Self-control-type storing bin

A storage bin and bin body technology, applied in the field of storage equipment and storage bins, can solve the problems of influence, inability to continuously and uniformly feed materials, unfavorable mixing of raw materials, etc., and achieve the effect of uniform and stable discharging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

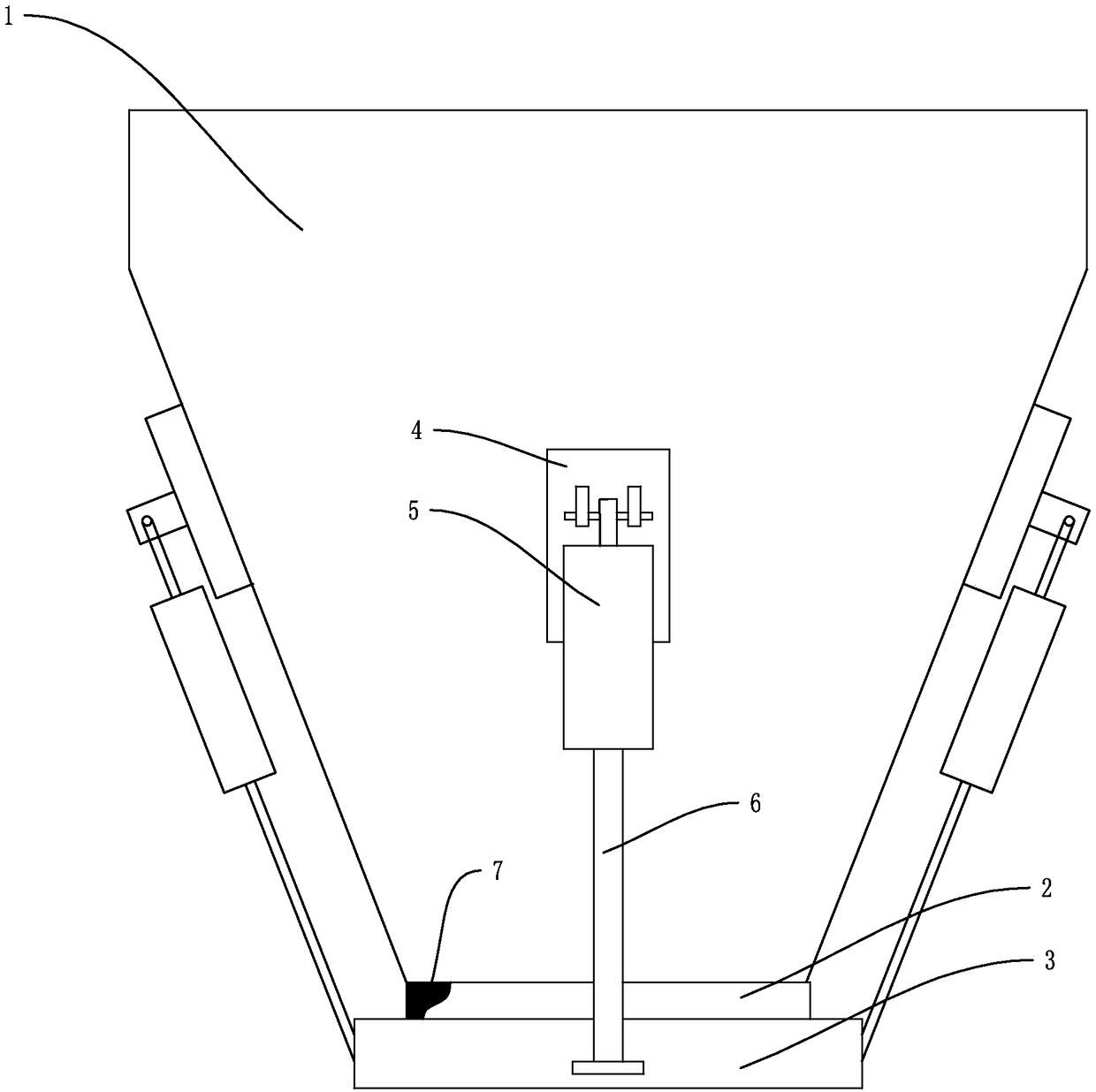

[0015] Such as figure 1 The self-control storage bin shown includes a bin body 1, a closing plug 3, a fixing seat 4, an electro-hydraulic push rod 5, and a solid flow meter. In this embodiment, the bin body 1 is conical, the lower end of the bin body is provided with a discharge port 2, and a closure plug 3 is also provided on the discharge port 2. One side of the closure plug 3 is convex, and the closure plug 3 The raised portion is upward and can close the discharge opening 2 . The shape of the closing plug 3 can be conical or conical. On the side of the warehouse body 1, there are also fixed seats 4, and the number of the fixed seats 4 is at least three, and the electro-hydraulic push rod 5 and the electric valve of the electro-hydraulic push rod 5 are also connected by bolts on the top of each fixed seat 4. The switch is equipped with a signal receiving module. The electro-hydraulic push rod 5 has the function of stopping at any position within the specified stroke range...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com