Electrode structure with high power, high-pressure, big-volume stable-uniform clischarge

A technology of electrode structure and high pressure, applied in the direction of circuits, electrical components, laser components, etc., can solve the problems of poor pre-ionization uneven effect, poor quality of discharge beam, etc., to solve the problem of poor quality of discharge beam, low price, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

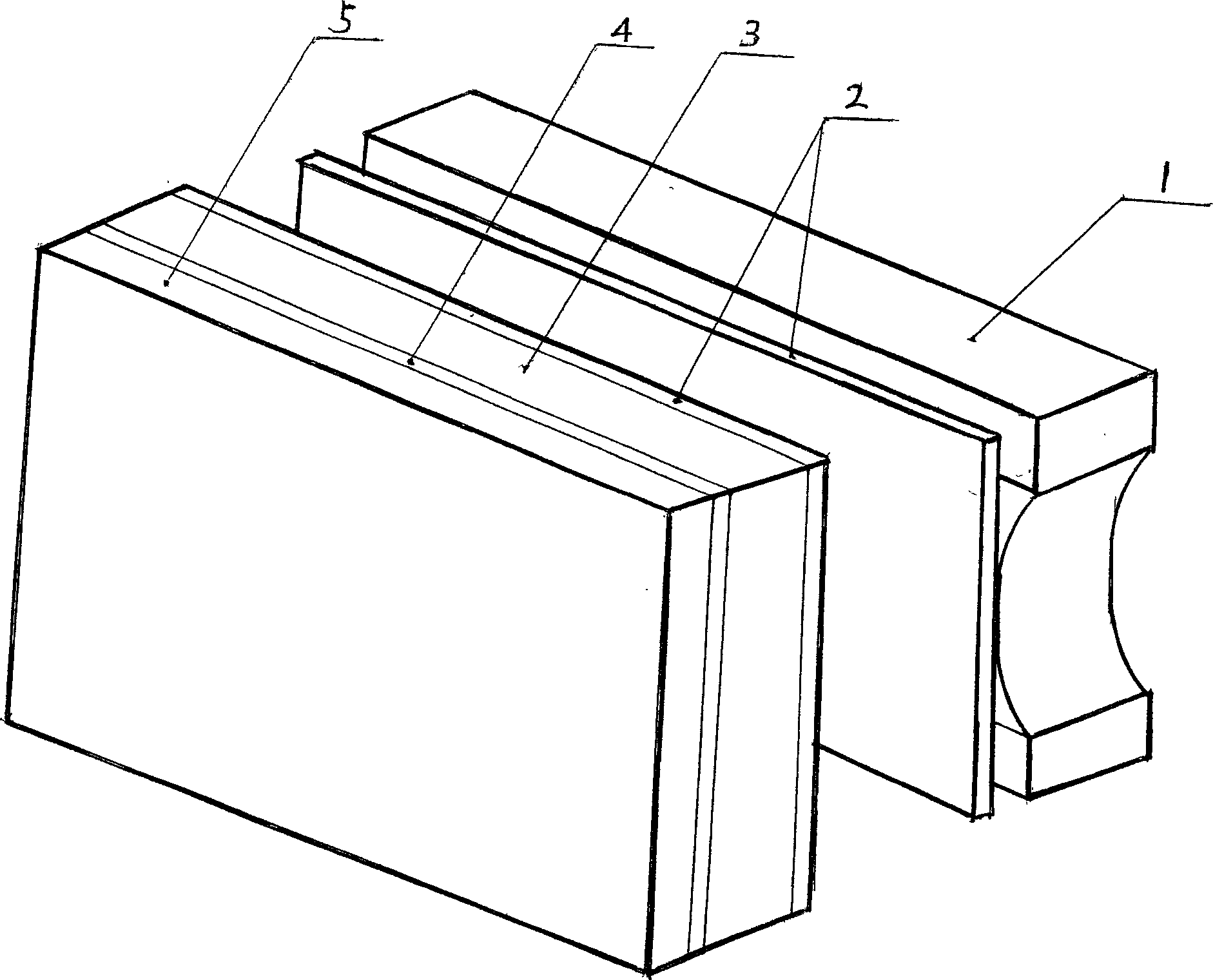

[0021] The invention provides a high-power, high-pressure, large-volume, stable and uniform discharge electrode structure, which is characterized in that:

[0022] It is composed of a cathode (1), a ballast medium (2), a main discharge anode (3), an insulating medium (4), and a pre-ionized anode (5). One piece of ballast medium (2) and cathode (1), on one side of the discharge area, another piece of ballast medium (2) and the main discharge anode (3), insulating medium (4), and pre-ionized anode (5). The other side of the discharge area, and the pre-ionization anode (5) is at the outermost side. The insulating medium (4) is between the main discharge anode (3) and the pre-ionization anode (5). The periphery of the discharge area of the cathode (1) is an improved Zhukovsky shape, composed of several thin copper plates, and both sides of each thin copper plate are plated with insulating dielectric layers. The main discharge anode (3), pre-ionization anode (5), insulating medium (4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com