Novel tubular bus system

A tubular busbar, a new type of technology, applied in the directions of power cables, conductive connections, conductors, etc., can solve the problems that humidity and temperature cannot be matched, impurities are brought in, and the electrical insulation performance of the tube and busbar is reduced. Good fit and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

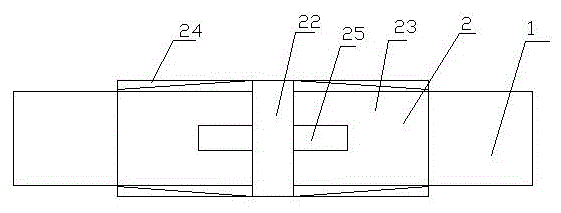

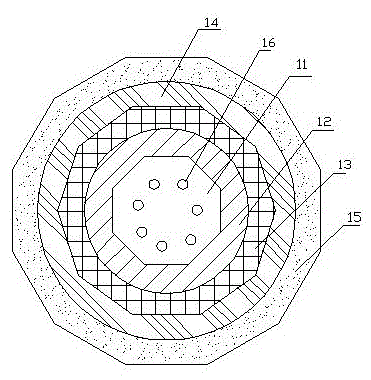

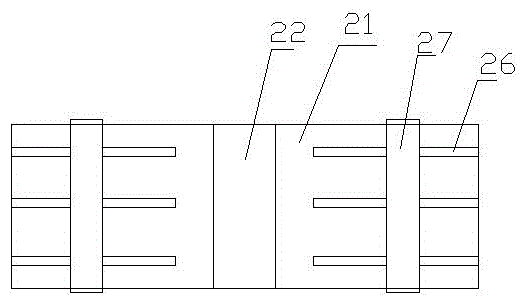

[0019] A new tubular busbar system, including tubular busbars 1 and connecting structures 2, adjacent tubular busbars 1 are fixedly connected through the connecting structure 2, the tubular busbars 1 include wire cores 11, and the outside of the wire cores 11 are insulated in turn layer 12, shielding layer 13, heat-shrinkable sheath 14 and insulating sheath 15, the thicknesses of the insulating layer 12, shielding layer 13, heat-shrinkable sheath 14 and insulating sheath 15 are successively decreasing, and the wire core 11 is positive eight Hexagonal structure, the core 11 is provided with a number of heat dissipation channels 16, the core 11 is covered with a layer of polytetrafluoroethylene as the insulating layer 12, the insulating layer 12 is a cylindrical structure, and the insulating layer 12 is covered A layer of regular decagonal shielding layer 13, the shieldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com