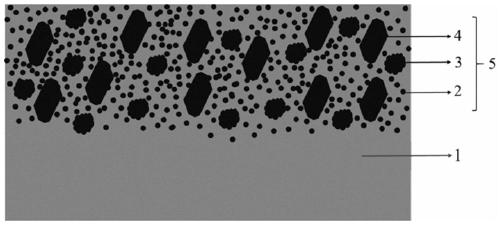

Multi-scale titanium carbide particle reinforced copper-based composite coating and preparation method and application thereof

A copper-based composite, particle-reinforced technology, applied in the direction of titanium carbide, coating, carbide, etc., can solve the problems of low production efficiency, harsh production conditions, low coating/substrate bonding strength, etc., and achieve good wear resistance. , the effect of less holes and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The sintered titanium electrode and the copper substrate are respectively clamped on the negative electrode and the positive electrode of the spark machine tool, and immersed in the graphene-spark oil mixed medium; the preparation process of the graphene-spark oil mixed medium is as follows: Weigh 1.5g of the spark oil with the function of octadecylamine Chemically modified graphene powder (0.05-5 μm in size) is placed in 10L of general-purpose spark oil, and can be prepared after ultrasonic dispersion for 30 minutes with a concentration of 0.15g L -1 graphene-spark oil hybrid media. The spark discharge parameters are set as follows: peak current is 10A, pulse width is 8μs, pulse gap is 256μs, and discharge time is 30min. A copper-based composite coating containing large-diameter titanium carbide particles was obtained.

Embodiment 2

[0029] The difference from Example 1 is that the concentration of graphene in the graphene-spark oil mixed medium is 0.01g L -1 , the spark discharge parameters are set as follows: the peak current is 15A, the pulse width is 16μs, the pulse gap is 128μs, and the discharge time is 10min.

Embodiment 3

[0031] The difference from Example 1 is that the concentration of graphene in the graphene-spark oil mixed medium is 0.5g L -1 , the spark discharge parameters are set as follows: the peak current is 5A, the pulse width is 64μs, the pulse gap is 256μs, and the discharge time is 60min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com