Photopolymer composition and grating

A technology of photopolymer and composition, applied in the field of holographic recording system of green-sensitive polymer, can solve the problems of damaged hologram, hologram fringe deformation, etc. the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0211] A green sensitive holographic recording material is prepared according to the following steps:

[0212] 1) In a dark room or red light environment, mix the components in the following proportions to form a mixture, and heat up to 100°C and stir evenly;

[0213] 2) Maintain 100°C, apply the mixed solution obtained in step (1) on the glass substrate under red light, then cover another substrate on the surface, and obtain a solid photopolymer dry plate after cooling down to room temperature;

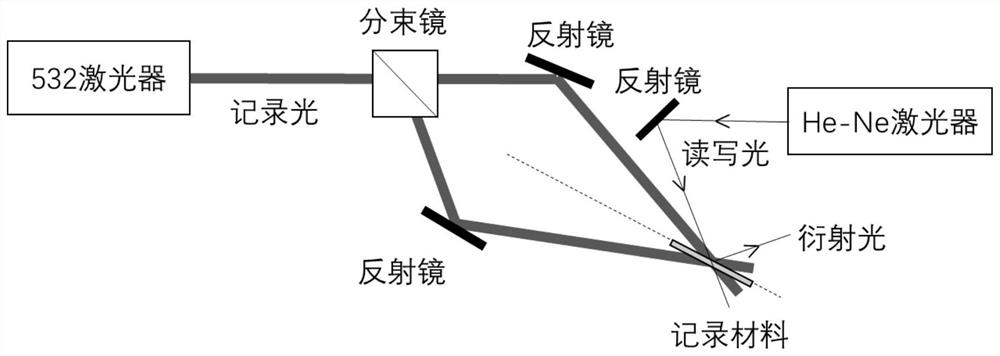

[0214] 3) Expose the dry plate obtained in step (2) with 532nm laser interference in a double-beam optical path (see attached figure 1 ), forming a holographic grating; using high laser intensity and short exposure time mode, the exposure energy density is 20mJ / cm 2 ;

[0215] 4) The holographic polymer grating obtained in step (3) can be completely fixed and bleached after being irradiated with natural light for about 30 minutes, and no post-processing is required.

[0216] The ...

Embodiment 2

[0222] The same method as in Example 1, but the exposure energy density is at 8mJ / cm 2 , and the resulting photopolymer dry film component content is shown in Table 2 below:

[0223] Table 2

[0224] composition content Basic Red 2 0.2% N-phenylglycine 0.8% 2-(4-Chlorophenyl)-4,5-diphenylimidazole 1% 2-naphthylthioethyl acrylate (n=1.620) 33% 9,9-bis(methylacrylate) fluorene (n=1.606) 11% Cellulose acetate butyrate (n=1.475) 22% N-vinylpyrrolidone 32%

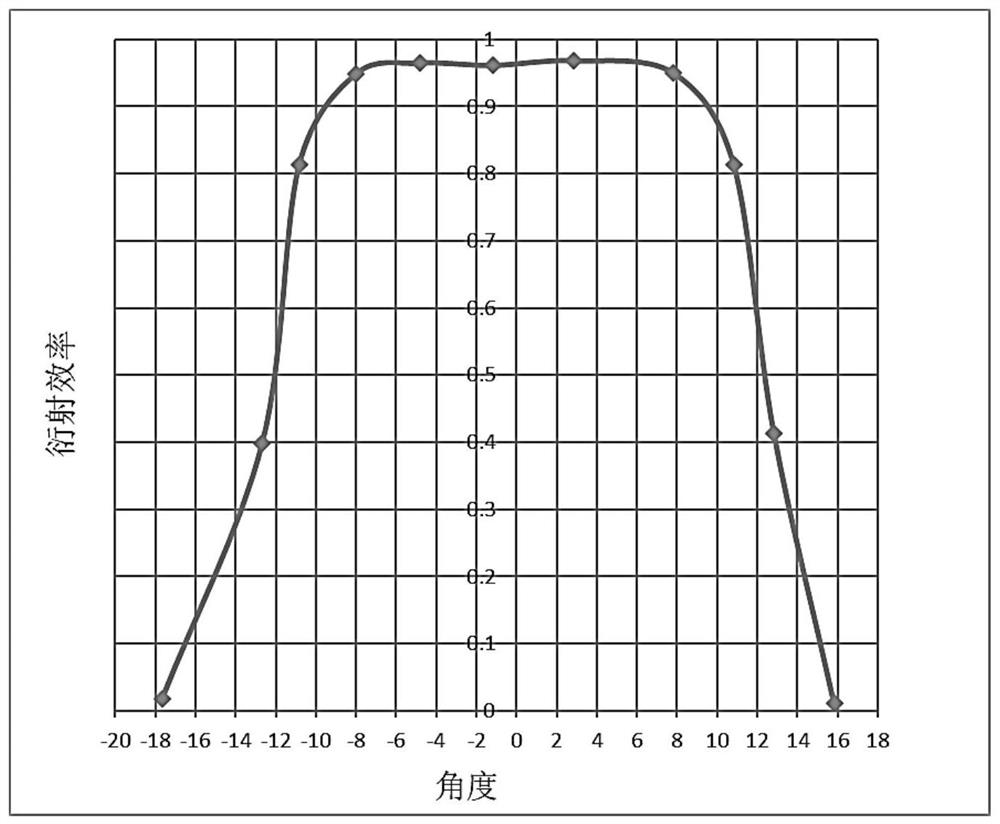

[0225] The reflective grating diffraction efficiency that present embodiment obtains is greater than 95% (see attached figure 2 ), the angular selectivity reaches ±12°, the exposure is sensitive, and the refractive index modulation reaches 0.08.

Embodiment 3

[0227] Same as embodiment 1 method, but the photopolymer dry film component content of gained is as shown in table 3 below:

[0228] table 3

[0229] composition content Basic Red 2 0.2% 4-Dimethylaminobenzoic acid ethyl ester 0.8% Diphenyliodonium hexafluorophosphate 1% 2-naphthyl acrylate (n=1.608) 39% 9,9-bis(methylacrylate) fluorene (n=1.606) 13% Cellulose acetate butyrate (n=1.475) 13% Glutaric anhydride 7% polyethylene glycol 26%

[0230] In this embodiment, polyethylene glycol is modified with glutaric anhydride and mixed with cellulose acetate butyrate, and the diffraction efficiency of the reflection grating obtained is greater than 85%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com