Method for avoiding or reducing V-defect of blue-green light LED material

A light-emitting diode, blue-green light technology, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as large lattice mismatch and large difference in thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

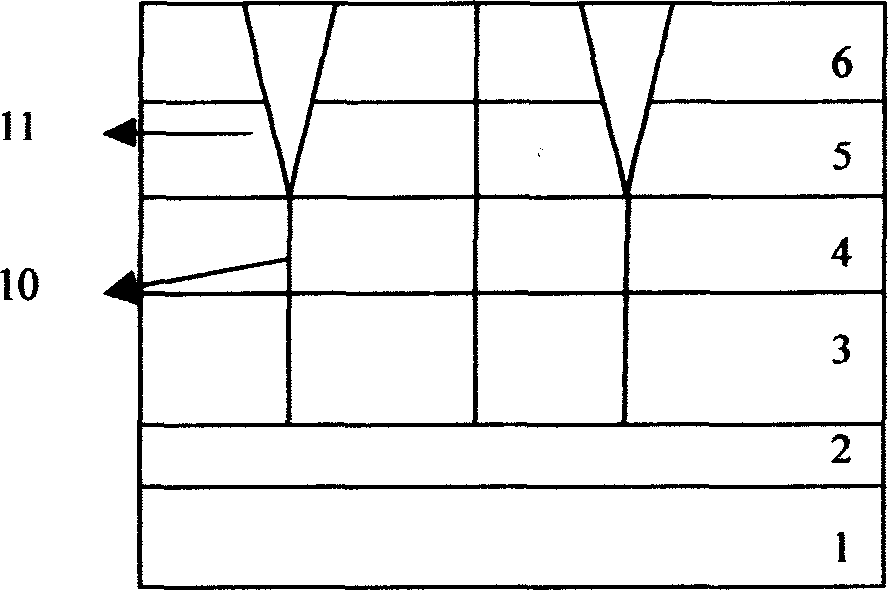

Embodiment 1

[0029] First, the substrate material sapphire Sapphire substrate layer 1 is desorbed and cleaned for 1 to 10 minutes at a temperature greater than 1100°C in a hydrogen atmosphere;

[0030] Lower the temperature to 500°C, and grow a 25nm-thick low-temperature GaN nucleation layer 2. During this growth process, the growth pressure is 200 Torr, and the V / III molar ratio is 5000;

[0031] Raise the substrate temperature to 1100°C, anneal the low-temperature GaN nucleation layer in situ, and the annealing time is 1 minute; after annealing, adjust the temperature to 1100°C, grow a 4 micron n-type doped GaN layer 3, The growth pressure is 200Torr, the V / III molar ratio is 3000, and the doping concentration is 1×10 19 cm -3 ;

[0032] Adjust the temperature to a higher temperature region of 1120°C, and control the growth pressure at 75 Torr to grow n-type doped Al x Ga 1-x N / GaN (x=0.2) superlattice layer 8 structure, where Al 0.2 Ga 0.8 The thickness of the N layer is 2nm, the ...

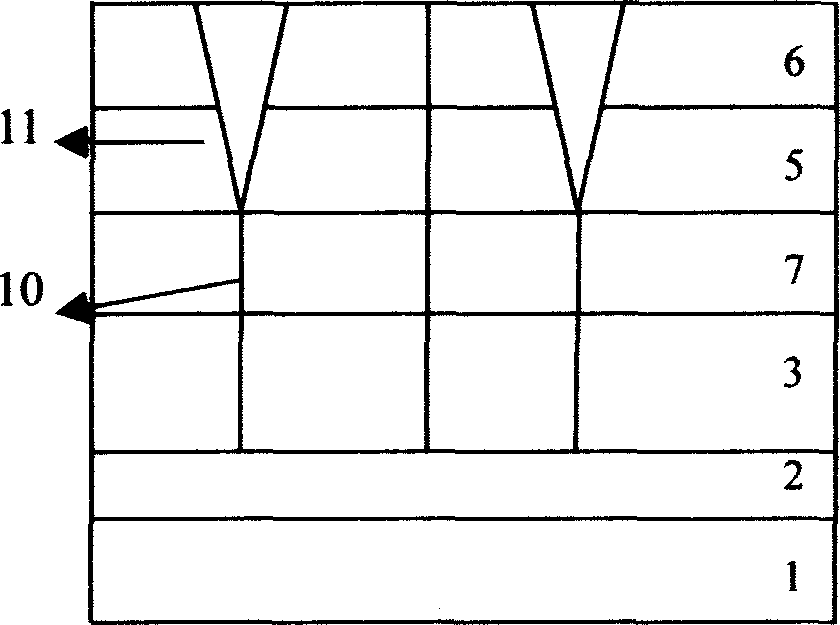

Embodiment 2

[0039] First, the substrate material sapphire Sapphire substrate layer 1 is desorbed and cleaned for 1 to 10 minutes at a temperature greater than 1100°C in a hydrogen atmosphere;

[0040] Lower the temperature to 500°C, and grow a 25nm-thick low-temperature GaN nucleation layer 2. During this growth process, the growth pressure is 200 Torr, and the V / III molar ratio is 5000;

[0041] Raise the substrate temperature to 1100°C, anneal the low-temperature GaN nucleation layer in situ, and the annealing time is 1 minute; after annealing, adjust the temperature to 1050°C, grow a 4 micron n-type doped GaN layer 3, The growth pressure is 200Torr, the V / III molar ratio is 3000, and the doping concentration is 1×10 19 cm -3 ;

[0042] Adjust the temperature to a higher temperature region of 1120°C, and control the growth pressure at 75 Torr to grow n-type doped Al x Ga 1-x N / GaN (x=0.1) superlattice layer 8 structure, where Al 0.2 Ga 0.8 The thickness of the N layer is 2nm, the ...

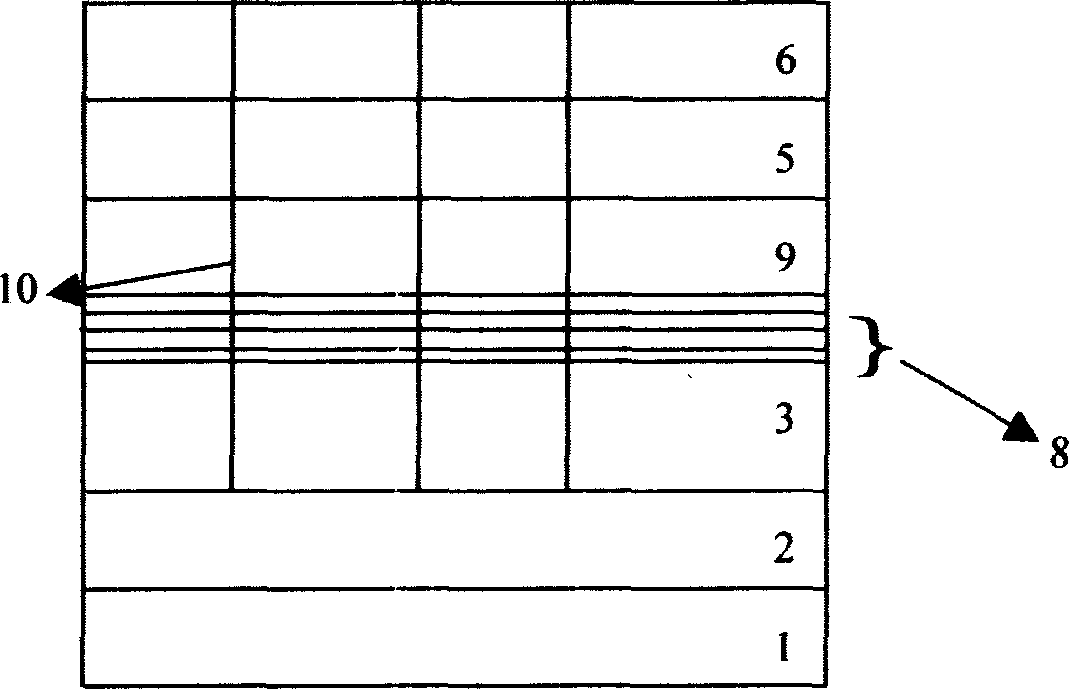

Embodiment 3

[0049] First, the substrate material sapphire Sapphire substrate layer 1 is desorbed and cleaned for 1 to 10 minutes at a temperature greater than 1100°C in a hydrogen atmosphere;

[0050] Lower the temperature to 500°C, and grow a 25nm-thick low-temperature GaN nucleation layer 2. During this growth process, the growth pressure is 200 Torr, and the V / III molar ratio is 5000;

[0051] Raise the substrate temperature to 1100°C, anneal the low-temperature GaN nucleation layer in situ, and the annealing time is 1 minute; after annealing, adjust the temperature to 1050°C, grow a 4 micron n-type doped GaN layer 3, The growth pressure is 200Torr, the V / III molar ratio is 3000, and the doping concentration is 1×10 19 cm -3 ;

[0052] Adjust the temperature to a higher temperature region of 1120°C, and control the growth pressure at 75 Torr to grow n-type doped Al x Ga 1-x N / GaN (x=0.1) superlattice layer 8 structure, where Al 0.2 Ga 0.8 The thickness of the N layer is 2nm, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com