Method for repairing composite insulator testing sampling part

A technology of composite insulators and insulators, applied in the direction of overhead lines/cable equipment, etc., can solve problems such as replacement or repair, composite insulators can not meet the requirements of normal operation, etc., to avoid power outages, excellent water repellency and water mobility, Reduce the effect of grid investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the purpose, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the invention.

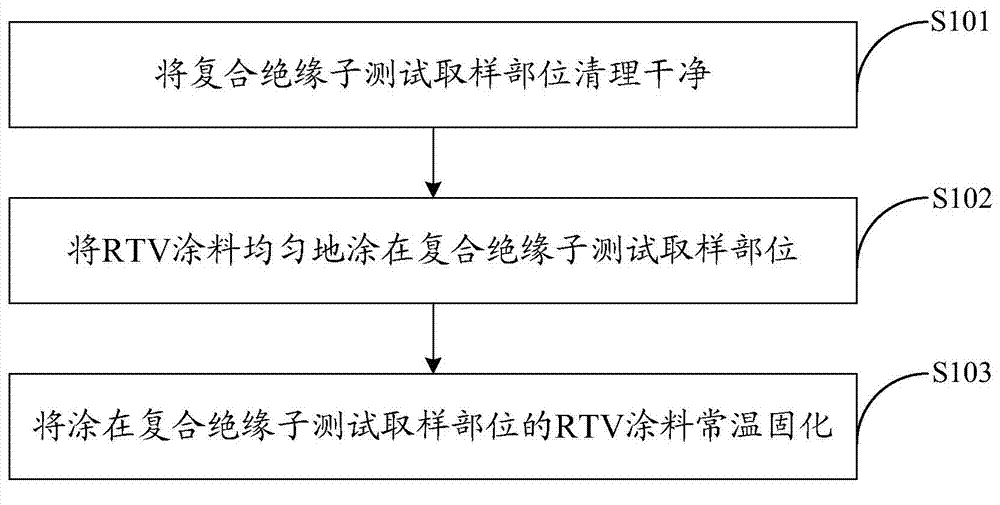

[0030] figure 1 The implementation flow of the method for repairing the test sampling part of the composite insulator provided by the embodiment of the present invention is shown.

[0031] The method includes the following steps:

[0032] Step S101, cleaning up the test sampling part of the composite insulator;

[0033] After sampling the surface of the insulator with a special tool for sample collection on the surface of composite insulators, small burrs will be formed at the sampling place. The burrs need to be removed with a wallpaper knife, and the sampling part should be polished with sandpaper ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com