Gas laser

A gas laser and gas storage chamber technology, applied in the field of lasers, can solve the problems of high operating noise, large gas consumption, high use and maintenance costs, and achieve the effects of processing accuracy requirements, high installation accuracy, improved output power, and guaranteed stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

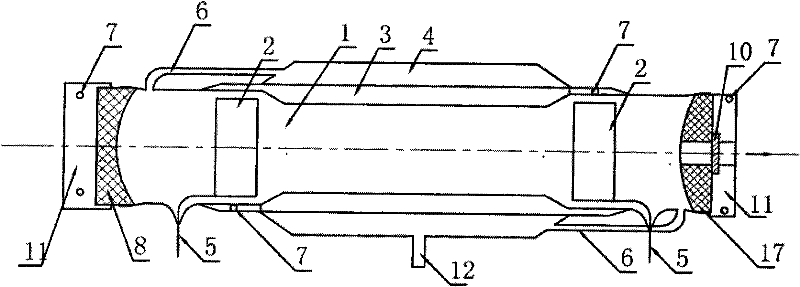

[0022] Below in conjunction with accompanying drawing and example the present invention is described in further detail.

[0023] Such as figure 1 As shown, the gas laser provided by the present invention includes a discharge cavity 1, a discharge electrode 2, a water cooling channel 3, a gas storage chamber 4, a strip reflector 8 at the tail mirror end, a strip reflector 9 at the output end and a fully transparent output mirror 10.

[0024] The discharge chamber 1 is made of non-metal such as glass or ceramics. The discharge electrodes 2 are located at the front and rear ends of the discharge chamber 1, or on the left and right sides, and are connected to the electrode wires 5. The electrode wires 5 are respectively connected to external electrodes. The power supply is connected, and the power supply can use a common DC power supply instead of an RF power supply. The water-cooling channel 3 is distributed outside the discharge chamber 1, which can cool the area where the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com