Method for making fibre-optical grating for sensing detection

A fiber grating and manufacturing method technology, applied in the field of optoelectronics, can solve the problems of low pressure and temperature response sensitivity, and achieve the effect of wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

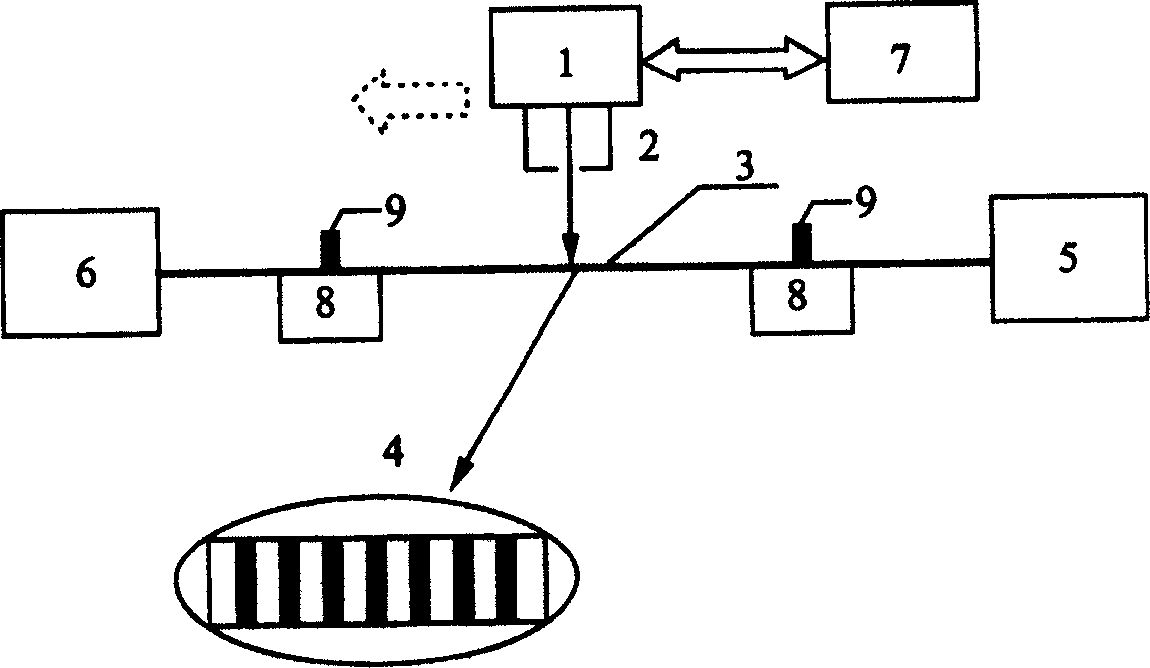

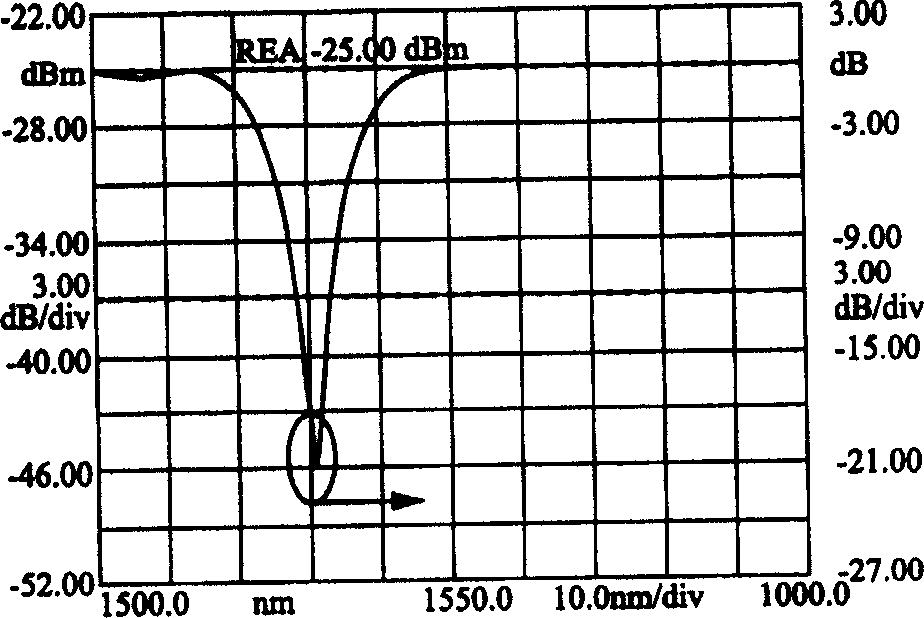

[0037] Since the silicon fiber is sensitive to temperature changes, a Corning SMF-28 silicon fiber was selected, CO 2 The output power of the pulsed laser is 10W, using the device figure 1 The long-period fiber grating used for sensing and detecting temperature is produced. The period of the LPFG is Λ=450 μm, the number of periods is 500, the resonant wavelength λ=1530.82nm in its free state, and the transmission peak is 21.09dB. Its transmission spectrum is as figure 2 as shown,

[0038]The written LPFG is encapsulated with temperature-sensitive material epoxy resin polymer material.

Embodiment 2

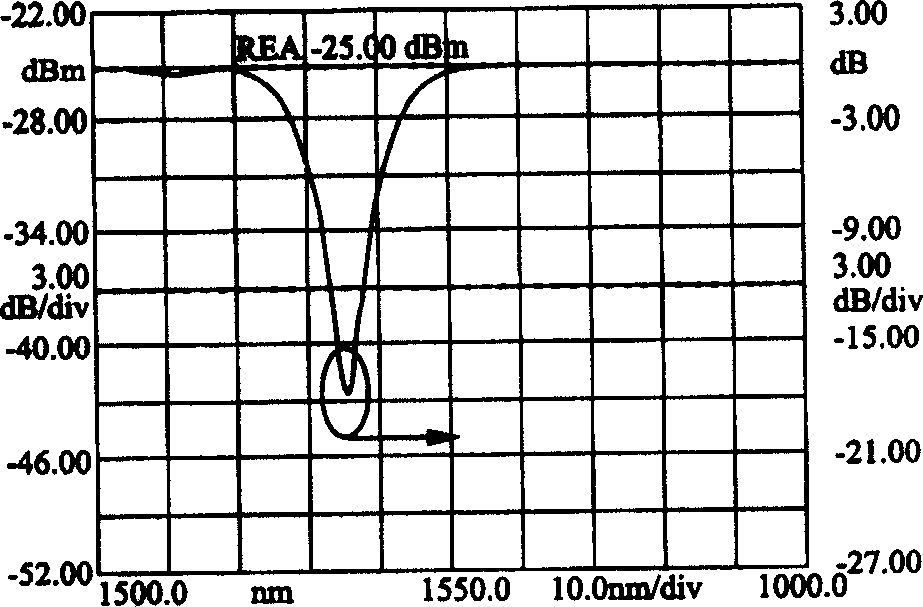

[0040] In order to enhance the mechanical strength of the fiber grating, a silicon fiber with a large core diameter is selected. 2 The output power of the pulsed laser is 20W, using the device figure 1 The long-period fiber grating used for sensing and detecting temperature is manufactured. The period Λ of the LPFG is 600 μm, and the number of periods is 500. Its transmission spectrum is as follows: image 3 shown.

[0041] Encapsulate the written LPFG with temperature-sensitive polyamide fiber polymer material.

Embodiment 3

[0043] Since the plastic optical fiber is sensitive to pressure changes, an anti-fatigue plastic optical fiber is selected, CO 2 The output power of the pulsed laser is 10W, using the device figure 1 Fabricated long-period fiber gratings for sensing and detecting pressure. The period Λ of this LPFG is 450μm, and the number of periods is 500, and its transmission spectrum is as follows Figure 4 shown.

[0044] The written LPFG is encapsulated with the pressure-sensitive material Teflon.

[0045] In addition to the above-mentioned various embodiments, using the method described in this patent, it is also possible to fabricate long-period fiber gratings for sensing tests with different wavelengths and characteristics in single-mode fibers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com