Microcrystalline material MgCaO powder, microcrystalline material as well as preparation methods and applications of MgCaO powder and microcrystalline material

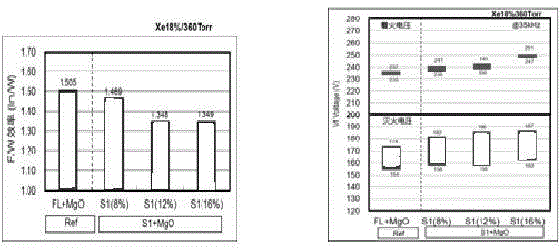

A technology of microcrystalline materials and powders, which is applied in the direction of calcium/strontium/barium oxide/hydroxide, discharge tubes, electrical components, etc., can solve the problems of small image quality improvement and deterioration, and achieve the improvement of discharge spots, Good protective effect, the effect of improving the problem of freckles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

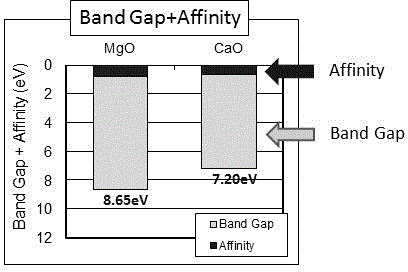

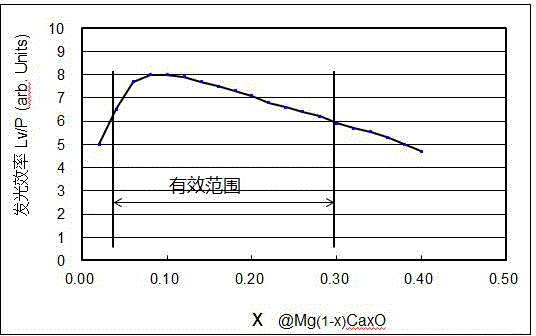

[0043] Calcium oxide (CaO) and magnesium oxide (MgO) powder are mixed according to the mass ratio x: 1-x, x=0.3, and the compound of CaO and MgO is formed after sintering, that is, the microcrystalline material MgCaO powder; the sintering temperature is 1100°C, The sintering time is 7h, and the MgCaO powder is obtained.

[0044] The microcrystalline material MgCaO powder is white and cubic powder with a particle size of 50nm to 500nm. Specifically, it can improve luminous efficiency, resist speckle and improve display quality.

Embodiment 2

[0047] Calcium oxide (CaO) and magnesium oxide (MgO) powder are mixed according to the mass ratio x: 1-x, x=0.04, and the compound of CaO and MgO is formed after sintering, that is, the microcrystalline material MgCaO powder; the sintering temperature is 1400°C, The sintering time is 4h, and the MgCaO powder is obtained.

Embodiment 3

[0049] Calcium oxide (CaO) and magnesium oxide (MgO) powder are mixed according to the mass ratio x: 1-x, x=0.06, and the compound of CaO and MgO is formed after sintering, that is, the microcrystalline material MgCaO powder; the sintering temperature is 1300°C, The sintering time is 6h, and the MgCaO powder is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com