Application of nano material in ferrite

A nanomaterial and ferrite technology, applied in the field of nanomaterials, can solve the problems of reducing the cost of ferrite, uneven distribution of additive ions, increasing costs, etc., to improve magnetic properties, prevent excessive growth, and increase the effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

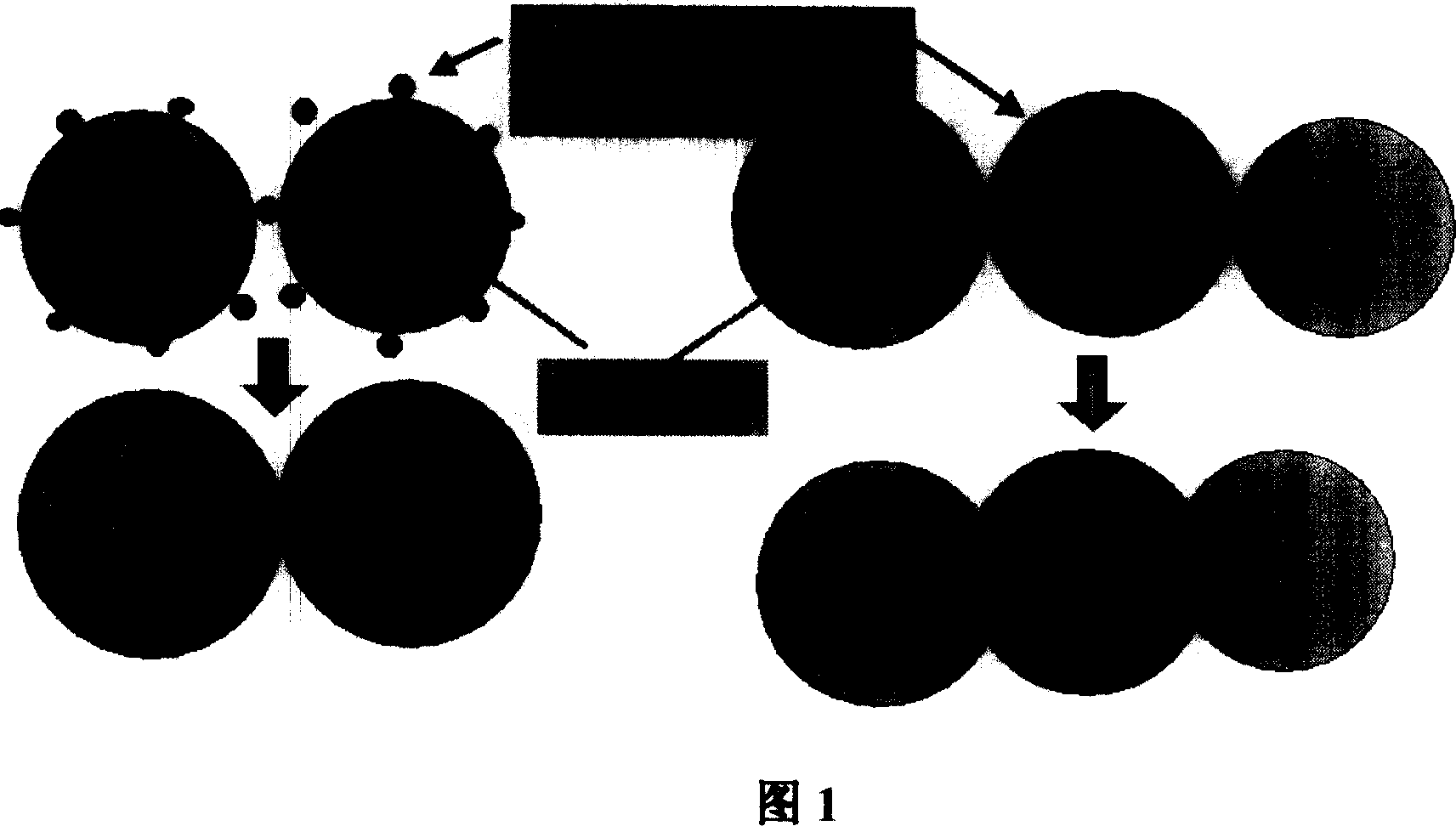

Image

Examples

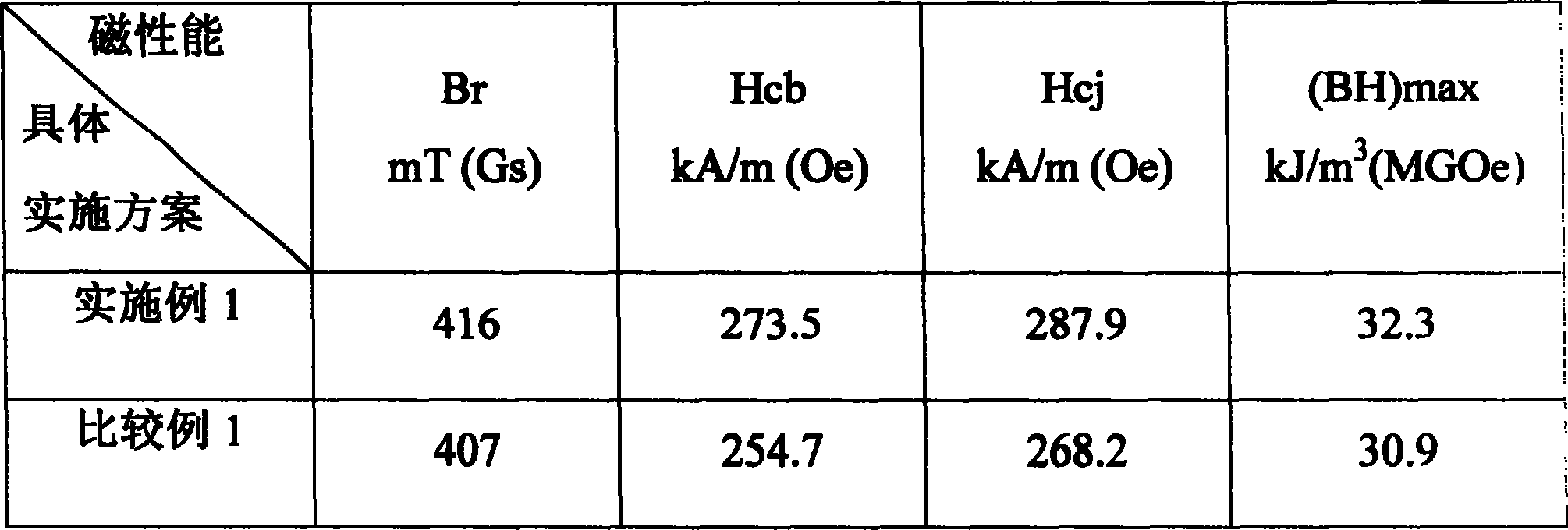

Embodiment 1

[0022] Take the following recipe:

[0023] Select SrO·6Fe 2 o 3 The calcined material is processed into a powder with a particle size of about 3.5 μm by dry vibration grinding, and the following nano-materials are used as additives:

[0024] CaCO 3 Powder (purity ≥ 99.0wt%, primary particle size of particles: 100-300nm) 1.1wt%;

[0025] SiO 2 Powder (purity ≥ 99.0wt%, primary particle size of particles: 100-300nm) 0.7wt%;

[0026] Al 2 o 3 Powder (purity ≥ 99.0wt%, primary particle size of particles: 100-300nm) 0.8wt%;

[0027] Vibrate and disperse the nano-scale additives in an ultrasonic vibration container for 10-20 minutes, and add the above-mentioned ferrite calcined powder into a small ball mill for wet grinding for 26 hours. After grinding, the particle size fineness of the discharged material is about It is 0.75μm. After wet grinding, the slurry is precipitated and dehydrated, and then shaped.

[0028] Sintering is carried out in the air, the heating rate is 1...

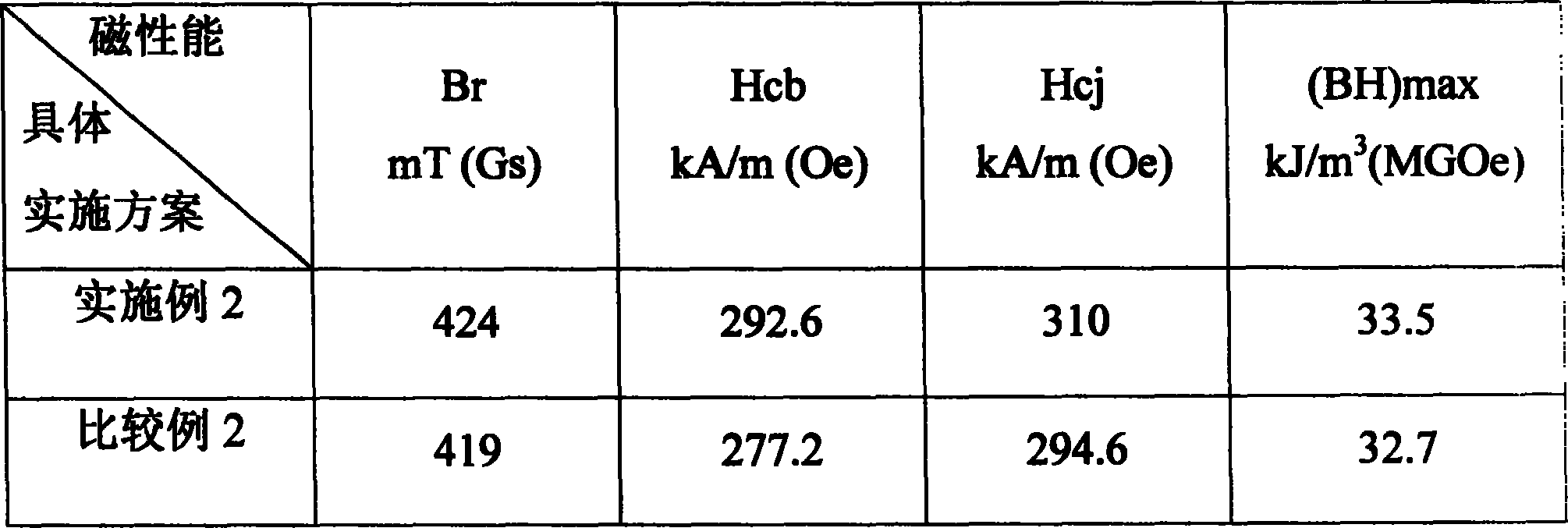

Embodiment 2

[0039] Take the following recipe:

[0040] Select SrO·6Fe 2 o 3 The calcined material is processed into a powder with a particle size of about 3.5 μm by dry vibration grinding.

[0041] The following nanomaterials are used as additives:

[0042] CaO powder (purity ≥ 99.0wt%, primary particle size of particles: 1-3μm) 0.6wt%

[0043] co 2 o 3 Powder (purity ≥ 99.0wt%, primary particle size of particles: 1-300nm) 0.3wt%

[0044] La 2 o 3 Powder (purity ≥ 99.0wt%, primary particle size of particles: 1-300nm) 0.5wt%

[0045] SiO 2 Powder (purity ≥ 99.0wt%, primary particle size of particles: 1-3μm) 0.5wt%

[0046] Vibrate and disperse the nano-scale additives in an ultrasonic vibration container for 10-20 minutes, and add the above-mentioned ferrite calcined powder into a small ball mill for wet grinding for 26 hours. After grinding, the particle size fineness of the discharged material is about It is 0.75μm. After wet grinding, the slurry is precipitated and dehydrated...

Embodiment 3

[0060] ZnO (20.5-25.5 mol%), MnO (21.5-26.5 mol%) and the rest are Fe 2 o 3 It is used as the main component for batching, vibrating ball milling and dry mixing, and the obtained mixture is put into a rotary kiln at 850° C. to 950° C. for 1 to 3 hours of pre-calcination. The obtained calcined body is added with the nanomaterials in Table 4 as additives, and the particle size of these nanomaterials is between 1 and 300 nm: the nanomaterials are first dispersed by ultrasonic waves and then put into a sand mill together with the main components for sand milling. Then, add PVA and dispersant to it and granulate it by spray drying, and use an automatic molding machine to shape it into a blank with a certain shape; heat it, keep it at 1350-1390°C for 3-8 hours, and then lower the temperature to sinter it. From the obtained compact, toroidal magnetic cores (samples 1 to 6) having an outer diameter of 10 mm, an inner diameter of 6 mm, and a height of 4 mm were obtained. Sintering is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com