A kind of photothermographic refraction mid-infrared glass and its preparation method

An infrared glass and photothermographic technology, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of photobleaching, poor work stability, poor photosensitive stability of chalcogenide glass, etc., and achieve simple preparation process and environmental protection friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

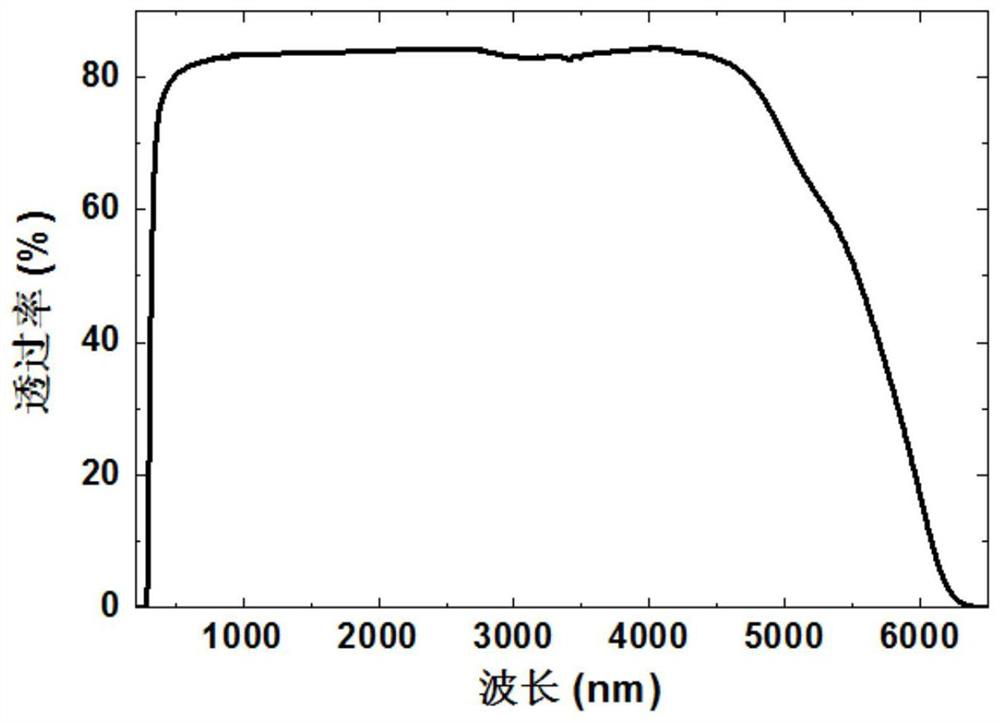

[0024] A photothermographic refractive mid-infrared glass made of the following molar percentages of raw materials: 79.97% GeO 2 , 5% Al 2 o 3 , 5% BaO, 5% ZnF 2 , 5% LiF, 0.02% MnF 2 , 0.01% Ag 2 O.

[0025] The preparation process is as follows: the compound GeO with a purity of 99.99% 2 、Al 2 o 3 , BaO, ZnF 2 , LiF, MnF 2 、Ag 2 O is the raw material, weigh each component according to the molar percentage of the glass composition, and configure the glass mixture; put the glass mixture into a platinum crucible and cover it, then put it in an electric furnace and heat it up to 1400°C and keep it warm for 3 hours. Melting, stirring the molten glass 6 times during the melting process; taking the platinum crucible out of the electric furnace, pouring the molten glass into a copper mold to cool to form glass, and then putting the glass into an electric furnace preheated to 500°C for annealing for 6 Hours, and finally cooled to room temperature at a rate of 1°C / min to ob...

Embodiment 2

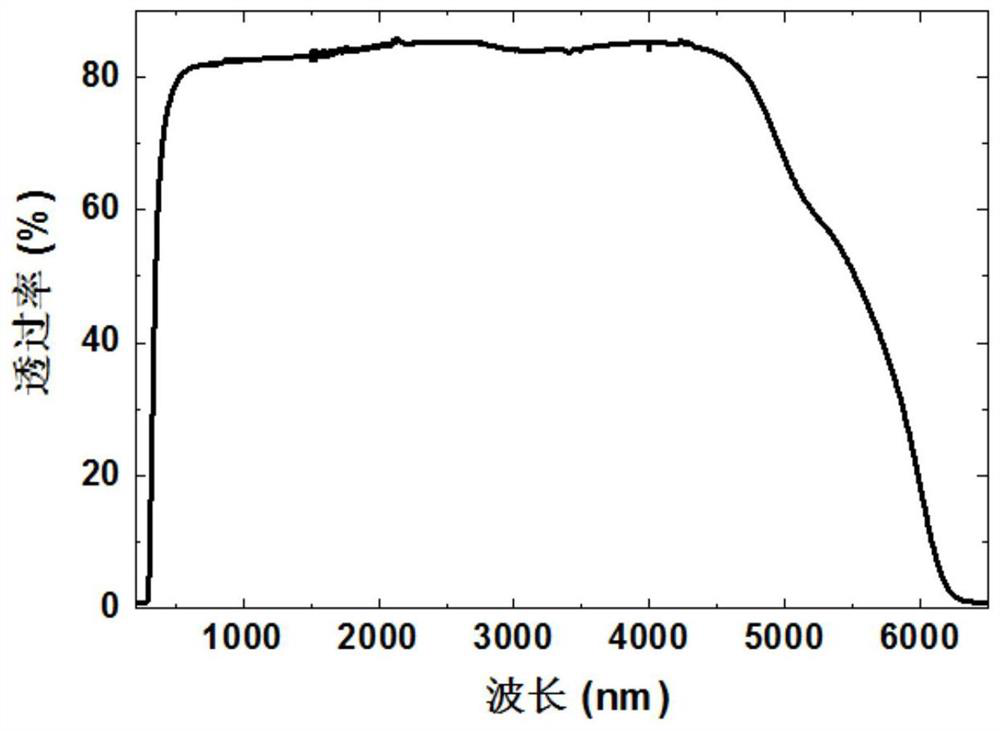

[0029] A photothermographic refractive mid-infrared glass made of the following molar percentages of raw materials: 60% GeO 2 , 10% Ga 2 o 3 , 18% ZnO, 6% BaF 2 , 5.9% NaF, 0.04% MnF 2 , 0.06% Ag 2 O.

[0030] The preparation process is as follows: the compound GeO with a purity of 99.99% 2 , Ga 2 o 3 , ZnO, BaF 2 , NaF, MnF 2 、Ag 2 O is the raw material, weigh each component according to the mole percentage of the glass composition, and configure the glass mixture; put the glass mixture into a platinum crucible and cover it, then put it in an electric furnace and heat it up to 1300°C and keep it warm for 2 hours. Melting, stirring the molten glass 4 times during the melting process; taking the platinum crucible out of the electric furnace, pouring the molten glass into a copper mold to cool to form glass, and then putting the glass into an electric furnace preheated to 475°C for annealing 4 Hours, and finally cooled to room temperature at a rate of 0.5°C / min to obt...

Embodiment 3

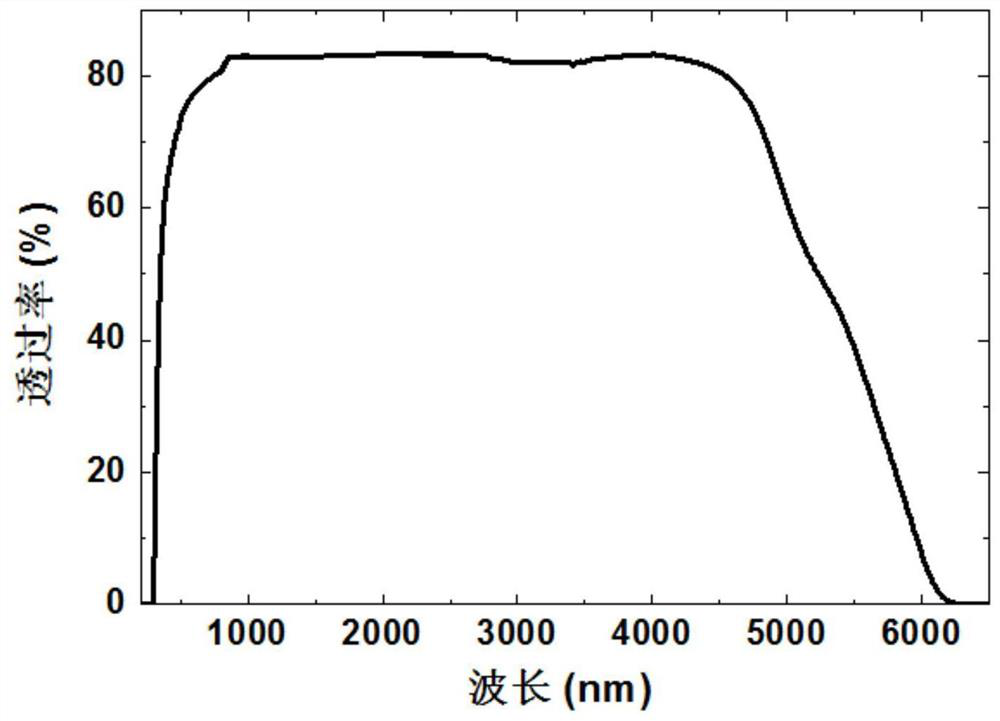

[0034] A photothermographic refractive mid-infrared glass made of the following molar percentages of raw materials: 65% GeO 2 , 6% Ga 2 o 3 , 8.9% BaO, 10% ZnF 2 , 10% KF, 0.1% MnF 2 , 0.1% Ag 2 O.

[0035] The preparation process is as follows: the compound GeO with a purity of 99.99% 2 , Ga 2 o 3 , BaO, ZnF 2 , KF, MnF 2 、Ag 2 O is the raw material, weigh each component according to the mole percentage of the glass composition, and configure the glass mixture; put the glass mixture into a platinum crucible and cover it, then put it in an electric furnace and heat it up to 1200°C and keep it warm for 1 hour. Melting, stirring the molten glass 3 times during the melting process; taking the platinum crucible out of the electric furnace, pouring the molten glass into a copper mold to cool to form glass, and then putting the glass into an electric furnace preheated to 460°C for annealing 2 Hours, and finally cooled to room temperature at a rate of 0.2°C / min to obtain p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com