A kind of composite current collector and preparation method thereof

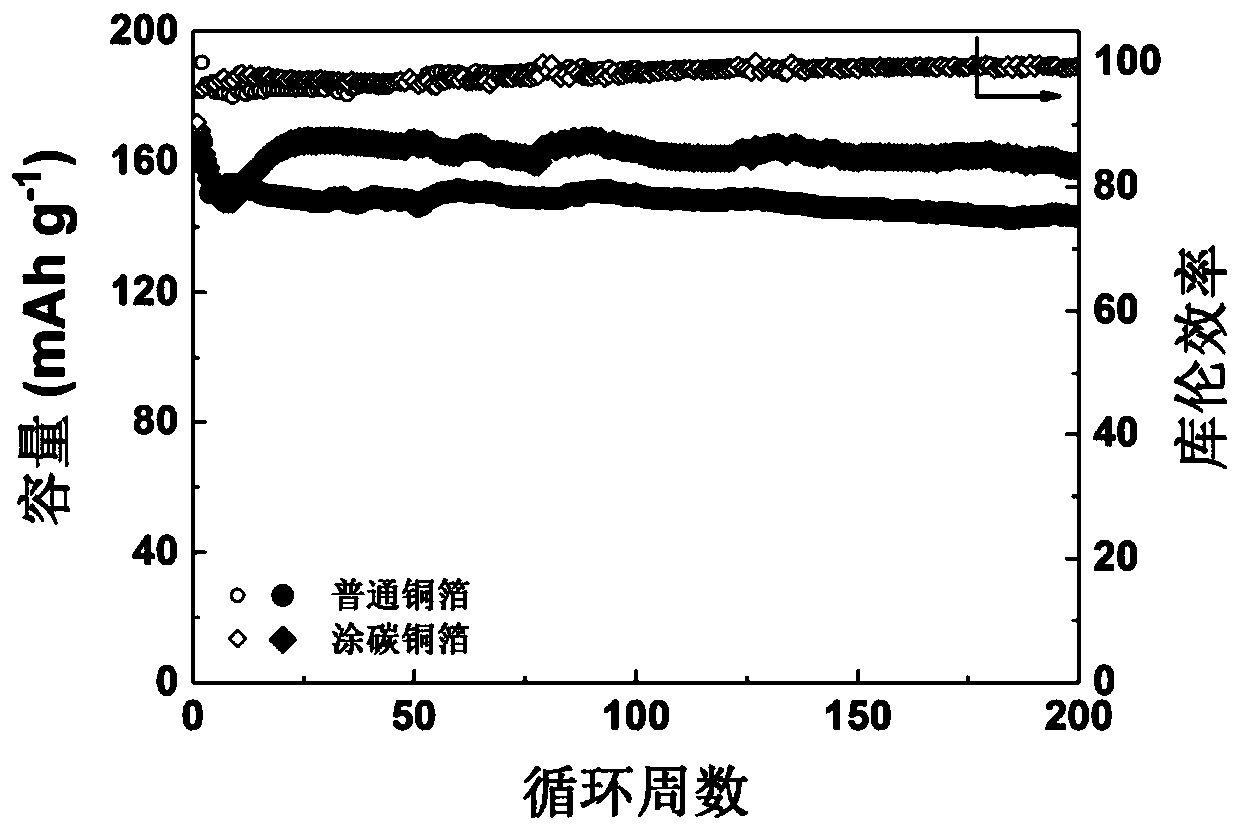

A current collector and drying technology, which is applied in the field of composite current collectors and its preparation, can solve the problems of limited contact resistance reduction capability, large-area material drop of pole pieces, and reduced product qualification rate, and achieves not easy to fall off, uniform pore size distribution, The effect of long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1. A method for preparing a composite current collector, comprising the steps of:

[0041] (1) Copper foil pretreatment: the copper foil is respectively cleaned in ethanol, acetone and deionized water in an ultrasonic cleaner to remove oil from the current collector, and dried in a vacuum drying oven at 80°C for 10 minutes.

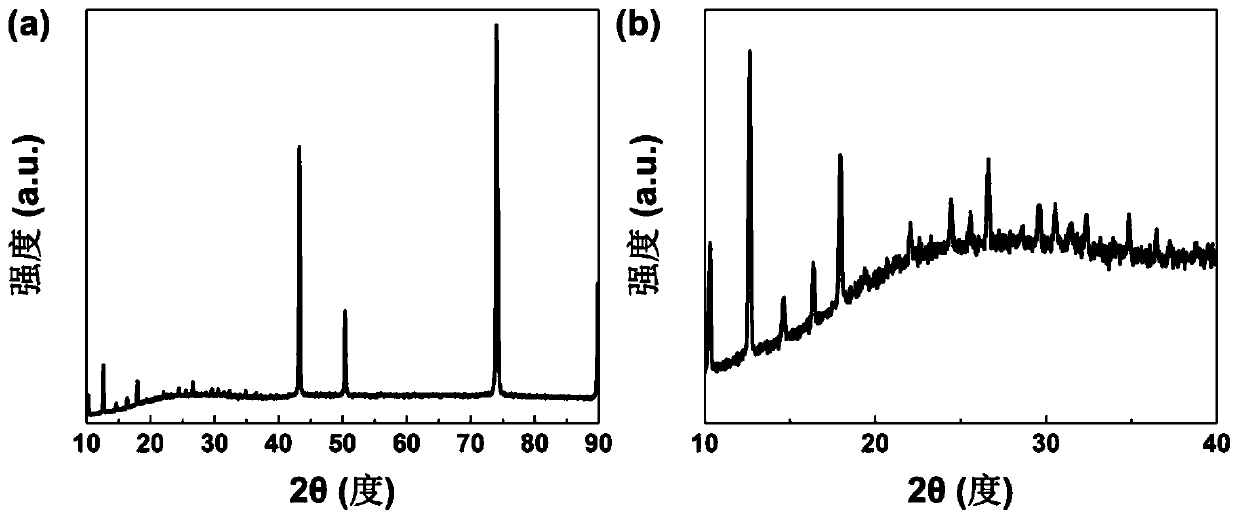

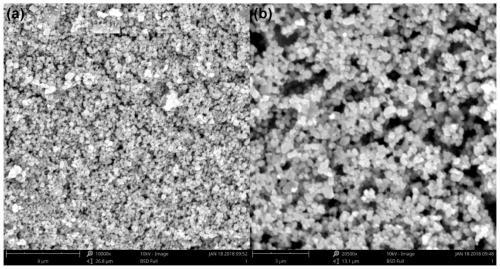

[0042] (2) Coating carbon slurry: Prepare MOF-Co solution: take 0.3mmol potassium naphthalate and 0.3mmol cobalt nitrate, add 100ml of water, then put in the treated copper foil, and react at 80°C for 20h.

[0043] (3) Dry carbonization: first place the copper foil in step (2) in a vacuum drying oven, and dry it at 60° C. for 10 minutes, then place the copper foil in an argon atmosphere, and react at 600° C. for 10 hours.

[0044] (4) Pickling: Soak the copper foil in step (3) with 1 mol / L hydrochloric acid to obtain a copper foil with a carbon coating on the surface.

[0045] 2. A method for preparing a negative electrode material, comprising the...

Embodiment 2

[0048] 1. A method for preparing a composite current collector, comprising the steps of:

[0049] (1) Copper foil pretreatment: the copper foil is respectively cleaned in ethanol, acetone and deionized water in an ultrasonic cleaner to remove oil from the current collector, and dried in a vacuum drying oven at 60°C for 20 minutes.

[0050] (2) Coating carbon slurry: Prepare MOF-Co solution: take 0.3mmol potassium naphthalate and 0.3mmol cobalt nitrate, add 100ml of water, then put in the treated copper foil, and react at 100°C for 15h.

[0051] (3) Dry carbonization: first place the copper foil in step (2) in a vacuum drying oven, dry at 60°C for 10 minutes, then place the copper foil in an argon atmosphere, and react at 800°C for 5 hours.

[0052] (4) Pickling: Soak the copper foil in step (3) with 1 mol / L sulfuric acid to obtain a copper foil with a carbon coating on the surface.

[0053]2. A method for preparing a negative electrode material, comprising the following steps...

Embodiment 3

[0056] 1. A method for preparing a composite current collector, comprising the steps of:

[0057] (1) Copper foil pretreatment: the aluminum foil is respectively cleaned in ethanol, acetone and deionized water in an ultrasonic cleaner to remove oil from the current collector, and dried in a vacuum drying oven at 80°C for 10 minutes.

[0058] (2) Coating carbon slurry: configure MOF-Al solution, 0.01mol of aluminum nitrate nonahydrate and 0.01mol of terephthalic acid, add 65ml of N-N-dimethylformamide (DMF) to dissolve, put into aluminum foil, 220 ℃ heating 20h.

[0059] (3) Dry carbonization: first place the copper foil in step (2) in a vacuum drying oven, and dry it at 60° C. for 10 minutes, then place the copper foil in an argon atmosphere, and react at 600° C. for 10 hours.

[0060] (4) Pickling: Soak the aluminum foil in step (3) with 1 mol / L hydrochloric acid to obtain an aluminum foil with a carbon coating on the surface.

[0061] 2. A method for preparing a positive e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com