Method for preparing rare earth doped yttrium oxide fluorescent nanoparticles through DBD technology

A fluorescent nanoparticle and rare earth doping technology, applied in the field of ions, can solve the problems of long time, cumbersome process, and difficulty in constructing related nanostructures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

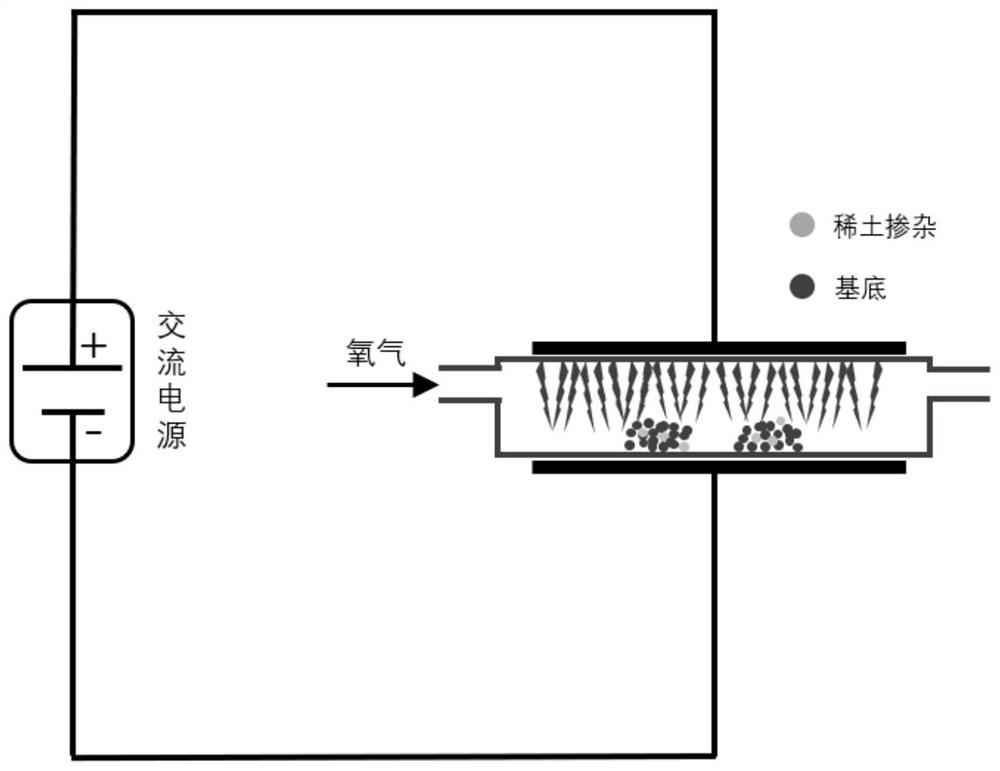

[0034] A kind of method that prepares yttrium oxide rare earth doping by DBD technology, described method comprises the steps:

[0035] (1) 0.5g yttrium acetylacetonate is mixed with 0.025g europium acetylacetonate, and the mixture is ground as a reaction precursor;

[0036] (2) Place the precursor obtained in step (1) in a quartz container, and the powder should be spread flat at a position 2.5cm away from the center of the container; the top of the container is covered with a 90mm diameter, 3mm thick quartz sheet; the container is placed on the yin and yang of the plasma reactor Between poles (diameter of electrode cylinder is 56.1mm, height is 20mm), the distance between positive and negative poles is 13mm;

[0037] (3) Regulate 60 sccm of oxygen into the quartz container through a mass flow controller, and maintain it until the reaction is completely completed to ensure that the oxygen atmosphere always exists during the reaction process, and the applied alternating curren...

Embodiment 2

[0041] The preparation method is the same as that in Example 1, except that the power of the applied alternating current is 240W, and the oxygen flow rate of the mass flow meter is adjusted to 80 sccm. In this example, due to the expansion of oxygen flux and reaction power, the carbon peak in the X-ray energy spectrum is lower than that of Example 1, which can further improve the purity of yttrium oxide in the product.

Embodiment 3

[0043] The preparation method is the same as in Example 1, except that the precursor is prepared by mixing and grinding 0.5 g of yttrium acetylacetonate and 0.025 g of terbium acetylacetonate. In Example 3, due to the difference of doped precursors, the peak position at 33° in XRD is slightly different from that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com