InGaN epitaxy film and growth method and application in solar cell

A growth method, InGaN technology, applied in crystal growth, single crystal growth, single crystal growth, etc., can solve problems such as solar cells that have not been reported in the literature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

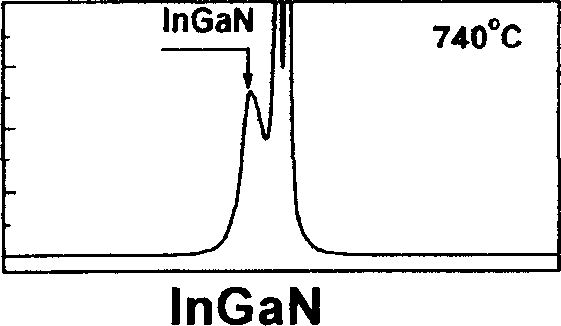

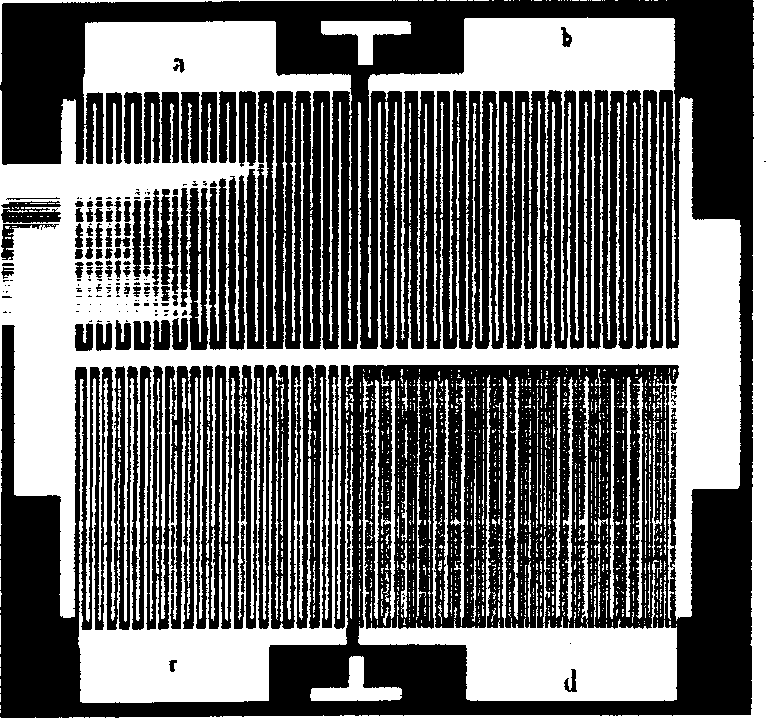

[0024] The complete solution is as follows: firstly, heat-treat the grown sapphire substrate material at a temperature of 1050°C in the MOCVD system, and then pass the carrier gas N in a certain temperature range of 500-700°C. 2 , ammonia and metal-organic Ga sources, by controlling the carrier gas, source gas flow rate and growth temperature and other parameters, a layer of low-temperature GaN buffer layer material is grown on the sapphire substrate, and then the low-temperature GaN buffer layer material is subjected to 900°C-1100°C ℃ high-temperature annealing, followed by growing a high-temperature GaN buffer layer at 1000-1100 ℃ or directly growing In in the temperature range of 500-700 ℃ x Ga 1-x N film material.

[0025] The present invention grows a low-temperature GaN buffer layer after high-temperature treatment on a (100) sapphire substrate, and then grows In x Ga 1-x The range of optimal growth conditions for N is shown in Table 1.

[0026] growth layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com