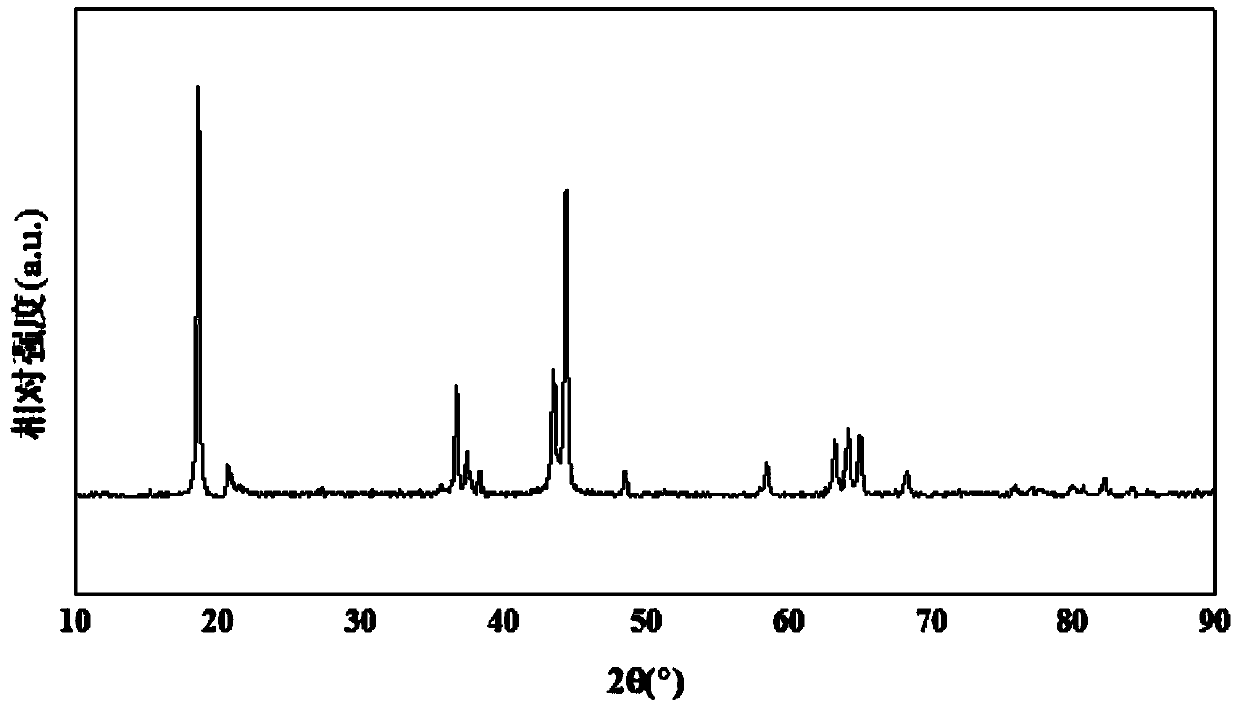

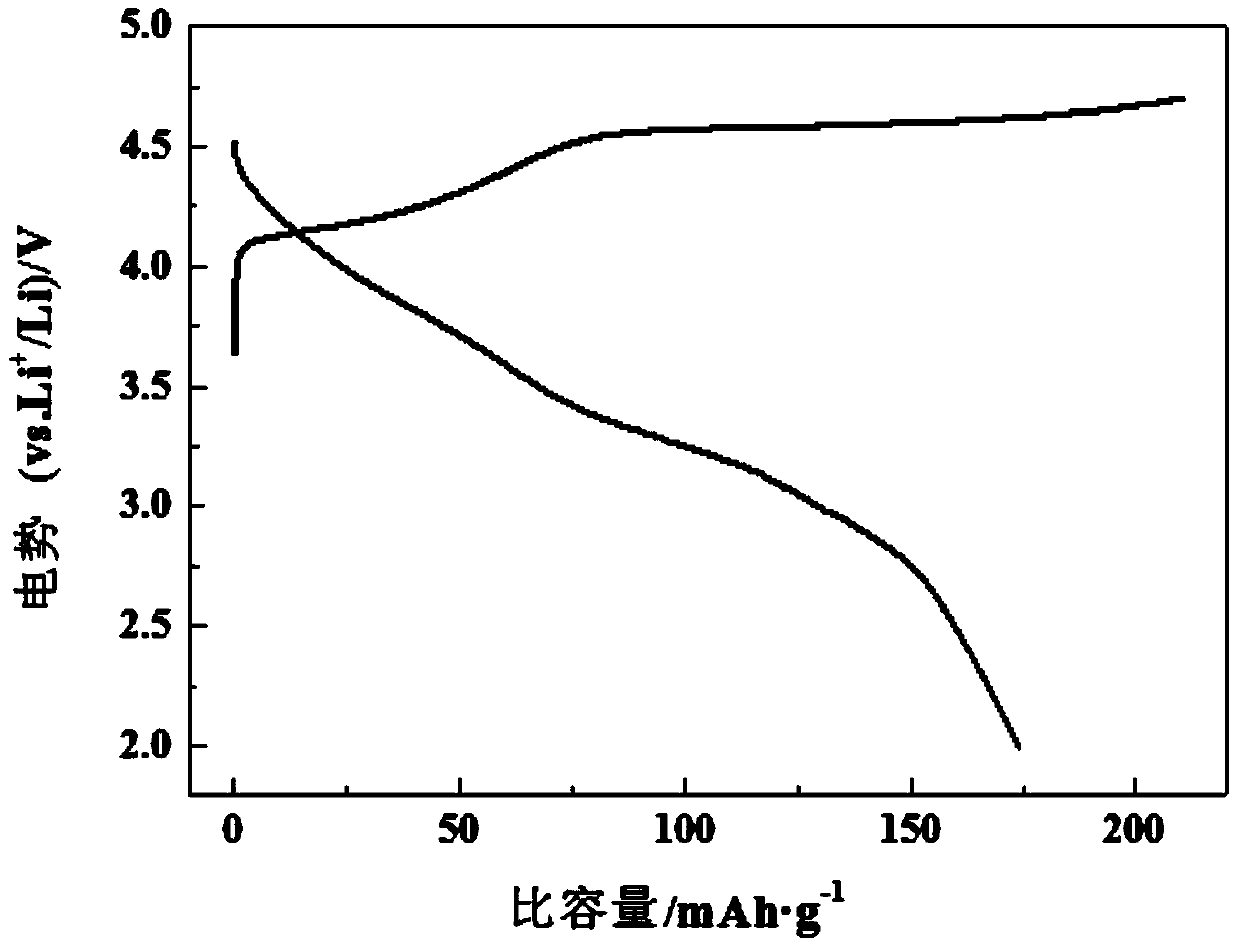

Preparing method for submicron particles of nickel-manganese-base lithium ion battery anode material

A technology of submicron particles and ion batteries, applied in battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc., can solve the problems of large particles and poor electrical properties, achieve uniform particle size, and improve discharge The effect of easy control of specific capacity and particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0016] Embodiment 1: A method for preparing submicron particles of a nickel-manganese-based lithium-ion battery positive electrode material according to this embodiment is carried out in the following steps:

[0017] 1. According to the stoichiometric formula Li(M x Ni y mn 1-x-y ) Ni, Mn and M mol ratio in O2 Nickel nitrate, manganese nitrate, M nitrate and excess lithium nitrate, first add nickel nitrate, manganese nitrate and M nitrate to N,N-dimethyl In formamide, stir magnetically at room temperature until all the inorganic salts are completely dissolved, add polyvinylpyrrolidone and lithium nitrate, and stir until the polyvinylpyrrolidone is completely dissolved to obtain an electrospinning precursor solution; wherein Li(M x Ni y mn 1-x-y )O 2 M is a combination of one or several elements in Co, Fe and Al, 0<x≤0.5, 0<y≤0.5, and x+y<1;

[0018] 2. Inject the obtained spinning precursor liquid into the syringe with stainless steel needle of the electrospinning machin...

specific Embodiment approach 2

[0020] Embodiment 2: This embodiment differs from Embodiment 1 in that the amount of lithium nitrate added in step 1 is 1.02 to 1.15 times the stoichiometric ratio. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0021] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the total mass concentration of lithium nitrate, nickel nitrate, manganese nitrate and M nitrate in the electrospinning precursor solution in step one is 8% to 25%. , the mass concentration of polyvinylpyrrolidone is 8-15%. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com