Electrode material in hollow tubular structure, and preparation method for electrode material

A technology of tubular structure and electrode material, which is applied in the field of hollow tubular structure electrode material and its preparation, can solve problems such as insufficient, achieve the effect of shortening the path, good supercapacitive performance, and accelerating effective transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

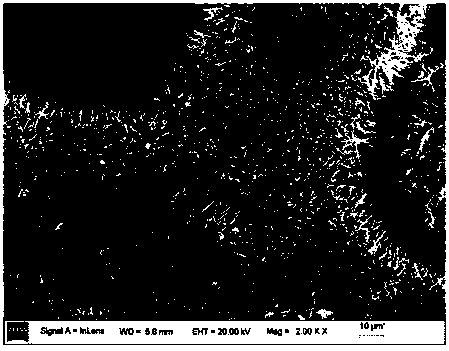

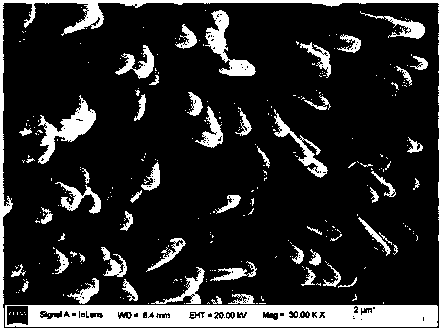

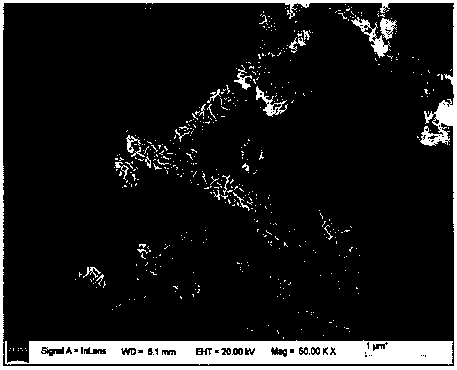

Image

Examples

Embodiment 1

[0044] A. Pretreatment of copper foam.

[0045] Use copper foam with a purity greater than 90% as raw material, cut into 4.0*3.0cm 2 Slices of the same size were ultrasonically cleaned with 10% hydrochloric acid for 5 minutes, rinsed with deionized water and absolute ethanol respectively, and dried in an oven at 60°C for later use.

[0046] B. Weigh 10.0g of sodium hydroxide and 2.28g of ammonium persulfate and dissolve them in 100mL of deionized water to form a mixed solution with a concentration of 2.5mol / L and 0.1mol / L respectively. After dipping the substrate in the mixed solution for 20 minutes, take it out, rinse it with deionized water, and dry it in an oven at 60°C for later use. Then, copper hydroxide nanorods can be grown on the foamed copper substrate.

[0047] C. Weigh 2.18g of nickel nitrate and 2.18g of cobalt nitrate and dissolve them in 50mL of deionized water as the electrolyte solution. The copper hydroxide / copper foam obtained in step B is used as a workin...

Embodiment 2

[0049] A. Select a copper mesh with a purity greater than 99% and cut it into 4.0*3.0cm 2 The sheet of area size is processed with the processing method of embodiment 1.

[0050] B. Weigh 5.0g of sodium hydroxide and 1.85g of ammonium persulfate, dissolve them in 100mL of deionized water to make a mixed solution, immerse the pretreated copper mesh substrate in the mixed solution for 25min, take it out, and use Rinse with deionized water and dry in an oven at 60°C for later use.

[0051] C. Weigh 1.09g of cobalt nitrate and 0.41g of ferric chloride and dissolve them in 50mL of deionized water as an electrolyte solution. The copper hydroxide / copper grid obtained in step B is used as a working electrode, Pt is used as a counter electrode, and Ag / AgCl is used as a reference electrode. Co 0.5 Fe 0.33 (OH) 2 Cobalt-iron composite hydroxide / copper hydroxide / copper mesh tubular structure material.

Embodiment 3

[0053] A. With embodiment 1.

[0054] B. Weigh 5.0g of sodium hydroxide and 1.44g of ammonium persulfate, dissolve them in 100mL of deionized water to make a mixed solution, immerse the pretreated foamed copper substrate in the mixed solution for 30min, take it out, and use Rinse with deionized water and dry in an oven at 45°C for later use.

[0055] C. Weigh 1.09g of nickel nitrate and 0.60g of ferric sulfate, and dissolve them in 50mL of deionized water as an electrolyte solution. The copper hydroxide / copper foam obtained in step B is used as a working electrode, Pt is used as a counter electrode, and Ag / AgCl is used as a reference electrode. Ni 0.625 Fe 0.25 (OH) 2 Nickel-iron composite hydroxide / copper hydroxide / copper foam hollow tubular structure material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com