A nanoscale lithium ion conductor and its preparation method

A nanoscale, lithium-ion technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as battery safety hazards, achieve low cost, reduce phase transition temperature, and increase electrical conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 14

[0021] Example 14LiBH 4 -LiF, 4LiBH 4 -LiCl, 4LiBH 4 -LiBr, 4LiBH 4 - Preparation of LiBr

[0022] 4LiBH 4 - Preparation of solid solution phases such as LiF: LiBH with a purity of 95% 4 Mixed with LiF with a purity of 99% at a molar ratio of 4:1, and mechanically milled by a planetary ball mill, the ball-to-material ratio is 40:1, the ball milling time is 2 hours, and the revolution speed is 400rpm to obtain nano-scale particles. .

[0023] 4LiBH 4 - Preparation of LiCl solid solution phase: LiBH with a purity of 95% 4 Mixed with LiCl with a purity of 99% at a molar ratio of 4:1, and mechanically milled by a planetary wheel ball mill, the ball-to-material ratio is 40:1, the ball milling time is 2 hours, and the revolution speed is 400rpm to obtain nano-scale particles. .

[0024] 4LiBH 4 - Preparation of LiBr solid solution phase: LiBH with a purity of 95% 4 It is mixed with LiBr with a purity of 99% at a molar ratio of 4:1, and is mechanically ball milled by a pla...

Embodiment 2

[0026] Example 2LiBH 4 Preparation of / SBA-15

[0027] in the isolated air (H 2 O2 4 The mixture of the particles and the mesoporous silicon material SBA-15 was placed in a steel ball tank equipped with stainless steel grinding balls. The weight ratio of grinding balls to the sample was 40:1. Under the protection of high-purity (99.9999%) inert gas, using The planetary wheel ball mill was mechanically ball milled for 5h, and the revolution speed was 400rpm, and the lithium ion conductor LiBH with nanoscale was obtained.4 / SBA-15. Since samples readily react with oxygen and water, all sample manipulations were performed in a glove box filled with high-purity argon gas with oxygen and water content below 1 ppm concentration.

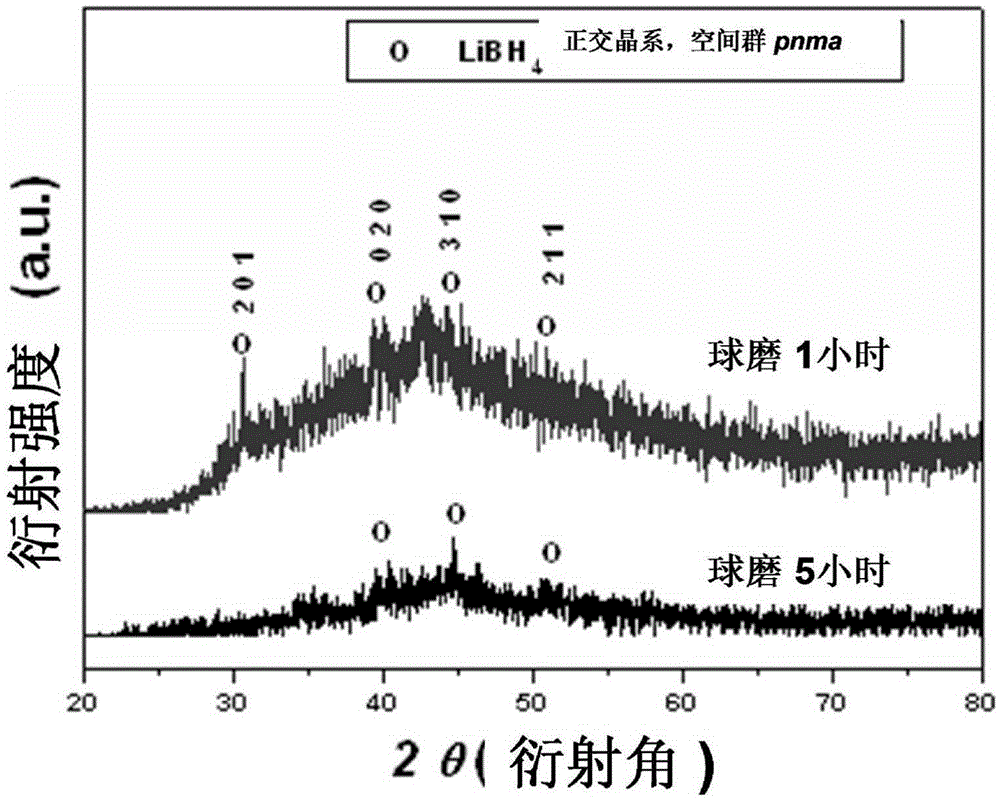

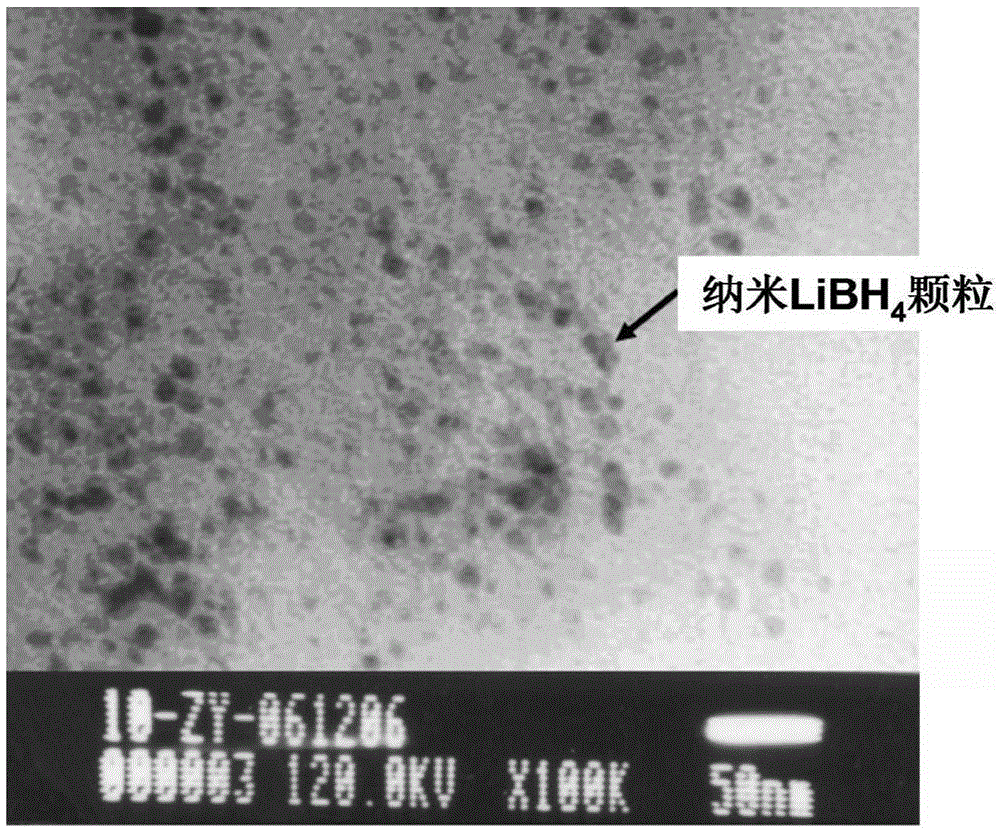

[0028] Detection of LiBH by X-ray Diffraction (XRD) Experiment 4 / SBA-15. The sample cell is covered with a specific polymer film, and is sealed with a glass slide with vacuum grease to prevent the action of water and oxygen in the air on the sample. T...

Embodiment 34

[0031] Example 34 LiBH 4 - Preparation of LiI / SBA-15

[0032] in the isolated air (H 2 O2 4 -The mixture of LiI particles and mesoporous silicon material SBA-15 is placed in a steel ball tank equipped with stainless steel grinding balls, the weight ratio of grinding balls to sample is 20:1, under the protection of high-purity (99.9999%) inert gas , using a planetary wheel ball mill for 6 hours of mechanical ball milling and a revolution speed of 600 rpm to obtain a nanoscale lithium ion conductor 4LiBH 4 -LiI / SBA-15. Since samples readily react with oxygen and water, all sample manipulations were performed in a glove box filled with high-purity argon gas with oxygen and water content below 1 ppm concentration.

[0033] The XRD and TEM patterns are consistent with Example 2.

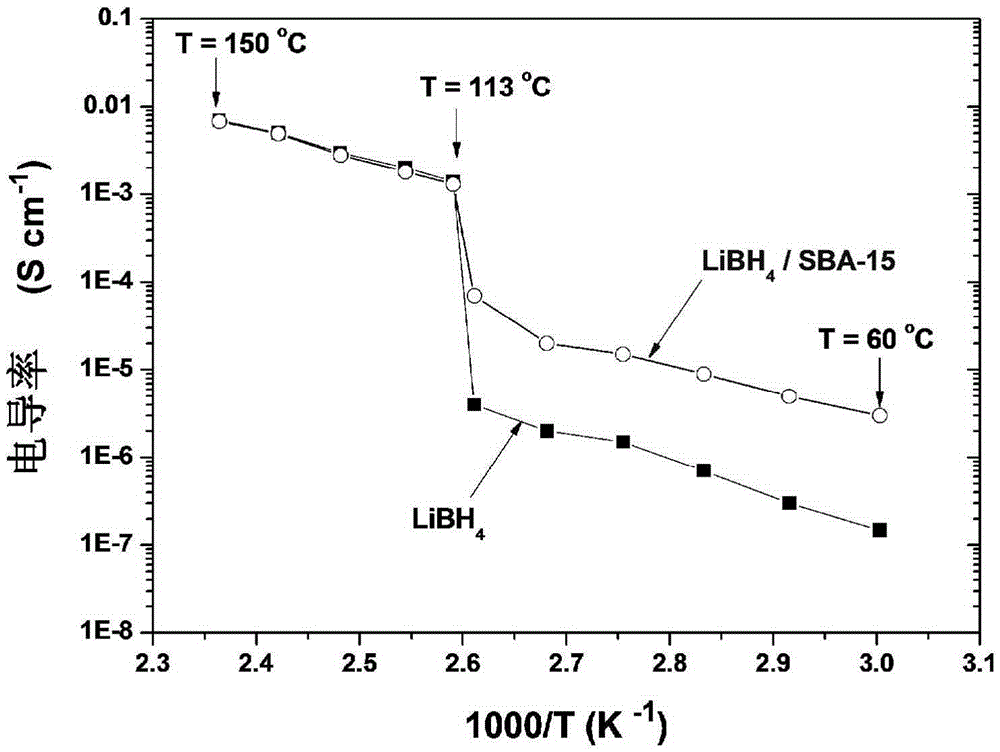

[0034] The change curve of conductivity with temperature is shown in Figure 4 , it can be seen from the figure: the nano-dispersed 4LiBH 4 -LiI / SBA-15 at lower temperature (60 o c) The ionic condu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com