1,3-propane sultone preparation method

A technology of propane sultone and hydroxypropanesulfonic acid, which is applied in the field of synthesis of pharmaceutical intermediates, can solve the problem that 1,3-propane sultone is difficult to meet market demand, the overall yield is not high, and it is unfavorable to scale up production, etc. problems, to achieve the effect of environmentally friendly process, short process route and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

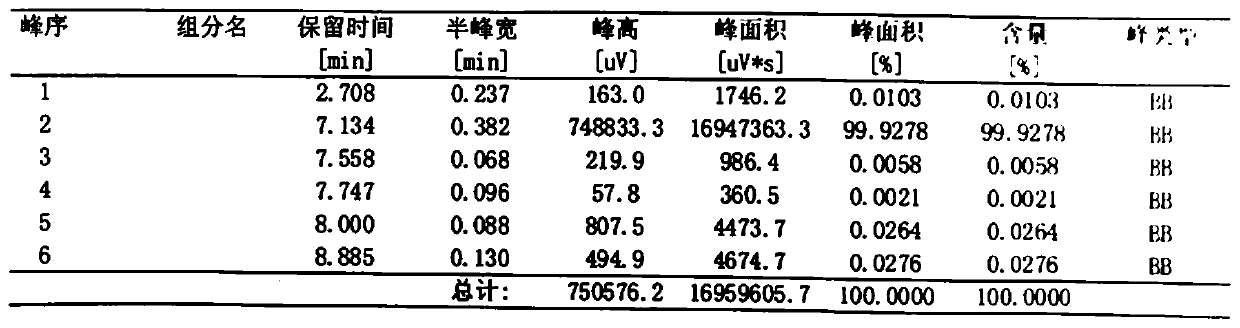

Examples

Embodiment 1

[0034] A kind of preparation method of 1,3-propane sultone, it comprises the steps:

[0035] S1. Put 1 mol of 3-chloropropanol and sodium sulfite solution (concentration is 10wt%) into the reaction vessel and mix thoroughly. The ratio of the amount of 3-chloropropanol to sodium sulfite is 1:1.5, and the temperature is controlled at 25°C. After reacting for 48h, dehydration and concentration under reduced pressure at a vacuum degree of -0.08MPa and 90°C. Then add concentrated hydrochloric acid (concentration: 30wt%) to the concentrated solution for acidification, the ratio of HCl to 3-chloropropanol in the added concentrated hydrochloric acid is 3:1, control the temperature at 25°C and stir for 12h, then filter , the filtrate is concentrated to obtain a concentrated solution containing 3-hydroxypropanesulfonic acid;

[0036] S2. The concentrated solution was distilled under reduced pressure at 40-110°C (vacuum degree is -0.05MPa) to dehydrate and ring-close 3-hydroxypropanesul...

Embodiment 2

[0039] A kind of preparation method of 1,3-propane sultone, it comprises the steps:

[0040] S1. Put 1mol of 3-chloropropanol and sodium sulfite solution (concentration is 20wt%) into the reaction vessel and mix thoroughly, the ratio of the amount of 3-chloropropanol to sodium sulfite is 1:1.2, and the temperature is controlled at 90°C. After reacting for 12 hours, dehydration and concentration under reduced pressure at a vacuum degree of -0.08MPa and 85°C. Then add concentrated hydrochloric acid (concentration is 33.5wt%) acidification in concentrated solution, the ratio of the substance amount of HCl and 3-chloropropanol in the added concentrated hydrochloric acid is 2:1, control temperature at 60 ℃ and stir 8h, then Filtrate, and concentrate the filtrate to obtain a concentrated solution containing 3-hydroxypropanesulfonic acid;

[0041] S2. Distill the concentrated solution under reduced pressure at 40-110°C (vacuum degree is -0.05MPa) to dehydrate and ring-close 3-hydrox...

Embodiment 3

[0044] A kind of preparation method of 1,3-propane sultone, it comprises the steps:

[0045] S1. Put 1mol of 3-chloropropanol and sodium sulfite solution (concentration is 30wt%) into the reaction vessel and mix thoroughly, the ratio of the amount of 3-chloropropanol to sodium sulfite is 1:1.0, and the temperature is controlled at 120°C. After reacting for 4h, dehydration and concentration under reduced pressure at a vacuum degree of -0.1MPa and 80°C. Then add concentrated hydrochloric acid (concentration: 36wt%) to the concentrated solution for acidification, the ratio of HCl to 3-chloropropanol in the added concentrated hydrochloric acid is 1:1, control the temperature at 80°C and stir for 2h, then filter , the filtrate is concentrated to obtain a concentrated solution containing 3-hydroxypropanesulfonic acid;

[0046] S2. Distill the concentrated solution under reduced pressure at 40-110°C (vacuum degree is -0.05MPa) to dehydrate and ring-close 3-hydroxypropanesulfonic aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com