Preparation method of titanium dioxide/hollow microsphere composite filler

A technology of hollow microspheres and titanium dioxide, applied in the direction of reflection/signal coatings, etc., can solve problems such as difficult control of reaction speed, particle agglomeration, and uneven coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

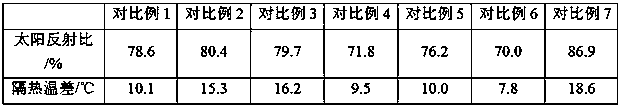

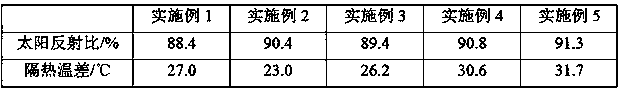

Examples

Embodiment 1

[0030] (1) After the surface is cleaned and degreased, the hollow ceramic microspheres are sieved to obtain hollow ceramic microspheres with a particle size distribution in the range of 150-1250nm.

[0031] (2) Add 50g of hollow microspheres to the mixed solution of 1gTx-10, 0.8g of dimethylamine and 60g of water, and stir until the mixture is uniform.

[0032] (3) Put the mixed solution obtained in step (2) into 1000 g of n-octane and stir vigorously to form an inverse microemulsion.

[0033] (4) Slowly add 20g of tetraethyl titanate to the mixture obtained in step (3) at 10°C, and at the same time turn on the ultrasonic oscillator with an oscillation frequency of 60KHz and a power of 700W, and continue the oscillation reaction for 8 hours.

[0034] (5) Take out the material obtained in step (4) and place it in a closed autoclave, add 30g of propanol and 70g of water, and heat to 165°C for a constant reaction for 16h.

[0035] (6) Wash and separate after the reaction, filter...

Embodiment 2

[0040] (1) After the surface is cleaned and degreased, the hollow ceramic microspheres are sieved to obtain hollow ceramic microspheres with a particle size distribution in the range of 150-1250nm.

[0041] (2) Add 50g of hollow microspheres into the mixed solution of 6g of Tween 20, 3g of ethylenediamine and 150g of water, and stir until the mixture is uniform.

[0042] (3) Put the mixed solution obtained in step (2) into 2000 g of cyclohexane and stir vigorously to form an inverse microemulsion.

[0043] (4) Slowly add 100g of tetraethyl titanate to the mixture obtained in step (3) at 8°C, and at the same time turn on the ultrasonic oscillator with an oscillation frequency of 40KHz and a power of 600W, and continue the oscillation reaction for 16 hours.

[0044] (5) Take out the material obtained in step (4) and place it in a closed autoclave, add 100g of ethanol and 500g of water, and heat to 175°C for a constant reaction for 36h.

[0045] (6) Wash and separate after the r...

Embodiment 3

[0047] (1) After the surface is cleaned and degreased, the hollow ceramic microspheres are sieved to obtain hollow ceramic microspheres with a particle size distribution in the range of 150-1250nm.

[0048] (2) Add 50g of hollow microspheres to the mixed solution of 10gspan-20, 2g of 1,2-propylenediamine and 300g of water, and stir until they are evenly mixed.

[0049] (3) Put the mixed solution obtained in step (2) into 3000 g of oleic acid and stir vigorously to form an inverse microemulsion.

[0050] (4) Slowly add 150g of tetrabutyl titanate into the mixture obtained in step (3) at 6°C, and at the same time turn on the ultrasonic oscillator with an oscillation frequency of 50KHz and a power of 700W, and continue the oscillation reaction for 26 hours.

[0051] (5) Take the material obtained in step (4) and place it in a closed autoclave, add 180g of ethanol and 200g of water, and heat to 195°C for a constant reaction for 40h.

[0052] (6) After the reaction, wash and separ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com