Memory based on polymer composite material and preparation method thereof

A composite material and polymer technology, applied in the field of memory based on polymer composite materials and its preparation, can solve the problems of poor memory stability and storage performance, difficulty in large-scale preparation of memory, etc., and achieve low cost and easy large-scale Synthesis and preparation of simple and controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

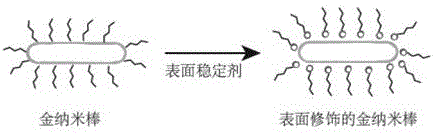

[0047] Preparation of functional group modified gold nanorods:

[0048] Firstly mix cetyltrimethylammonium bromide and tetrachloroalloy acid evenly, then add sodium borohydride and stir for 1 min, and then place it at room temperature for 2 hours to obtain a seed solution for later use;

[0049] Mix hexadecyltrimethylammonium bromide with silver nitrate, tetrachloroalloy acid and vitamin C evenly, then add the seed solution, and leave for 28 hours to generate a gold nanorod solution;

[0050] Firstly, the surface modification material is added to the gold nanorod solution and mixed evenly, and then dichlorobenzene is quickly added to obtain the functional group modified gold nanorod solution.

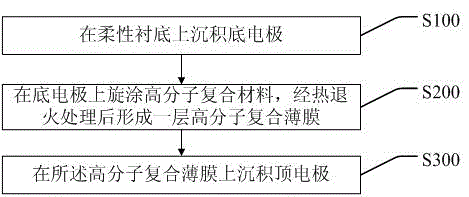

[0051] Fabrication of memories based on polymer composites:

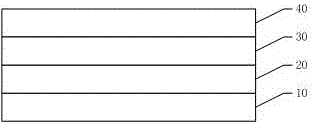

[0052] Deposit a bottom electrode with a thickness of 80nm on a flexible substrate; spin-coat a polymer composite material on the bottom electrode, and form a polymer composite film with a thickness of 50nm after thermal ann...

Embodiment 2

[0054] Preparation of functional group modified gold nanorods:

[0055] Firstly mix cetyltrimethylammonium bromide and tetrachloroalloy acid evenly, then add sodium borohydride and stir for 3 minutes, and then leave it at room temperature for 3 hours to obtain a seed solution for later use;

[0056] Mix hexadecyltrimethylammonium bromide with silver nitrate, tetrachloroalloy acid and vitamin C evenly, then add the seed solution, and leave it for 33 hours to generate a gold nanorod solution;

[0057] Firstly, the surface modification material is added to the gold nanorod solution and mixed evenly, and then dichlorobenzene is quickly added to obtain the functional group modified gold nanorod solution.

[0058] Fabrication of memories based on polymer composites:

[0059] Deposit a bottom electrode with a thickness of 100nm on a flexible substrate; spin-coat a polymer composite material on the bottom electrode, and form a polymer composite film with a thickness of 70nm after the...

Embodiment 3

[0061] Preparation of functional group modified gold nanorods:

[0062] Firstly mix cetyltrimethylammonium bromide and tetrachloroalloy acid evenly, then add sodium borohydride and stir for 5 minutes, and then place it at room temperature for 4 hours to obtain a seed solution for later use;

[0063] Mix hexadecyltrimethylammonium bromide with silver nitrate, tetrachloroalloy acid and vitamin C evenly, then add the seed solution, and leave it for 36 hours to generate a gold nanorod solution;

[0064] Firstly, the surface modification material is added to the gold nanorod solution and mixed evenly, and then dichlorobenzene is quickly added to obtain the functional group modified gold nanorod solution.

[0065] Fabrication of memories based on polymer composites:

[0066] Deposit a bottom electrode with a thickness of 120nm on a flexible substrate; spin-coat a polymer composite material on the bottom electrode, and form a polymer composite film with a thickness of 100nm after th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com