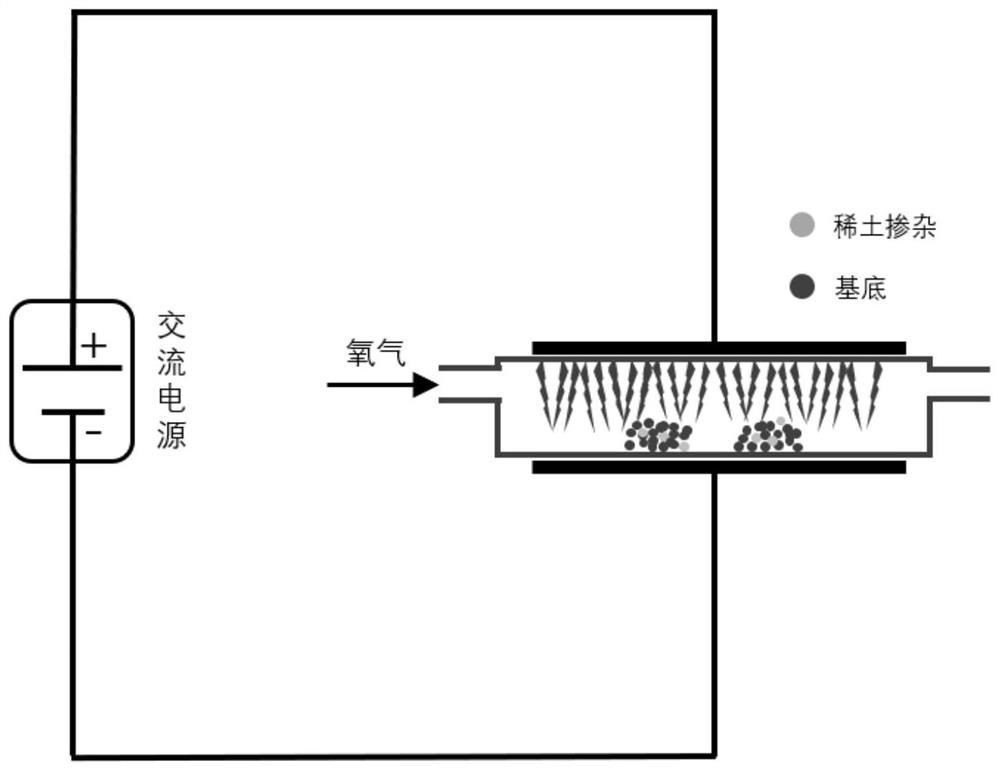

Method for preparing rare earth doped yttrium oxide fluorescent nanoparticles through DBD technology

ActiveCN112920799AControllable equipmentHigh activityNanoopticsLuminescent compositionsPlasma reactorAlternate current

The invention discloses a method for preparing rare earth doped yttrium oxide fluorescent nanoparticles through a DBD technology, and the method comprises the following steps: (1) mixing a substrate metal organic matter and a doped metal organic matter according to a mass ratio of (10-40): 1, and grinding the mixture as a reaction precursor; (2) putting the precursor obtained in the step (1) into a container, and putting the container between the positive electrode and the negative electrode of a plasma reactor; and (3) applying alternating current between the cathode and the anode of the plasma reactor in an oxygen atmosphere, treating the precursor for a period of time, taking out the product every a period of time, and grinding to obtain powder containing the rare earth doped yttrium oxide nanoparticles. According to the invention, powder of rare earth doped yttrium oxide fluorescent nanoparticles is prepared by using a high-activity oxidation component one-step method through a DBD technology. The method is simple and easy to implement, green and efficient, high-temperature and high-pressure further reaction is not needed, and energy consumption is effectively reduced.

Owner:JIANGNAN UNIV

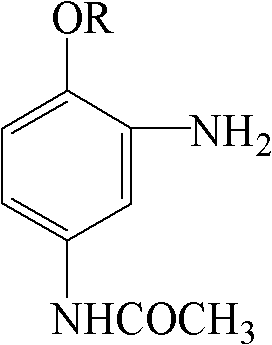

Method for producing 2-amino-4-acetamido benzene alkyl ether by reduction with sodium bisulfide

ActiveCN102633669BHigh reaction yieldQuality improvementOrganic compound preparationCarboxylic acid amides preparationSulfite saltResource utilization

The invention relates to a method for producing 2-amino-4-acetamido benzene alkyl ether by reduction with sodium bisulfide. The method comprises the following steps: adding 2-nitro-4-acetamido benzene alkyl ether in water the mass of which is 3-5 times of that of a reactant; adding glacial acetic acid; regulating the pH value of the material to 5-6 by using liquid caustic soda; raising the temperature to 90-105 DEG C, dropwise adding a 10-25% sodium bisulfide solution, carrying out insulation reaction for 1 hour after dropwise addition; cooling slowly to crystallize and separate out the product; filtering the crystal, washing the crystal with cold water until the pH value of the filtrate is 7 to obtain 2-amino-4-acetamido benzene alkyl ether, wherein the washing sleeve is still used in the next-batch reduction. The method disclosed by the invention has the advantages that (1) the reaction yield is above 90%; (2) the reaction speed is high so that the product is not easy to oxidize, and has good colour and high quality; (3) complex aftertreatment is not required, and the equipment and operation are simple; (4) wastewater is little and easy to treat, thus the method is a low-emission clean process; and (5) resource utilization is realized for recycling and managing hydrogen sulfide waste gas so as to obtain the sodium bisulfide solution in industries such as petrifaction industry, and cost is low.

Owner:YANCHENG OUHUA CHEM IND

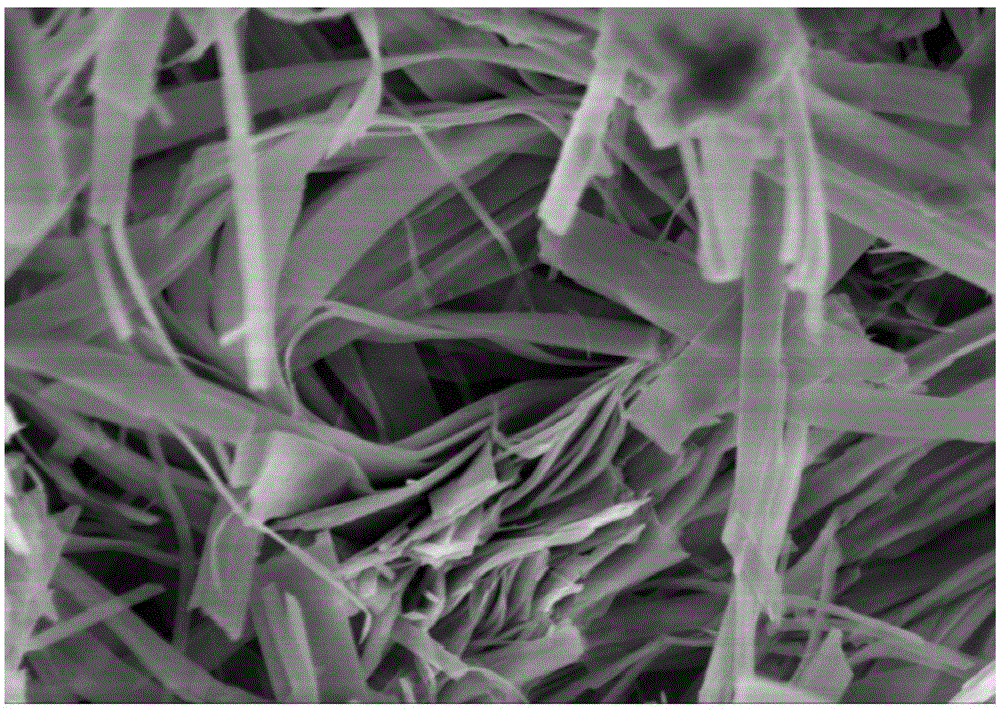

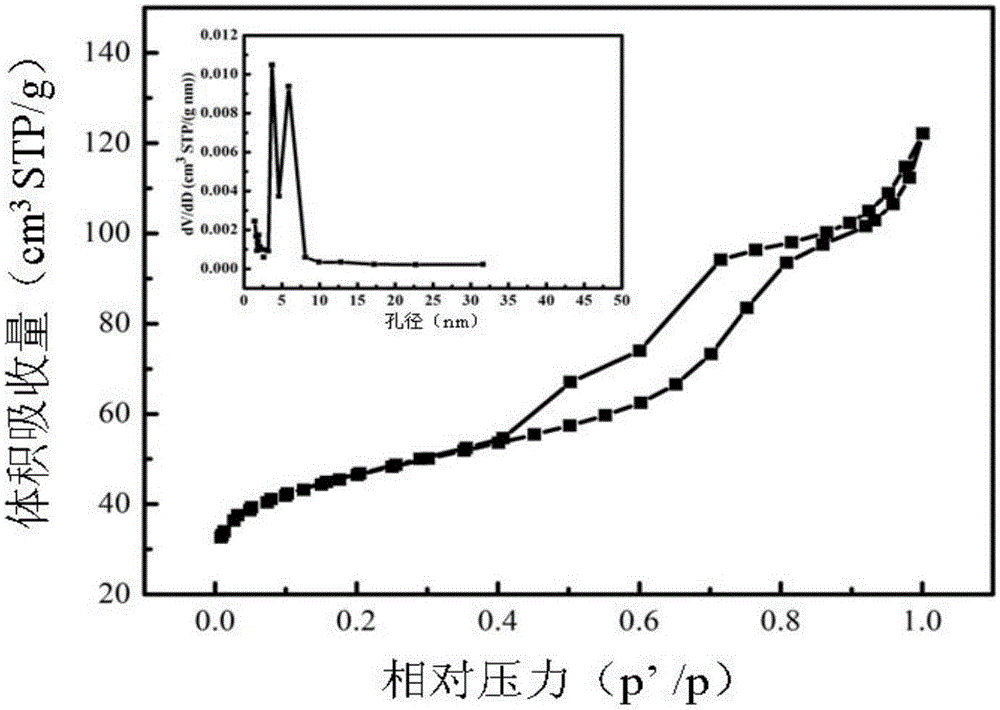

Preparation method of ribbon type graded mesoporous nickel oxide high-specific-capacitance electrode material

InactiveCN104140128AEasy accessShorten the pathway of diffusionNickel oxides/hydroxidesCapacitanceSulfate

The invention relates to a preparation method of a ribbon type graded mesoporous nickel oxide high-specific-capacitance electrode material. The preparation method comprises the steps that nickel sulfate, guanidine hydrochloride and sodium chloride are used as raw materials, mesoporous carbon is used as a template, and then the ribbon type graded mesoporous nickel oxide high-specific-capacitance electrode material is prepared through a template method. Compared with the prior art, the preparation method has the advantages that the mesoporous carbon is used as the template, the guanidine hydrochloride is used as precipitating agents firstly without adding any surface active agents, and deionized water is adopted as a reaction solvent; the raw materials are cheap, and the ribbon type graded mesoporous nickel oxide high-specific-capacitance electrode material is nontoxic, harmless, simple in technological process, controllable in particle morphology, free from complex postprocessing processes and low in cost, and has good application prospect.

Owner:TONGJI UNIV

Method for preparing high-strength α-titanium gypsum from industrial waste titanium dioxide waste residue

ActiveCN109133690BImprove solubilityPromote generationCalcium/strontium/barium sulfatesPhysical chemistryWhite powder

The invention discloses a method for preparing high-strength α-titanium gypsum by utilizing industrial waste titanium dioxide waste residue, specifically: adding water to finely ground titanium dioxide waste residue to prepare slurry, adding a composite nucleating agent to the slurry and adjusting pH value to 1.0 to 5.5, then add it to the reaction kettle, stir and continue to feed oxygen, heat to a slight boiling state, constant temperature dehydration and crystallization, after the reaction is completed, the prepared solution is filtered under reduced pressure, and successively use boiling water and ethanol Wash and dry to obtain short hexagonal α-titanium gypsum crystals, sieve the obtained crystals and make 15-30% of 10-30 μm, 50-75% of 30-80 μm, and 10-20% of 80-200 μm. The high-strength α-titanium gypsum with an average particle size of 20-60 μm, a compressive strength of more than 70 MPa, regular shape and uniform size can be obtained. The method has the advantages of simple process, low cost and high efficiency.

Owner:GUANGXI UNIV

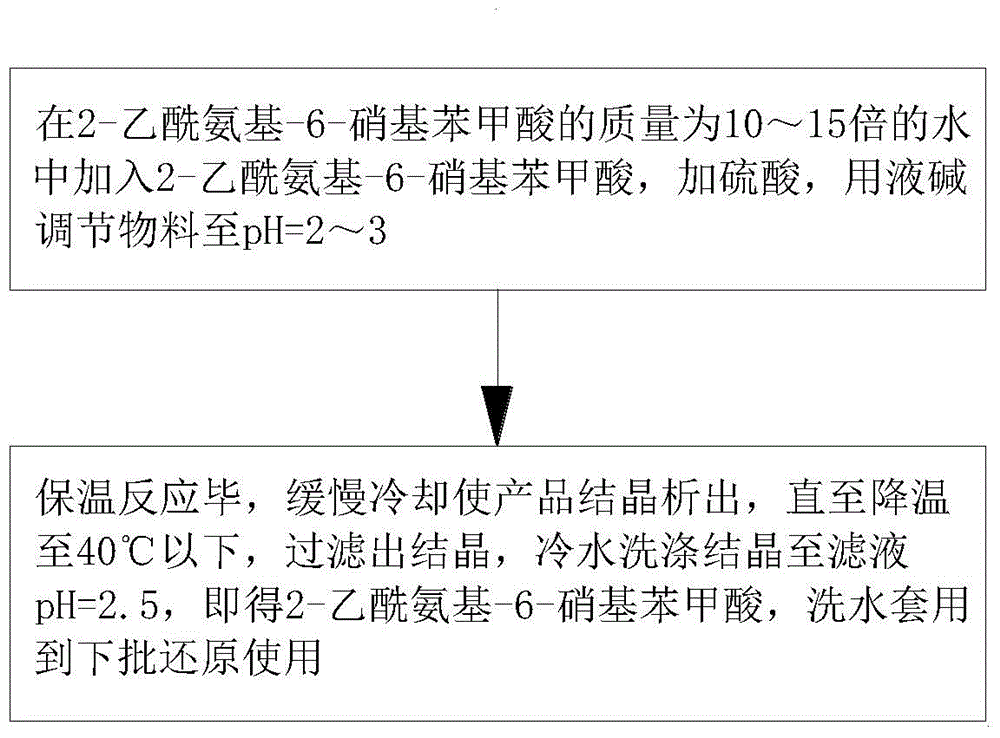

Method for producing 2-acetylamino-6-nitrobenzoic acid by sodium chloride reduction

InactiveCN106478444AHigh reaction yieldQuality improvementOrganic compound preparationCarboxylic acid amides preparationWastewaterPetrochemical

The invention discloses a method for producing 2-acetylamino-6-nitrobenzoic acid by sodium chloride reduction. By the aid of steps of the method, the reaction yield is high and reaches 90% or above; due to the strong reducing property of a sodium chloride solution, the reaction speed is high, and a product is not easily oxidized, has good color and luster and is high in quality; complicated aftertreatment is not required, and equipment and operation are simple; little wastewater is produced and is easy to treat, and the method is a low-emission clean process; the sodium chloride solution obtained through recovering and treatment of hydrogen sulfide waste gas in the industries such as petrochemical industry and the like is recycled, and the cost is low.

Owner:YANCHENG OUHUA CHEM IND

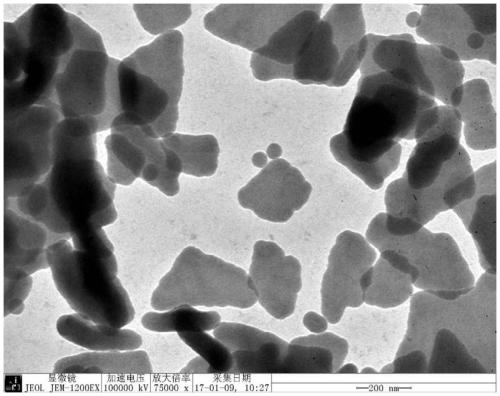

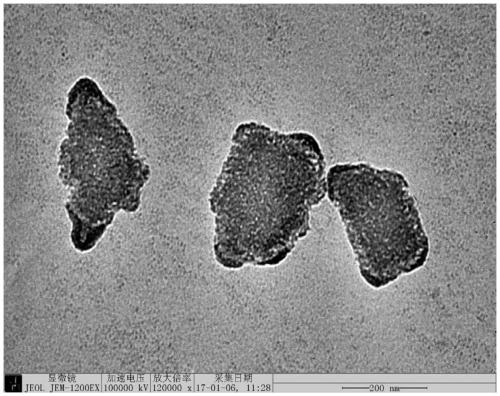

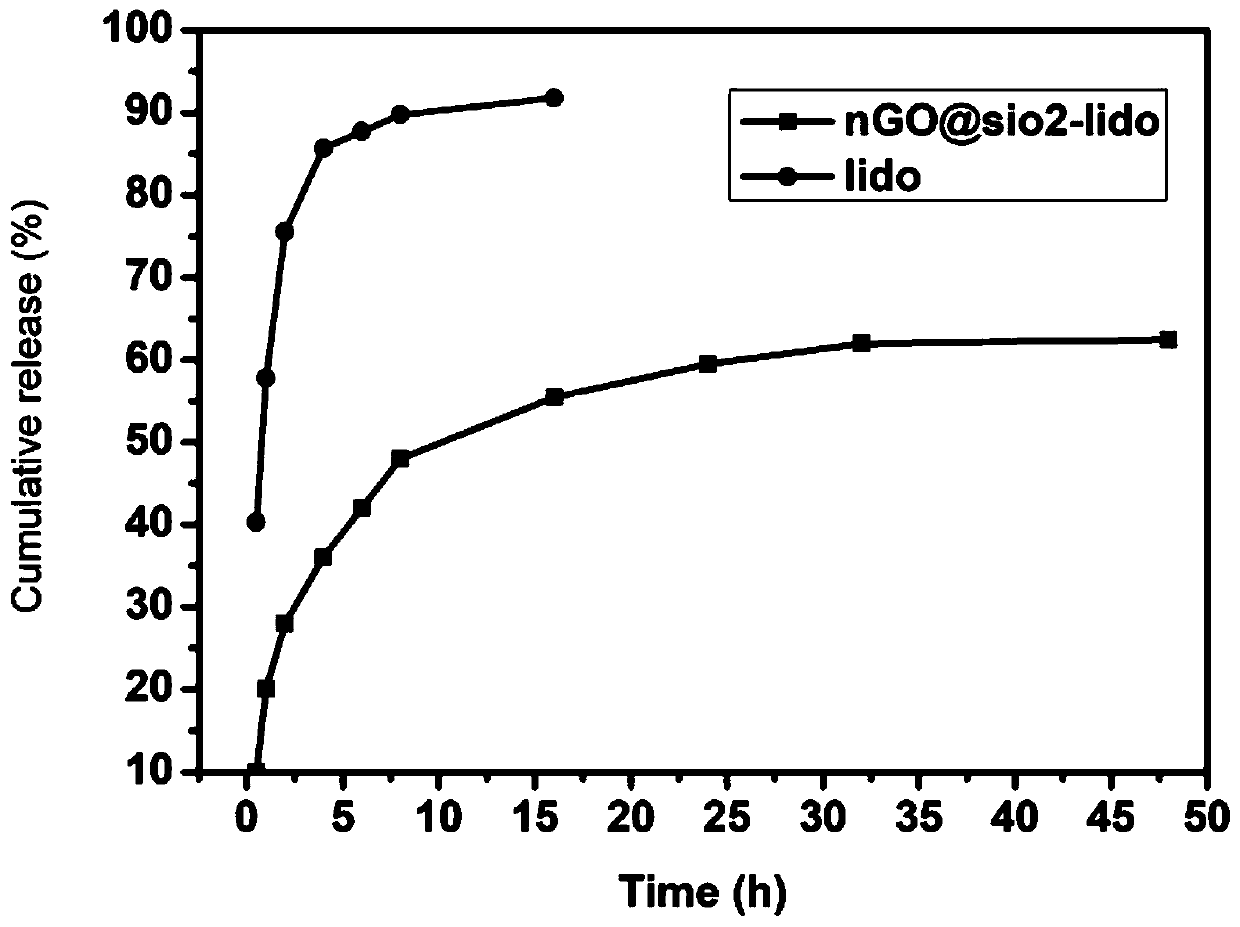

Porous silicon-coated graphene nano-sustained-release drug-carrying system and its preparation method and application, as well as loaded drug and its preparation

ActiveCN108187057BEasy to operateSimple stepsInorganic non-active ingredientsSilicon oxidePharmaceutical Substances

The invention provides a porous silicon coated graphene nano slow-release drug carrying system as well as a preparation method and application thereof, and a supported drug and preparation. The preparation method provided by the invention has the advantages of simple operation process and concise steps, does not need complicated aftertreatment and is suitable for large-scale production of a silicon dioxide protection type graphene oxide material. Meanwhile, the porous silicon coated graphene nano slow-release drug carrying system prepared by the preparation method has good drug carrying performance, avoids residue of meso-porous silicon template, and thus can further serve as a carrier for preparing the supported drug; moreover, the system has perfect safety in use.

Owner:JILIN UNIV

A preparation method of a ribbon-shaped hierarchical mesoporous nickel oxide high specific capacitance electrode material

InactiveCN104140128BEasy accessShorten the pathway of diffusionNickel oxides/hydroxidesCapacitanceSulfate

The invention relates to a preparation method of a ribbon type graded mesoporous nickel oxide high-specific-capacitance electrode material. The preparation method comprises the steps that nickel sulfate, guanidine hydrochloride and sodium chloride are used as raw materials, mesoporous carbon is used as a template, and then the ribbon type graded mesoporous nickel oxide high-specific-capacitance electrode material is prepared through a template method. Compared with the prior art, the preparation method has the advantages that the mesoporous carbon is used as the template, the guanidine hydrochloride is used as precipitating agents firstly without adding any surface active agents, and deionized water is adopted as a reaction solvent; the raw materials are cheap, and the ribbon type graded mesoporous nickel oxide high-specific-capacitance electrode material is nontoxic, harmless, simple in technological process, controllable in particle morphology, free from complex postprocessing processes and low in cost, and has good application prospect.

Owner:TONGJI UNIV

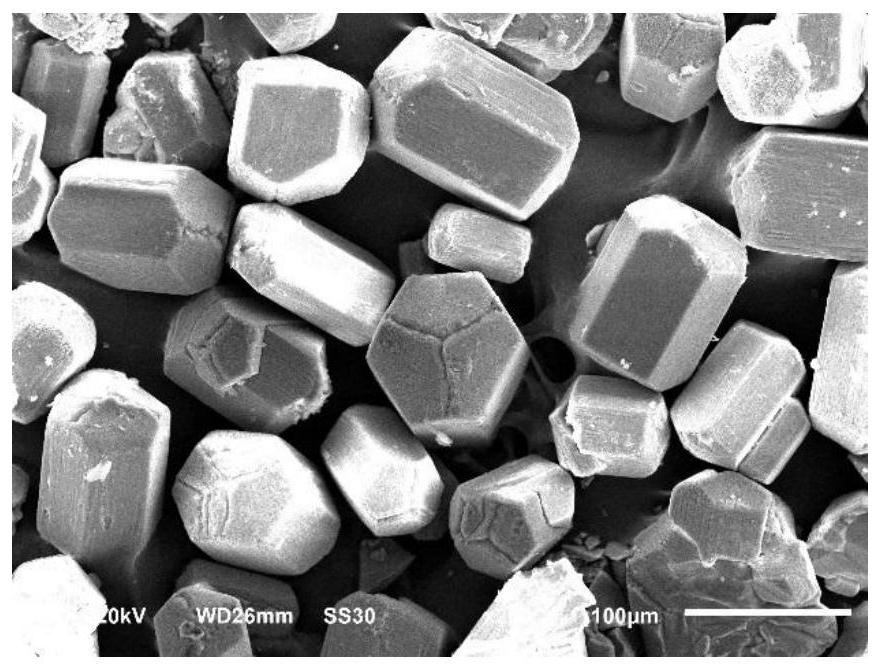

A kind of preparation method of spinel type porous high entropy oxide material

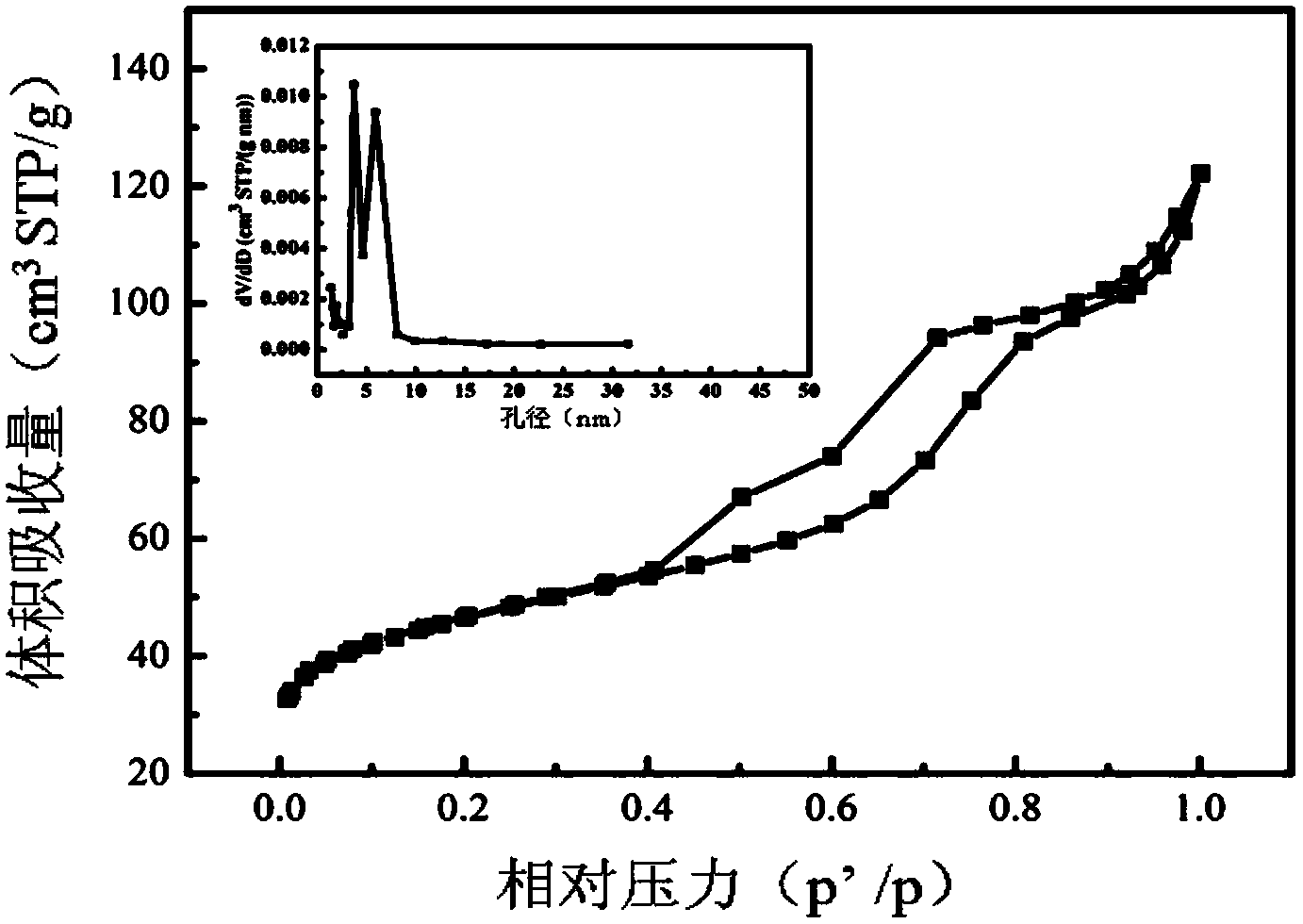

ActiveCN108821351BAchieving a stoichiometric ratioReduce energy consumptionMaterial nanotechnologyNickel compoundsHexamethylenetetramineFuel type

Belonging to the field of inorganic oxide powder materials, the invention discloses a preparation method of a spinel-type porous high entropy oxide material. The method is low temperature combustion synthesis method. Specifically, a metal nitrate is adopted as the metal source, one of or a mixture of several of citric acid, ethylenediamine tetraacetic acid, hexamethylenetetramine and glucose is adopted as the fuel, by controlling the concentration of the metal salt raw materials, the fuel type and adding amount, the combustion improver type and adding amount, and the ignition way, the granularity, morphology and other characteristics of the spinel-type transition metal high entropy oxide (CoCrFeMnNi)3O4 nanopowder can be regulated. The preparation method adopts liquid phase compounding toensure molecular level uniform mixing of the raw materials, and the product achieves stoichiometric ratio. At the same time, the method has the advantages of energy saving, high production efficiency,green and environmental protection, no need for complicated post-treatment and the like. The high entropy oxide powder prepared by the method provided by the invention has high purity and uniform particle size distribution.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Photopolymer composition and grating

ActiveCN112759959BIncreased refractive index modulationHigh sensitivityDiffraction gratingsCoatingsAmbient humidityPlasticizer

The invention relates to a green-sensitive photopolymer composition and a grating. The composition includes the following components: a polymerization active monomer; a dye compound, which has excitation activity at least near the wavelength of 532nm light; agents; film-forming components and plasticizers. The refractive index difference (n 聚合活性单体 ‑n 成膜组分 ) value above 0.075. Compared with the existing holographic recording photopolymer materials, the grating obtained based on the composition of the present invention has higher refractive index modulation degree, exposure sensitivity and light transmittance, and has improved diffraction efficiency at the same time, and preferably With improved size shrinkage, in addition, the photosensitive material of the present invention has wider angle selectivity and is less affected by environmental humidity.

Owner:LIGHTIN INC

Biomolecule fixing method

InactiveCN102091541BNo complex post-processing requiredComplex post-processingSemi-permeable membranesSolid substrateMaterials science

Owner:NANJING NORMAL UNIVERSITY

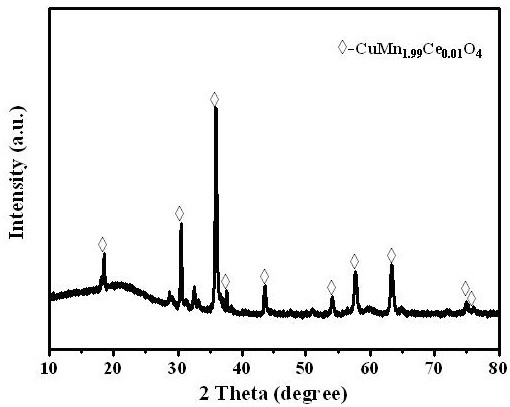

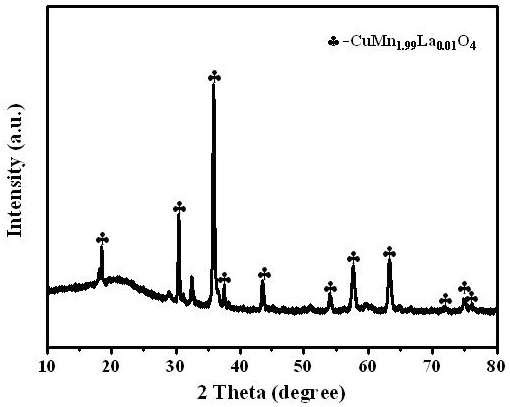

Light absorbing material and preparation method thereof

ActiveCN113401946ABig vibrationEnhanced light absorptionOther chemical processesManganates/permanganatesAbsorptanceSolar absorptance

The invention relates to a light absorbing material, which has a spinel crystal structure, wherein the chemical general formula of the material is CuMn2-yREyO4, RE is Ce or La, and y is more than or equal to 0 and less than or equal to 0.20. The invention also discloses a preparation method of the material. According to the invention, the preparation method adopts a mechanical wet grinding method for mixing and a solid-phase synthesis method for sintering, and has the advantages of simplicity in operation, short production period, no need of complex post-treatment, capability of realizing industrial production and the like, the solar energy absorption rate of the prepared material at the wave band of 0.3-2.5 microns is greater than or equal to 0.90, and the prepared material is good in thermal stability in air and stable in structure.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Biomolecule fixing method

InactiveCN102091541AFixing is simple and convenientQuick fixSemi-permeable membranesSolid substrateNanometre

The invention provides a novel simple biomolecule fixing method, comprising the following steps: firstly synthesizing a metal nano material by a liquid-liquid interface method; then adding biomolecules to a water phase for fixing the biomolecules to the liquid-liquid interface by a bonding action, thus obtaining a composite membrane of the metal nano material and the biomolecules; and finally, extracting the biomolecule-metal composite monodisperse membrane on the liquid-liquid interface by a langmuir technology or directly by a solid substrate. The method for fixing biomolecules provided by the invention has a simple preparation process for forming the biomolecule-metal nano composite material, and has the characteristic that the biomolecules are dispersed in order in a single layer and have good stability.

Owner:NANJING NORMAL UNIVERSITY

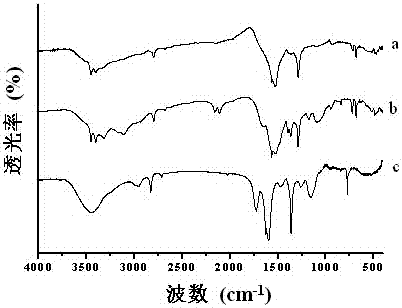

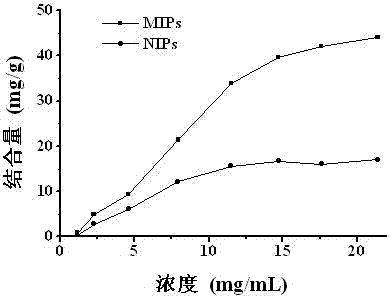

A kind of method for preparing melamine molecularly imprinted polymer by distillation precipitation polymerization

InactiveCN104725547BGood monodispersityUniform particle sizeOther chemical processesPolymer scienceDistillation

The invention discloses a method for preparing a melamine molecularly imprinted polymer by virtue of distillation, precipitation and polymerization. The method comprises the following steps: (1) dissolving melamine, a polymerization reaction monomer and divinylbenzene in acetonitrile, and standing; (2) adding an initiating agent into the solution of the step (1), removing oxygen, and heating to distill acetonitrile; and (3) after the distillation in the step (2), filtering the reaction solution, performing refluxing extraction on filter residues by using a methanol-acetic acid mixed solution, and drying to obtain the melamine molecularly imprinted polymer. By adopting the method disclosed by the invention, the problems that the molecularly imprinted polymer obtained by the conventional method is non-uniform in particle size, difficult in size control and low in binding capacity; the method disclosed by the invention is simple to operate and does not need a complex after-treatment process, and the obtained molecularly imprinted polymer microspheres have good monodispersity and binding capacity of 32-44mg / g, and can be used for separating and detecting melamine in a sample.

Owner:SHIHEZI UNIVERSITY

A preparation method of rare earth-based fluorite-type high-entropy oxide powder material

ActiveCN108946787BAchieving a stoichiometric ratioReduce energy consumptionRare earth metal oxides/hydroxidesMaterial nanotechnologyOXALIC ACID DIHYDRATEAcetic acid

Owner:内蒙古广禾元纳米高科技有限公司

A kind of preparation method of rock salt type (mgcocunizn) O high entropy oxide powder material

ActiveCN109019701BAchieving a stoichiometric ratioIncrease productivityCobalt compoundsMetal nitrateNitrate salts

Belonging to the field of high entropy oxide powder materials, the invention discloses a preparation method of a (MgCoCuNiZn)O high entropy oxide powder material with a rock salt type structure. The method is low-temperature combustion synthesis method, uses a metal nitrate as the metal source, and takes one or more of citric acid, tartaric acid and glucose with an appropriate carbon content as the fuel. The concentration of the metal salt raw material, the fuel variety and adding amount, the combustion improver variety and adding amount, and the ignition way are controlled to regulate the granularity, morphology and other characteristics of the high entropy oxide (MgCoCuNiZn)O nanopowder. According to the invention, the reactants exist in a solution, so that the raw materials in the solution can easily reach molecular level blending, and the product realizes a stoichiometric ratio. At the same time, the method provided by the invention has the advantages of energy saving, high production efficiency, simple and feasible process, green and environmental protection, no need for complex post-treatment, etc., and the prepared high entropy oxide powder has high purity and fine particlesize, and is uniformly distributed.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

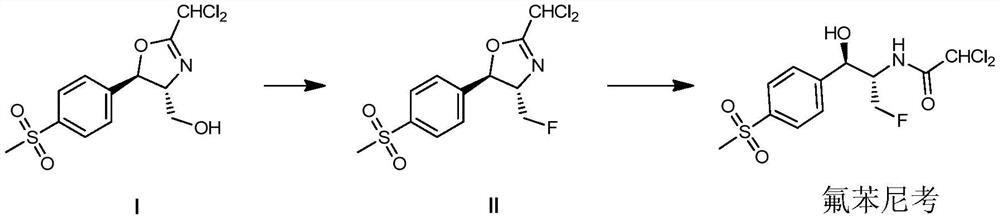

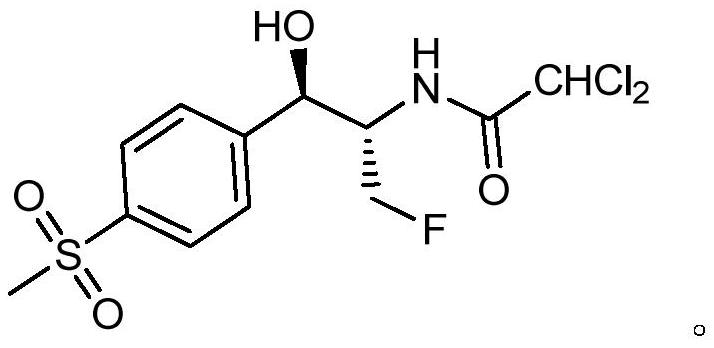

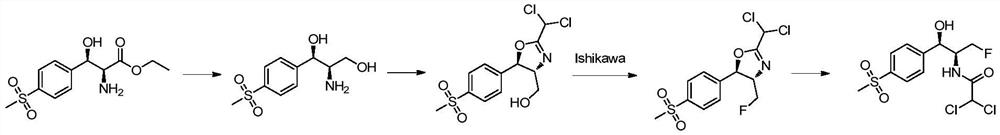

Florfenicol synthesis method

InactiveCN111978218ALow costReduce dosageOrganic chemistryOrganic compound preparationBiochemical engineeringProcess engineering

The invention relates to a florfenicol synthesis method. The method comprises the step of carrying out a ring opening reaction on a product obtained by fluorinating a compound I by using sulfuryl fluoride as a fluorination reagent in a water-containing system to easily prepare florfenicol. The method has the advantages of simple operation, few by-products, safety, environmental protection, low production cost and the like, and is very suitable for industrial use.

Owner:SHANGHAI VASTPRO TECH DEV CO LTD

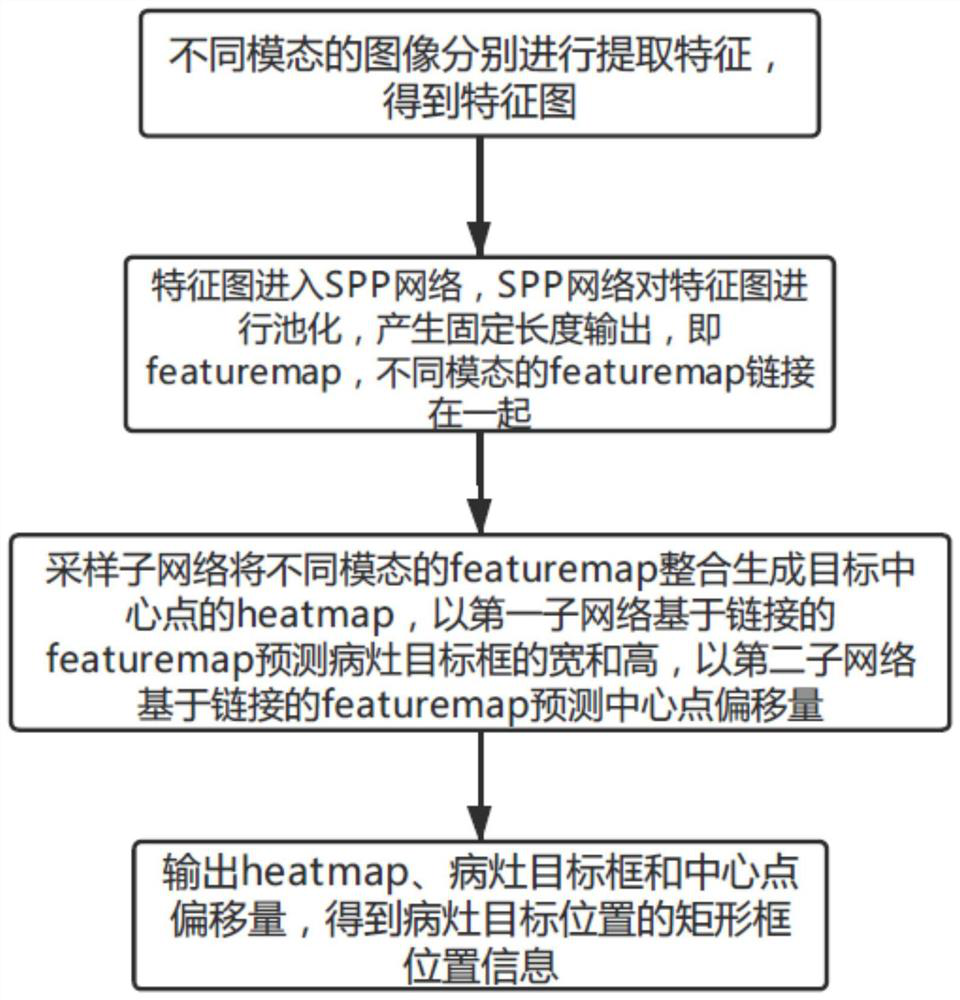

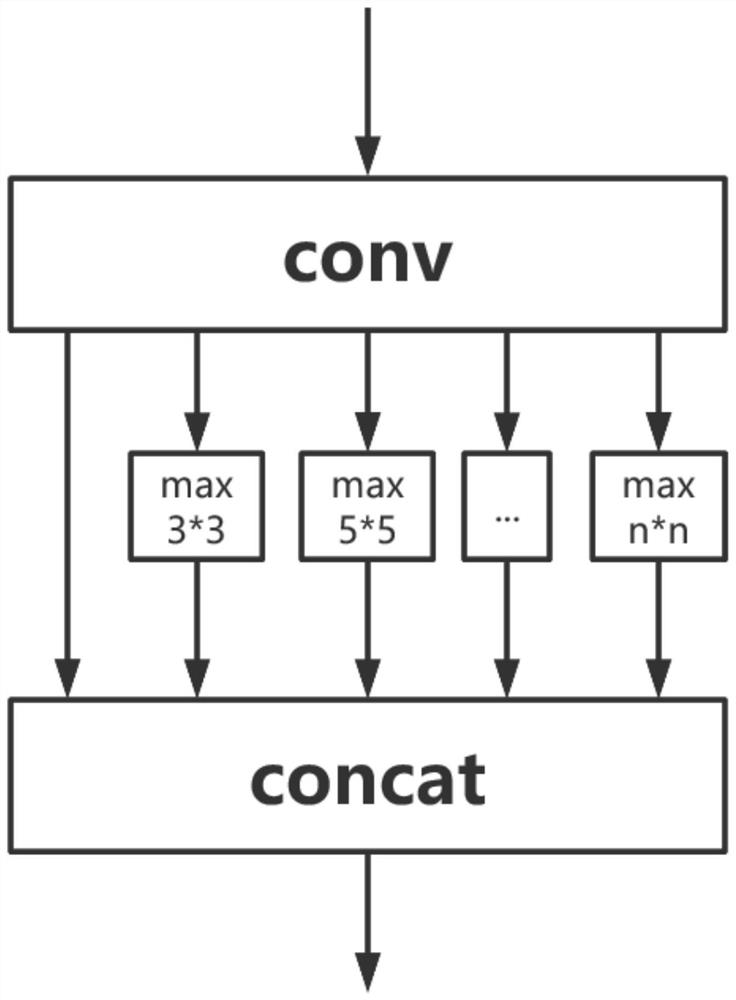

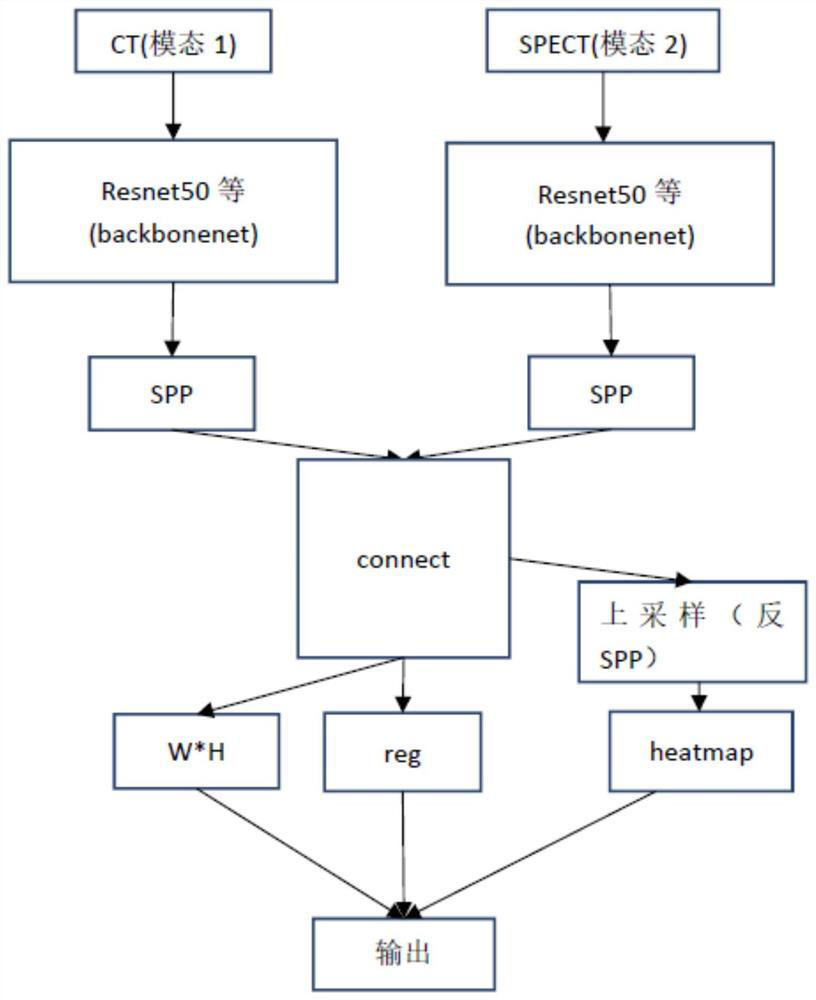

Nuclear medicine multi-mode lesion image detection method and system

InactiveCN113362325AValid reservationImprove compatibilityImage enhancementImage analysisLesion mappingImage detection

The invention discloses a nuclear medicine multi-mode lesion image detection method and system. The method and system can effectively carry out the detection and integration processing of a lesion target image through the information of different modes, do not need extra multi-mode preprocessing work, and can comprehensively and completely reserve the information of each mode. After multi-scale feature fusion, the information of different modes is integrated, detail information of the different modes can be effectively reserved, and subsequent target detection by using the information of the different modes is facilitated. The principle part of a target detection head adopts the Centernet design concept in the prior art, a focus target is described as a central point, other characteristics such as the size of the target are obtained through direct regression in a feature map, and thus, the method is simple in principle and high in compatibility, does not need complex post-processing and achieves end-to-end detection.

Owner:ATOMICAL MEDICAL EQUIP FO SHAN LTD +1

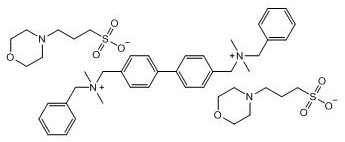

Quaternary ammonium salt ionic liquid, preparation method thereof and application of quaternary ammonium salt ionic liquid as metal corrosion inhibitor

PendingCN114853693ALow priceThe synthesis method is simpleAmino preparation from aminesOrganic compound preparationMg alloysPhysical chemistry

The invention discloses three quaternary ammonium salt ionic liquids, and the molecular structural formulas of the quaternary ammonium salt ionic liquids are shown in the specification. The invention also provides a preparation method of the quaternary ammonium salt ionic liquids ([DMBAB] [MOPS], [DMBAB] [Phe] and [DMBAB] [Trp]) and application of the quaternary ammonium salt ionic liquids in the aspect of magnesium alloy corrosion inhibition. The invention aims to solve the problems of corrosion of magnesium metal and alloy thereof and the like, the maximum anti-corrosion efficiency of the compound is about 88.8%, an AZ91D Mg alloy sample is soaked in a solution prepared from different corrosion inhibitors and 0.5 wt.% NaCl for 10 hours, a compact film layer can be formed on the surface of the magnesium alloy, so that a good corrosion inhibition effect is achieved, and the corrosion resistance of the AZ91D Mg alloy sample is greatly improved. The ionic liquid provided by the invention has the advantages of low raw material price, simple synthesis method, mild reaction conditions, no need of complex post-treatment and the like.

Owner:HENAN UNIVERSITY

A method for preparing rare earth-doped yttrium oxide fluorescent nanoparticles by dbd technology

ActiveCN112920799BControllable equipmentHigh activityNanoopticsLuminescent compositionsPlasma reactorMaterials science

The invention discloses a method for preparing rare earth-doped yttrium oxide fluorescent nanoparticles by DBD technology, the method comprising the following steps: (1) base metal organic matter and doped metal organic matter are carried out at a mass ratio of 10 to 40:1. Mixing, the mixture is ground as a reaction precursor; (2) the precursor obtained in step (1) is placed in a container, and the container is placed between the positive and negative electrodes of the plasma reactor; (3) after that, under an oxygen atmosphere, An alternating current is applied between the cathode and anode of the plasma reactor, the precursor is treated for a period of time, and the product is taken out and ground at intervals to obtain a powder containing rare earth-doped yttrium oxide nanoparticles. The invention adopts the DBD technique to prepare the powder of the rare earth-doped yttrium oxide fluorescent nano-particles by using the highly active oxidizing component in a one-step method. The method is simple and easy, green and efficient, and does not require further reaction under high temperature and high pressure, effectively reducing energy consumption.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com