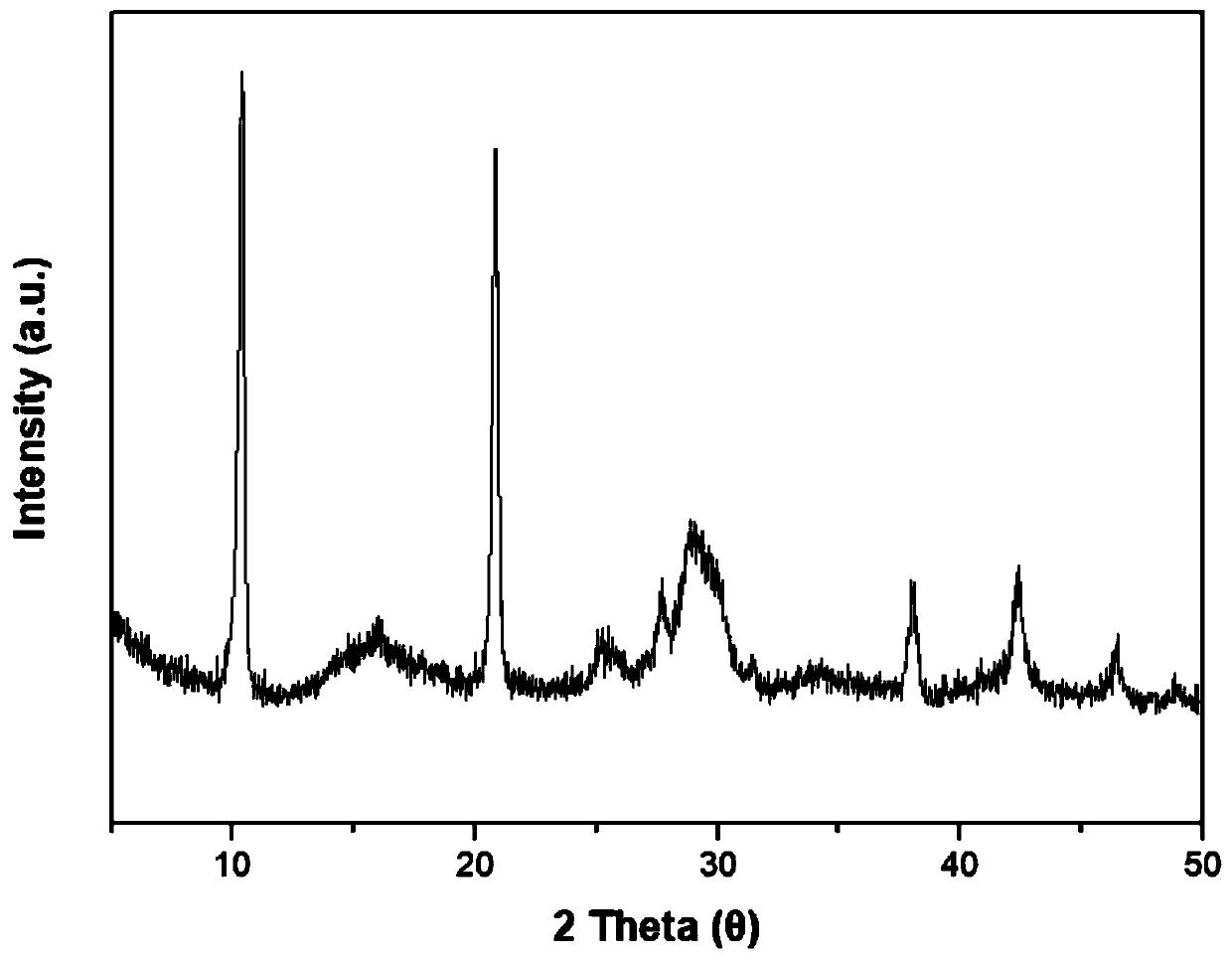

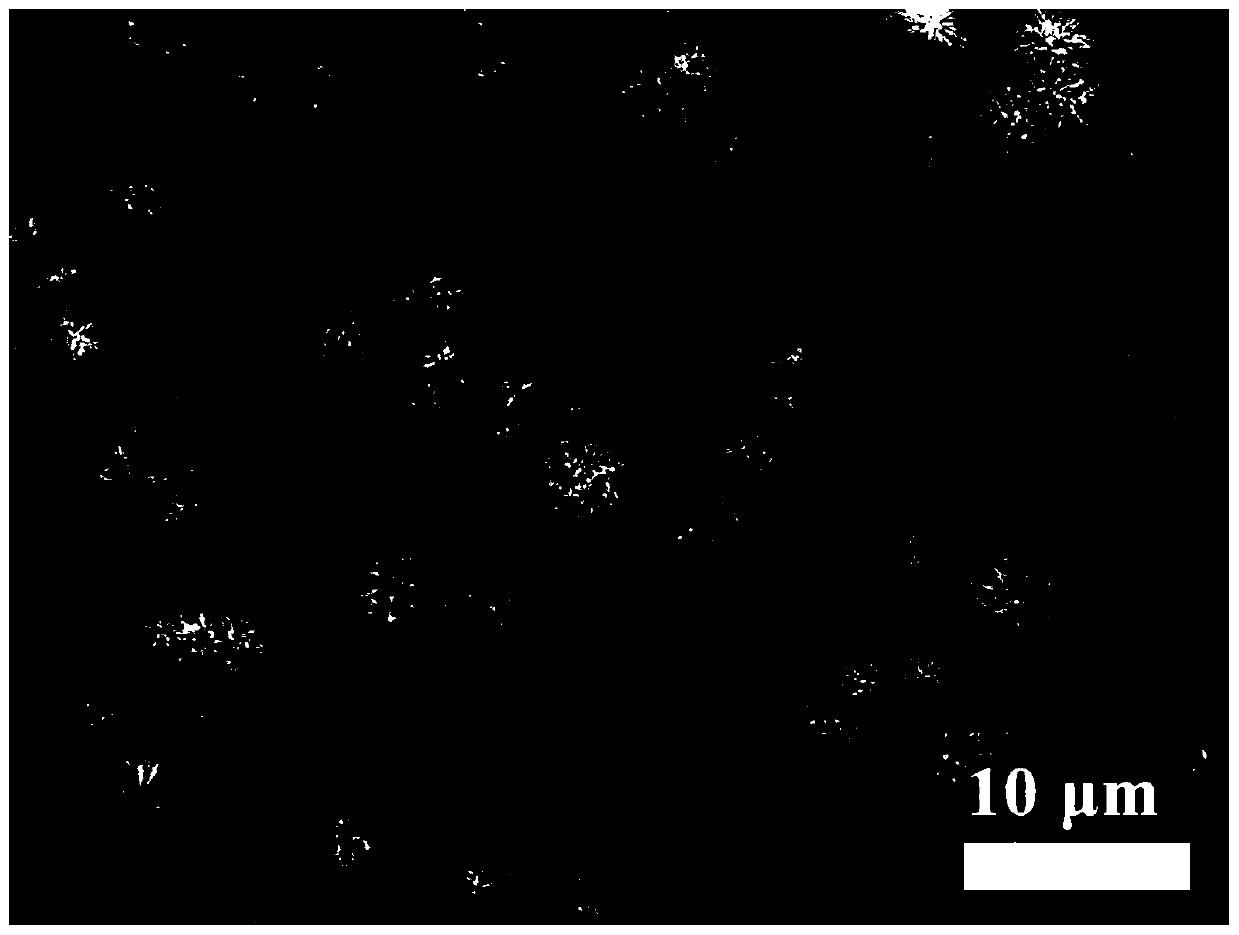

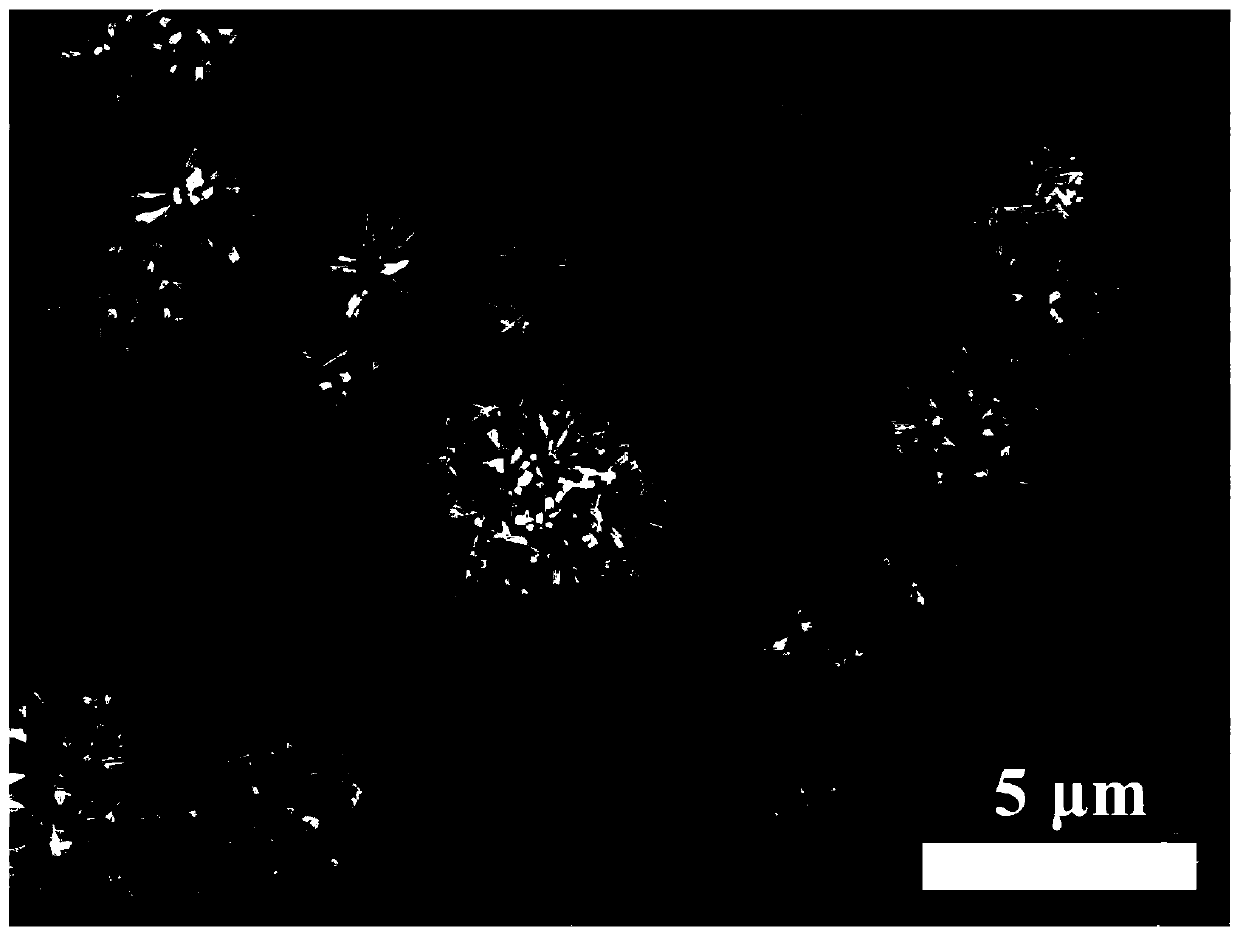

Application of chestnut-shaped graded manganese selenide/carbon composite material as lithium ion battery anode material

A technology of carbon composite materials and lithium-ion batteries, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of complex preparation methods and processes of manganese selenide, difficulty in preparing single-phase manganese selenide, and difficulty in large-scale production, etc. problem, to achieve the effect of promoting fast ion transmission, shortening ion diffusion path, and environmental protection yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Take 10mmol manganese acetate dihydrate (Aladdin reagent, chemically pure) and 3.25g polyvinylpyrrolidone dissolved in 75mL absolute ethanol / deionized water (volume ratio 1:1), take 13.4mmol trimesic acid (Aladdin Reagents, chemically pure) and 3.25g polyvinylpyrrolidone were dissolved in 75mL absolute ethanol / deionized water (volume ratio 1:1), and the two were continuously stirred until completely dissolved. The trimesic acid / polyvinylpyrrolidone solution was slowly added dropwise to the manganese acetate / polyvinylpyrrolidone solution at 1ml / min with constant stirring. A white suspension was observed gradually in the solution. After the dropwise addition is completed, stir at room temperature for 20 min. The resulting suspension was allowed to stand at room temperature for 6 hours, washed with ethanol and deionized water for three times, and then put into an oven and kept at 60°C for 12 hours to obtain a manganese-based metal organic framework.

[0041] Take 100mg of t...

Embodiment 2

[0047] Dissolve 20mmol manganese acetate dihydrate (Aladdin reagent, chemically pure) and 7.5g polyvinylpyrrolidone in 75mL absolute ethanol / deionized water (volume ratio 1:1), take 13.4mmol trimesic acid (Aladdin) Reagent, chemically pure) and 7.5g polyvinylpyrrolidone were dissolved in 75mL absolute ethanol / deionized water (volume ratio 1:1), and the two were continuously stirred until completely dissolved. The trimesic acid / polyvinylpyrrolidone solution was slowly added dropwise to the manganese acetate / polyvinylpyrrolidone solution at 0.5ml / min with constant stirring. A white suspension was observed gradually in the solution. After the dropwise addition is completed, stir at room temperature for 20 min. The resulting suspension was allowed to stand at room temperature for 24 hours, washed with ethanol and deionized water three times, and then put into an oven, and kept at 60° C. for 12 hours to obtain a manganese-based metal organic framework.

[0048] Take 100mg of the obt...

Embodiment 3

[0051] Dissolve 20mmol of anhydrous manganese acetate or manganese acetate dihydrate (Aladdin's reagent, chemically pure) and 15g of polyvinylpyrrolidone in 150mL of water, and take 26.8mmol of trimesic acid (Aladdin's reagent, chemically pure) in 150mL of anhydrous In ethanol, the two were continuously stirred until completely dissolved. The trimesic acid solution was slowly added dropwise to the manganese acetate / polyvinylpyrrolidone solution at 1ml / min with constant stirring. A white suspension was observed gradually in the solution. After the dropwise addition is completed, stir at room temperature for 20 min. The resulting suspension was allowed to stand at room temperature for 24 hours, washed with ethanol and deionized water three times, and then put into an oven, and kept at 60° C. for 12 hours to obtain a manganese-based metal organic framework.

[0052] Take 200mg of the manganese-based metal organic frame and 1g of selenium powder and put them in two high-temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com