Dielectric Barrier Discharge Inner Electrode and Reactor for Treating Particulate Organic Matter

A dielectric barrier discharge and internal electrode technology, applied in the field of internal electrodes, can solve the problems of low discharge intensity, uneven discharge, poor degradation of organic matter, etc., achieve uniform discharge, increase carbonization rate, and control the formation of harmful by-products Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

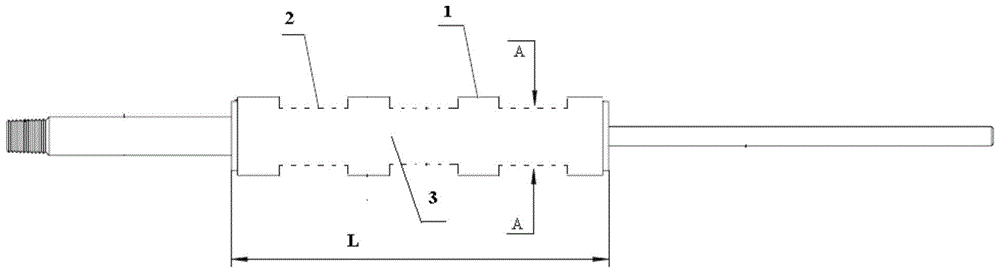

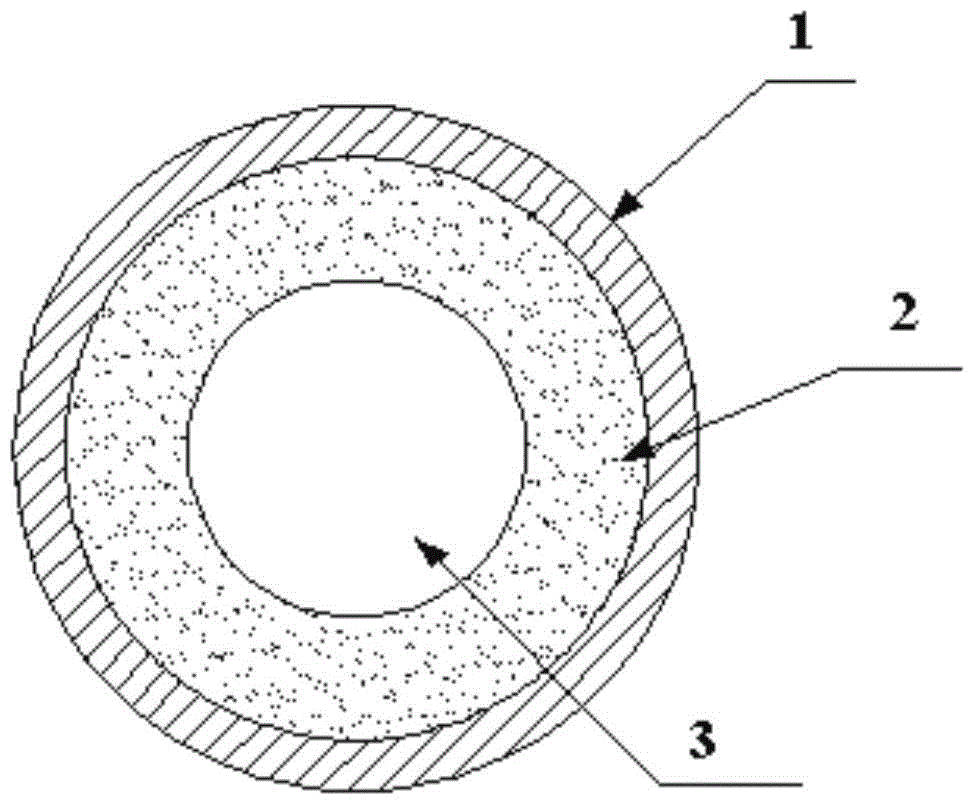

[0046] Embodiment 1, a kind of such as figure 1 with figure 2 The inner electrode of the dielectric barrier discharge reactor for treating granular organic matter shown is composed of stainless steel tube 1 and stainless steel powder sintered tube 2 alternately; the stainless steel tube 1 and stainless steel powder sintered tube 2 are sealed and connected to form a multi-stage composite The internal electrode of the formula (a multi-stage composite internal electrode with the combined functions of filtration, chemical catalysis and plasma oxidation). The stainless steel powder sintered tube 2 is a porous material with a rigid structure made of spherical or irregular stainless steel powder through compression molding and high-temperature sintering, and supports noble metal catalysts. The supported catalyst is preferably Au or Pt, and the loading capacity is generally 0.5-1 μg / cm 2 (outer surface area of stainless steel powder sintered tube 2). That is, per cm 2 The outer...

Embodiment 2

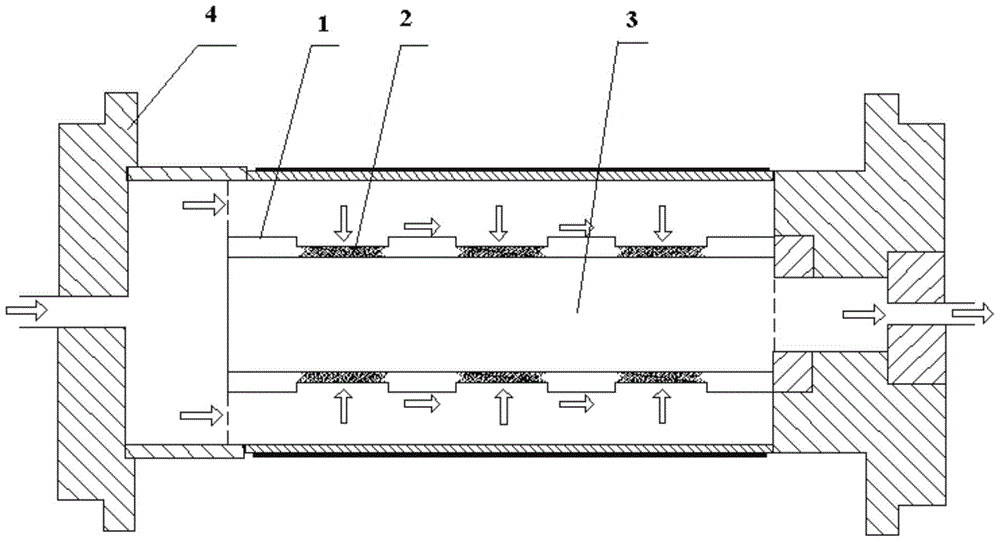

[0048] Embodiment 2. A reactor designed and processed using the internal electrode described in Embodiment 1, such as image 3 Said, including housing 4, one end of the housing is an air inlet, and the other end is an air outlet; the outer wall of the housing 4 is wrapped with a metal conductor, and the metal conductor is grounded as an external electrode for dielectric barrier discharge; in the housing 4 The above-mentioned multi-section composite electrode is arranged in the middle, and the external AC power supply or pulse power supply becomes the inner electrode of the dielectric barrier discharge reactor; the end of the inner electrode close to the air inlet is closed, and the end of the inner electrode close to the air outlet is open and communicated with the air outlet; The gap between the inner wall of the housing and the outer wall of the stainless steel pipe 1 is 1-5 mm; the gap forms a dielectric barrier discharge gap, and the dielectric barrier discharge gap is conn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com