Porous silicon-coated graphene nano-sustained-release drug-carrying system and its preparation method and application, as well as loaded drug and its preparation

A nano-sustained release and graphene technology, applied in the field of materials, can solve the problems of difficult large-scale product production and preparation, difficulty, cumbersome steps, etc., and achieve the effect of simple steps, good use safety, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

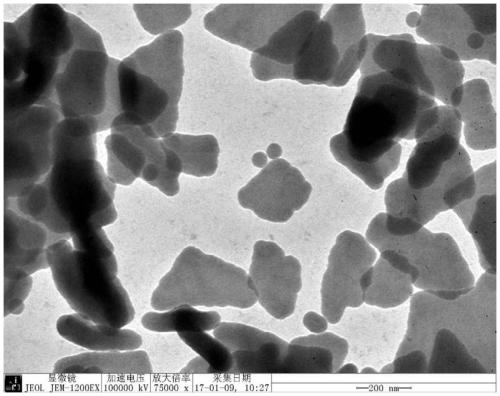

[0064] Take 0.2g of micron-sized single-layer graphene oxide, add it to 100ml of deionized water, and place it in an ultrasonic pulverizer under ice bath conditions, and ultrasonically treat it for 1 hour to obtain a nanometer graphene oxide aqueous dispersion with a size of about 200 nanometers;

[0065] According to the mass ratio of 1:1, measure an appropriate amount of nano-graphene oxide aqueous dispersion, mix it with an appropriate amount of PVP k30, and ultrasonically treat it for 30 minutes to obtain nGO-PVP;

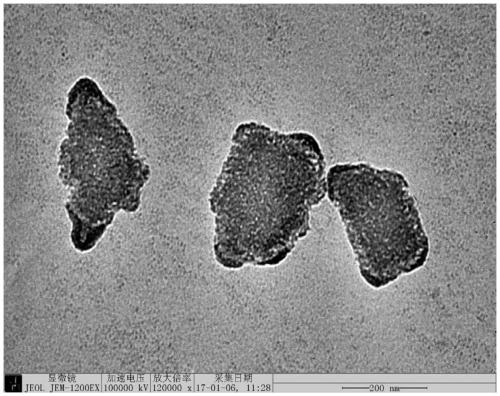

[0066] Then, the STOBER growth method was used to coat SiO on the surface of nano-graphene oxide. 2 , that is, 50ml ethanol, 10mgGO-PVP, 5ml ammonia water and 2ml TOES were mixed and reacted at 25°C for 3h; then, the product system was centrifuged at 12000r / min for 20min, the supernatant was removed, and the precipitate was recovered, which was nGO -PVP@SiO 2 , that is, the outer surface is SiO 2 The structure of the coated nGO-PVP was detected by scanning el...

Embodiment 2

[0072] Take 0.5g of micron-sized single-layer graphene oxide, add it to 100ml of deionized water, and place it in an ultrasonic pulverizer under ice bath conditions, and ultrasonically treat it for 45 minutes to obtain a nanometer graphene oxide aqueous dispersion with a size of about 200 nanometers;

[0073] According to the mass ratio of 1:2, measure an appropriate amount of nano-graphene oxide aqueous dispersion, mix it with an appropriate amount of PVP k30, and ultrasonically treat it for 30 minutes to obtain nGO-PVP;

[0074] Mix 100ml of ethanol, 20mg of GO-PVP, 10ml of ammonia water and 5ml of TOES at 30°C for 5h; then, centrifuge the product system at 12000r / min for 20min, remove the supernatant, and recover the precipitate, which is nGO -PVP@SiO 2 , that is, the outer surface is SiO 2 Coated nGO-PVP;

[0075] Next, the GO-PVP@SiO 2 Mix with PVP k15 at a mass ratio of 1:2, then reflux at 95°C for 3 hours; then centrifuge the product system at a speed of 12,000r / min ...

Embodiment 3

[0078] Take 0.3g of micron-sized single-layer graphene oxide, add it to 100ml of deionized water, and place it in an ultrasonic pulverizer under ice bath conditions, and ultrasonically treat it for 90 minutes to obtain a nanometer graphene oxide aqueous dispersion with a size of about 200 nanometers;

[0079] According to the mass ratio of 1:3, measure an appropriate amount of nano-graphene oxide aqueous dispersion, mix it with an appropriate amount of PVP k30, and ultrasonically treat it for 30 minutes to obtain nGO-PVP;

[0080] Mix 80ml of ethanol, 15mg of GO-PVP, 10ml of ammonia water and 3ml of TOES at 20°C for 5h; then, centrifuge the product system at 12000r / min for 20min, remove the supernatant, and recover the precipitate, which is nGO -PVP@SiO 2 , that is, the outer surface is SiO 2 Coated nGO-PVP;

[0081] Next, the GO-PVP@SiO 2 Mix with PVP k15 at a mass ratio of 1:3, then reflux at 95°C for 3 hours; then centrifuge the product system at a speed of 12000r / min fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com