Photopolymer composition, episulfide/epoxy writing monomer, and grating

A technology of photopolymer and writing monomer, applied in the field of optical materials, can solve the problems of reducing the solubility of materials, poor stability of iodine, affecting the optical properties of polymers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0088]The present invention also provides a method for preparing a grating, including: S1) mixing the above-mentioned photopolymer composition to obtain a hybrid; S2) forming a film on the hybrid and forming a grating structure to obtain a grating.

[0089]The above-mentioned photopolymer composition is mixed to obtain a mixture. In some specific embodiments of the present invention, a mixture in the form of a melt or a liquid is obtained by mixing the photopolymer composition.

[0090]In the present invention, the composition can be mixed in a suitable container in proportions, and when necessary, mechanical stirring or other methods can be used to make the mixing uniform. There is no particular restriction on the mixing temperature. Generally, the mixing can be carried out under ambient conditions at room temperature or under heating (preheating).

[0091]In some other specific embodiments, the mixing step may be performed under appropriate heating conditions. The heating temperature can b...

Embodiment 1

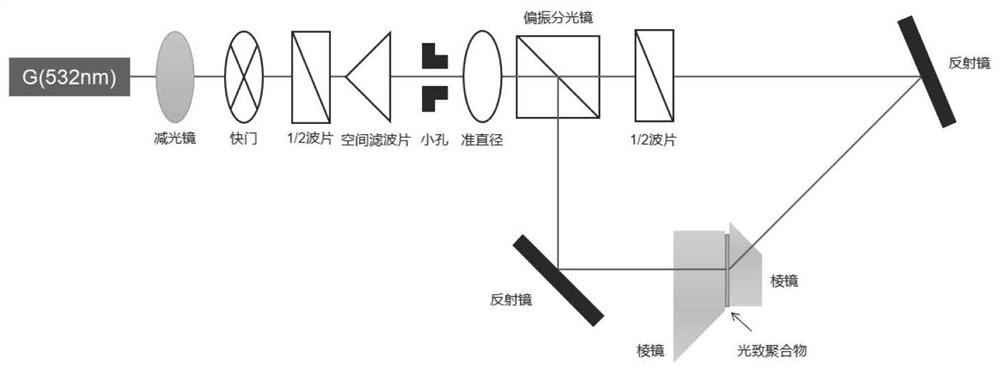

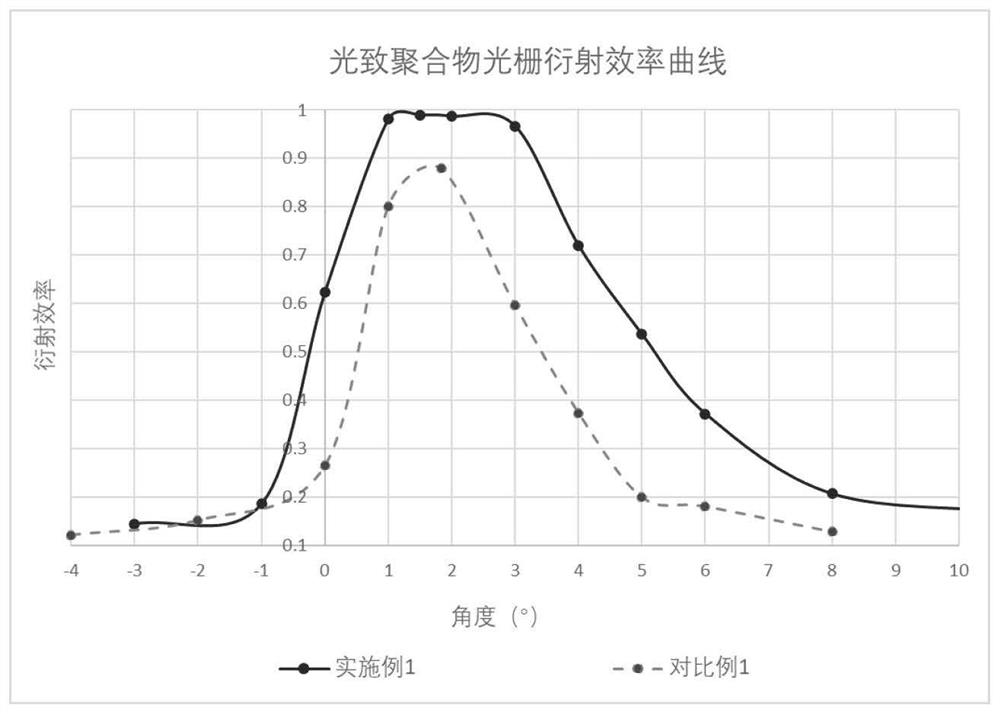

[0106]Add compound 1 (Z and Z'are both S), 9,9-bis(methyl acrylate) fluorene, solvent butyl acetate, film-forming agent cellulose acetate butyrate, and initiator N-benzene into the sample bottle Glycine and 2-(4-chlorophenyl)-4,5-diphenylimidazole, after stirring at room temperature until completely clear, add the dye Eosin Y in the dark or under red light and stir for 30min to obtain uniform and clear light Polymer solution (the ratio of all ingredients is shown in the table below). Then coat the mixed solution on a 1mm thick glass substrate under dark or red light, with a coating thickness of about 20μm, and let it stand horizontally until the dye is completely volatilized and cover the surface with a 40μm thick TAC protective film to obtain photopolymerization Material dry board. The final dry board is infigure 2 The energy density used in the double beam optical path shown is 15mJ / cm2532nm laser interference exposure, irradiated by a green LED lamp for about 30 minutes, fixed an...

Embodiment 2

[0111]Add compound 2 (Z is S), compound 3 (Z and Z'are both S), solvent butyl acetate, film forming agent cellulose acetate butyrate, initiator N-phenylglycine and 2-( 4-Chlorophenyl)-4,5-diphenylimidazole, after stirring at room temperature until completely clear, add the dye Eosin Y under dark or red light and stir for 30min to obtain a uniform and clear photopolymer solution (all components The ratio is shown in the table below). Subsequently, the mixed solution was coated on a 1mm thick glass substrate under dark or red light, with a coating thickness of about 20μm. After the dye was completely volatilized, it was placed horizontally and covered with a TAC protective film with a thickness of 40μm. Polymer dry board. The final dry board is infigure 2 The energy density used in the double beam optical path shown is 15mJ / cm2532nm laser interference exposure, irradiated by a green LED lamp for about 30 minutes, fixed and bleached to form a reflective holographic grating.

[0112] co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com