Patents

Literature

39results about How to "Uniform and stable discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

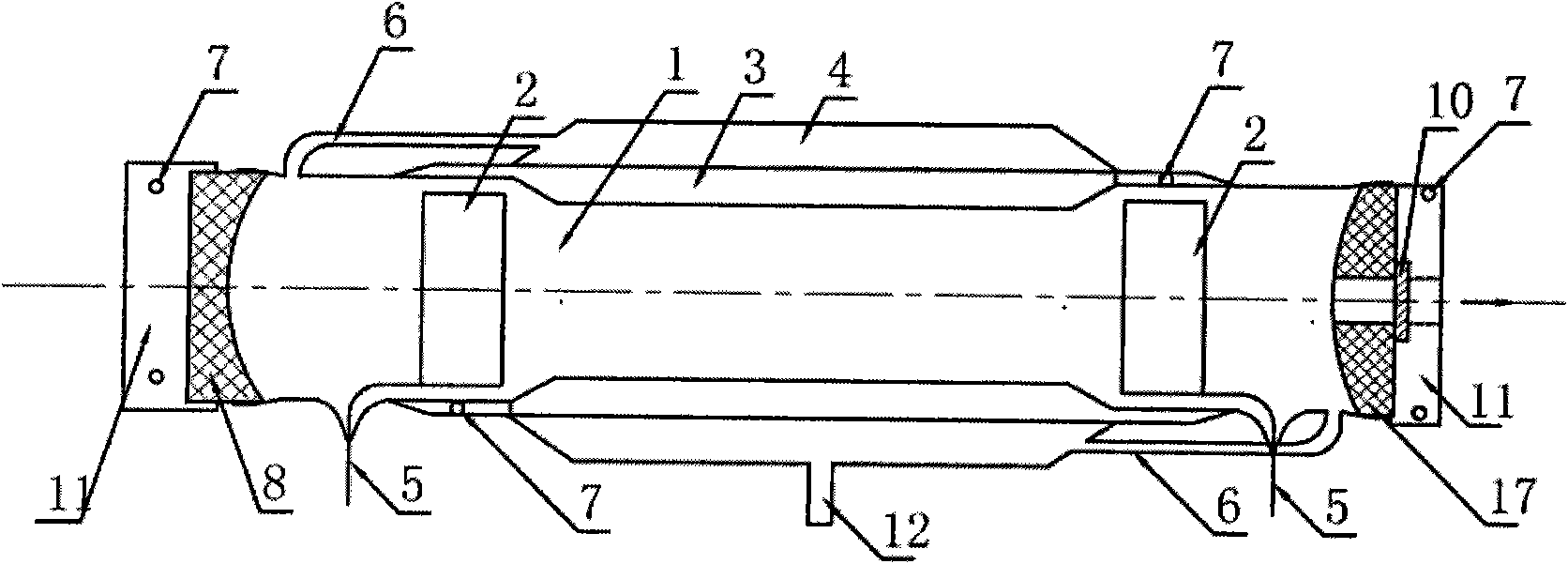

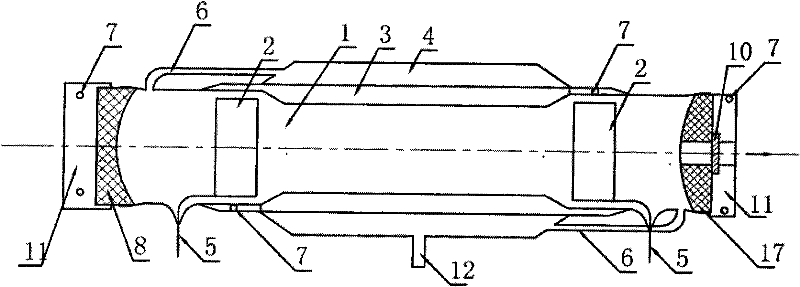

Harmful gas conversion device with non-thermal plasma induced by dielectric barrier discharge

InactiveCN101462021AUniform and stable dischargeGovernance H <sub>2<</sub> Dispersed particle separationPhysicsIndustrial waste

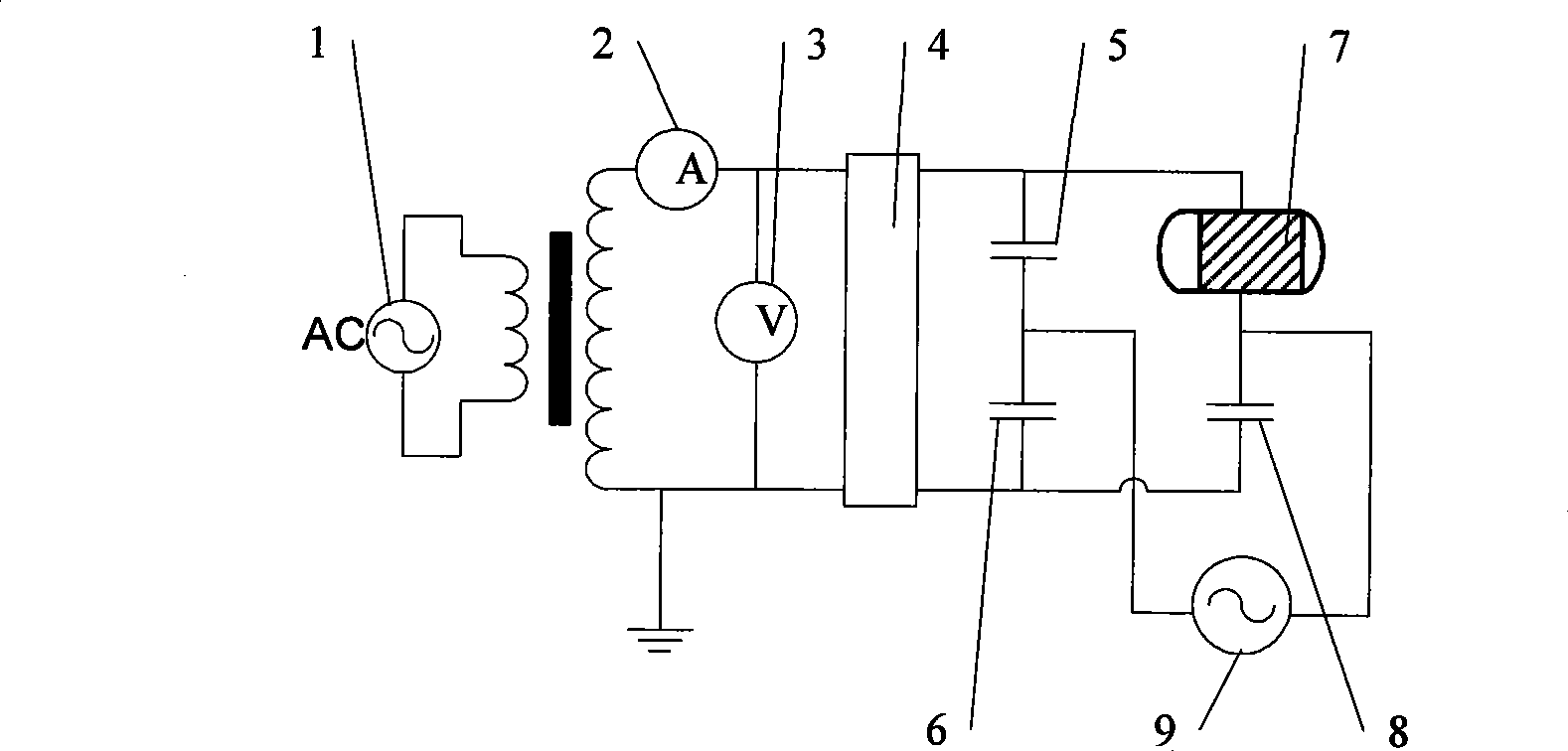

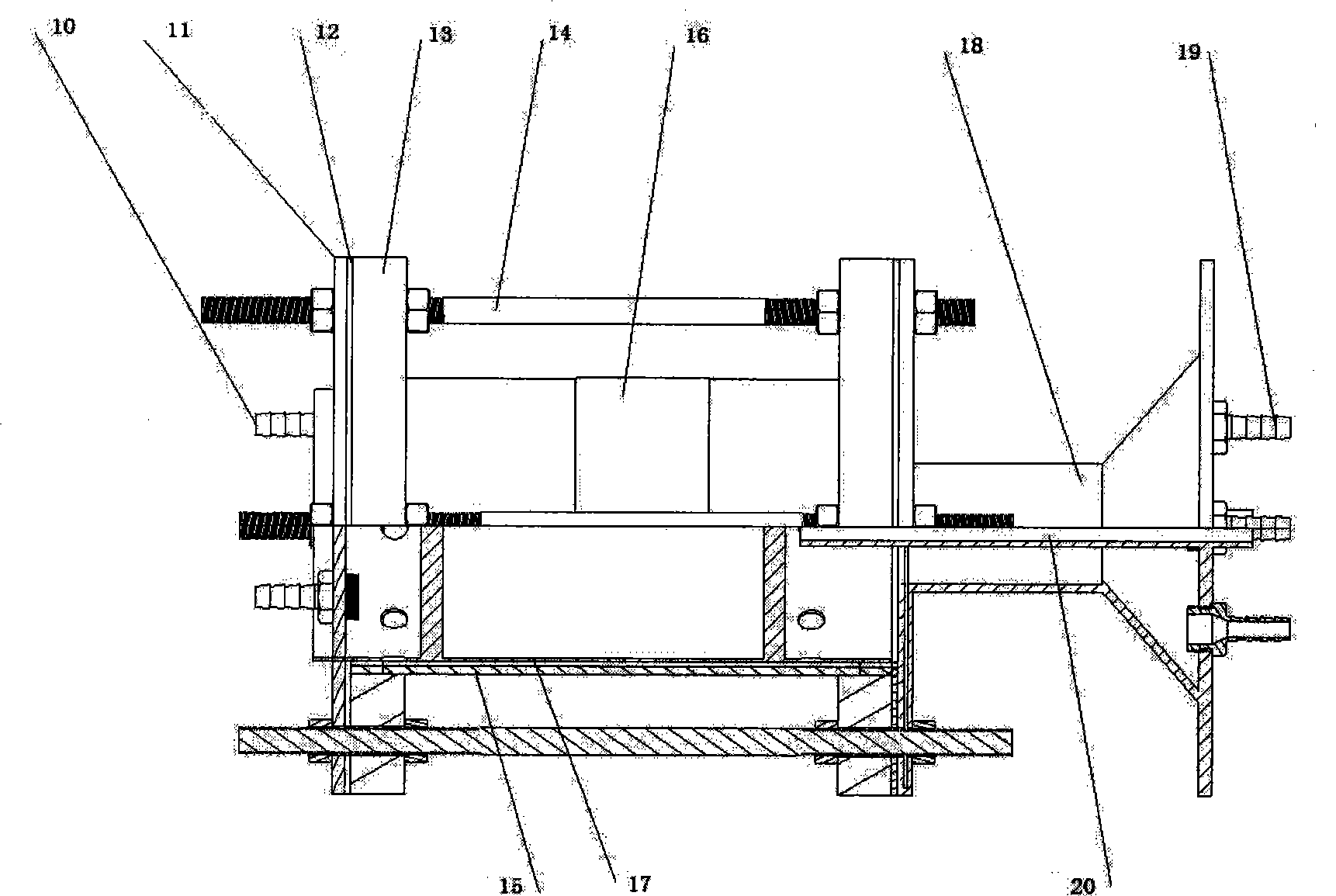

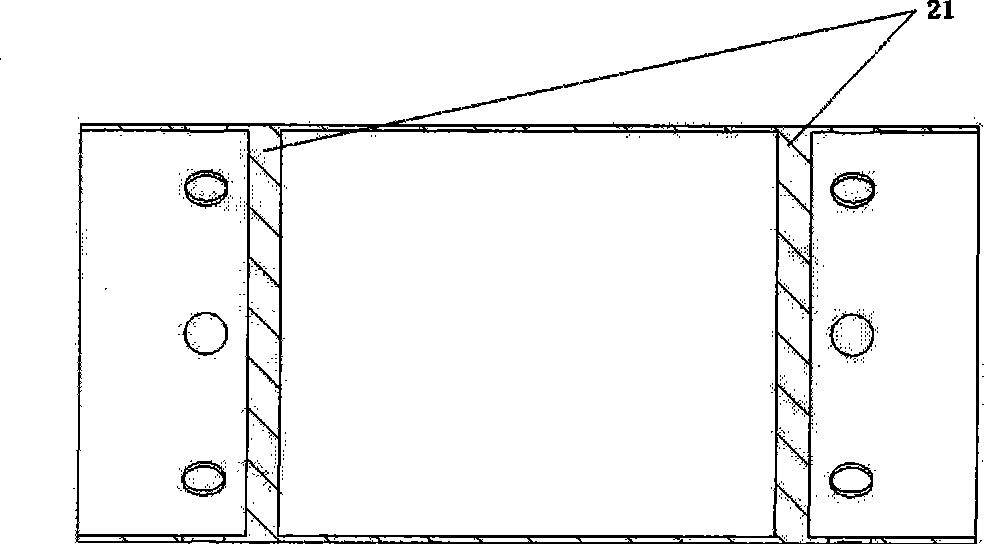

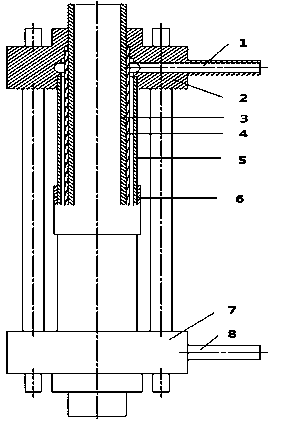

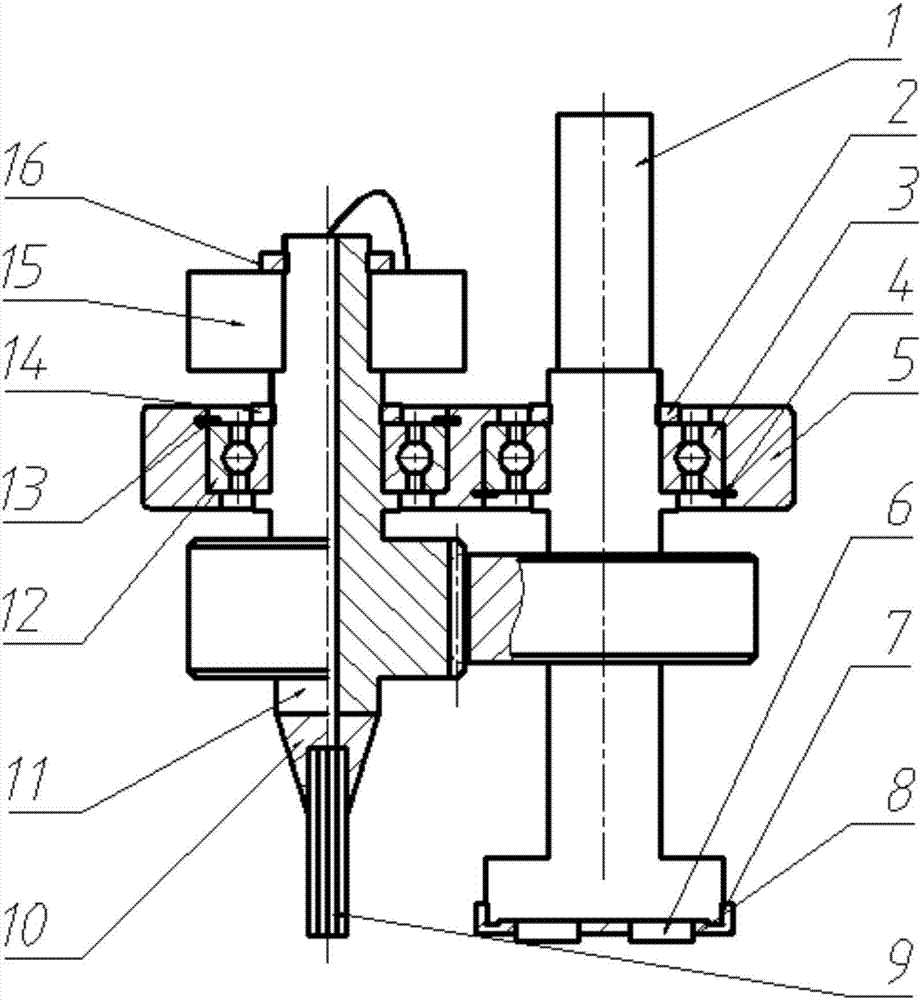

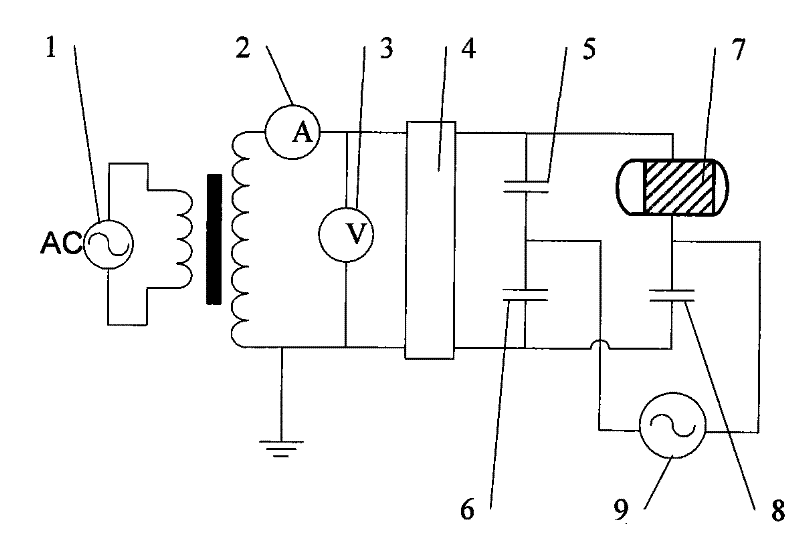

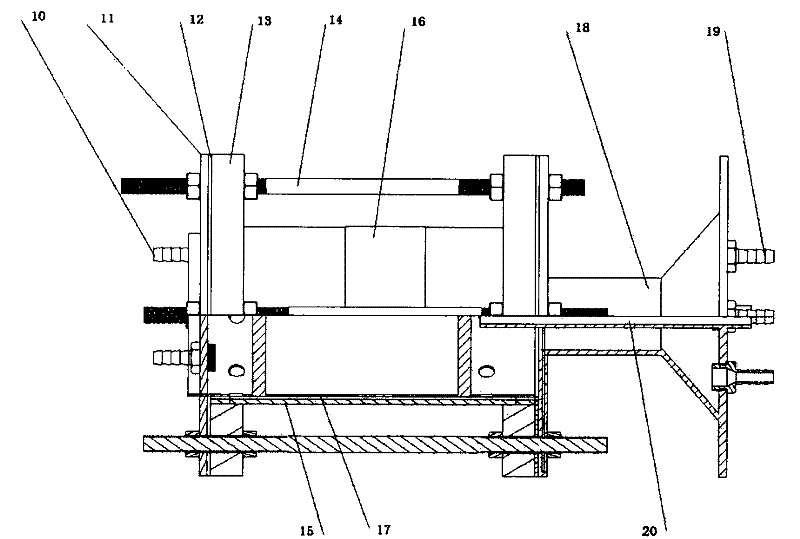

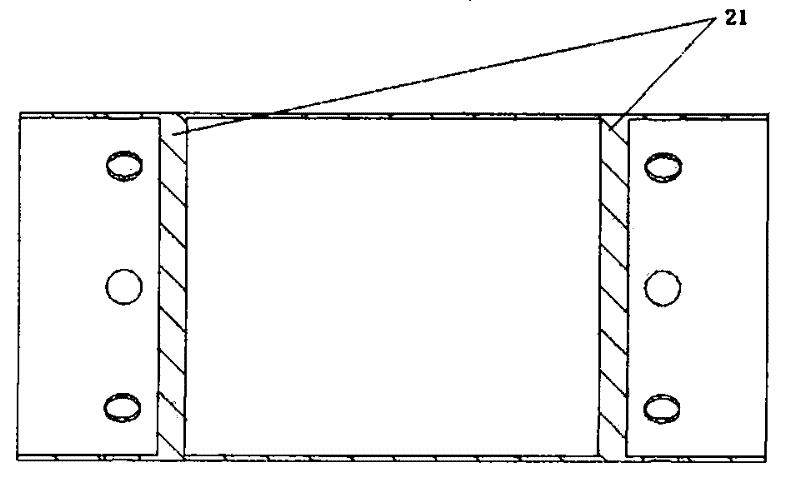

The invention relates to a dielectric barrier discharge low-temperature plasma harmful gas converter, which belongs to the technical field of control of industrial waste gas and harmful emission of motor vehicles, wherein a low-temperature plasma reactor (7) of the dielectric barrier discharge low-temperature plasma harmful gas converter is a coaxial tubular dielectric barrier discharge low-temperature plasma reactor, and consists of a central low-voltage electrode (17), a quartz dielectric (15) which is coaxial with the central low-voltage electrode (17), a high-voltage electrode (16) which is packed on the outer wall of the dielectric, a polyfluortetraethylene connecting rod (14), a front end cover (11), a rear end cover (18), a front end cover air inlet interface (10), a rear end cover air outlet interface(19), a selectable air inlet and outlet interface (20), and a low-temperature plasma reaction zone which is formed by gaps between the outer wall of the central low-voltage electrode (17) and the inner wall of the quartz dielectric (15). The dielectric barrier discharge low-temperature plasma harmful gas converter has high treatment efficiency, simple equipment and no secondary pollution, does not need subsequent treatment, is easy to operate, and is suitable for treating harmful substances such as NO, CO, HC, H2S and PM.

Owner:JIANGSU UNIV

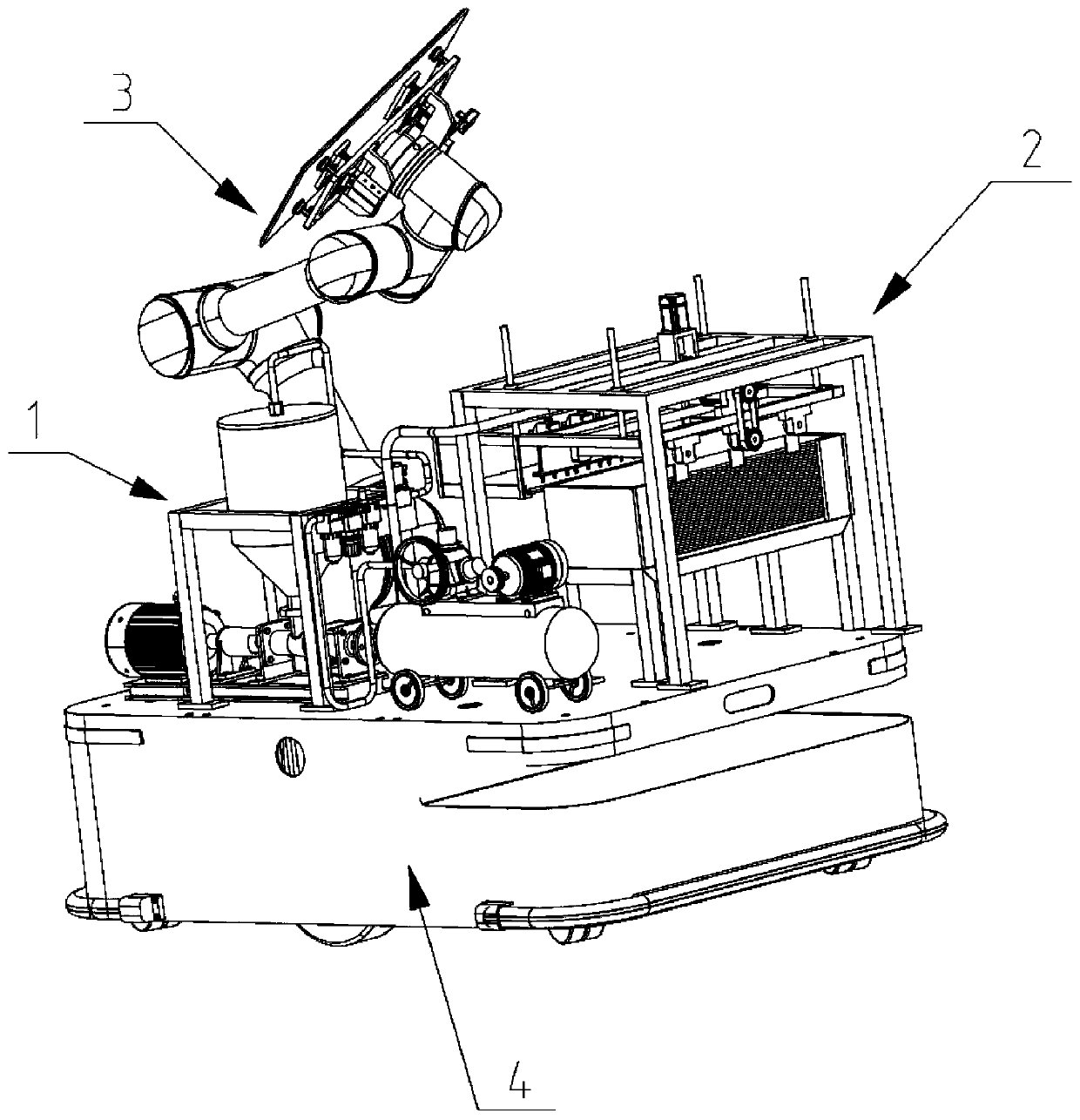

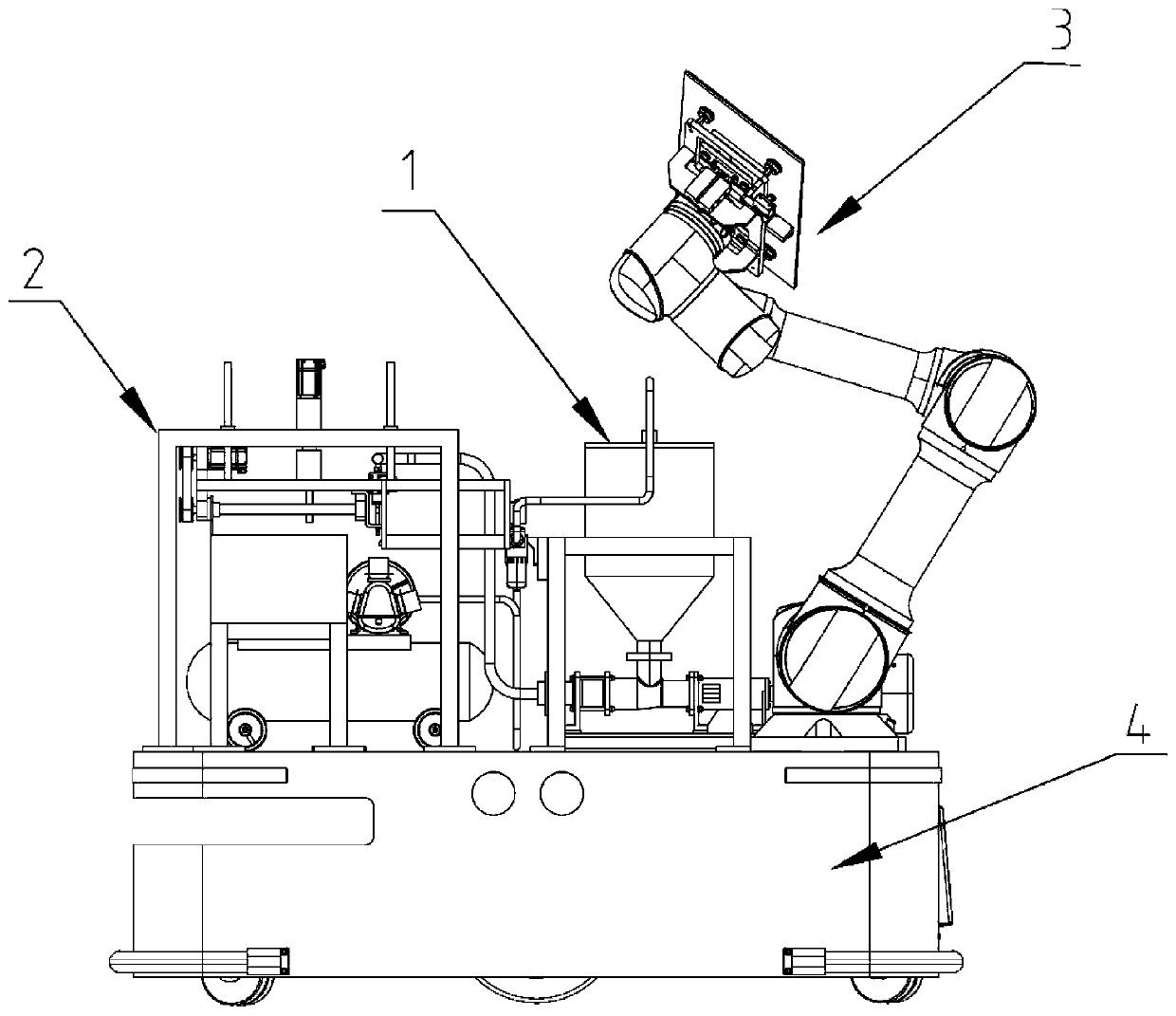

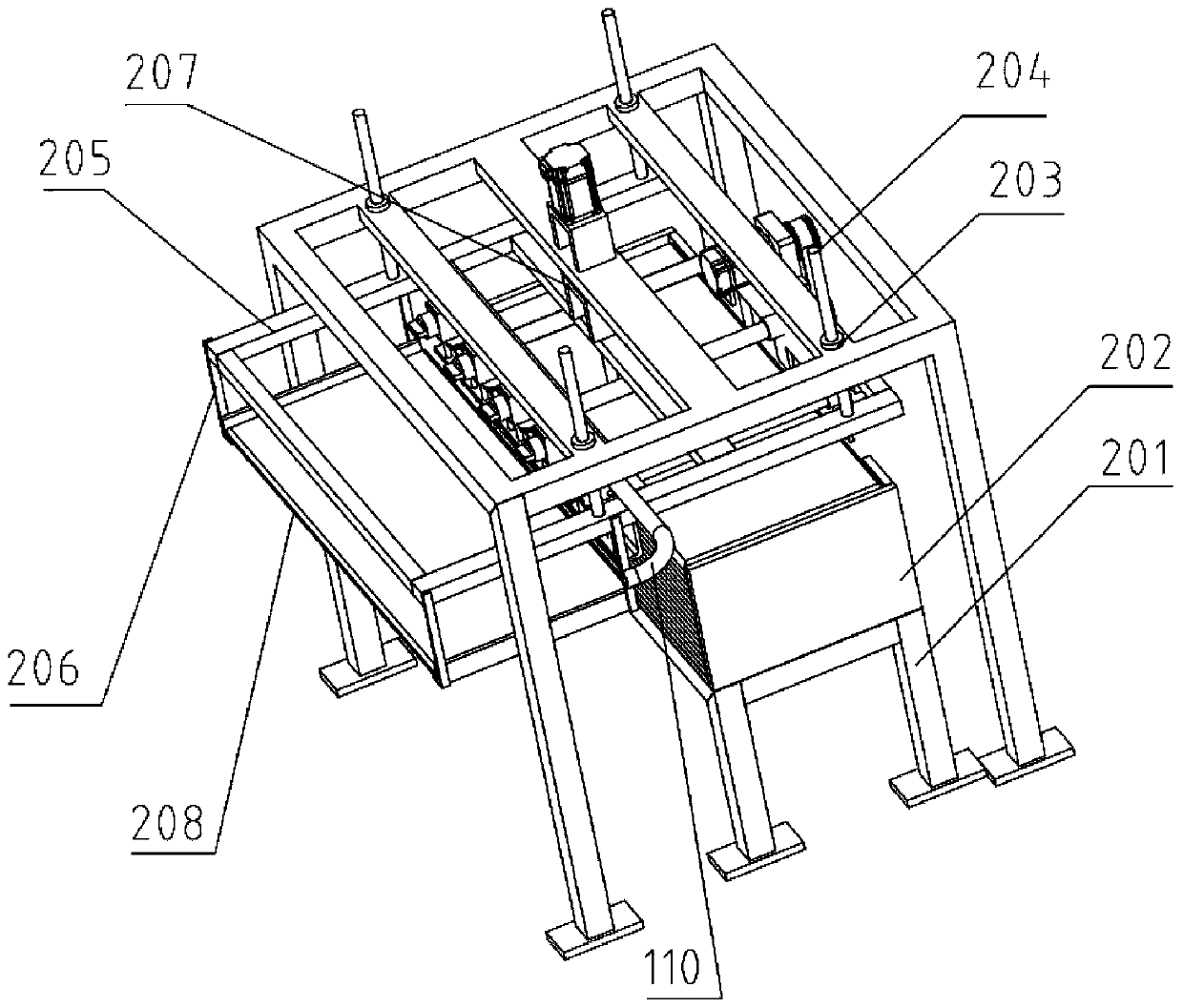

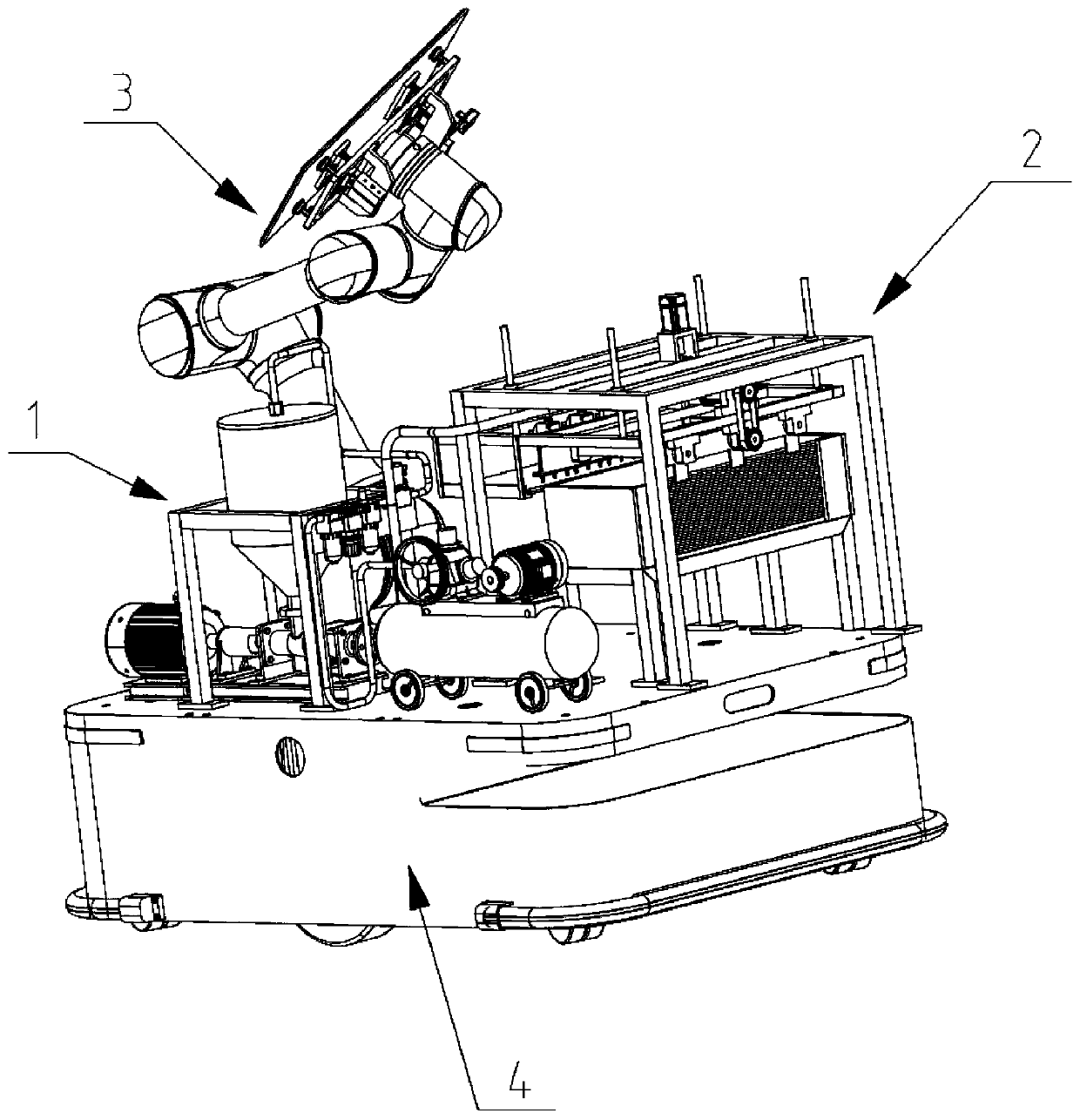

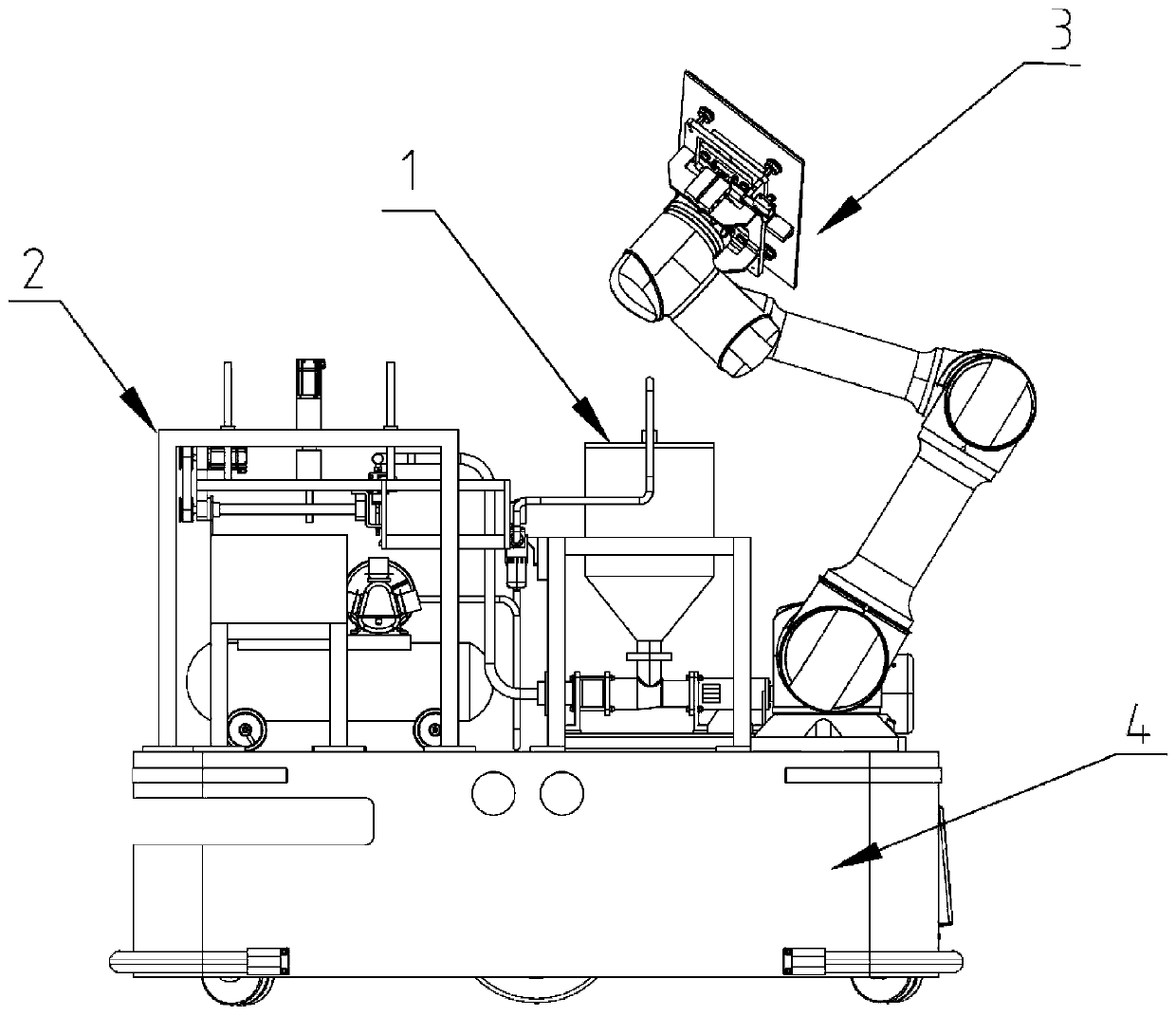

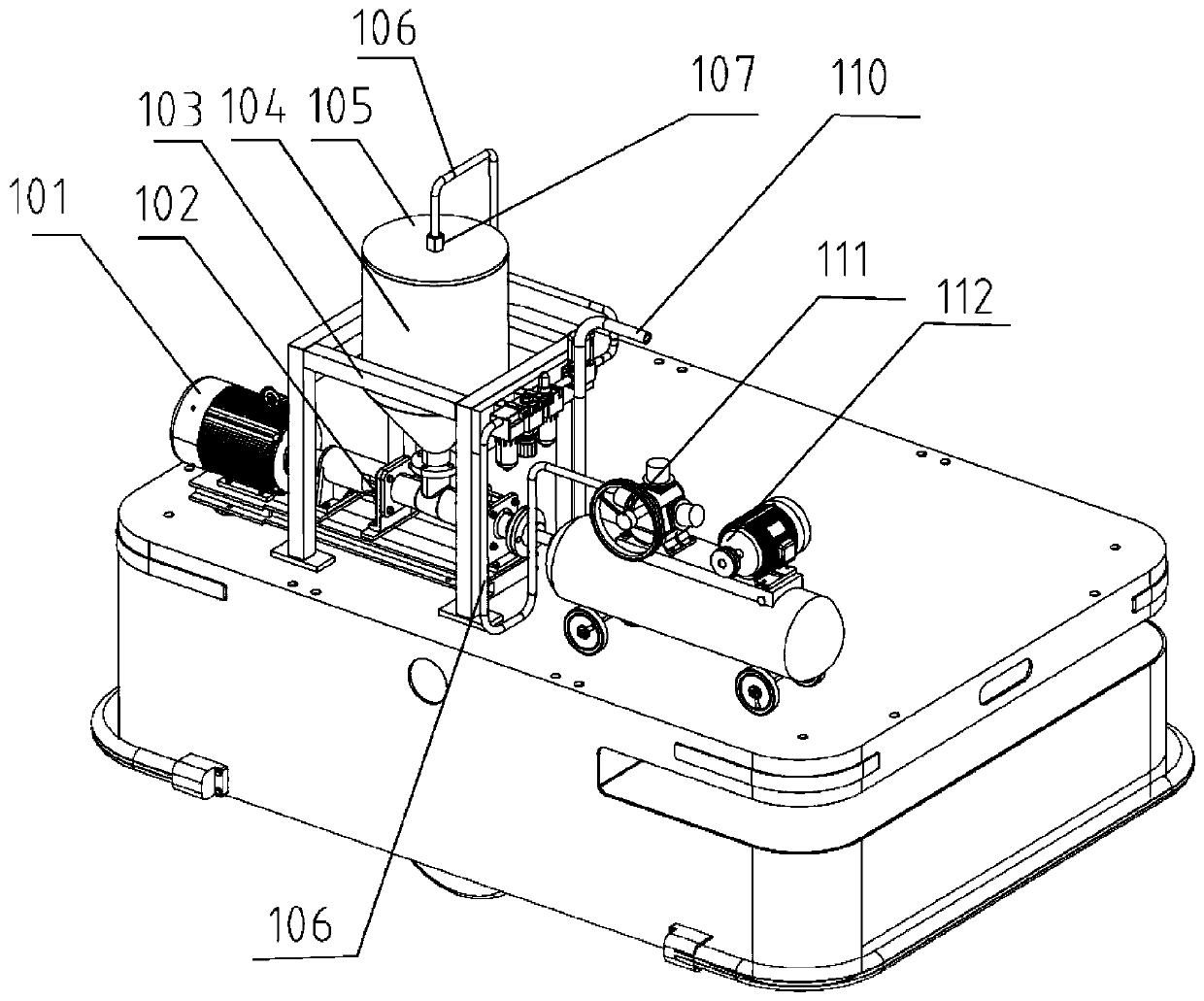

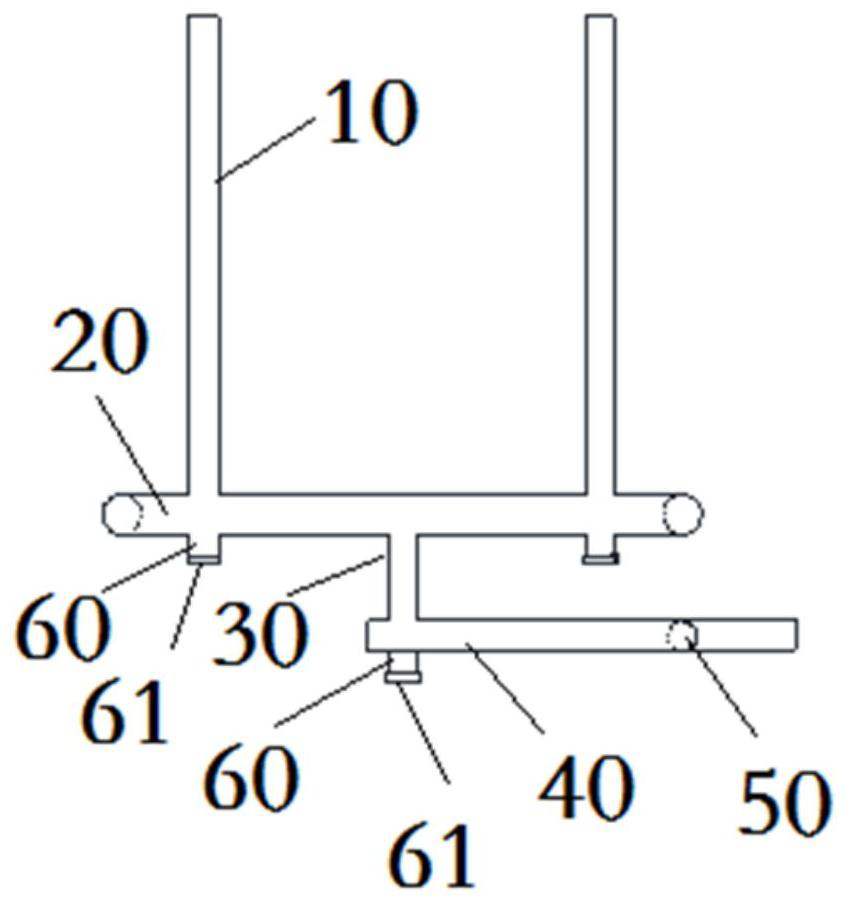

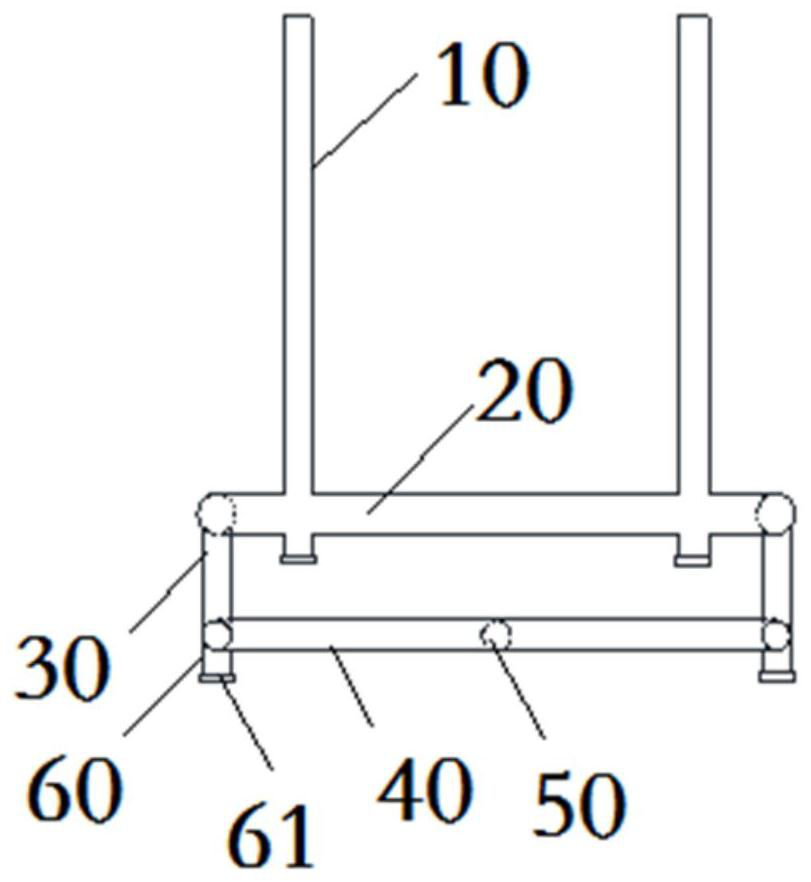

Wall tile gluing device and wall tile gluing and laying robot

ActiveCN110607896AImprove gluing efficiencySmall footprintBuilding constructionsEngineeringMechanical engineering

The invention discloses a wall tile gluing device and a wall tile gluing and laying robot. The wall tile gluing device comprises a tile discharging box for storing to-be-glued tiles, a tile receivingbox for receiving the glued tiles, a gluing mechanism, a tile conveying mechanism and a lifting driving mechanism, wherein the gluing mechanism is used for coating the back surface of the tiles with tile glue; the tile conveying mechanism is used for conveying the to-be-glued tiles from the tile discharging box to the gluing mechanism and conveying the glued tiles to the tile receiving box; the lifting driving mechanism is configured to drive the tile receiving box, the tile conveying mechanism and the gluing mechanism to lift together. The wall tile gluing device achieves automatic gluing andgreatly improves gluing efficiency of the wall tiles, the tile receiving box, the tile conveying mechanism and the gluing mechanism can be driven to descend together by distance of one tile after gluing of one tile, the next tile is glued continuously, and space can be saved by the structural design.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

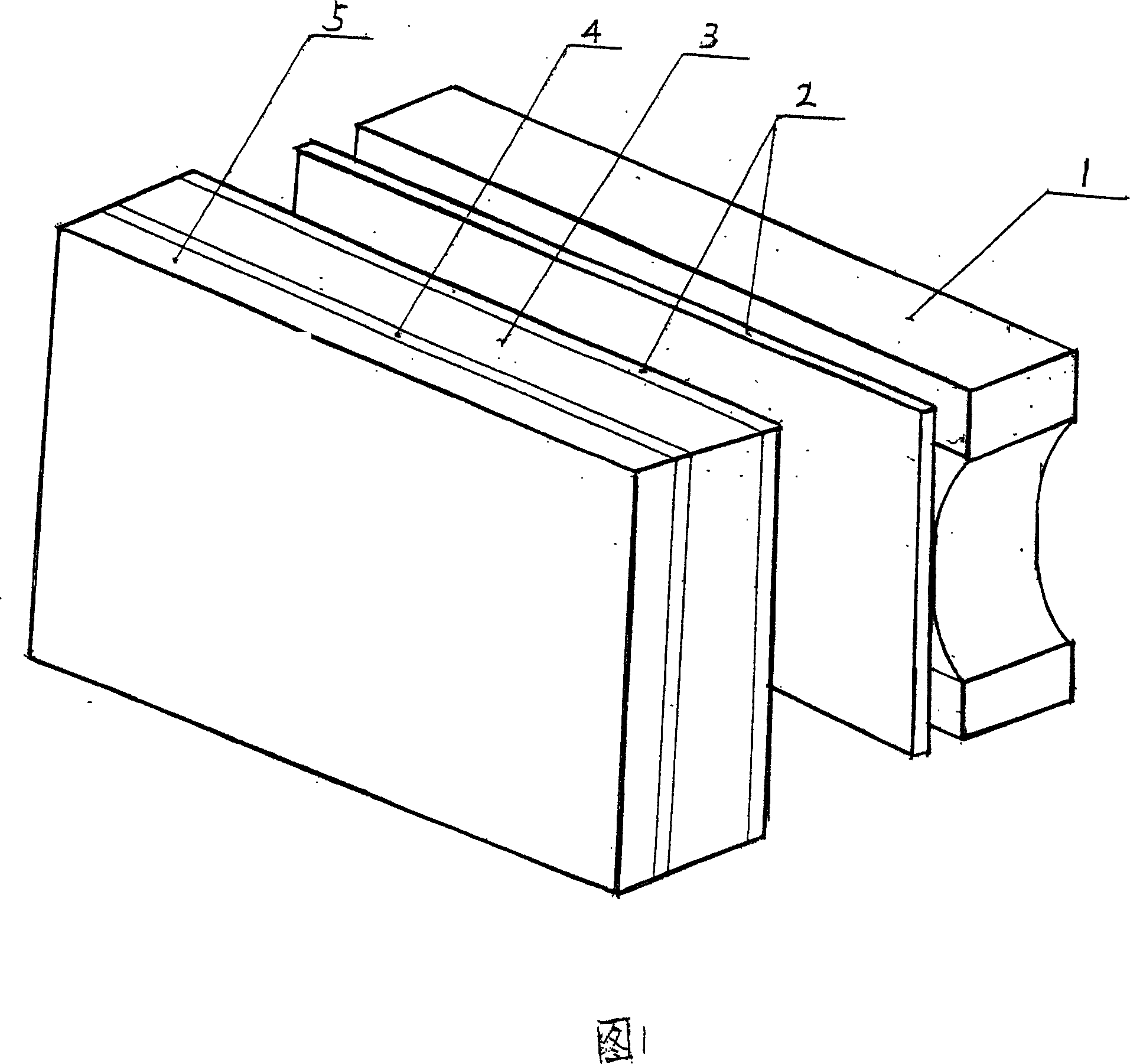

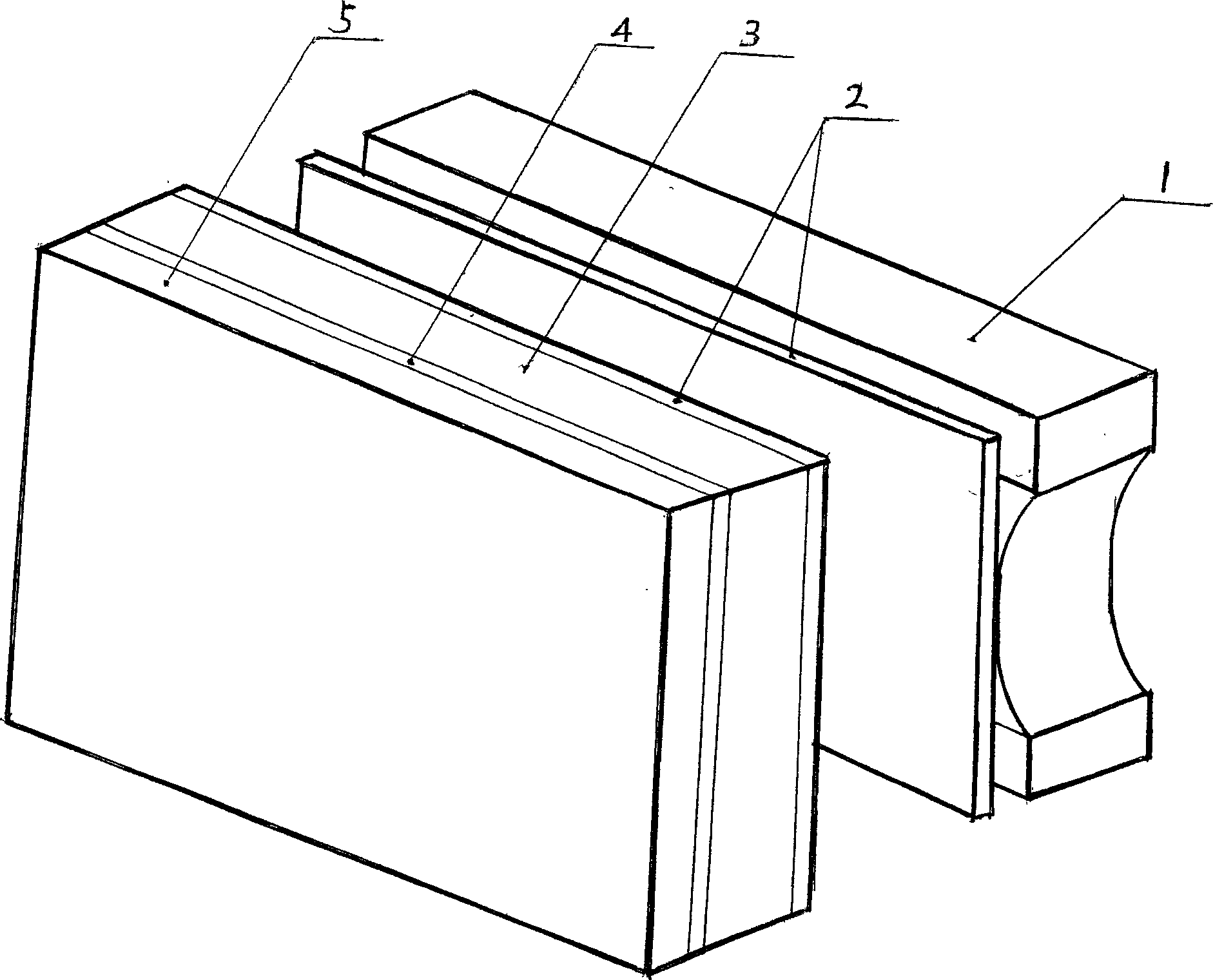

Gas laser

InactiveCN101789559ASimple structureIncrease powerActive medium materialGas laser constructional detailsLaser processingMetallic materials

The invention discloses a gas laser, which comprises a discharge chamber, a discharge electrode, a water-cooling channel and a gas storage chamber, wherein the water-cooling channel is distributed on the ektexine of the discharge chamber, the gas storage chamber is positioned outside the water-cooling channel, the discharge chamber and the gas storage chamber are communicated through a muffler, the discharge chamber is a sealed cavity which consists of a discharge cavity, a strip-shaped reflector on a tail end mirror, a strip-shaped reflector on an output end and a full-through output mirror, the discharge cavity is in a lath-shaped hollow-core structure which is made of nonmetal materials, the tail end mirror, the strip-shaped reflector on the output end are respectively positioned on the front end and the rear end of the discharge cavity, an aperture is left on the middle or one side of the strip-shaped reflector of the output end, the full-through output mirror is positioned at the position of the aperture and is used as a laser output window, and the discharge electrode is poisoned in the front end and rear end of the discharge cavity, or in the left side and the right side of the discharge cavity. The gas laser has small size, light weight, simple structure, a cooling system with good cooling effect, high output power and stable laser beam with good mode, and can be used for the laser processing industry.

Owner:HUAZHONG UNIV OF SCI & TECH

High-density and high-precision printed circuit board copper electroplating process

InactiveCN103806031AIntense and even stirring actionGuaranteed cleanlinessPrinted circuit manufactureNumerical controlUltrasonic assisted

The invention belongs to the field of electroplating, and especially relates to a high-density and high-precision printed circuit board copper electroplating process used during a copper plating process in circuit board production manufacturing. According to the present invention, the electroplating solution comprises a copper sulfate solution and a dispersant; the high-density and high-precision printed circuit board copper electroplating process is characterized in that a plating tank added with a copper plating solution is placed in a numerical control ultrasonic generator, a prepared printed circuit board is placed into the plating solution, and ultrasonic waves with a certain power are applied during the electroplating process to enhance electroplating; and ultrasonic waves are adopted to enhance copper electroplating, such that the obtained plating layer has characteristics of delicate appearance, good gloss, uniform grain, tight covering and excellent comprehensive performance, and provides good bonding force and good corrosion resistance compared with the plating layer obtained through the treatment with no ultrasonic wave assisted effect.

Owner:WUXI XINSANZHOU STEEL

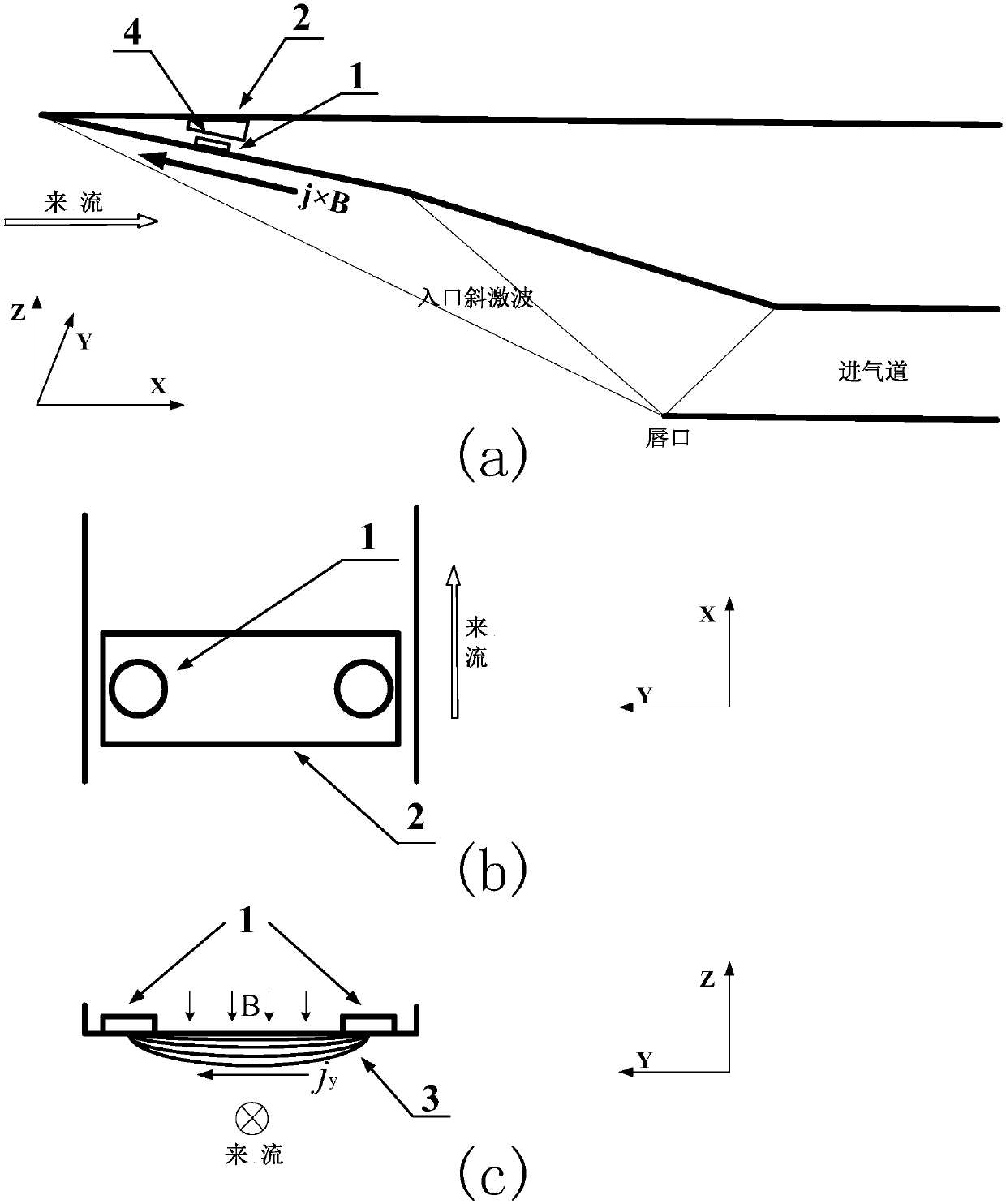

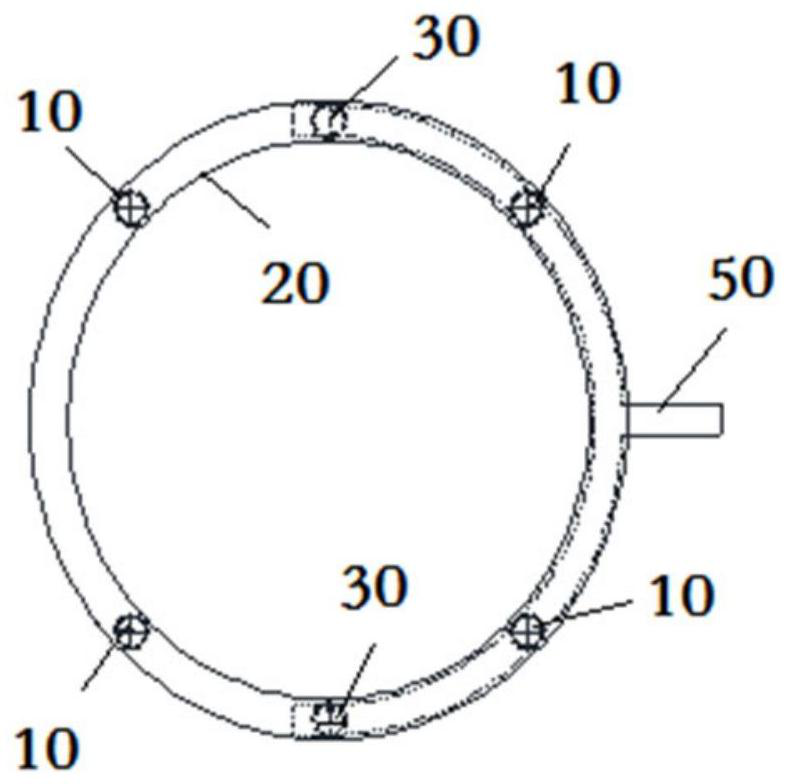

Air inlet shock wave control device and method based on surface magnetron arc discharge

InactiveCN107645822AImprove conductivityReduce volumeTurbine/propulsion air intakesPlasma techniqueShock waveLow voltage

The invention provides an air inlet shock wave control device and method based on surface magnetron arc discharge, and relates to the technical field of plasmas and magnetic fluids. The method comprises the steps that 1 a combination discharge mode maintained by high voltage pulse breakdown-low voltage direct current is used to produce an arc discharge plasma on the inner wall of an air inlet; 2 apermanent magnet is arranged on the wall of the air inlet to exert a magnetic field perpendicular to the direction of the wall; and 3 the shock wave angle is increased through the thermal effect of the discharge plasma, and at the same time the Lorentz force decelerating airflow in the reverse flow direction is generated under the action of the magnetic field. In the step 3, the discharge plasmais restrained to enhance the control effect, so that shock waves of the air inlet intersect at a lip mouth again. According to the invention, the working performance of the hypersonic speed air inletat the non-designed Mach number can be effectively improved, and the stable working range of an aircraft is broadened.

Owner:AIR FORCE UNIV PLA

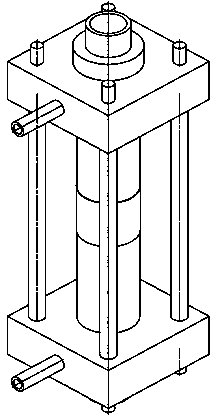

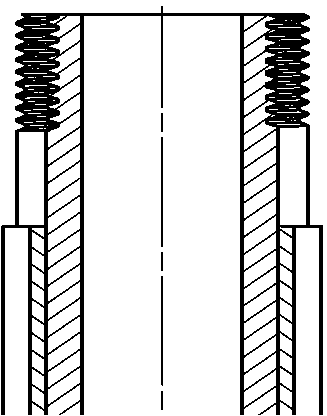

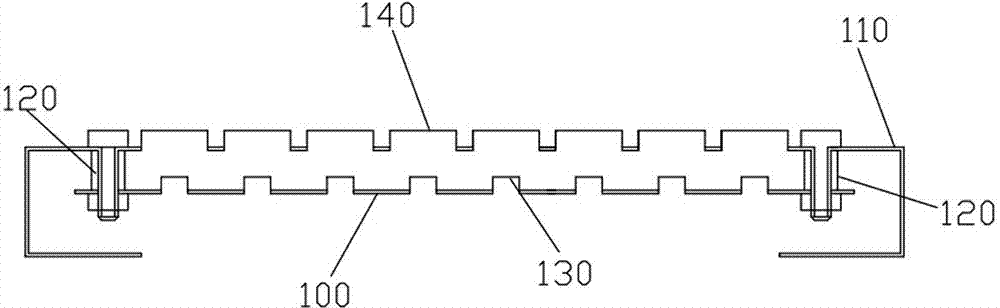

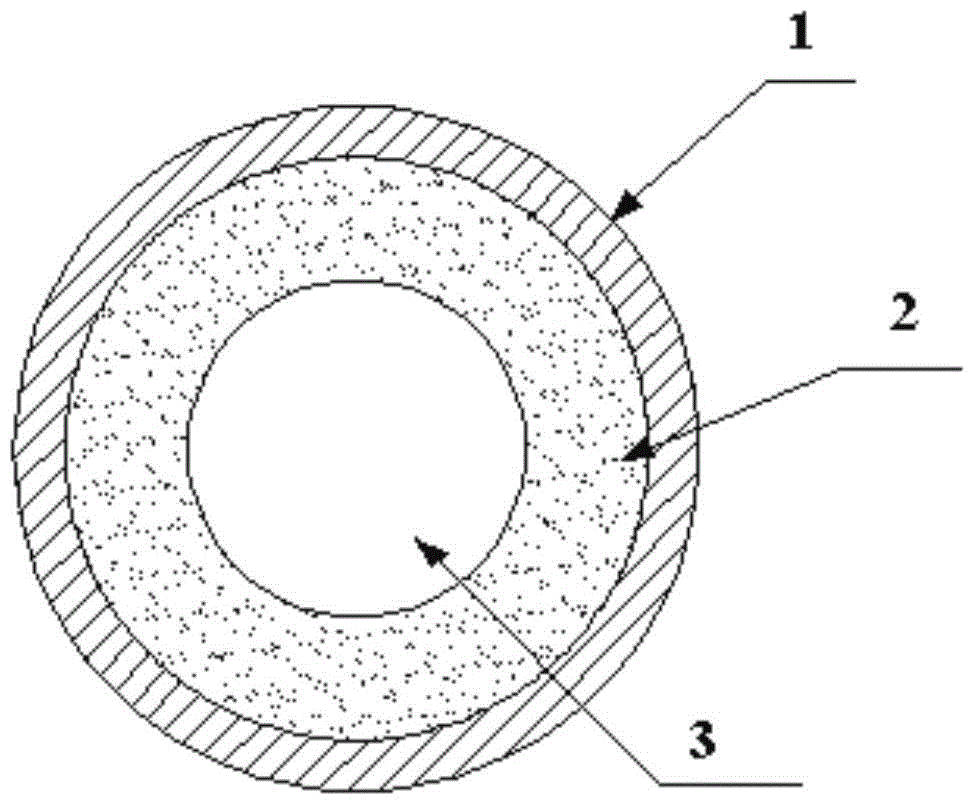

Double-medium low-temperature plasma generator

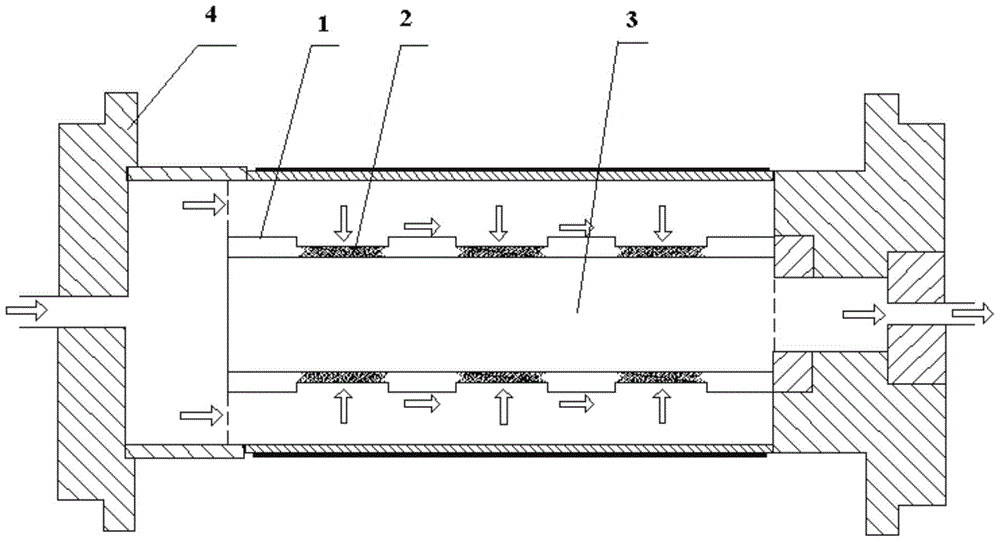

The invention discloses a double-medium low-temperature plasma generator, which comprises two end plugs with annular grooves inside, reduces a back pressure of an air intake pipe, enables gas flow to be smoother, and prevents a harmful gas from corroding an electrode as a discharge gap is composed by two layers of quartz glass tubes. The scheme of the double-medium low-temperature plasma generator is as follows: when a gas enters into the end plugs from the air intake pipe, the gas is firstly full of the annular grooves, and further uniformly enters into a discharge region, so that circulation performance and uniformity of the gas are improved, and blockage of the inner parts of the end plugs due to particle deposition is avoided; the discharge region is located between the two layers of the quartz tubes, and the gas flows through the discharge region and does not contact directly with the electrode, so that electrode corrosion is avoided. The double-medium low-temperature plasma generator can be widely applied to the field of harmful emission control of engines.

Owner:JIANGSU UNIV

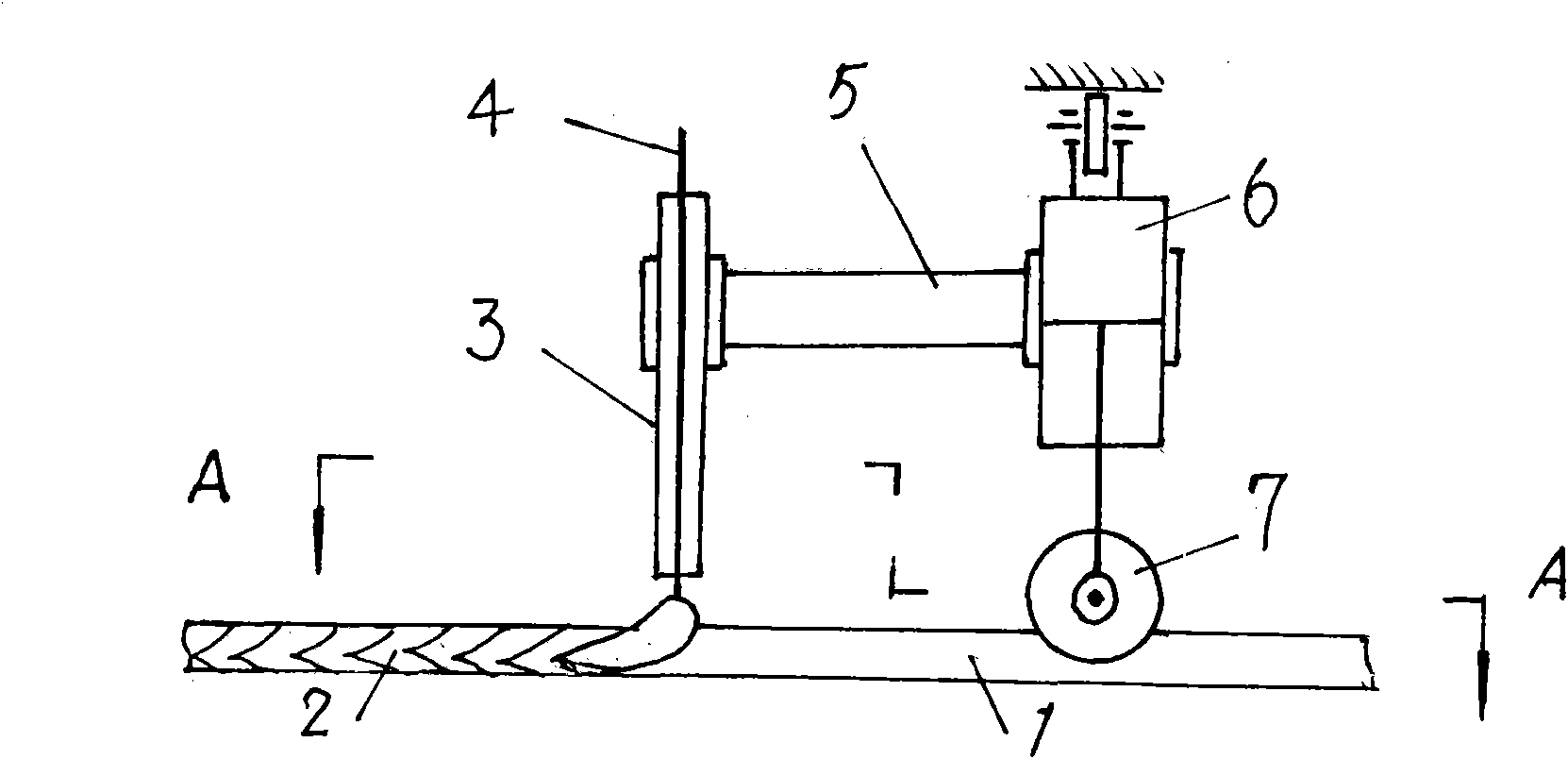

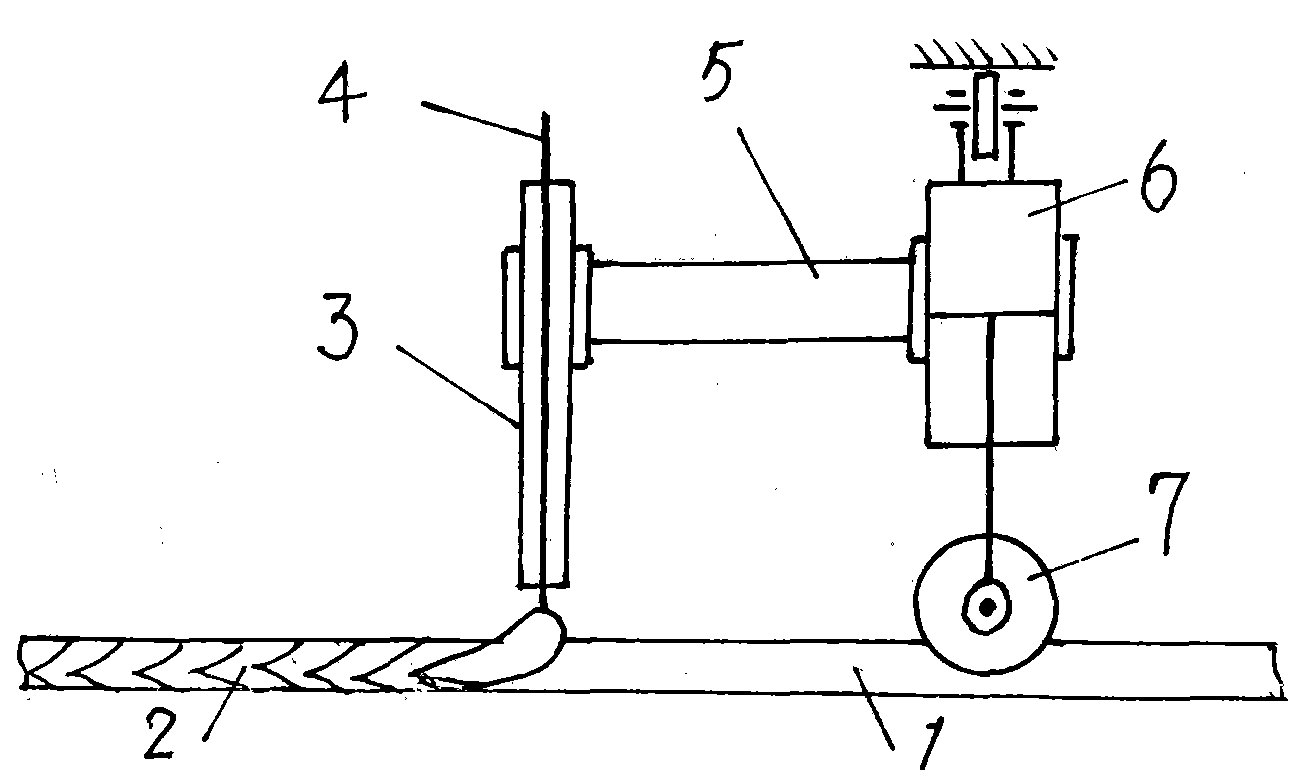

Welding method of spiral steel pipe

InactiveCN101966625AUniform and stable dischargeDischarge symmetrical averageArc welding apparatusSteel platesSheet steel

The invention discloses a welding method of a spiral welded pipe, which is characterized in that an extrusion device is firstly used for extruding the inner surfaces of steel plates at the two sides of a non-welded seam to eliminate uneven bulges and ensure that the inner sides of the steel plates at the two sides of the non-welded seam are clean and smooth, and then welding is carried out. At the same time, the extrusion device further serves as a location device of a welding head, namely, the extrusion device is used for tightly fixing the welding head and the extrusion device together to ensure that the welding head also can correctly move along the non-welded seam when the extrusion device moves along the non-welded seam, and thus, the welding head is ensured to be located at the middle position of the seam all the time. Accordingly, the quality of the seam automatically welded by a production line is guaranteed to be stable and excellent, and manual repair is basically not needed.

Owner:SUZHOU BOHENGHAO TECH

Flexible electrode electrospark deposition composite rolling machining tool

A flexible electrode electrospark deposition composite rolling machining tool includes a bearing plate, a rolling knife spindle, a rotating disk, pin rollers, an electrode spindle, a rotating joint, and a flexible electrode; the rolling knife spindle is rotatably mounted on the right side of the bearing plate, the pin rollers are rotatably mounted on the rotating disk, and the rotating disk is rotatably mounted on the lower end of the rolling knife spindle through an annular cover; the electrode spindle is rotatably mounted on the left side of the bearing plate, and the flexible electrode is mounted on an electrode clamp in a retractable mode; and the electrode clamp is installed on the lower end of the electrode spindle, and the inner ring of the rotating joint is fixed to the upper end of the electrode spindle. The invention provides the flexible electrode electrospark deposition composite rolling machining tool. The flexible electrode electrospark deposition composite rolling machining tool can be used to prepare a layer of nanocrystal on metal materials and perform flexible electrode electrospark deposition machining at the same time, so that the quality of the material surfaceis greatly improved.

Owner:ZHEJIANG UNIV OF TECH

A Dielectric Barrier Discharge Low Temperature Plasma Harmful Gas Conversion Device

InactiveCN101462021BUniform and stable dischargeDispersed particle separationLow voltageHazardous substance

The invention relates to a dielectric barrier discharge low-temperature plasma harmful gas conversion device, which belongs to the technical field of industrial waste gas and motor vehicle harmful emissions control. The low-temperature plasma reactor (7) of the present invention is a coaxial tubular dielectric barrier discharge low-temperature plasma reactor, consisting of a central low-voltage electrode (17), a quartz medium (15) coaxial with it, and a high-voltage electrode wrapped on the outer wall of the medium. Electrode (16), Teflon connecting rod (14), front end cover (11), rear end cover (18), front end cover air inlet port (10), rear end cover air outlet port (19) and optional inlet 1. The exhaust interface (20), the gap between the outer wall of the central low-voltage electrode (17) and the inner wall of the quartz medium (15) forms a low-temperature plasma reaction zone. The invention has high treatment efficiency, no secondary pollution, no need for follow-up treatment, simple equipment and easy operation, and is suitable for the treatment of NO, CO, HC, H2S, PM and other harmful substances.

Owner:JIANGSU UNIV

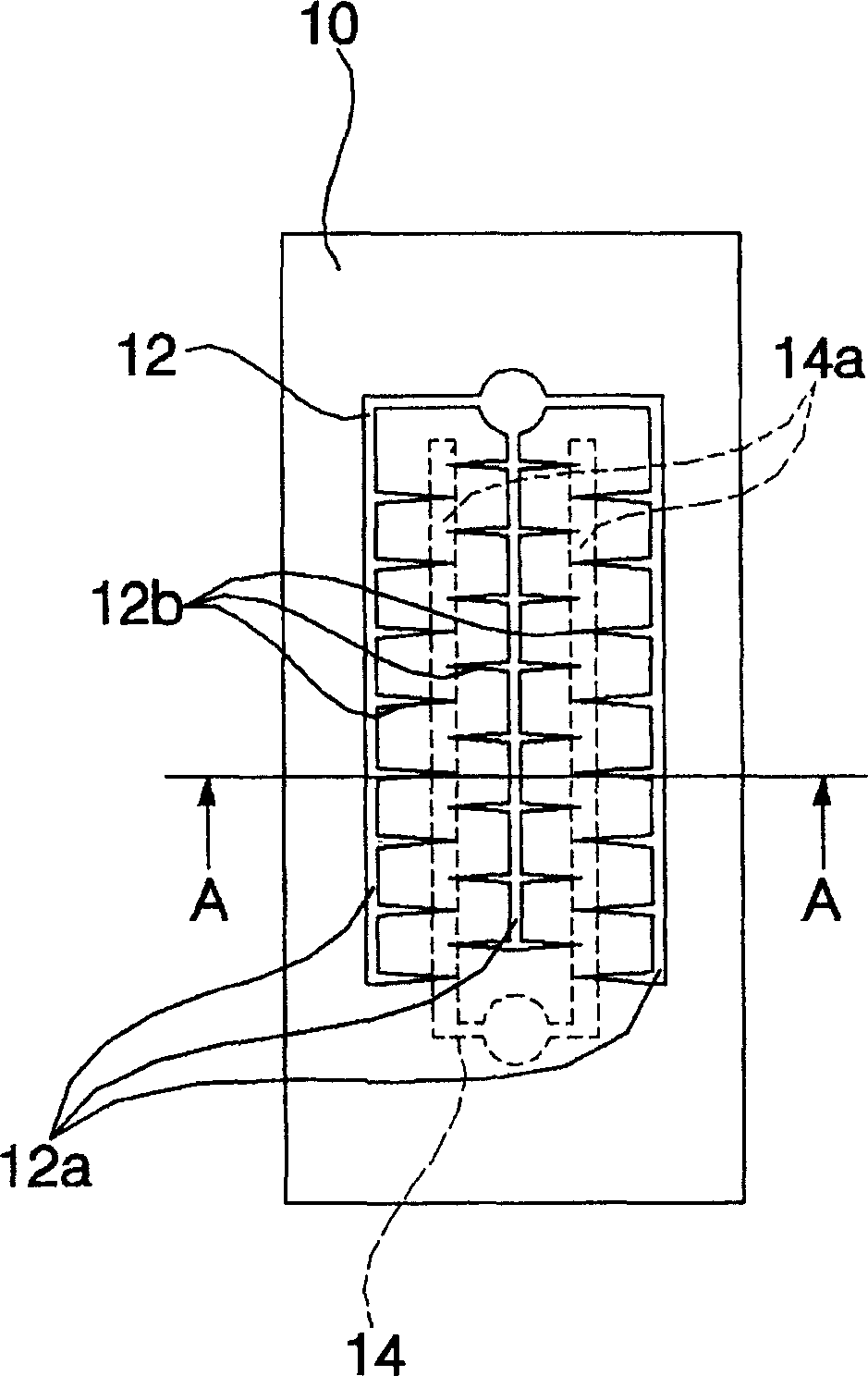

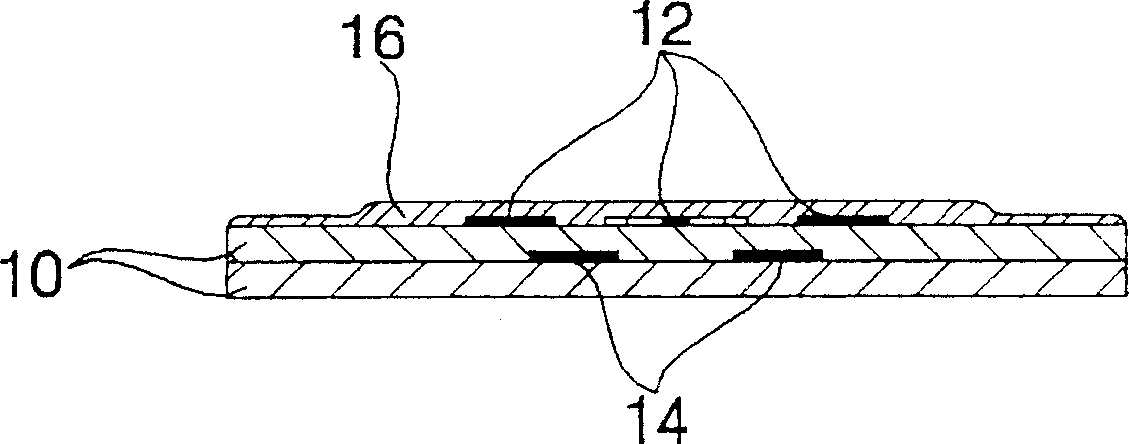

Surface discharge type air cleaning device

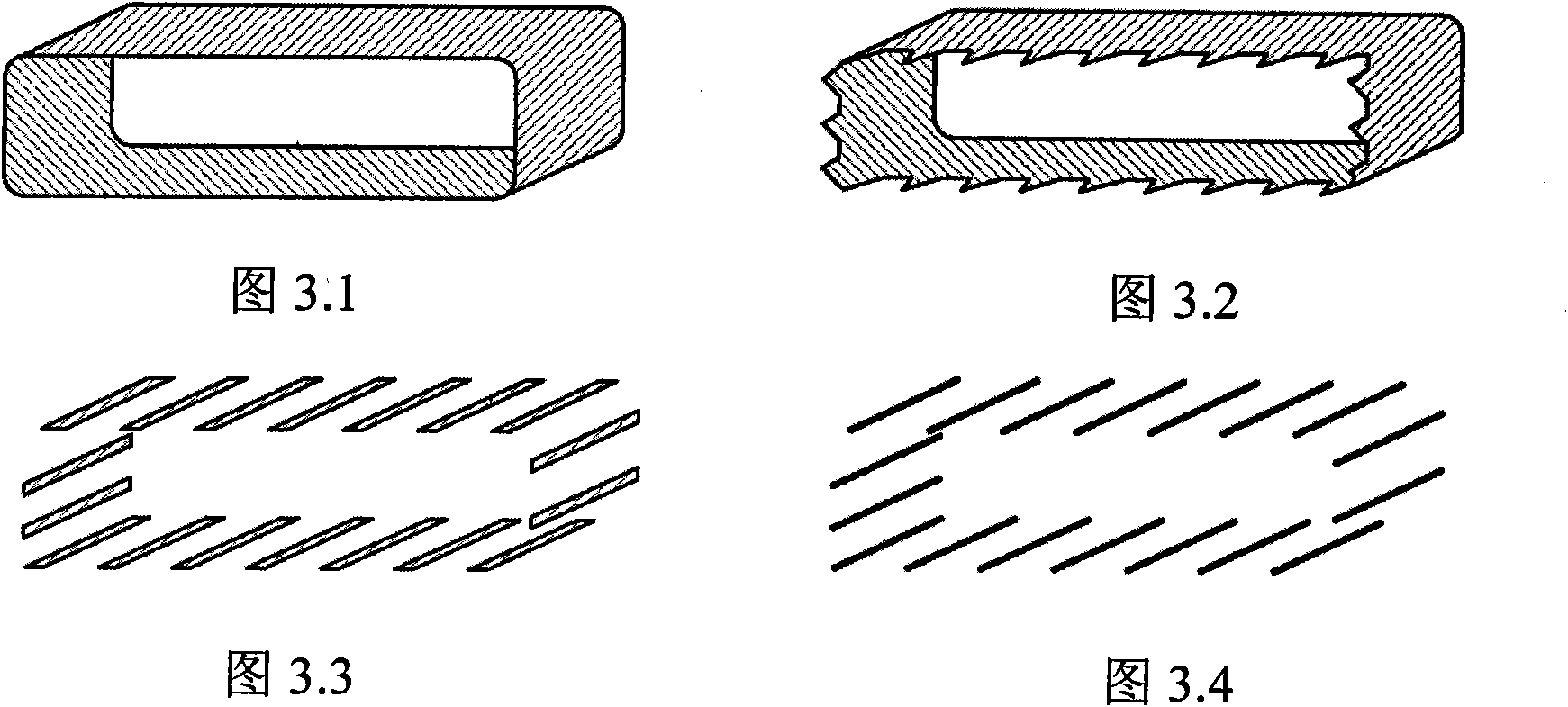

InactiveCN1749663AAvoid accumulationIncrease productionElectrode carrying meansMechanical apparatusAir cleaningEngineering

The invention provides a surface discharge type air cleaning device comprises an insulating dielectric body formed in the shape of a sheet, and a discharge electrode and a ground electrode formed at one surface of the insulating dielectric body, the discharge electrode and the ground electrode being disposed in parallel with each other while the discharge electrode and the ground electrode are spaced a predetermined distance from each other. The discharge electrode has a plurality of pointed ends protruding toward the ground electrode. Consequently, electrical charge accumulation is prevented and continuous discharge is possible, even when a DC power source is used. In addition, entirely uniform and stable discharge at the surface of the dielectric body is accomplished, and therefore, the generated number of hydroxyl radicals and negative ions is increased while the generated amount of ozone is decreased. Also, discharge safety is increased, and therefore, air cleaning efficiency is improved.

Owner:LG ELECTRONICS INC

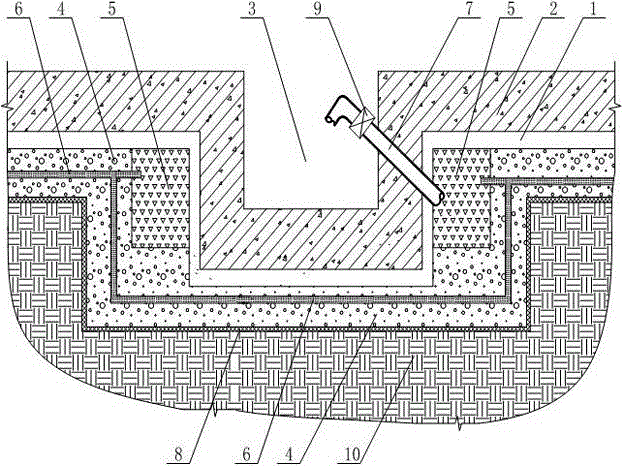

Pressure-releasing structure of basement anti-floating plate and construction method thereof

ActiveCN103147464BSolving Buoyancy ProblemsSolve the problem of water collectionProtective foundationBasementWater flow

The invention discloses a pressure-releasing structure of a basement anti-floating plate and a construction method thereof. The pressure-releasing structure comprises a cushion layer and a basement bottom plate on the cushion layer, wherein water-collecting pits are formed in the cushion layer and the basement bottom plate; a layer of hardpan is paved below the cushion layer; filtering layers are paved around the water-collecting pits; flow-guide pipes are paved in the hardpan and are gathered in the filtering layers; flow-leading pipes are arranged on the side walls of the water-collecting pits; and the water-collecting pits are communicated with the filtering layers through the flow-guide pipes. Water generating floatation outside a basement is led into the basement, so that the floatation is reduced. The hardpan is paved below the cushion layer, so that the problem that water outside foundation pits of the basement is gathered is solved, the underground water is collected through a flow-guide pipe arranged in the hardpan, the flow-leading pipes change the underground water into gravity water in the basement, and the problem of the floatation of the underground water is completely solved from the construction starting stage of a building.

Owner:四川省建研万瑞科技有限公司

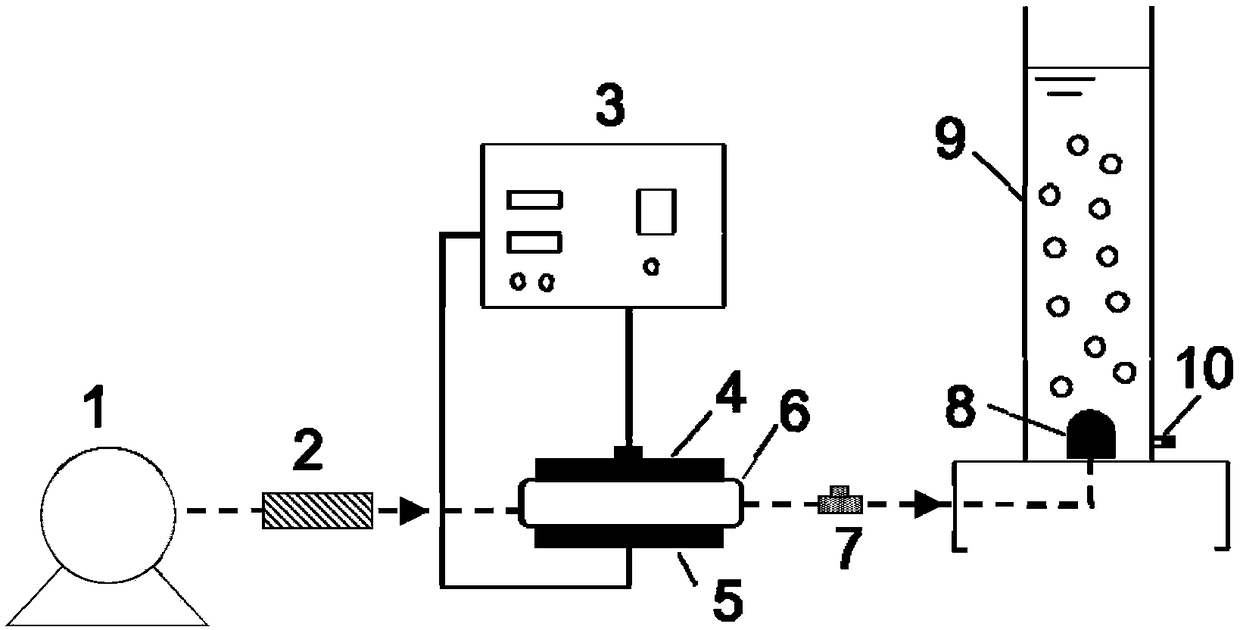

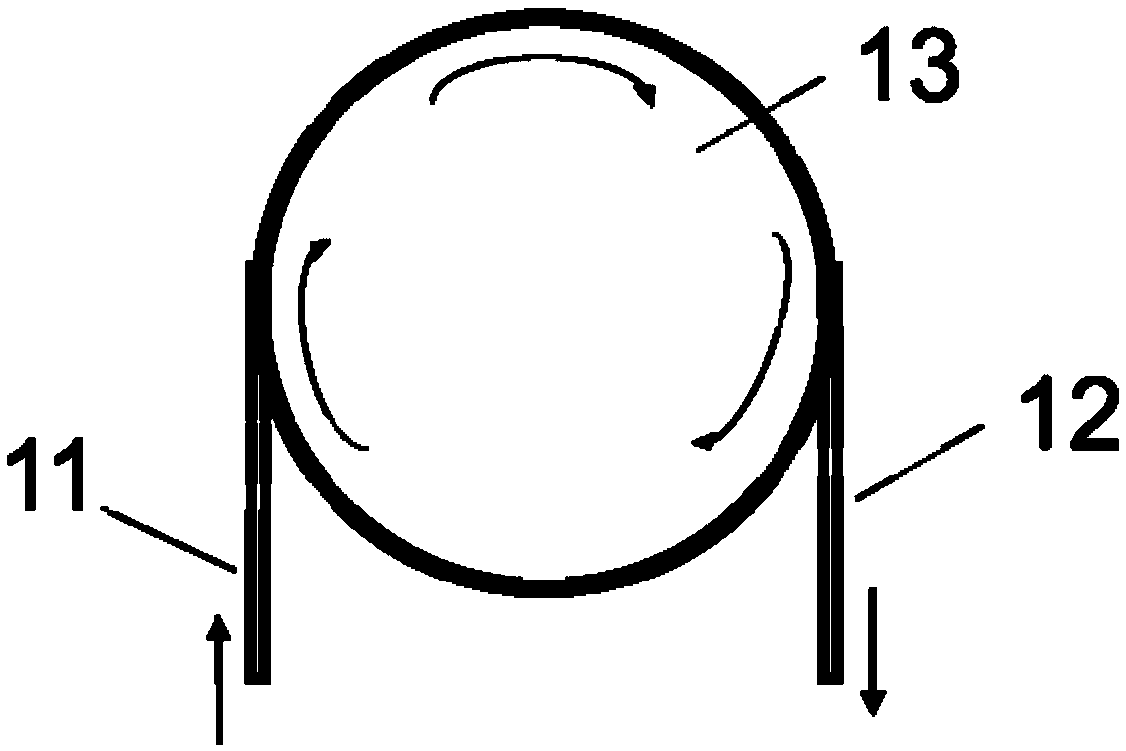

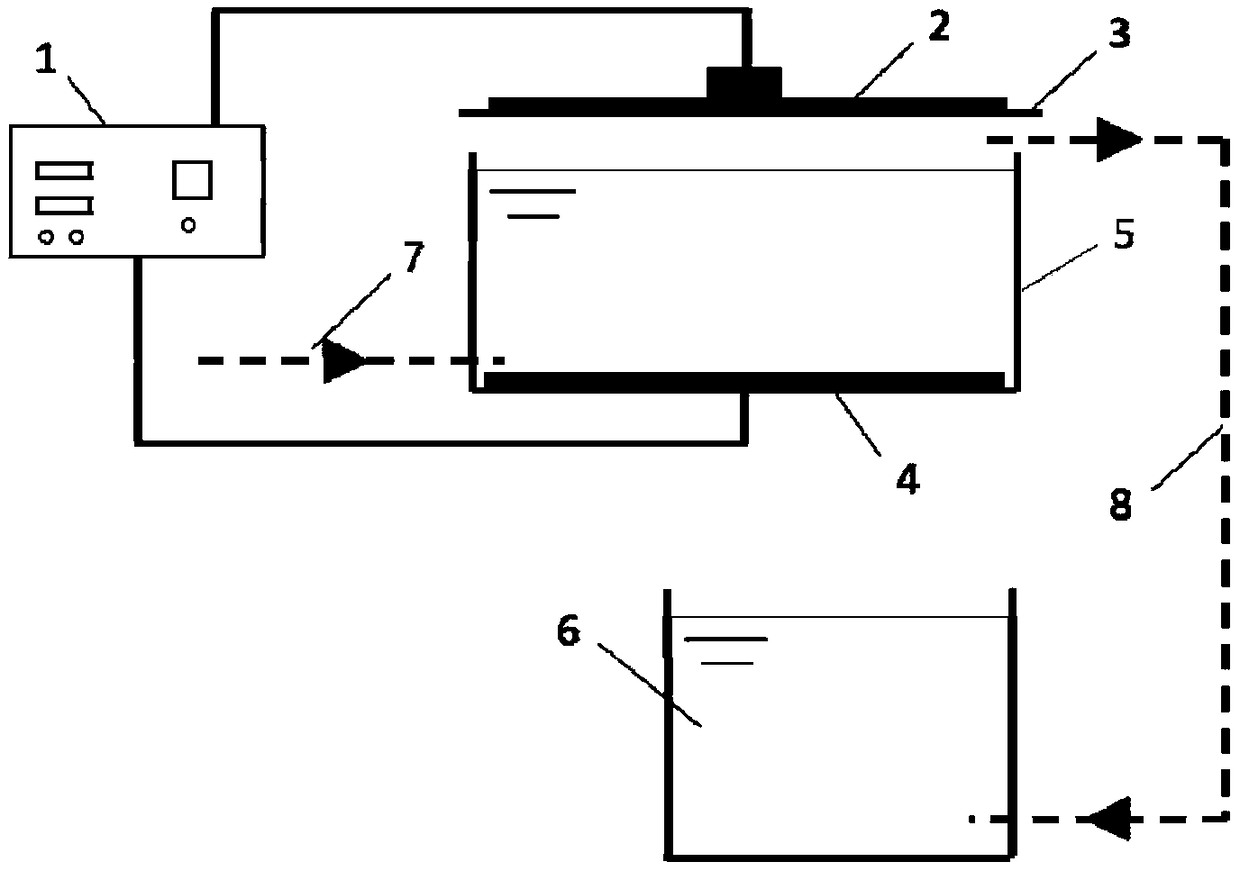

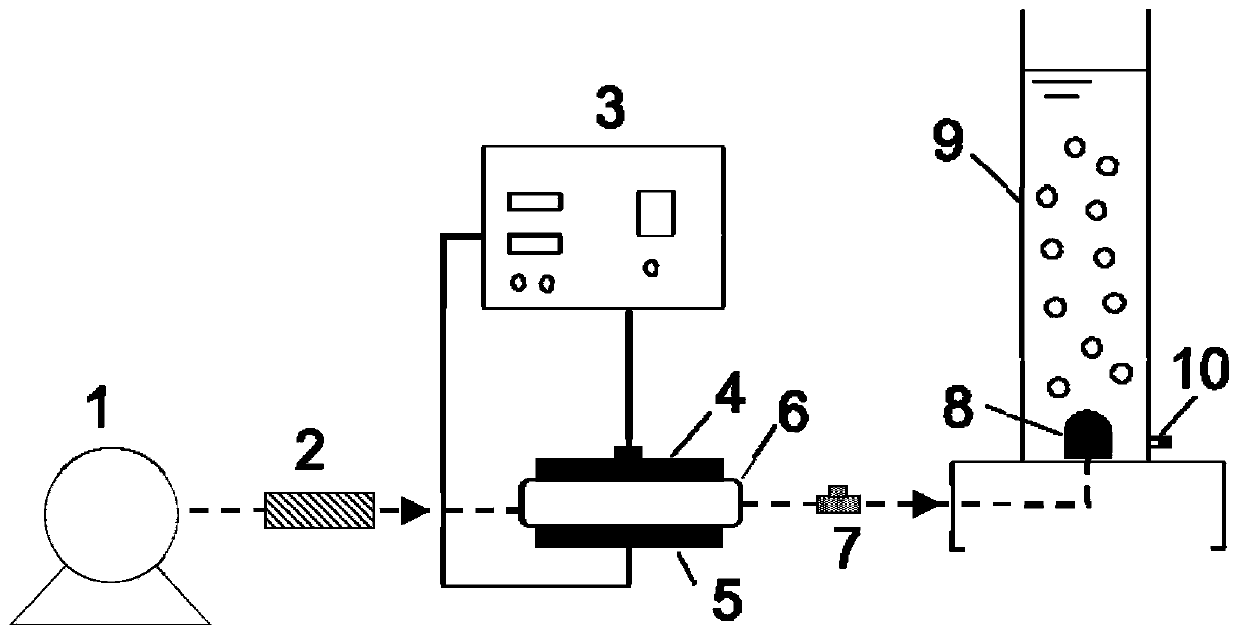

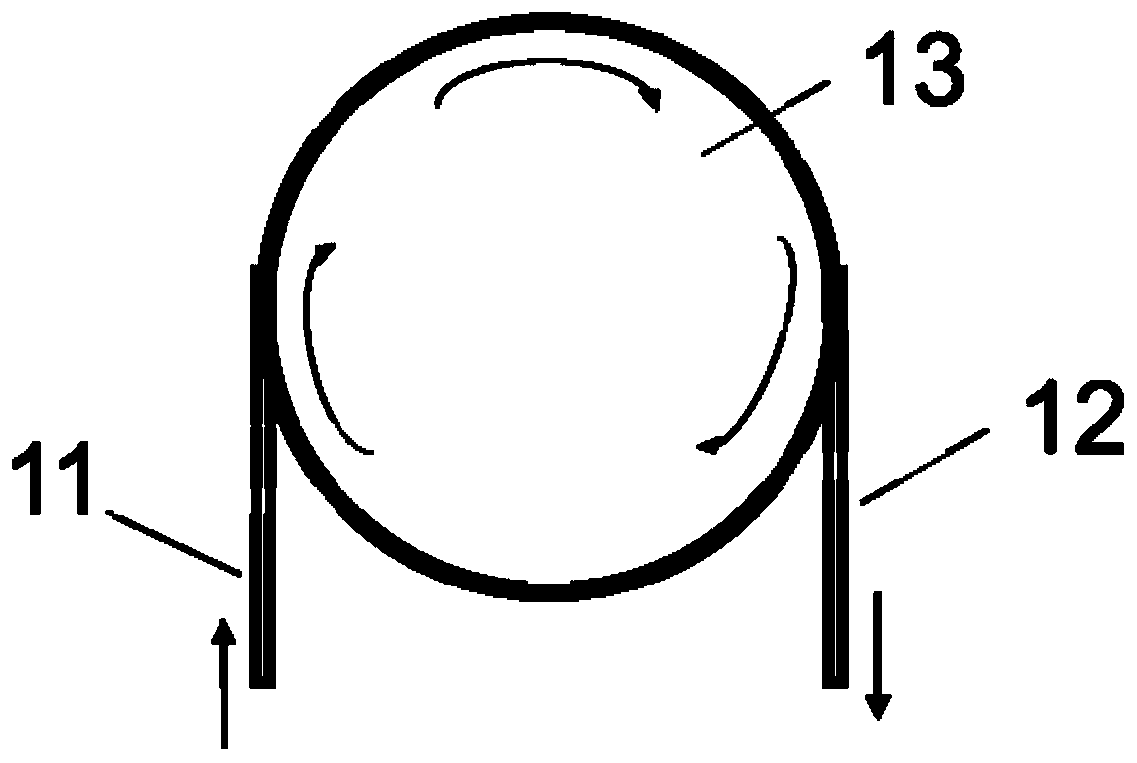

Method for treating high-concentration organic wastewater by utilizing dielectric barrier discharge-wastewater treatment combined equipment

ActiveCN109384336AGreen and efficient treatmentAchieve removalWater aerationWater/sewage treatmentHigh concentrationActive particles

The invention discloses a method for treating high-concentration organic wastewater by utilizing dielectric barrier discharge-wastewater treatment combined equipment. Firstly, gas rich in active particles is produced by utilizing the equipment and then is in full contact with the to-be-treated high-concentration organic wastewater in an equipment reaction column for reaction to realize the removalof contaminants in the organic wastewater; the dielectric barrier discharge-wastewater treatment combined equipment consists of a gas supply pump, a gas flow meter, a power supply, a high-voltage electrode, a grounding electrode, a rotary gas distributor, a gas flow regulating valve, a titanium steel aeration head, the wastewater treatment reaction column and a wastewater inlet and outlet openingin a reaction column body. A large quantity of gas rich in the active particles can be produced by utilizing the method and the equipment, and full contact between the active particles and the organic wastewater is ensured; no chemical reagent is required to be added in the treatment process, and the strict requirements for a discharge technology for wastewater treatment are reduced; the treatment efficiency is improved, and the cost and the energy consumption are reduced. Therefore, the method has a greater industrial application value.

Owner:SHANDONG UNIV

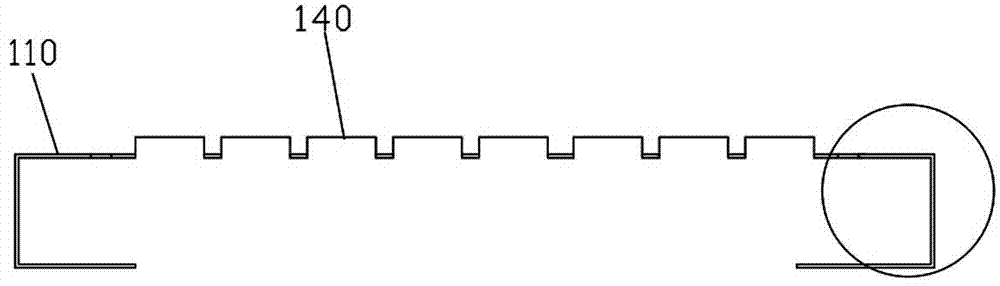

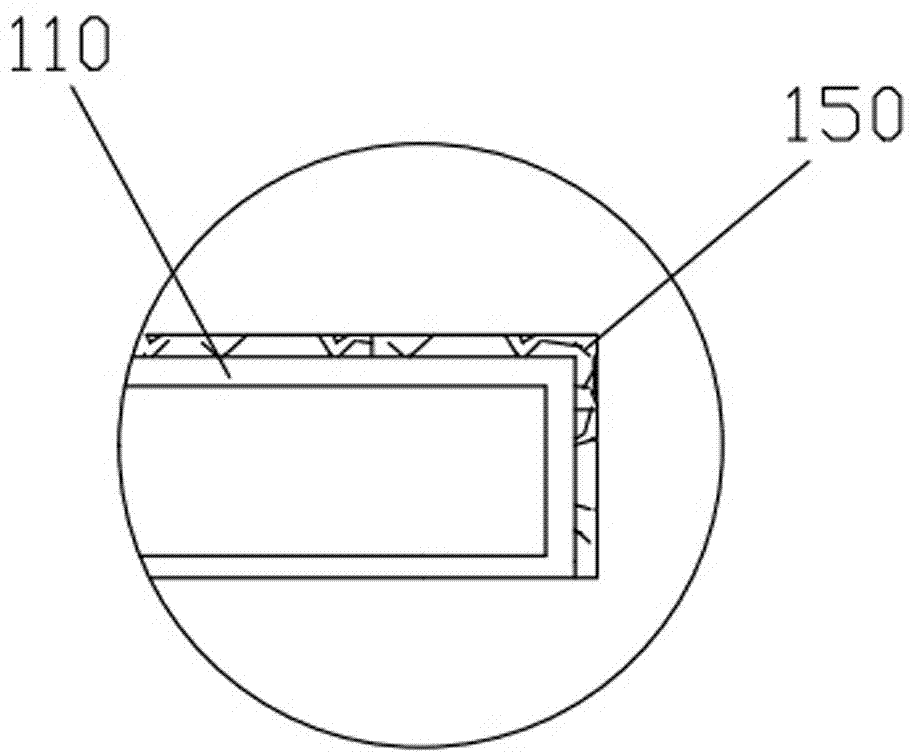

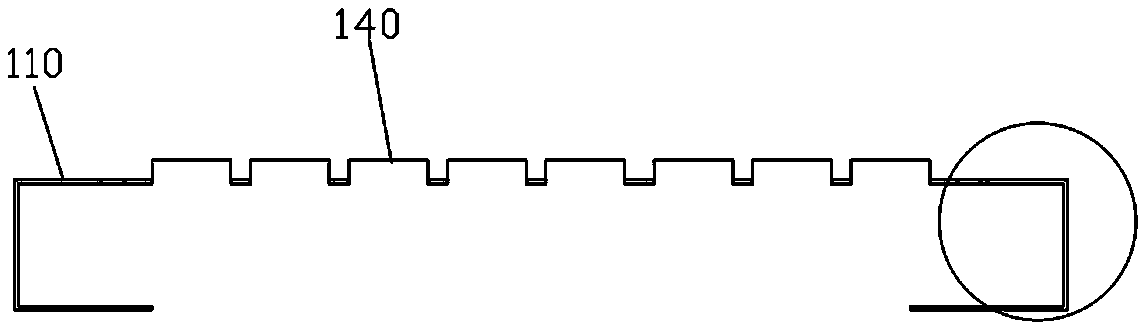

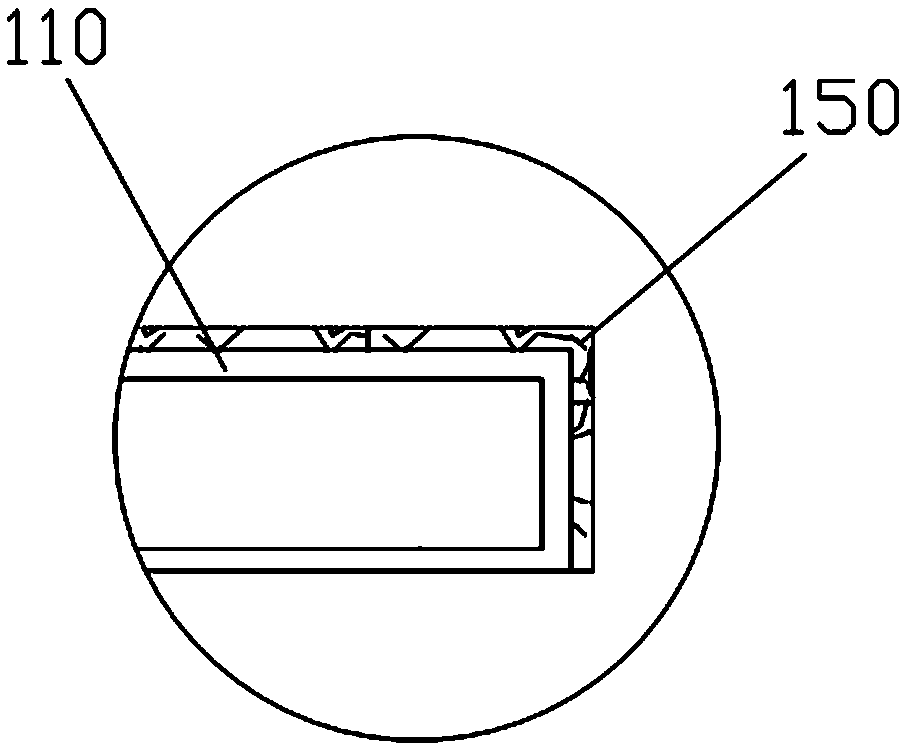

Glue discharging device and wall face tile gluing paving and pasting robot

InactiveCN110593530AUniform and stable dischargeMore difficult to avoidBuilding constructionsEngineeringScrew pump

The invention discloses a glue discharging device and a wall face tile gluing paving and pasting robot. The glue discharging device comprises a storage barrel, a pressurizing mechanism, a conveying pipeline and a screw pump assembly. The storage barrel is used for storing tile glue and provided with a glue discharging port communicating with the outside. The pressurizing mechanism is used for pressurizing the interior of the storage barrel so that the tile glue can be discharged out of the glue discharging port. The conveying pipeline is connected with the glue discharging port and used for communicating with the storage barrel and a tile gluing device. The screw pump assembly is arranged at the bottom of the storage barrel, and a screw of the screw pump assembly is arranged to rotate in the conveying pipeline so that the tile glue in the conveying pipe can be discharged to the tile gluing device. According to the glue discharging device, the manner of the joint action of the screw pump assembly and pressurizing is adopted, it can be guaranteed that the tile glue large in viscosity in the storage barrel is evenly and stably discharged, the problem that the sticky tile glue is not prone to being discharged is solved, and the wall face tile paving and pasting efficiency is greatly improved.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

High-precision circuit board electrotinning method

InactiveCN106119912ATin ion discharge process is uniform and stableImprove uniformity and finishIonDuctility

The invention discloses a high-precision circuit board electrotinning method. A circuit board comprises micro blind holes or micro through holes. An electrotinning process comprises a pretreatment procedure, an electrotinning procedure and an aftertreatment procedure. A strong and uniform stirring function is achieved on a plating solution through ultrasonic waves in the electroplating process, the surface of a material can keep clean all the time through the function, the tin ion discharge process is uniform and stable, and therefore the uniformity and smoothness of plating are improved; the binding force of the plating is increased through ultrasonic strengthening electroplating, and due to the fact that the surface of the plating keeps clean all the time through the strong and uniform stirring function of the ultrasonic waves, the binding force of the plating is increased; and an additive is adopted, an anionic surfactant of sodium salt of a sulfosuccinate group and oxygen vinyl serves as a dispersing agent, and therefore the comprehensive electroplating performance of an electrotinning solution is remarkably improved, the electrotinning solution has high dispersing performance and excellent ductility, and the quality of the plating is further improved.

Owner:乐凯特科技铜陵有限公司

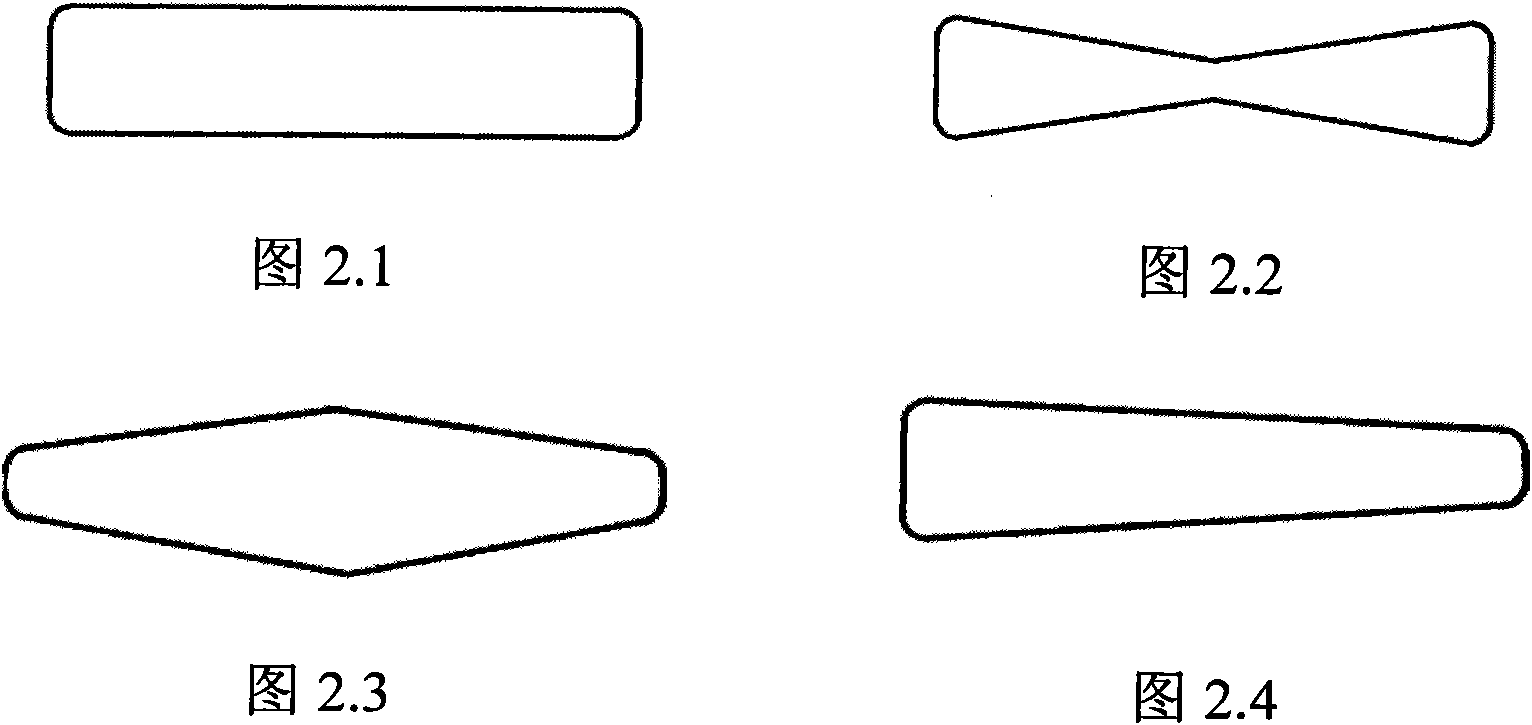

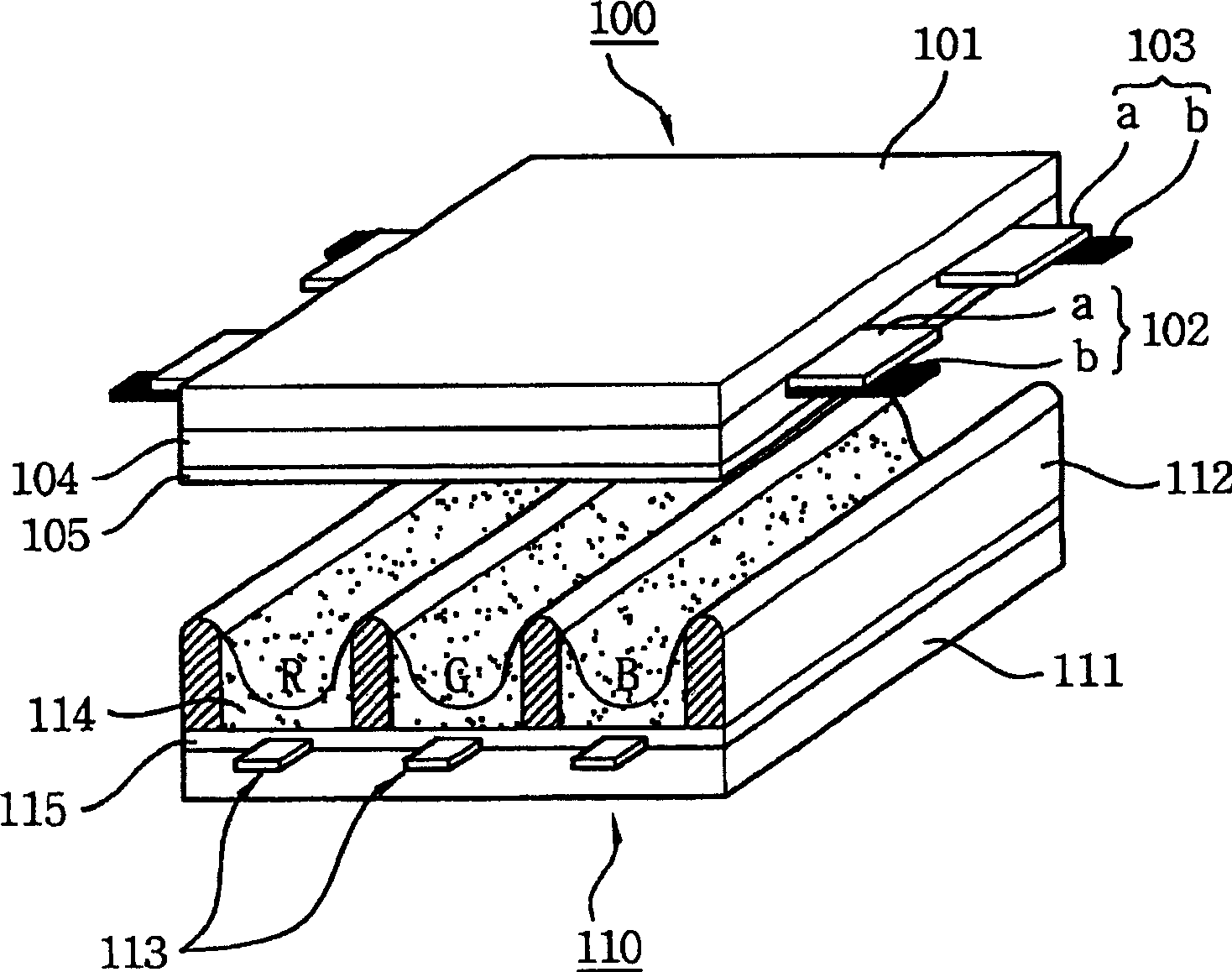

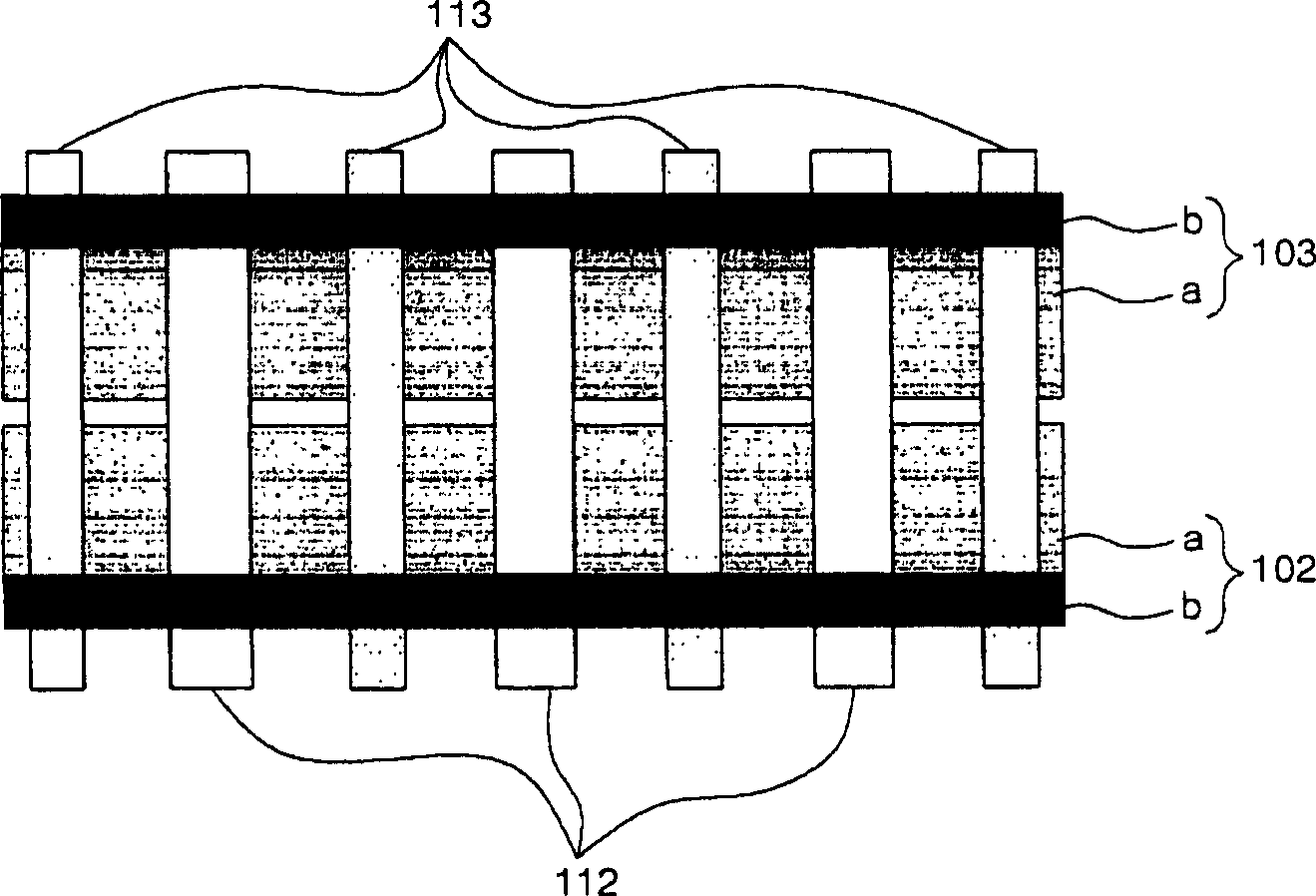

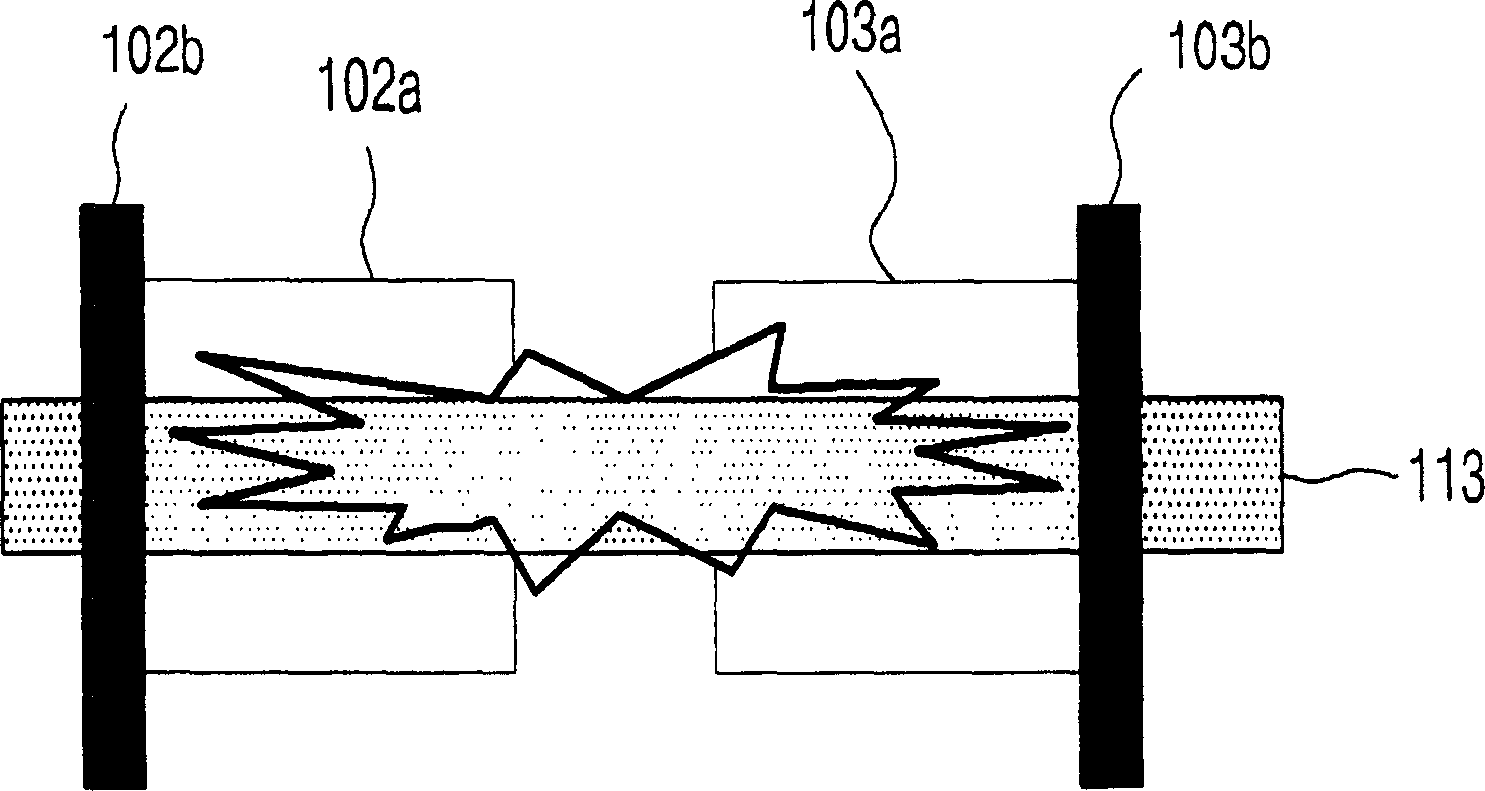

Plasma display panel

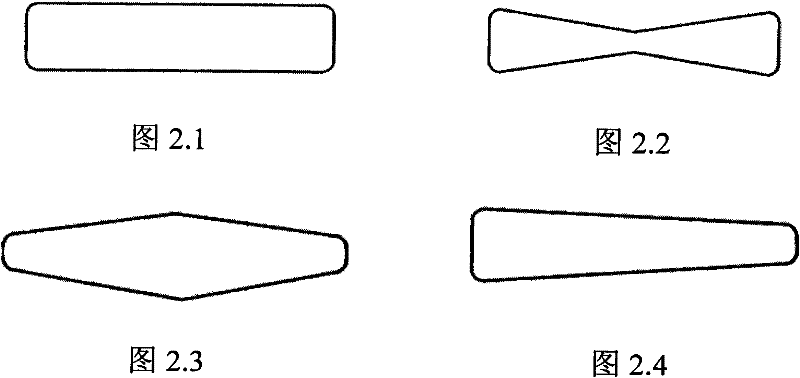

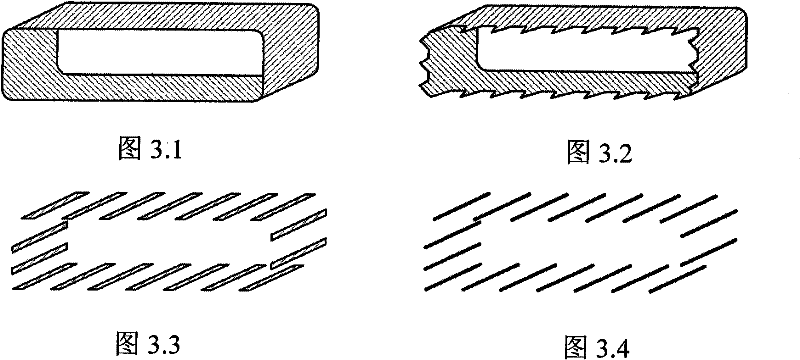

InactiveCN1862752AReduce manufacturing costImprove luminous efficiencyAddress electrodesSustain/scan electrodesEngineeringPlasma display

The present invention relates to a plasma display panel, particularly, to a plasma display panel equipped with an electrode structure which can perform readily a discharge between a scan electrode and a sustain electrode. A plasma display panel according to an aspect of the present invention comprises a front substrate comprising a scan electrode and a sustain electrode; and a rear substrate comprising a barrier rib for forming a discharge cell, wherein the scan electrode and the sustain electrode comprise a plurality of projecting electrode parts in the discharge cell. The present invention modifies the shape of the transparent electrode to broaden the discharge area, so that the luminous efficiency increases to improve a luminance. Moreover, since a stable and uniform discharge is generated, the white balance can be efficiently implemented. In addtion, the unnecessary expensive ITO area is removed and the fabrication cost of the plasma display panel can be lowered.

Owner:LG ELECTRONICS INC

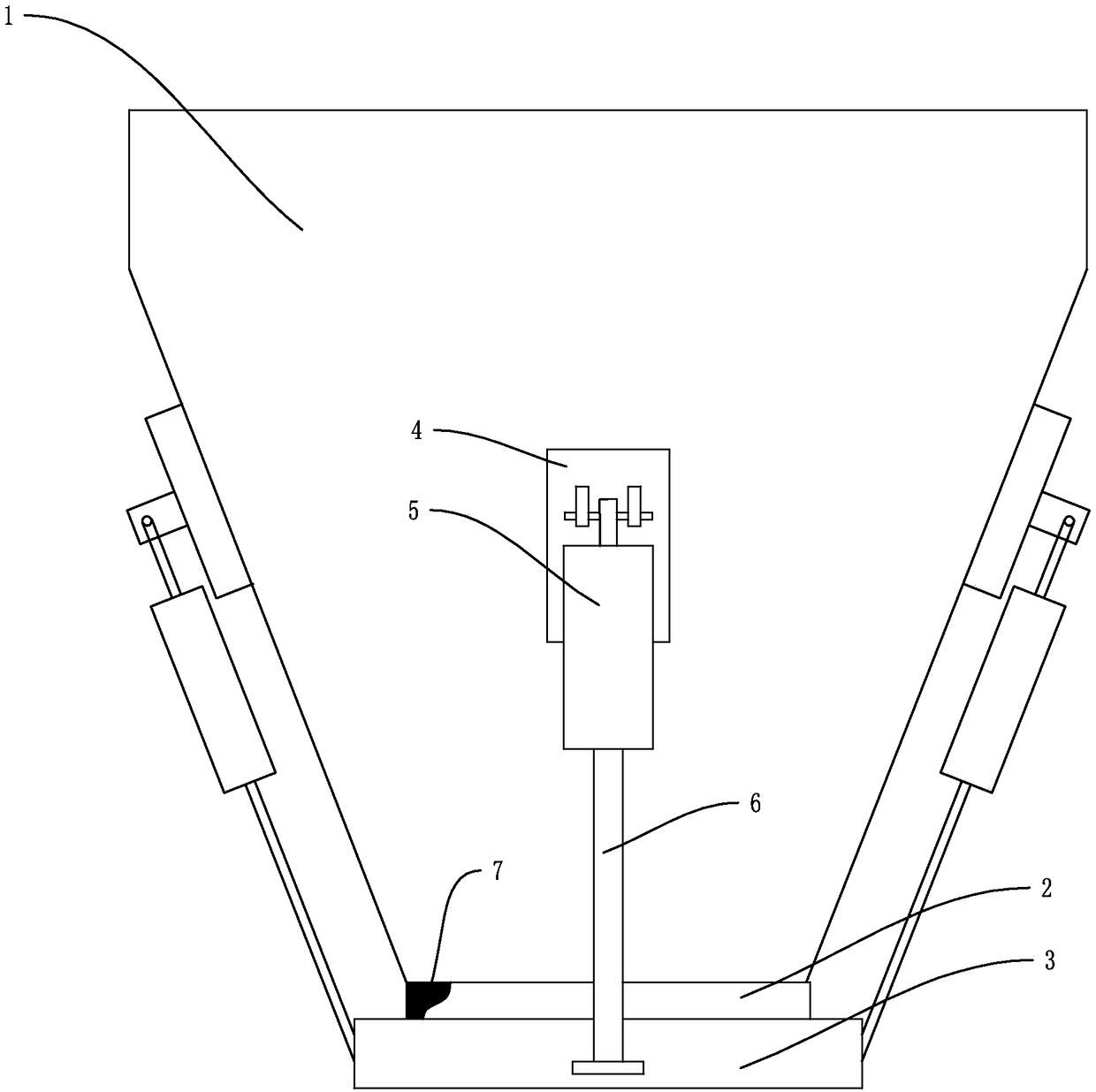

Self-control-type storing bin

PendingCN108750421AUniform and stable dischargeLarge containersElectro hydraulicElectrical and Electronics engineering

The invention discloses a self-control-type storing bin, and relates to the field of storing equipment, in particular to the field of storing bins. A bin body is provided with a discharging outlet inthe bottom, and a closing plug capable of closing the discharging outlet is arranged at the discharging outlet. The closing plug is in a protruded shape in the direction of the discharging outlet, anda plurality of fixing seats are arranged on the side face of the bin body. Electro-hydraulic push rods are further arranged on all the fixing seats, and the tops of telescopic rods of the electro-hydraulic push rods are connected with one side of the closing plug. Signal receiving modules are arranged on electric valves of the electro-hydraulic push rods, and a solid flowmeter is arranged on theinner wall of the discharging outlet and is in signal connection with a control module. The control module is further connected to switches of the electric valves through the signal receiving modules.By using the closing plug, the electro-hydraulic push rods and the solid flowmeter, a stored material is discharged along a gap between the discharging outlet and the protruded closing plug, uniformand stable unloading is achieved, the distance between the discharging outlet and the closing plug can further be controlled according to the detecting result of the solid flowmeter, and thus the purpose of discharging quantity control is achieved.

Owner:广州机械设计研究所

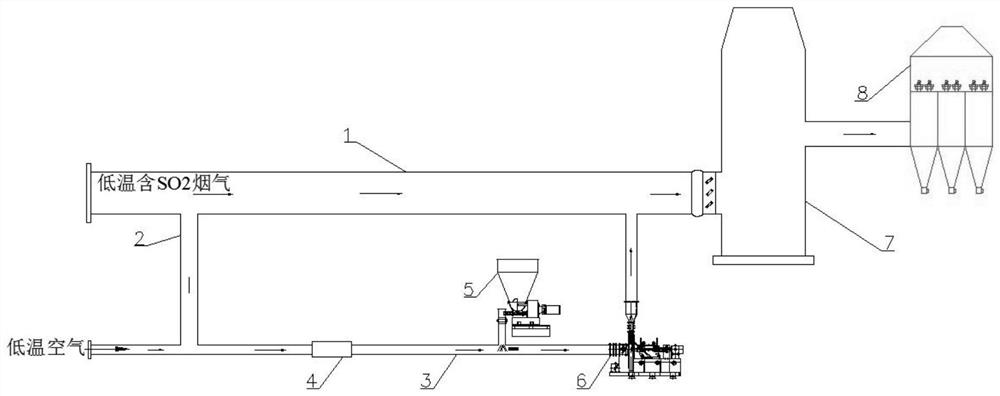

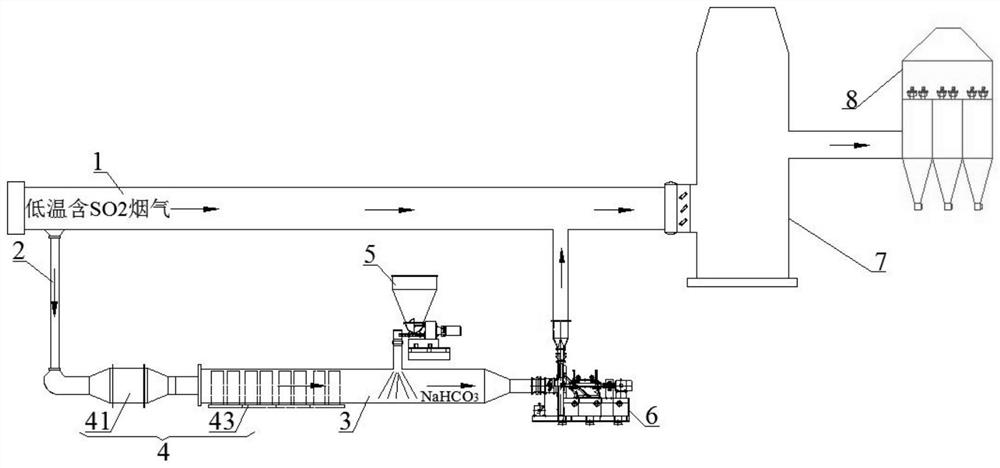

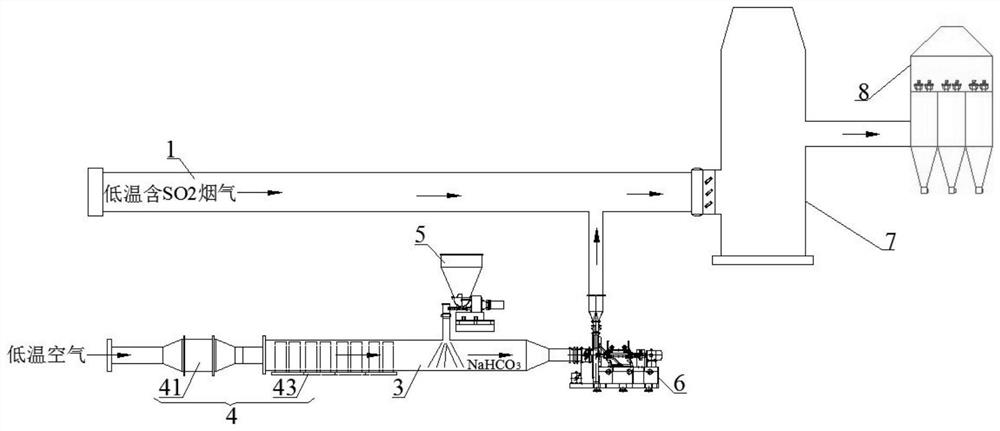

Low-temperature flue gas dry desulfurization process for preheating desulfurizer

InactiveCN113351005AReduce trafficImprove efficiencyGas treatmentDispersed particle filtrationThermodynamicsFlue gas

The invention provides a low-temperature flue gas dry desulfurization process for preheating a desulfurizer, and relates to the technical field of flue gas desulfurization. The low-temperature flue gas dry desulfurization method for preheating the desulfurizer comprises the following steps: feeding gas; taking gas; heating: heating the low-temperature gas introduced into a high-temperature flue gas pipeline by a heating device, so that the low-temperature gas is heated to become high-temperature gas; wherein the heating device is a gas-gas heat exchange device, an electric heating device or a hot air heating device; feeding: spraying 600-800-mesh desulfurizer into the middle section part of the high-temperature flue gas pipeline through a weighing feeder, and mixing the desulfurizer with the high-temperature gas; pre-decomposition: mixing high-temperature gas formed by heating with a desulfurizer sprayed into the high-temperature flue gas pipeline, and generating a popcorn type decomposition effect after the desulfurizer reaches a certain temperature; and post-processing. According to the method, NaHCO3 fine powder serving as the desulfurizer is heated in advance to be decomposed, so that the flow of gas needing to be heated is greatly reduced, the energy consumption is reduced, and the efficiency and the applicability and economical efficiency of the process are improved.

Owner:ANHUI TONGXING ENVIRONMENTAL PROTECTION ENG +1

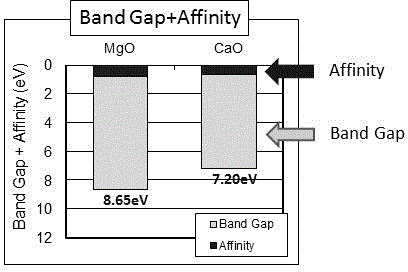

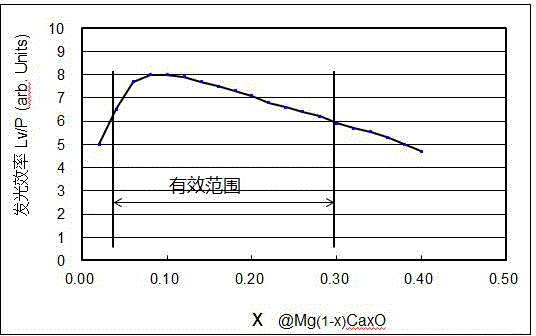

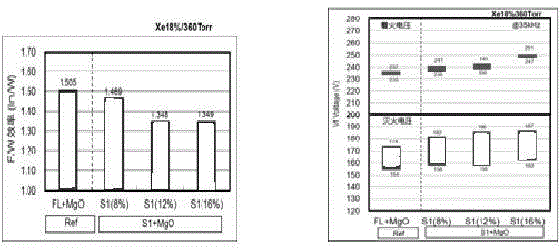

Microcrystalline material MgCaO powder, microcrystalline material as well as preparation methods and applications of MgCaO powder and microcrystalline material

InactiveCN104129807AImprove luminous efficiencyUniform and stable dischargeGas-filled discharge tubesCalcium/strontium/barium oxides/hydroxidesMineralogyEngineering

The invention belongs to the field of microcrystalline materials, and in particular relates to microcrystalline material MgCaO powder as well as a preparation method and an application thereof. The microcrystalline material MgCaO powder is characterized in that the specific gravity ratio of Mg, Ca and O in the MgCaO powder is shown as xMg(1-x)CaxO, wherein x is greater than or equal to 0.04 and less than or equal to 0.3; the MgCaO powder is formed by sintering CaO powder and MgO powder. A microcrystalline material is formed after the MgCaO powder is dissolved in a solvent. When the microcrystalline material containing the MgCaO powder is applied into a plasma panel, the low energy band width is maintained while the stable state of environmental gases is kept. The preparation method is low in cost, simple and easy to operate.

Owner:SICHUAN COC DISPLAY DEVICES

Method for treating Cr(VI)-containing waste water

InactiveCN109205870AShort processing timeUniform and stable dischargeWater contaminantsWater/sewage treatmentHigh energyWastewater

The invention discloses a method for treating Cr(VI)-containing waste water. According to the method, a part of waste water is introduced into a reaction container provided with a medium blocking discharging device; plasmas are conducted to generate a power supply; the reduction is performed on Cr(VI) in the waste water through generating low-temperature plasmas; meanwhile, hydroxyl radical or hydrogen radical type high-energy active particles are generated to obtain the pretreated waste water containing rich active particles; then, the obtained pretreated waste water is fast introduced into the rest part of Cr(VI)-containing waste water to be treated to be proportionally mixed with waste water to be treated; after the reaction, the goal of eliminating Cr(VI) contaminants in the waste water is realized. The method has the advantages that in the whole process, the additional addition of chemical reagents is not needed; the Cr(VI) removal rate being 90 percent or higher can be realized;meanwhile, organic contaminants in the waste water can be eliminated; the energy consumption and cost of the discharging technology applied to Cr(VI) elimination in waste water can be greatly reduced;great industrial application values are realized.

Owner:SHANDONG UNIV

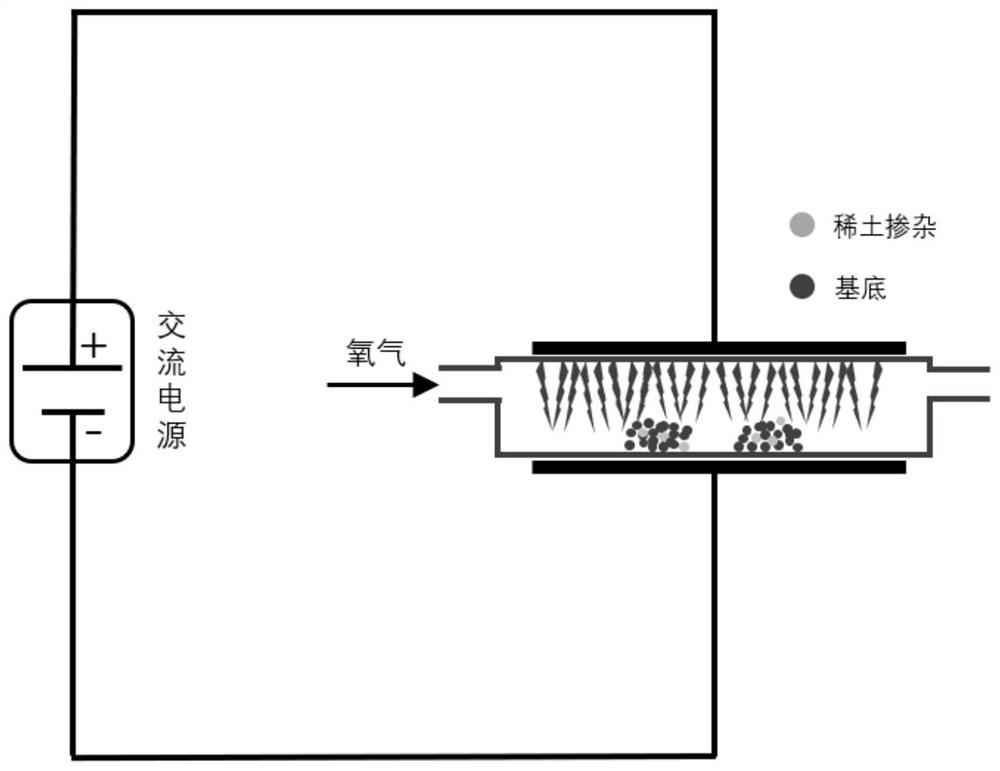

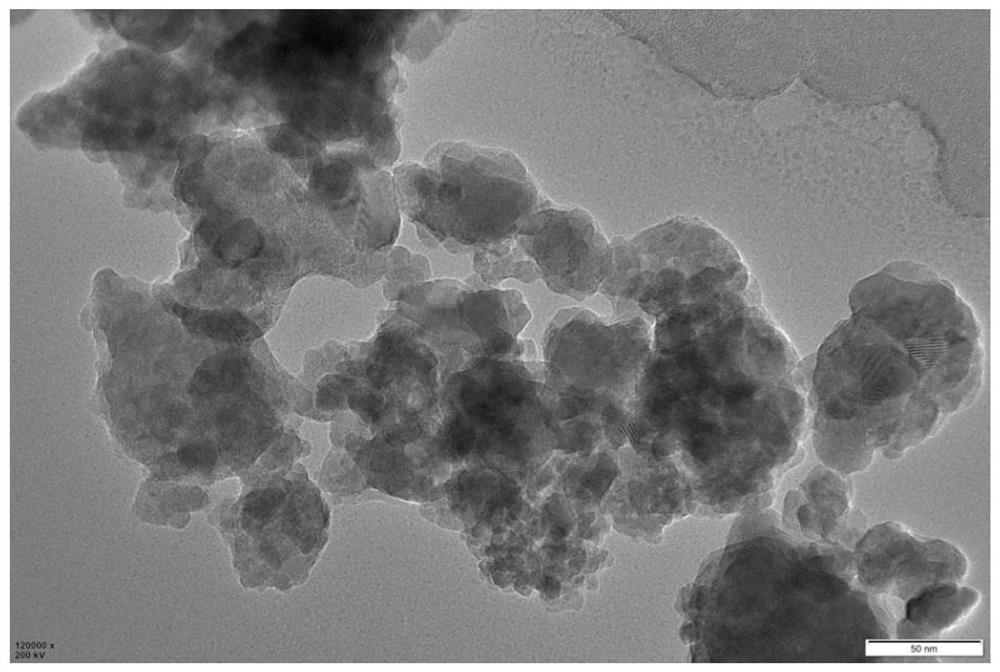

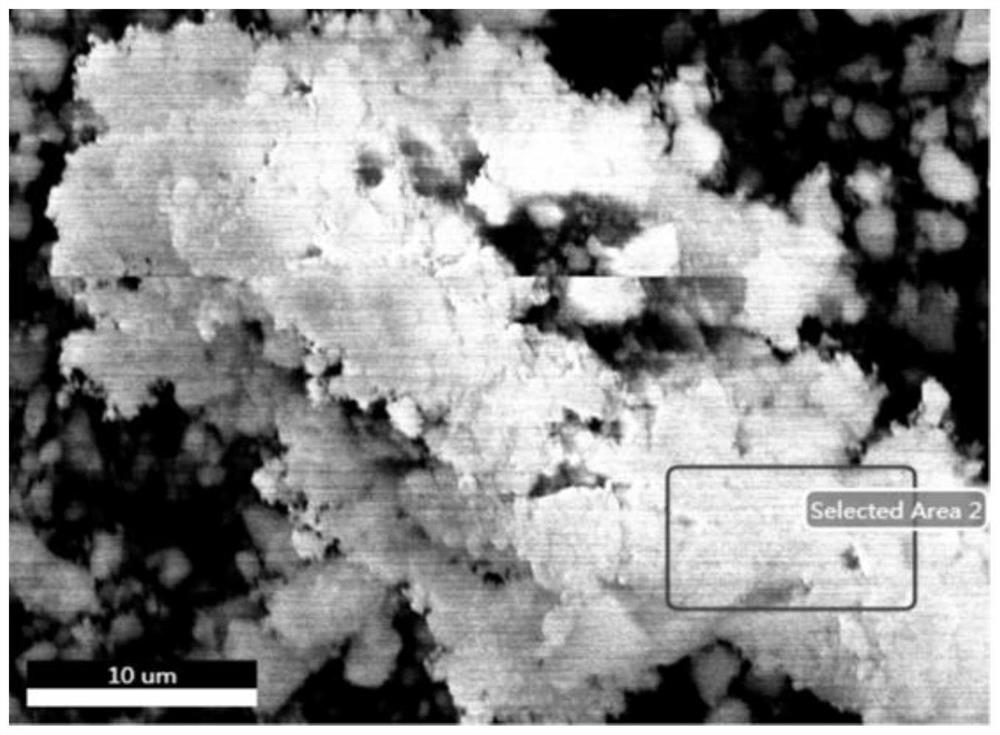

Method for preparing rare earth doped yttrium oxide fluorescent nanoparticles through DBD technology

ActiveCN112920799AControllable equipmentHigh activityNanoopticsLuminescent compositionsPlasma reactorAlternate current

The invention discloses a method for preparing rare earth doped yttrium oxide fluorescent nanoparticles through a DBD technology, and the method comprises the following steps: (1) mixing a substrate metal organic matter and a doped metal organic matter according to a mass ratio of (10-40): 1, and grinding the mixture as a reaction precursor; (2) putting the precursor obtained in the step (1) into a container, and putting the container between the positive electrode and the negative electrode of a plasma reactor; and (3) applying alternating current between the cathode and the anode of the plasma reactor in an oxygen atmosphere, treating the precursor for a period of time, taking out the product every a period of time, and grinding to obtain powder containing the rare earth doped yttrium oxide nanoparticles. According to the invention, powder of rare earth doped yttrium oxide fluorescent nanoparticles is prepared by using a high-activity oxidation component one-step method through a DBD technology. The method is simple and easy to implement, green and efficient, high-temperature and high-pressure further reaction is not needed, and energy consumption is effectively reduced.

Owner:JIANGNAN UNIV

Semiconductor air disinfection and purification device

InactiveCN103933598AUniform and stable dischargeIncreased discharge surfaceDeodrantsRadiationDischarge efficiencyEngineering

The invention discloses a semiconductor air disinfection and purification device of the technical fields of air purification and disinfection. The semiconductor air disinfection and purification device comprises a first ionization module and a light wave catalytic unit, the first ionization module comprises ionization discharge plates and ionization dust collecting plates, the ionization discharge plates and the ionization dust collecting plates are insulated, the ionization discharge plates and the ionization dust collecting plates are respectively connected with pulse ionization high voltage power supplies, the surface of the ionization discharge plates is provided with a plurality of neatly arranged discharge bodies perpendicular to the surface of the ionization discharge plates, air flow guide channels are formed between the discharge bodies and through holes, the discharge bodies are annular lug boss structures, the top ends of the discharge bodies are round planes, the through holes are lug boss hole structures which is formed by deep extending of convex holes, and the discharge bodies and the through holes are in corresponding concentric circle structures. Compared with a traditional structure, an annular discharge structure is adopted, the discharge is more stable, meanwhile the discharge surface is increased, the discharge efficiency is improved, the annular lug boss structure may not be broken, the service life is longer, and the sterilization efficiency is higher.

Owner:东莞市伟一环境科技有限公司

Tail gas emission structure and reduction furnace

PendingCN113375058AUniform and stable pressure flowUniform and stable pressurePipeline systemsSilicon compoundsEngineeringMechanics

The invention discloses a tail gas emission structure and a reduction furnace. The tail gas emission structure comprises a plurality of tail gas branch tubes, wherein the first end of each tail gas branch tube communicates with a converging tube, and the first ends of the multiple tail gas branch tubes are arranged in the circumferential direction of the converging tube at intervals; the first end of a collecting tube communicates with the converging tube; and the second end of the collecting tube communicates with one end of a tail gas mother tube. The tail gas emission structure can be applied to a reduction furnace, and the second ends of the tail gas branch tubes can communicate with an exhaust hole in the bottom of the reduction furnace, so that tail gas in the reduction furnace enters the tail gas branch tubes through the exhaust hole, and gas in the tail gas branch tubes can be balanced in the converging tube after entering the converging tube, and thus, pressure flow of the gas in the converging tube is more uniform and stable; and uniform and stable gas in the converging tube stably flows into the collecting tube, passes through the collecting tube and then is discharged from the tail gas mother tube, so that the tail gas is discharged more uniformly and stably, the pressure, the flow fields and the temperature fields in the reduction furnace are stable, and the production quality of polycrystalline silicon is improved.

Owner:新疆硅基新材料创新中心有限公司 +1

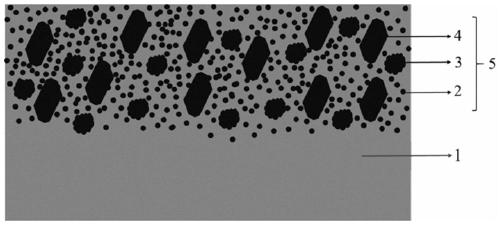

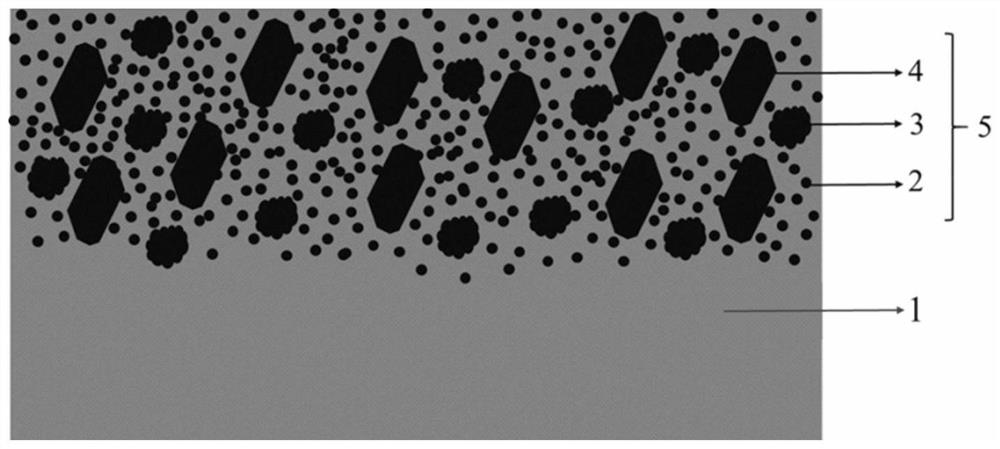

Multi-scale titanium carbide particle reinforced copper-based composite coating and preparation method and application thereof

ActiveCN111394722APlay a supporting roleHigh hardnessElectromagnetic launchersTitanium carbideSintered titaniumGraphite

The invention belongs to the field of surface strengthening and surface modification, and discloses a multi-scale titanium carbide particle reinforced copper-based composite coating and a preparationmethod and application thereof. According to the coating, multi-scale titanium carbide particles serve as a reinforcing phase, copper and a copper-titanium intermetallic compound serve as a matrix, the mass fraction of the titanium carbide particles ranges from 50% to 75%, and the mass fraction of the copper and titanium-copper intermetallic compound ranges from 25% to 50%. The preparation methodof the coating comprises the following steps of clamping a sintered titanium electrode and the copper matrix on a negative electrode and a positive electrode of a spark machine tool correspondingly, immersing the sintered titanium electrode and the copper matrix in a graphene-spark oil mixed medium, and setting spark discharge parameters to prepare the copper-based composite coating containing thelarge-particle-size titanium carbide particles; and then performing aging treatment, and finally obtaining the composite coating. The hardness of the coating is 1100 HV0.2 to 1300 HV0.2, and the coating has the advantages of being low in friction coefficient (0.2-0.32) and low in specific wear rate (1.2-5.8*10<-5 >mm < 3 > N <-1 > m <-1 >) as a wear-resistant coating.

Owner:GUANGDONG UNIV OF TECH

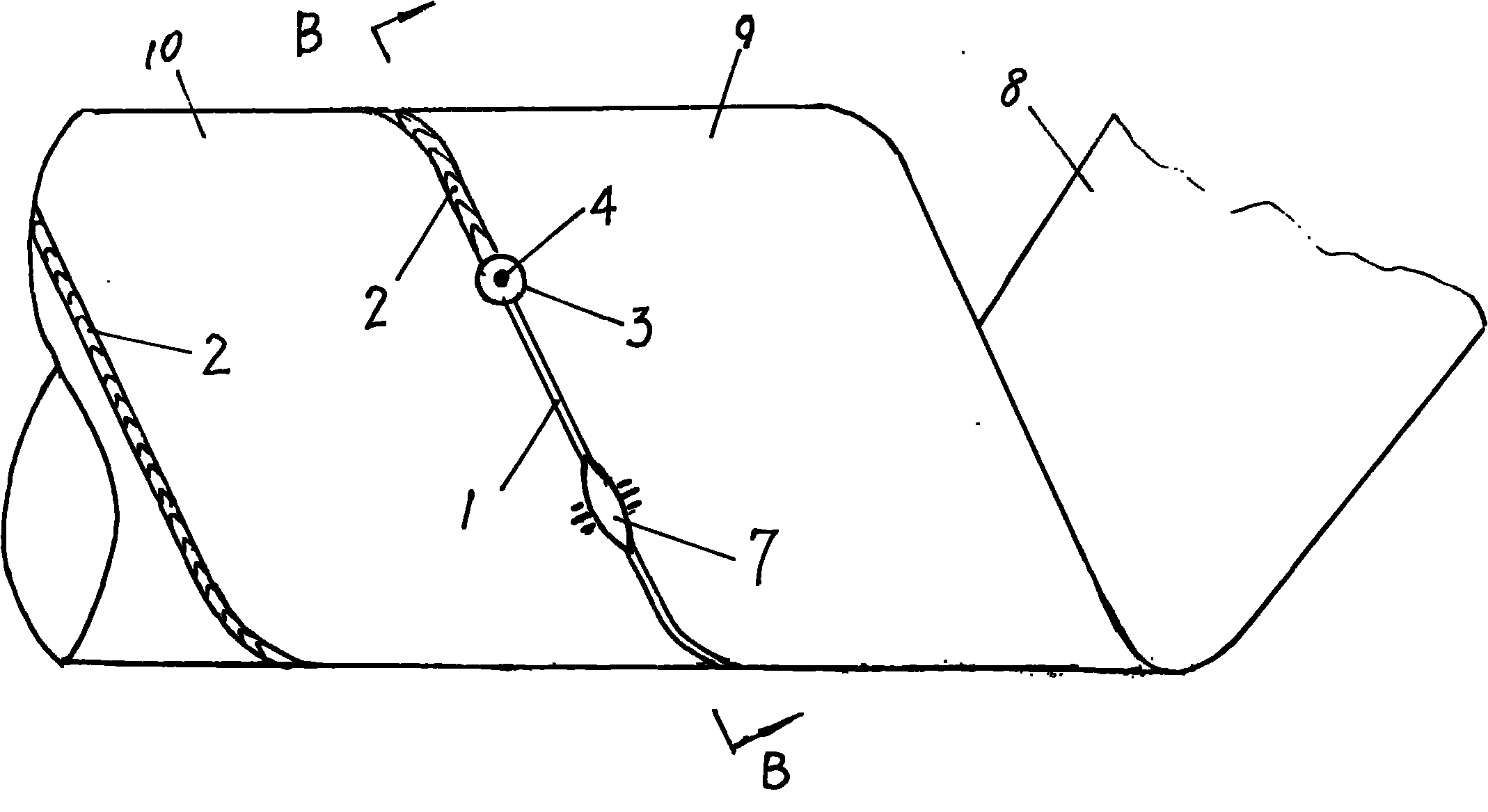

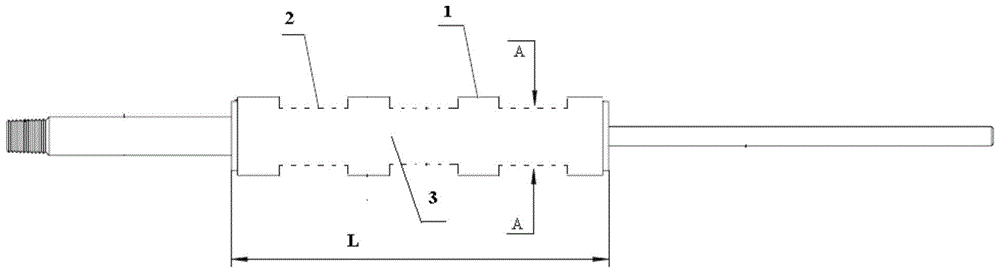

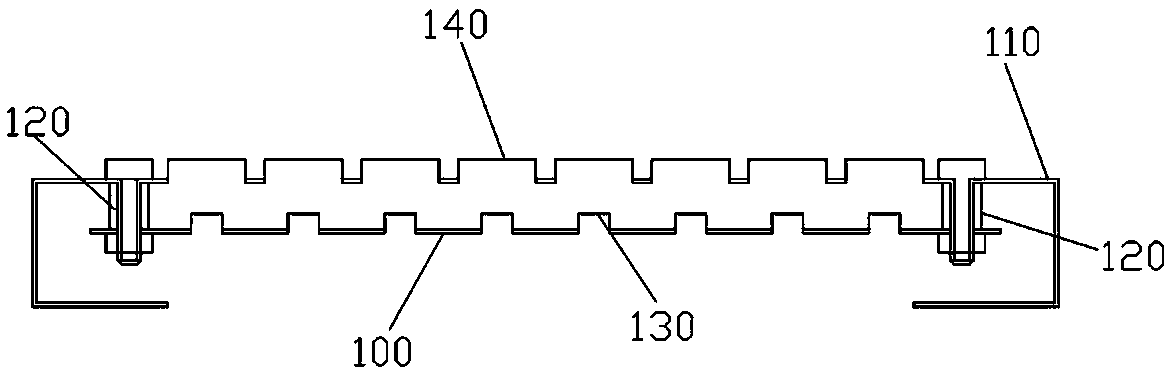

Dielectric Barrier Discharge Inner Electrode and Reactor for Treating Particulate Organic Matter

The invention discloses a dielectric-barrier discharging internal electrode for particle-state organic matter treatment. The internal electrode consists of stainless steel tubes (1) and stainless steel powder sintering tubes (2) which are sequentially and alternatively arranged, wherein the stainless steel tubes (1) and the stainless steel powder sintering tubes (2) are connected in a sealed mode, and accordingly the multi-section composite internal electrode is formed. The channels of the stainless steel tubes (1) and the channels of the stainless steel powder sintering tubes (2) form the inner channel (3) of the internal electrode. The stainless steel powder sintering tubes (2) are multi-hole metal reaction bodies. A noble metal catalyst is loaded on the outer surfaces of the stainless steel powder sintering tubes (2). The end close to an air inlet, of the internal electrode is closed, and the end close to an air outlet is opened and communicated with the air outlet. The invention further discloses a reactor manufactured by utilizing the internal electrode. The problems of uneven discharging, low discharging strength, poor organic matter degradation effect and the like of a conventional composite electro-catalysis dielectric-barrier reactor can be overcome.

Owner:江苏富春江环保热电有限公司

A multi-scale titanium carbide particle reinforced copper-based composite coating and its preparation method and application

ActiveCN111394722BPlay a supporting roleHigh hardnessElectromagnetic launchersTitanium carbideSintered titaniumGraphite

The invention belongs to the field of surface strengthening and surface modification, and discloses a multi-scale titanium carbide particle-reinforced copper-based composite coating, a preparation method and application thereof. The coating uses multi-scale titanium carbide particles as the reinforcing phase, copper and copper-titanium intermetallic compounds as the matrix, the mass fraction of titanium carbide particles is 50-75%, and the mass fraction of copper and titanium-copper intermetallic compounds is 25-50% %. The preparation of the coating includes the following steps: the sintered titanium electrode and the copper substrate are respectively clamped on the negative electrode and the positive electrode of the spark machine tool, and immersed in the graphene-spark oil mixed medium, and the spark discharge parameters are set to obtain a large particle size carbonized Copper-based composite coating of titanium particles; followed by aging treatment to finally obtain a composite coating. The hardness of the coating is 1100‑1300HV 0.2 , as a wear-resistant coating has a low coefficient of friction (0.2‑0.32), less specific wear rate (1.2‑5.810 ‑5 mm 3 N ‑1 m ‑1 )The advantages.

Owner:GUANGDONG UNIV OF TECH

Volume preionization high barometric large volume stable and even discharging compound electrode structure

InactiveCN101022202AOvercoming the disadvantages of pre-ionizationVolume pre-ionization is stable and uniformLaser detailsOptoelectronicsCopper

This invention provides a stable and uniform discharging compound electrode structure in a pre-ionized anticyclone large volume composed of a cathode, a ballast medium, a main discharge anode, an insulation medium and a pre-ionized anode, in which, the main discharge anode and the pre-ionized anode are in batten state, the cathode is the improved Ru khodorkovsky electrode, each kind of electrodes is composed of several thin copper plates and two sides of the plate are plated with insulation medium layers.

Owner:石景林

Semiconductor air disinfection and purification device

InactiveCN103933598BUniform and stable dischargeIncreased discharge surfaceDeodrantsRadiationDischarge efficiencyDevice material

The invention discloses a semiconductor air disinfection and purification device of the technical fields of air purification and disinfection. The semiconductor air disinfection and purification device comprises a first ionization module and a light wave catalytic unit, the first ionization module comprises ionization discharge plates and ionization dust collecting plates, the ionization discharge plates and the ionization dust collecting plates are insulated, the ionization discharge plates and the ionization dust collecting plates are respectively connected with pulse ionization high voltage power supplies, the surface of the ionization discharge plates is provided with a plurality of neatly arranged discharge bodies perpendicular to the surface of the ionization discharge plates, air flow guide channels are formed between the discharge bodies and through holes, the discharge bodies are annular lug boss structures, the top ends of the discharge bodies are round planes, the through holes are lug boss hole structures which is formed by deep extending of convex holes, and the discharge bodies and the through holes are in corresponding concentric circle structures. Compared with a traditional structure, an annular discharge structure is adopted, the discharge is more stable, meanwhile the discharge surface is increased, the discharge efficiency is improved, the annular lug boss structure may not be broken, the service life is longer, and the sterilization efficiency is higher.

Owner:东莞市伟一环境科技有限公司

Electrode structure with high power, high-pressure, big-volume stable-uniform clischarge

InactiveCN1776973AUniform electric field distributionAvoid edge effectsLaser detailsState of artLight beam

The disclosed structure of electrode is composed of cathode, ballasting medium, main discharge anode, insulating medium and pre ionization anode. Comparing with current technique, the invention possesses advantages: even pre ionization, good quality of continuous discharging light beam, even distribution of electric field of electrode. The invention is applicable to continuously even stably discharge of crossing current carbon-dioxide laser in large power, high air pressure and large volume.

Owner:石景林

Gas laser

InactiveCN101789559BSimple structureIncrease powerActive medium materialGas laser constructional detailsLaser processingMetallic materials

Owner:HUAZHONG UNIV OF SCI & TECH

A method for treating high-concentration organic wastewater using dielectric barrier discharge-wastewater treatment combined equipment

ActiveCN109384336BGreen and efficient treatmentAchieve removalWater aerationWater/sewage treatmentAir pumpActive particles

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com