PP/POE supercritical foaming composite material and preparation method thereof

A composite material and supercritical technology, which is applied in the field of PP/POE supercritical foam composite material and its preparation, can solve the problems of poor sealing, low foaming ratio, uneven cells, etc., and achieve optimal mechanical properties , Improve the tensile strength and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

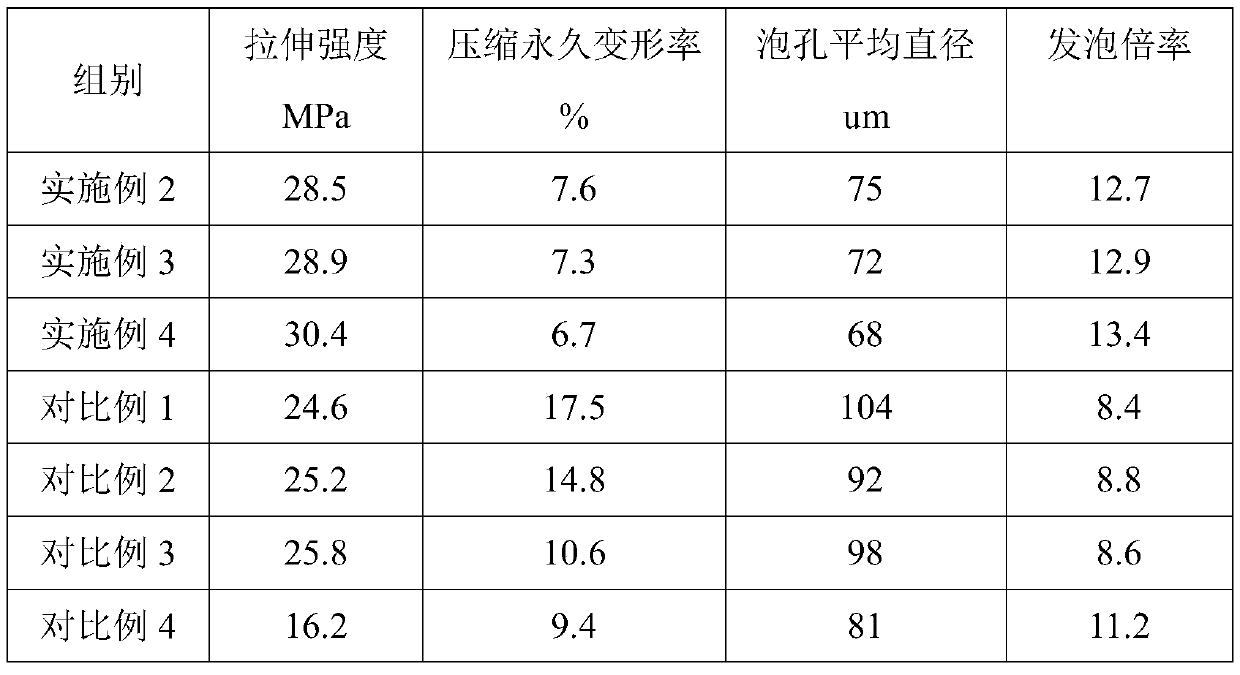

Examples

Embodiment 1

[0052] A PP / POE supercritical foam composite material, comprising the following raw materials in parts by weight:

[0053] 140-165 parts of polypropylene,

[0054] 35-42 parts of polyolefin elastomer,

[0055] 10-14 parts of maleic anhydride grafted polypropylene,

[0056] 10-14 parts of maleic anhydride grafted polypropylene modifier,

[0057] 2 to 3 parts of nucleating agent,

[0058] 8-12 parts of mesoporous silica,

[0059] 1.5-2 parts of dispersant,

[0060] 0.8-1.2 parts of cross-linking agent.

[0061] In this embodiment, the PP / POE supercritical foam composite material is preferably but not limited to include the following raw materials in parts by weight:

[0062] 153 parts of polypropylene,

[0063] 38.5 parts of polyolefin elastomer,

[0064] 12 parts of maleic anhydride grafted polypropylene,

[0065] 12 parts of maleic anhydride grafted polypropylene modifier,

[0066] 2.5 parts of nucleating agent,

[0067] Mesoporous silica 10 parts,

[0068] 1.8 par...

Embodiment 2

[0085] A PP / POE supercritical foam composite material, comprising the following raw materials in parts by weight:

[0086] 140 parts of polypropylene,

[0087] 35 parts of polyolefin elastomer,

[0088] 10 parts of maleic anhydride grafted polypropylene,

[0089] 10 parts of maleic anhydride grafted polypropylene modifier,

[0090] 2 parts of nucleating agent,

[0091] Mesoporous silica 8 parts,

[0092] 1.5 parts of dispersant,

[0093] 0.8 parts of crosslinking agent.

[0094] In this embodiment, the polyolefin elastomer is a mixture of ethylene-butene copolymer and ethylene-octene copolymer, and the mass ratio of the two is 1:0.4.

[0095] In this example, the maleic anhydride-grafted polypropylene modifier is a polypropylene-grafted polypropylene modifier prepared by reacting epoxy-group-containing polysiloxane with maleic anhydride-grafted polypropylene at a mass ratio of 1:2.4. branch silicon-containing copolymers.

[0096] In this embodiment, the pore diameter o...

Embodiment 3

[0108] A PP / POE supercritical foam composite material, comprising the following raw materials in parts by weight:

[0109] 165 parts of polypropylene,

[0110] 42 parts of polyolefin elastomer,

[0111] 14 parts of maleic anhydride grafted polypropylene,

[0112] 14 parts of maleic anhydride grafted polypropylene modifier,

[0113] 3 parts of nucleating agent,

[0114] Mesoporous silica 12 parts,

[0115] 2 parts of dispersant,

[0116] 1.2 parts of crosslinking agent.

[0117] In this embodiment, the polyolefin elastomer is a mixture of ethylene-butene copolymer and ethylene-octene copolymer, and the mass ratio of the two is 1:0.5.

[0118] In this example, the maleic anhydride-grafted polypropylene modifier is a polypropylene-grafted modifier prepared by reacting epoxy-group-containing polysiloxane with maleic anhydride-grafted polypropylene at a mass ratio of 1:3.2. branch silicon-containing copolymers.

[0119] In this embodiment, the pore diameter of the mesoporou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com