Multi-component photoinitiating system and photopolymer material

A photopolymer, light-induced technology, applied in the field of photosensitive materials, can solve the problems of monotonous two-dimensional information display, storage density close to the theoretical limit, and insufficient image information display.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

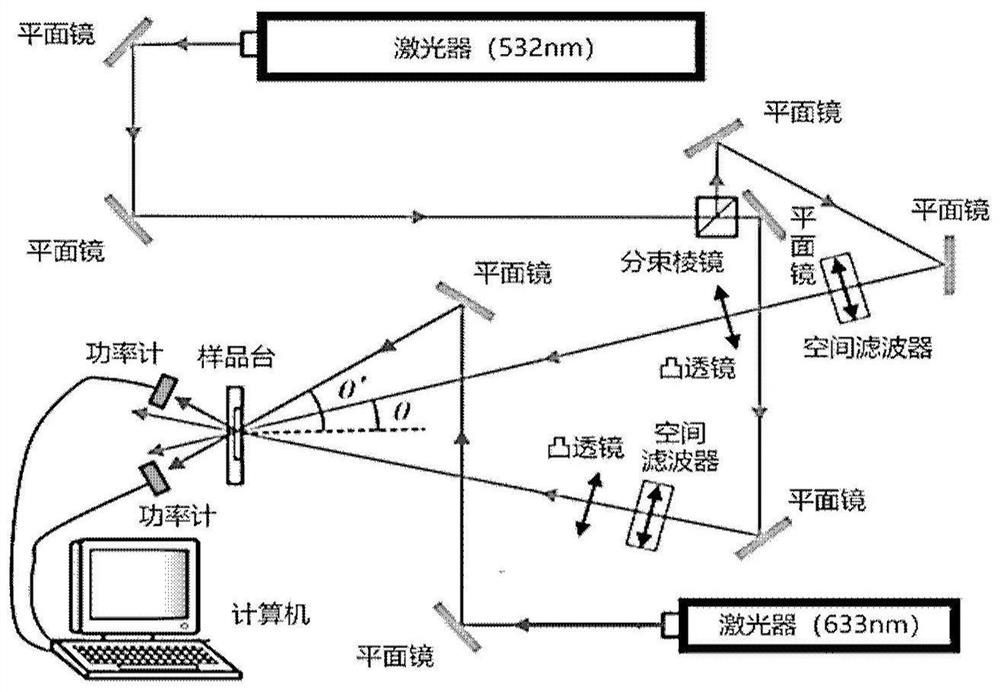

Method used

Image

Examples

Embodiment 1

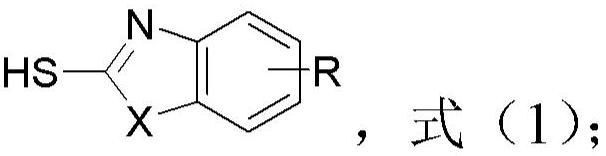

[0040] Step 1: Preparation of solvent-based photopolymer photosensitive liquid

[0041]Under a red safe light, according to the order of the method for preparing photopolymer materials involved in the present invention, film-forming agent PVAc 69.8wt%, photosensitizer BDMA 0.4wt%, nitrogen-containing condensed heterocyclic compound MBO with mercapto 2wt%, photoinitiator TCDM-HABI 8.8wt%, monomer POEA 8wt%, plasticizer tricresyl phosphate 11wt% dissolved in solvent DMF, and configured as a solvent-based photopolymer photosensitive liquid with a content of 15wt%.

[0042] Step 2: Preparation of solvent-based photopolymer film

[0043] Under the red safe light environment, take an appropriate amount of solvent-based photopolymer photosensitive liquid, apply it on the clean glass surface by drop coating, and dry it under heating at 40°C in the dark to obtain a final thickness of 60 μm. photopolymer films.

Embodiment 2

[0045] Step 1: Preparation of solvent-based photopolymer photosensitive liquid

[0046] Under the red safe lamp, according to the order of the method for preparing photopolymer material involved in the present invention, film-forming agent PVAc 77.5wt%, photosensitizer BDEA 0.5wt%, nitrogen-containing condensed heterocyclic compound MBO with mercapto 2.5wt%, photoinitiator o-Cl-HABI 10.3wt%, monomer POEA 9wt%, fluorosurfactant FC-4430 0.2% used as a leveling agent dissolved in the solvent DMF, configured to a content of 15wt% Solvent-based photopolymer photosensitive fluid.

[0047] Step 2: Preparation of solvent-based photopolymer film

[0048] Under the red safe light environment, take an appropriate amount of solvent-based photopolymer photosensitive liquid, apply it on the clean glass surface by drop coating, and dry it under heating at 40°C in the dark to obtain a final thickness of 60 μm. photopolymer films.

Embodiment 3

[0050] Step 1: Preparation of solvent-based photopolymer photosensitive liquid

[0051] Under the red safe light, according to the order of the method for preparing photopolymer material involved in the present invention, film-forming agent PVAc 77.5wt%, photosensitizer BDEA 0.5wt%, nitrogen-containing condensed heterocyclic compound MBI with mercapto 2.5wt%, photoinitiator o-Cl-HABI 10.5wt%, and monomer POEA 9wt% were dissolved in the solvent DMF to form a solvent-based photopolymer photosensitive liquid with a content of 15wt%.

[0052] Step 2: Preparation of solvent-based photopolymer film

[0053] Under the red safe light environment, take an appropriate amount of solvent-based photopolymer photosensitive liquid, apply it on the clean glass surface by drop coating, and dry it under heating at 40°C in the dark to obtain a final thickness of 60 μm. photopolymer films.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com