Method for treating Cr(VI)-containing waste water

A wastewater and pretreatment technology, applied in water/sewage treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc., can solve the problems of low water volume, high energy consumption, and restrictions on large-scale application, and achieve increased treatment Effects of scale, reduced energy consumption and processing costs, value for large industrial applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

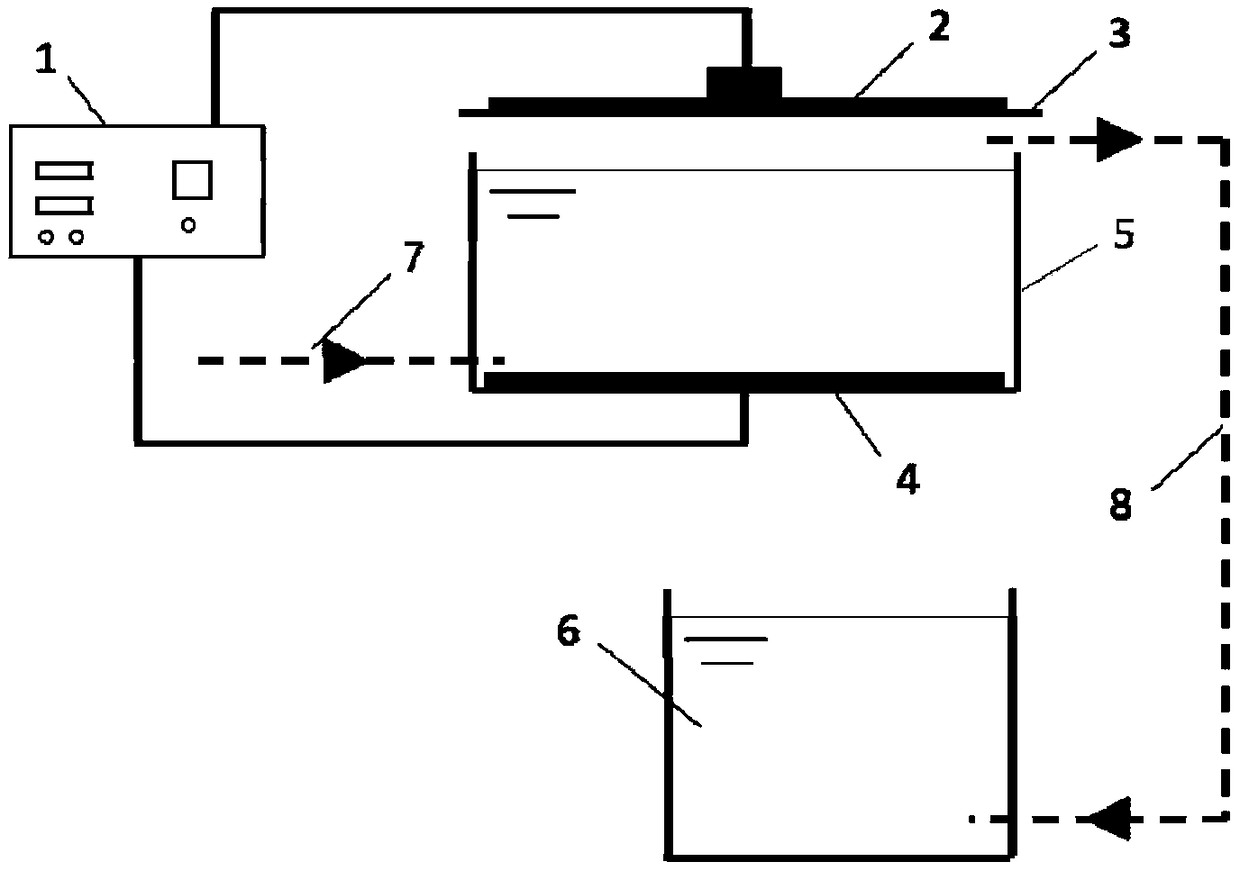

Image

Examples

Embodiment 1

[0028] A method for processing waste water containing Cr(VI), the specific steps are as follows:

[0029] (1) pre-determining the Cr(VI)-containing wastewater to be treated, and determining that its Cr(VI) content is 1mg / L; then a part of the Cr(VI)-containing wastewater is passed into a reaction vessel equipped with a dielectric barrier discharge device , wherein the dielectric barrier discharge device is provided with a plate-type high-voltage electrode and a ground electrode, and a barrier medium is installed below the high-voltage electrode; when the incoming Cr (VI) wastewater is submerged into the ground electrode and the distance between the water surface and the barrier medium above it is 6mm , turn on the plasma generating power supply, adjust the power supply input voltage to 30V, output frequency is 8KHz and make the discharge uniform and stable, the hydraulic retention time of the Cr(VI) wastewater in the reaction vessel is 10s; Reduction of Cr(VI) in the medium pr...

Embodiment 2

[0033] A method for processing waste water containing Cr(VI), the specific steps are as follows:

[0034] (1) Continuously feed simulated Cr(VI)-containing wastewater into the dielectric barrier discharge reaction vessel, wherein the Cr(VI) content is 50mg / L, and when the distance between the barrier medium and the liquid surface is 8mm, turn on the plasma generating power supply and adjust the power The input voltage of the power supply is 70V, the output frequency is 12KHz, and the hydraulic retention time is 60s; the Cr(VI) in the wastewater is reduced by generating low-temperature plasma, and at the same time, high-energy active particles such as hydroxyl radicals and hydrogen radicals are generated to obtain Cr(VI ) to remove pretreated wastewater rich in active particles.

[0035] (2) Rapidly pass the pretreated wastewater rich in active particles into the wastewater containing Cr(VI) to be treated, the mixing ratio is 1:1, and react for 25 minutes after mixing evenly to...

Embodiment 3

[0038] A method for processing waste water containing Cr(VI), the specific steps are as follows:

[0039] (1) Continuously feed the simulated Cr(VI)-containing wastewater into the dielectric barrier discharge reaction vessel, wherein the Cr(VI) content is 10mg / L, and the distance between the barrier medium and the liquid surface is 7mm; (VI) Reduction is carried out, and high-energy active particles such as hydroxyl radicals and hydrogen free radicals are produced at the same time to obtain pretreated wastewater rich in active particles after removal of Cr(VI). The input voltage is 50V, the output frequency is 10KHz, and the hydraulic retention time is 30s. ; Reduce Cr(VI) in wastewater by generating low-temperature plasma, and simultaneously generate high-energy active particles such as hydroxyl radicals and hydrogen free radicals, so as to obtain pretreated wastewater rich in active particles after removal of Cr(VI).

[0040] (2) Rapidly pass the pretreated wastewater rich in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com