Controllable graphene nanolayer preparation method

A nano-layer and graphene technology, which is applied in the field of controllable preparation of graphene nano-layers by laser irradiation, can solve the problems of high cost functional groups, doping, dependence on raw material quality and performance, etc., and achieve simple operation and low cost , the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

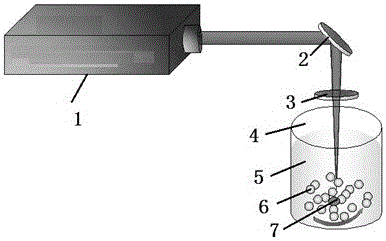

[0025] 1) Put the raw material graphite with a particle size of 4 μm in the reaction container, inject 50ml-200ml of deionized water, the concentration of graphite powder and solvent is 0.02g / ml, put the reaction container in the cavity of the ultrasonic cleaning machine, and turn on the cleaning machine. Disperse the graphite in deionized water; 2) Put the rotor into the reaction vessel, place the reaction vessel on the stirrer, start the stirrer, and control the speed to make the graphite evenly distributed in the deionized water; 3) Adjust the optical path of the pulse laser , so that the laser beam is focused 2-3mm below the liquid surface through the total reflection mirror and the focusing lens, the laser pulse frequency is 1-10Hz, and the laser energy is 4J; 4) Turn on the laser, and the laser irradiates the graphite in the liquid environment, and the reaction process continues Turn off the laser after 2 hours; 5) Place the reaction vessel in a desiccator to dry to obtai...

Embodiment 2

[0028] The difference from Example 1 is that in this example, raw material graphite with a particle size of 1 μm is placed in a reaction vessel, 50ml-200ml of deionized water is injected, the concentration of graphite powder and solvent is 0.025g / ml, and the reaction vessel is placed in ultrasonic cleaning In the machine cavity, turn on the washing machine to disperse the graphite in the deionized water; put the rotor into the reaction vessel, put the reaction vessel on the stirrer, start the stirrer, and control the speed so that the graphite is evenly distributed in the deionized water; adjust The optical path of the pulse laser makes the laser beam focus on 2-3mm below the liquid surface through the total reflection mirror and the focusing lens, the laser pulse frequency is 1-10Hz, and the laser energy is 8J; when the laser is turned on, the laser irradiates the graphite in the liquid environment, and the reaction After the process continued for 1.5 hours, the laser was turn...

Embodiment 3

[0030] The difference from Example 1 is that in this example, raw material graphite with a particle size of 0.5 μm is placed in a reaction vessel, 50ml-200ml of deionized water is injected, the concentration of graphite powder and solvent is 0.03g / ml, and the reaction vessel is placed in an ultrasonic wave. In the washing machine cavity, turn on the washing machine to disperse the graphite in the deionized water; put the rotor into the reaction vessel, put the reaction vessel on the stirrer, start the stirrer, and control the speed to make the graphite evenly distributed in the deionized water; Adjust the optical path of the pulsed laser so that the laser beam is focused 2-3mm below the liquid surface through the total reflection mirror and the focusing lens, the laser pulse frequency is 1-10Hz, and the laser energy is 12J; turn on the laser, and the laser irradiates the graphite in the liquid environment. After the reaction process continued for 1 hour, the laser was turned of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com