Patents

Literature

30results about How to "Reduce growth stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

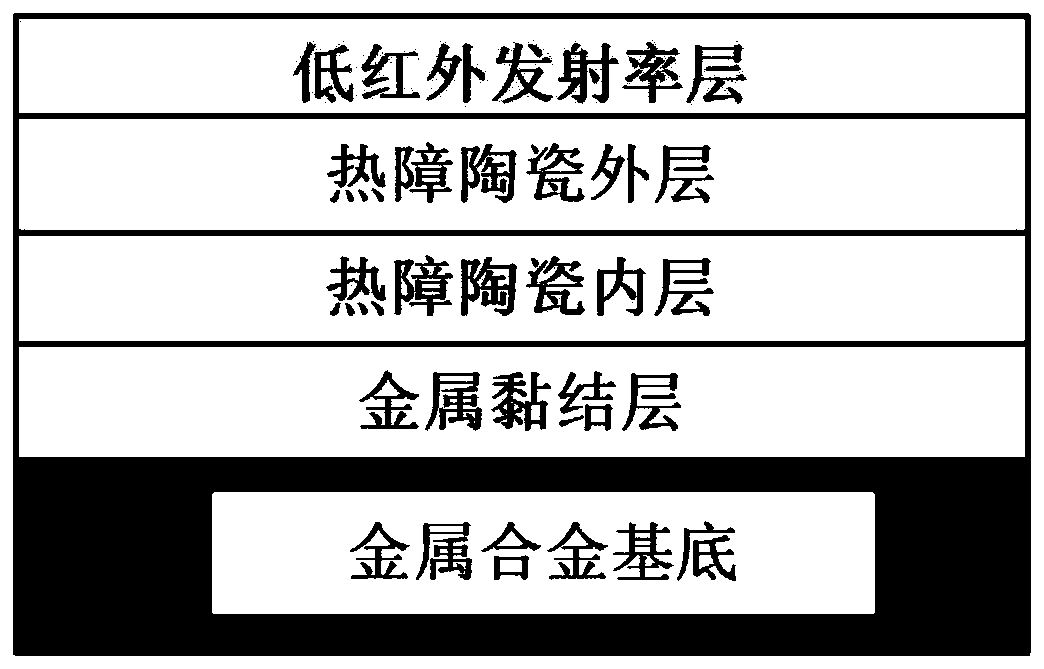

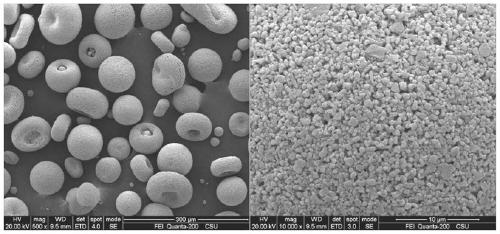

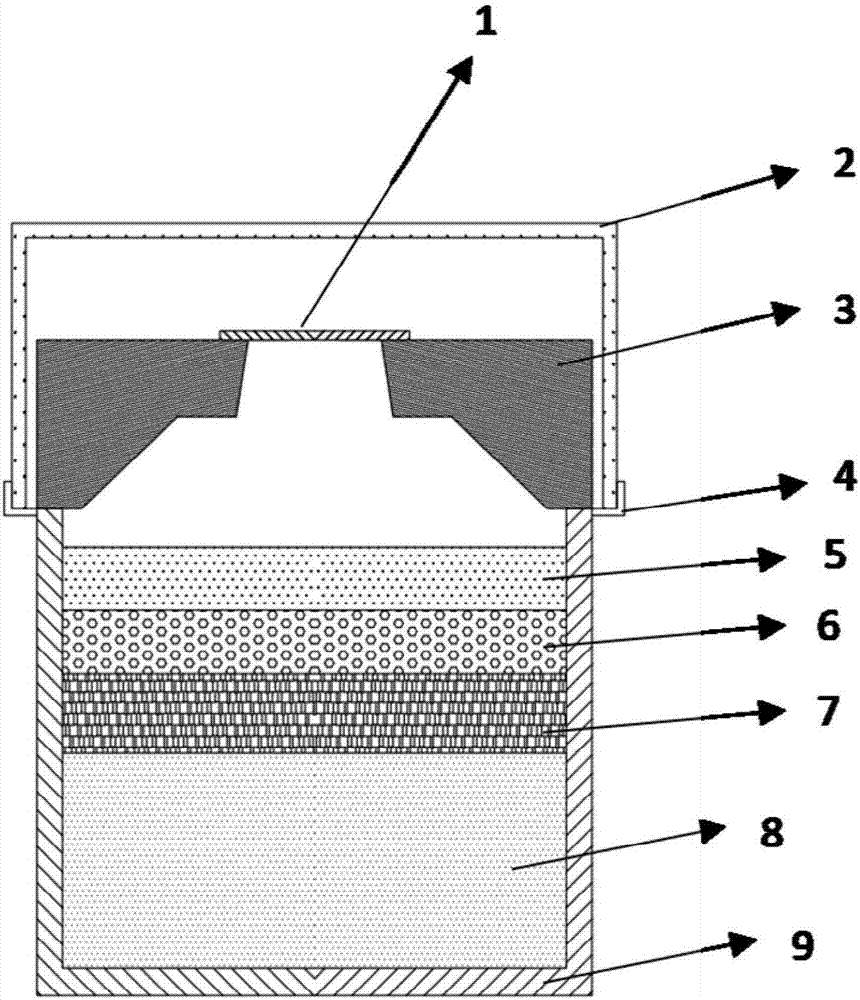

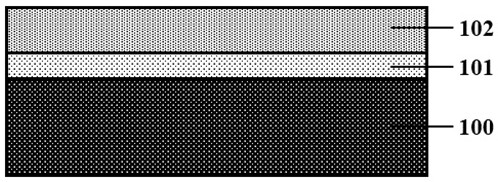

Double-layer thermal barrier/high-temperature low-infrared emissivity integrated coating, metal composite material with coating and preparation method thereof

ActiveCN110055486AGood oxygen barrier effectStop the spreadMolten spray coatingSuperimposed coating processEmissivityAlloy

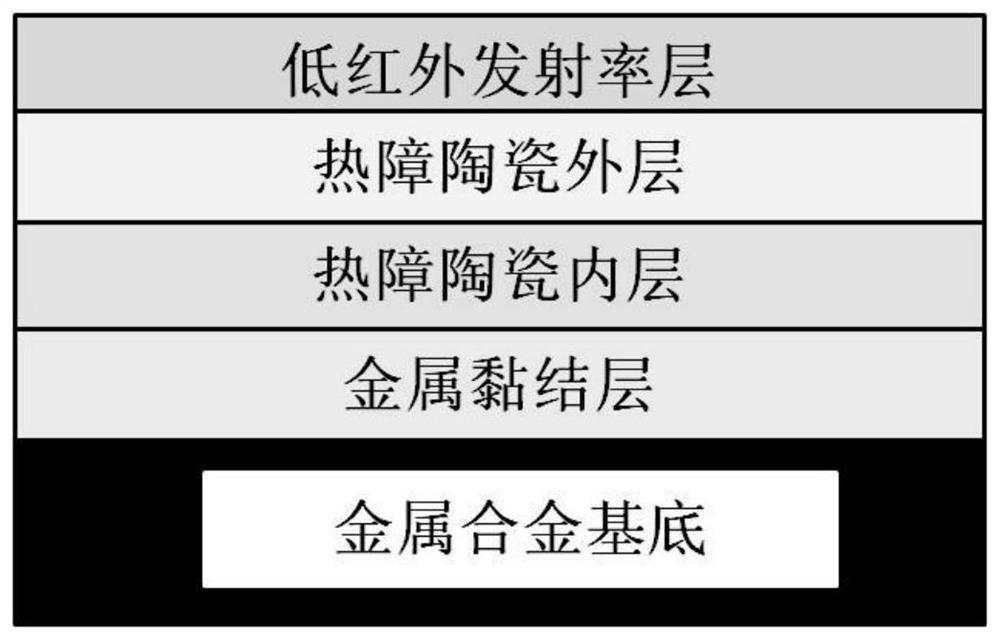

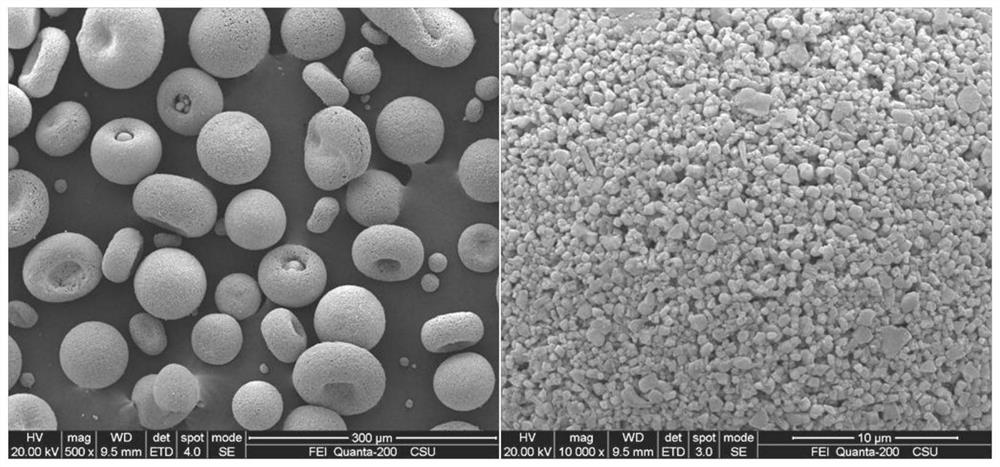

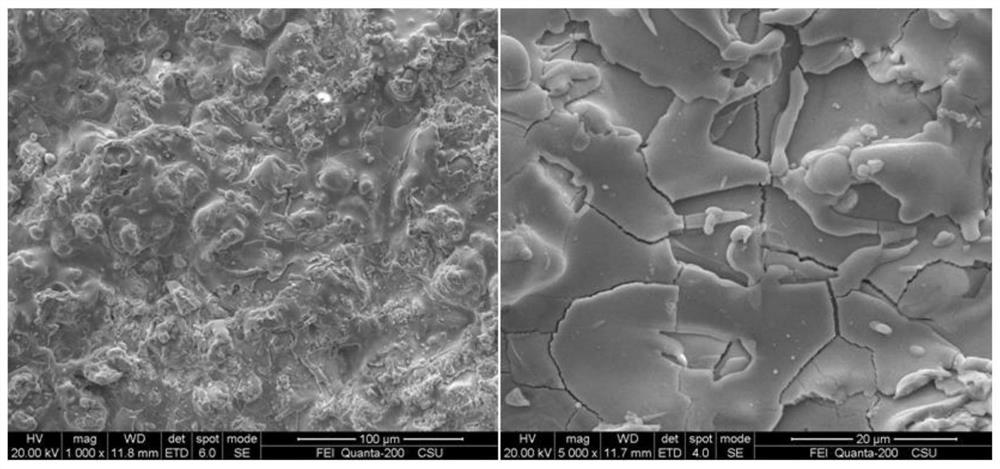

The invention discloses a double-layer thermal barrier / high-temperature low-infrared emissivity integrated coating which is of a multilayer superposition structure. The multilayer superposition structure sequentially comprises a metal bonding layer, a thermal barrier ceramic inner layer, a thermal barrier ceramic outer layer and a low-infrared emissivity layer from inside to outside, and the thermal barrier ceramic inner layer is La2Zr2O7-8YSZ mixture layer, wherein the mass fraction of La2Zr2O7 powder in the mixture is not more than 45%, the thermal barrier ceramic outer layer is a rare earthzirconate layer, and the low-infrared emissivity layer is a Bi2O3-Al2O3-ZrO2-CaO-SiO2 glass coating comprising conductive phase AuPt alloy powder. The invention also provides a metal composite material with the coating and a preparation method thereof. The integrated coating has the characteristics of heat insulation performance, high-temperature low infrared emissivity, excellent thermal shock resistance and the like.

Owner:NAT UNIV OF DEFENSE TECH

Method for producing aluminum oxide powder used as a raw material for producing sapphire crystals by flame melt process

InactiveCN101941727AHigh purityHigh transparencyAluminium oxide/hydroxide preparationSapphirePollution

The invention relates to a method for producing aluminum oxide powder, which is to product high-purity aluminum oxide powder by melting high-purity aluminum, atomizing and hydrolyzing. The aluminum oxide powder product prepared by the method has extremely high purity, and when used as a raw material for producing sapphire crystals by a flame melt process, can improve the transparency and color purity of the sapphire crystals effectively, reduce the defect rate of small sapphire crystals considerably and increase the volume of boule bars of the sapphire crystals produced by the flame melt process effectively. The method adopts a simple process flow, solves pollution problems such as waste gas emission and is environmentally-friendly.

Owner:李振亚

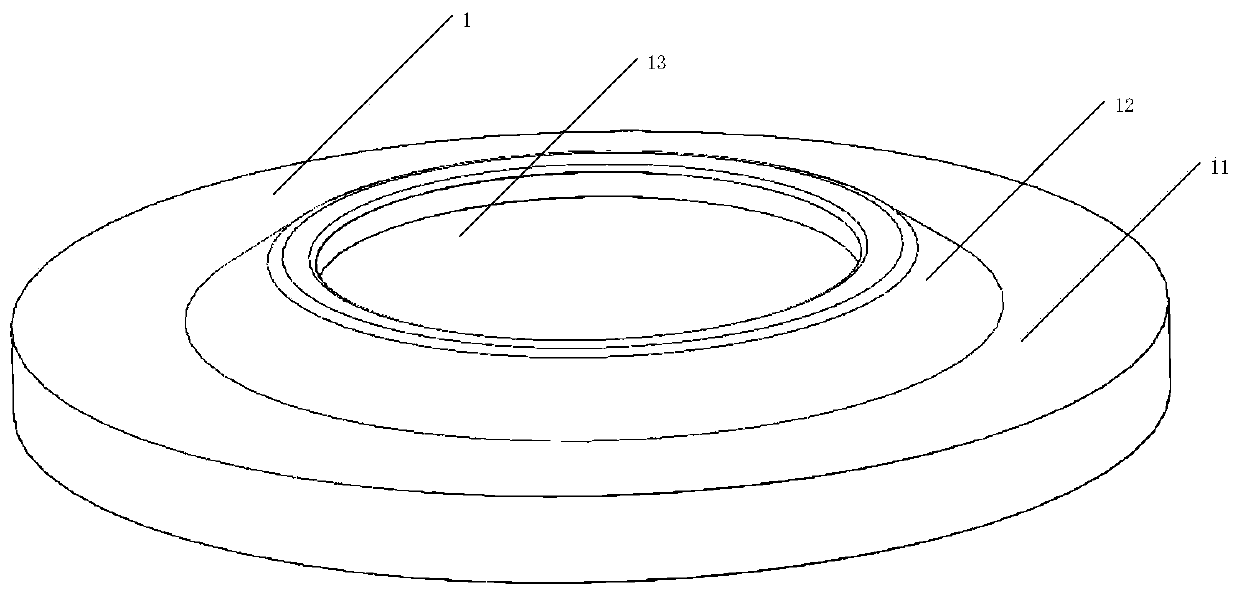

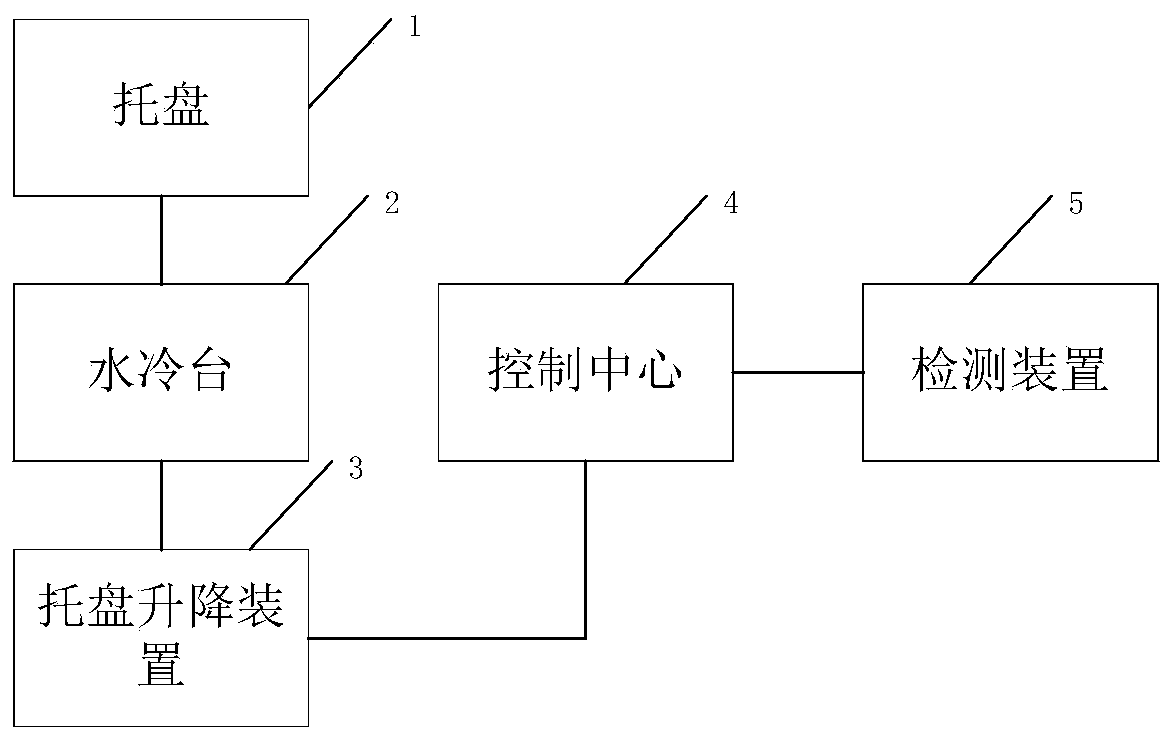

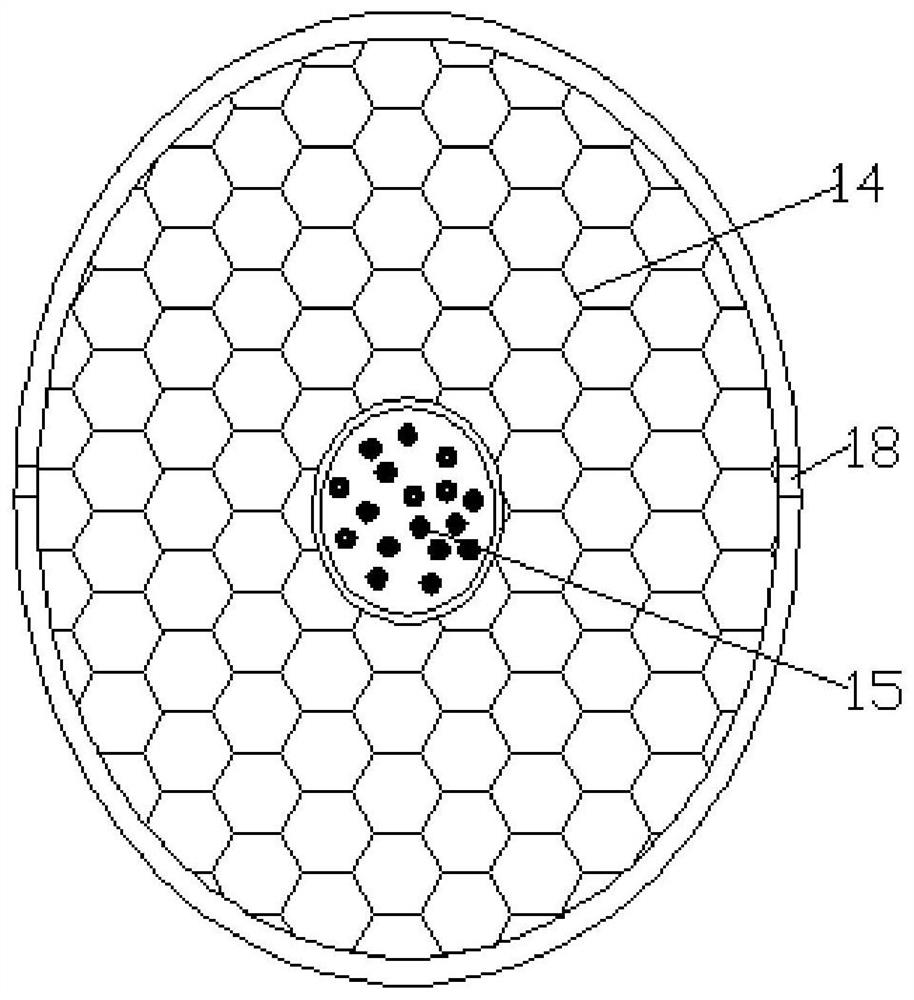

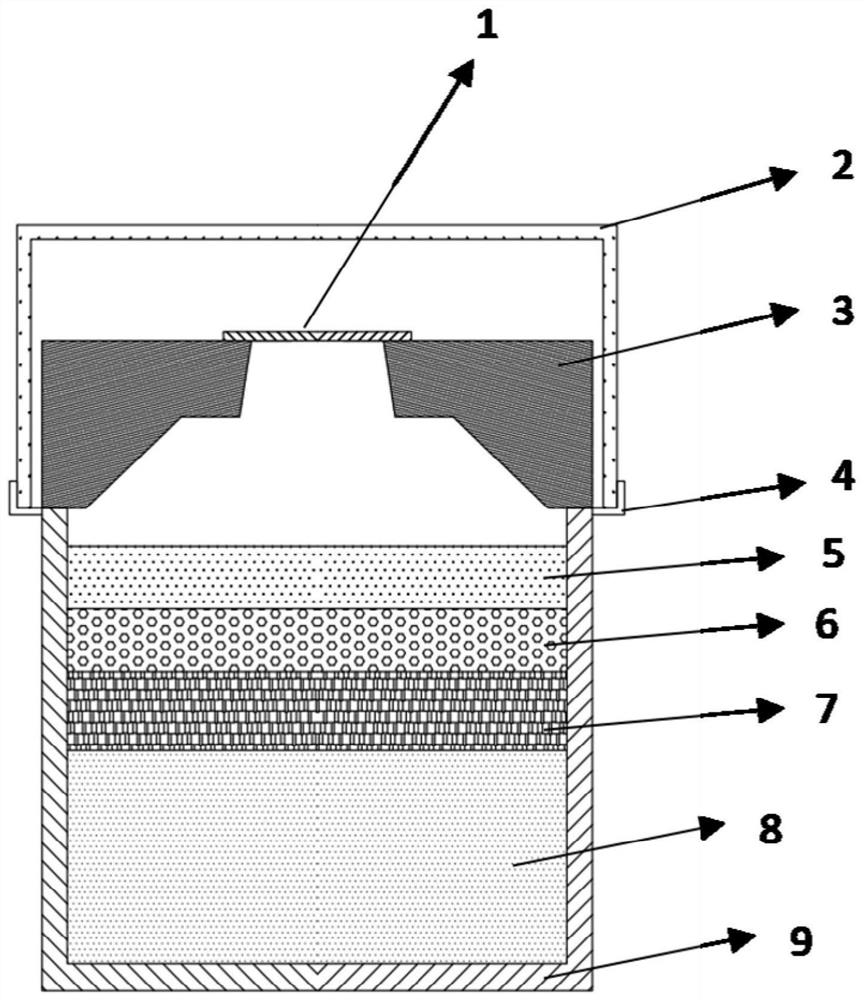

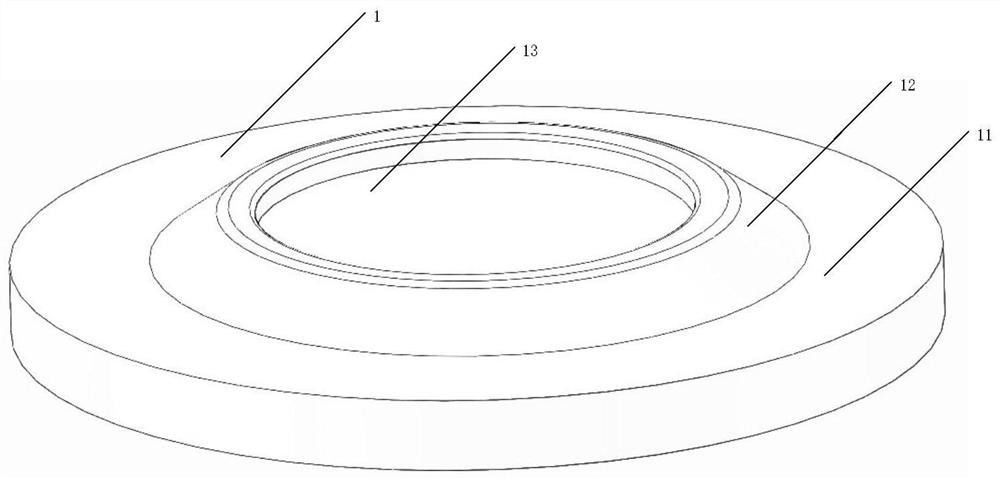

Diamond growth tray and system

ActiveCN110714225AStable growth environmentQuality improvementPolycrystalline material growthFrom chemically reactive gasesSeed crystalPhysics

The invention relates to the field of diamond manufacturing, in particular to a diamond growth tray and system. The diamond growth tray comprises a base portion and a bearing platform arranged on thebase portion. The bearing platform is in a regular polygon frustum shape or a circular truncated cone shape, a groove is formed in the upper surface of the bearing platform, and the edge of an openingof the groove is designed to be chamfered. Compared with the prior art, the tray has the advantages that through the newly designed seed crystal tray, plasma distribution and electric field distribution on the surface of the seed crystal can be kept in the optimal state, it is guaranteed that the growth environment of the diamond seed crystal is stable, the number of surface growth defects is reduced, and finally a high-quality single crystal diamond piece is synthesized; by means of the newly designed seed crystal tray, the growth rate of impurities such as carbon black on the edge of the seed crystal tray can be remarkably reduced, it is guaranteed that the single stable growth time is longer, thicker products can grow at a time, and the production efficiency is improved.

Owner:CHANGSHA ADVANCED MATERIALS IND RES INST CO LTD

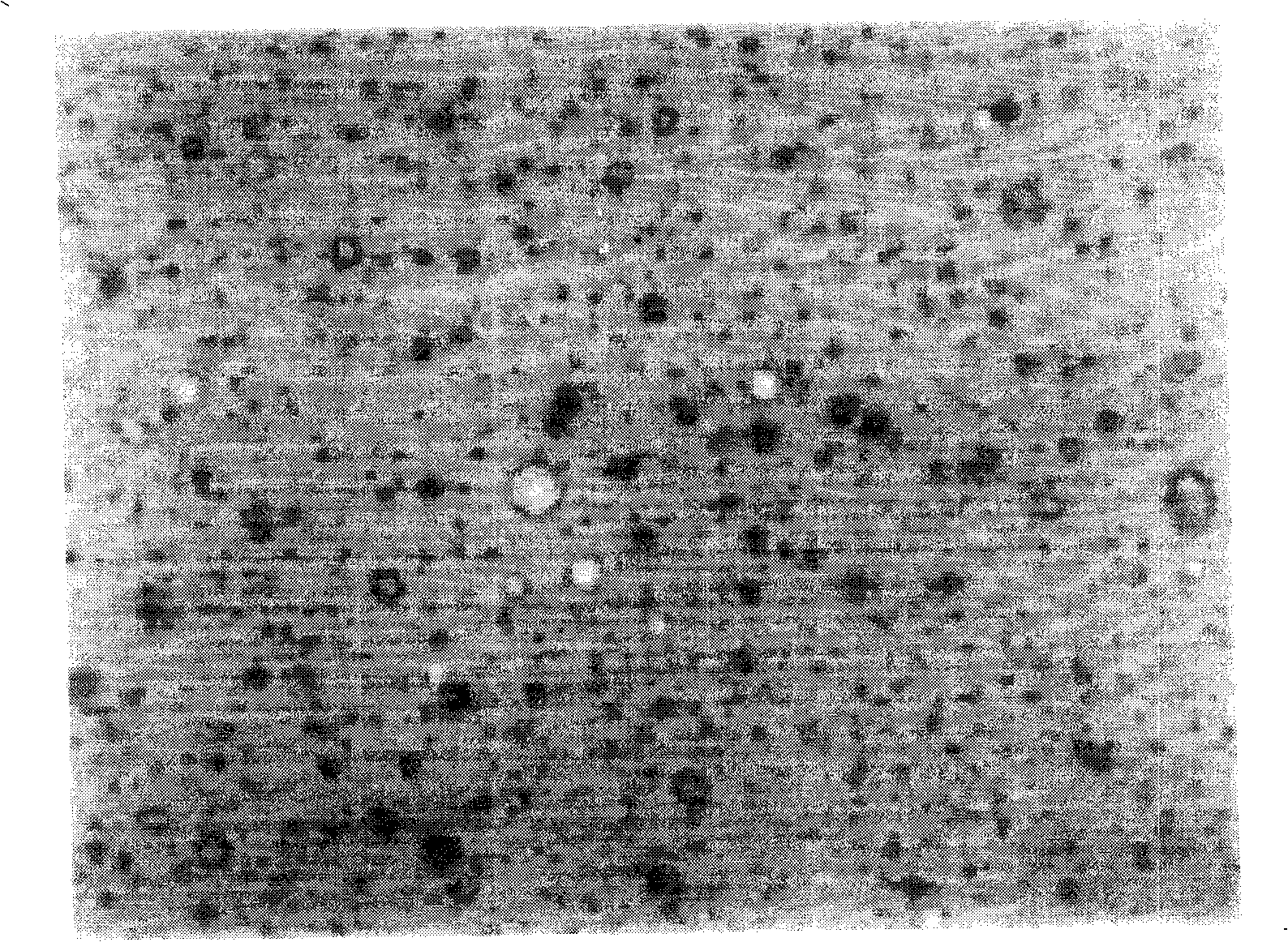

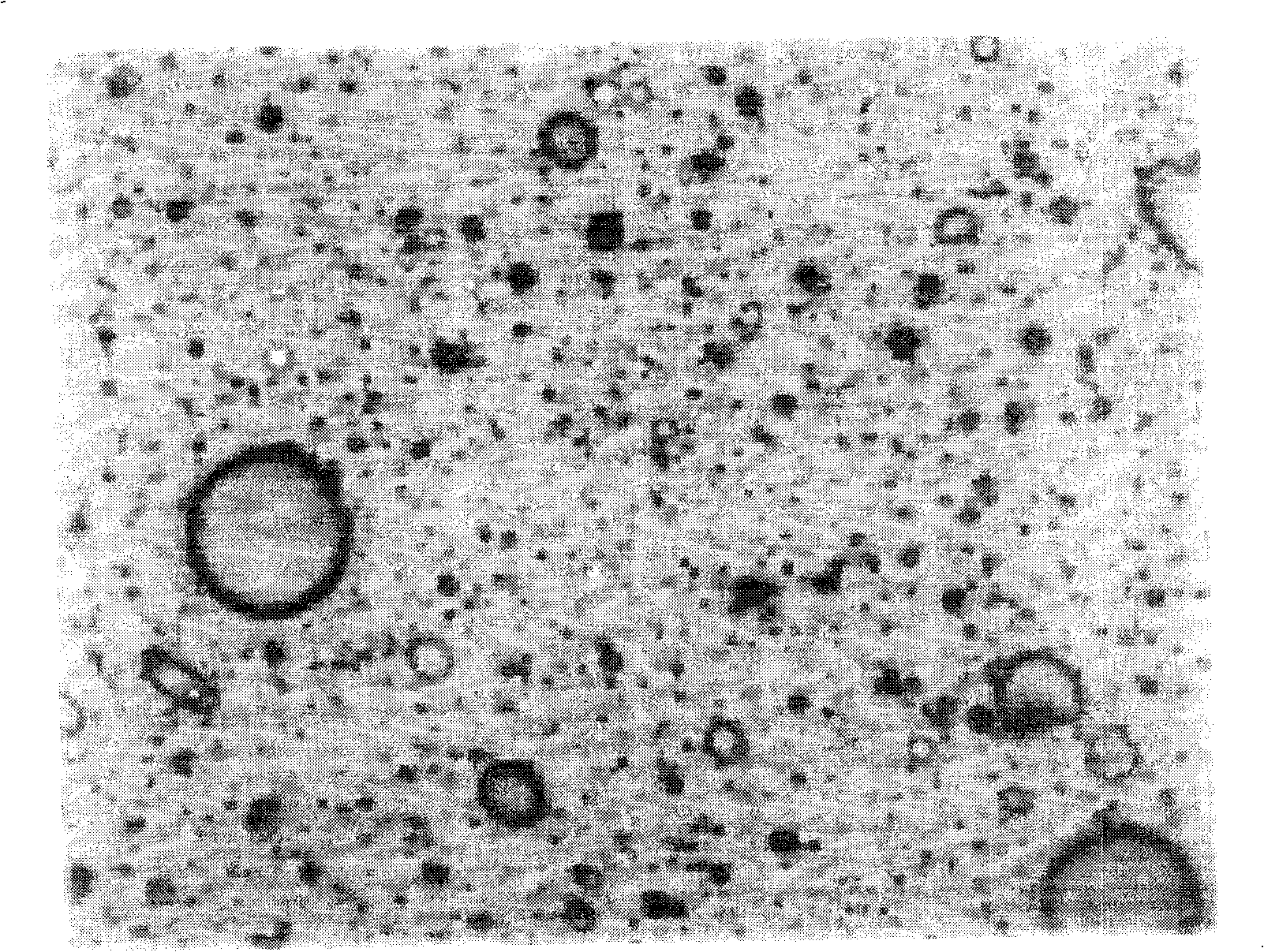

High-quality aluminum nitride monocrystal growth method

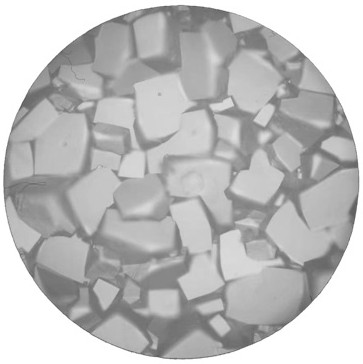

ActiveCN107955970ARelieve growth stressReduce growth stressPolycrystalline material growthFrom condensed vaporsCrucibleSingle crystal

The invention discloses a high-quality aluminum nitride monocrystal growth method. The method comprises the steps that an initial deposition layer adopts a large aluminum nitride / silicon carbide mixedfilling mode, then, high-purity aluminum nitride powder is adopted, temperature and pressure are changed in the growth process, and aluminum nitride filling layers in a crucible include the first aluminum nitride powder layer, the second aluminum nitride sintered granular layer, the third aluminum nitride and silicon carbide granular mixture layer and the fourth aluminum nitride and silicon carbide granular mixture source layer from bottom to top. The silicon carbide powder is mixed into the aluminum nitride powder, and different silicon carbides are adopted in different interlayers, due to the ratio of aluminum nitride, the growth strain between a silicon carbide substrate and the aluminum nitride monocrystal is relieved, the temperature and pressure changing technology is adopted in thegrowth process, the temperature increase and decrease speed is controlled, material source bodies are arranged from top to bottom, the content of silicon carbide is gradually lowered, the concentration of the silicon carbide in the material sources is adjusted so as to adjust the content of silicon carbide in the aluminum nitride monocrystal, and therefore the growth strain of the aluminum nitride monocrystal is lowered.

Owner:BEIJING HUAJINCHUANGWEI ELECTRONICS CO LTD

Method for cooperative control of microcystis aeruginosa by using chub, bighead, silver xenocypris fish and daphnia magna

ActiveCN103880192ASustained growth inhibitionSolve stubborn problemsBiological water/sewage treatmentEutrophicationFood chain

The invention discloses a method for cooperative control of microcystis aeruginosa by using chub, bighead, silver xenocypris fish and daphnia magna, and belongs to the technical field of water treatment. The microcystis aeruginosa in water is controlled through a food chain relationship; the chub, the bighead, the silver xenocypris fish and the daphnia magna can directly eat the microcystis aeruginosa in a filtering manner; meanwhile, the chub, the bighead and the silver xenocypris fish also can intake the daphnia magna, so as to indirectly consume the microcystis aeruginosa in water; the fish, the daphnia magna and the microcystis aeruginosa form the food chain relationship. In addition, the upper, middle and lower microcystis aeruginosa and a microcystis aeruginosa resting body at the bottom can be controlled by fully utilizing the vertical spatial distribution difference of the three fishes in the water, the content of the microcystis aeruginosa in the water can be more effectively controlled, the eutrophication level is reduced, the balance of an ecological system of the water is facilitated, and meanwhile, certain economic value can be obtained by catching the chub, the bighead, the silver xenocypris fish. The method has the advantages of low cost, no secondary pollution and the like, and is simple and feasible.

Owner:NANJING INST OF ENVIRONMENTAL SCI MINIST OF ECOLOGY & ENVIRONMENT OF THE PEOPLES REPUBLIC OF CHINA

Multi-ion doped large-size LaBr monocrystal scintillator and preparation method thereof

ActiveCN105154973AOvercoming growth crackingOvercoming defects such as envelopesPolycrystalline material growthFrom frozen solutionsOptical propertyScintillation crystals

The invention relates to the field of scintillation crystal materials and discloses a multi-ion doped large-size LaBr monocrystal scintillator. The multi-ion doped large-size LaBr monocrystal scintillator is characterized in that a general chemical formula of the monocrystal scintillator is (CexSryHfy)La(1-x-2y)Br3, wherein x is larger than 0.001 and smaller than 0.12, and y is larger than 0.0001 and smaller than 0.05. The multi-ion doped large-size LaBr monocrystal scintillator has the benefits as follows: with the adoption of the method for growth of a large-size LaBr crystal, a seed crystal elimination direction can be optimized, the defects of cracking, enveloping and the like during crystal growth can be effectively overcome, the crystal growth stress is reduced, the finished product ratio of the crystal is increased, the optical property of the crystal can be improved, and the scintillation effect of the crystal is improved.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

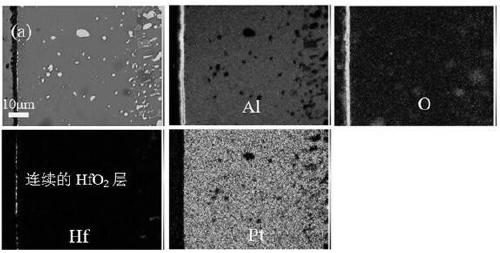

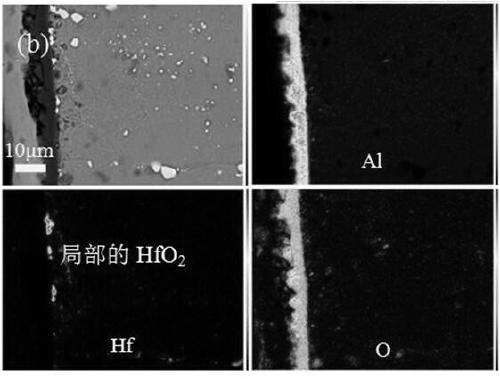

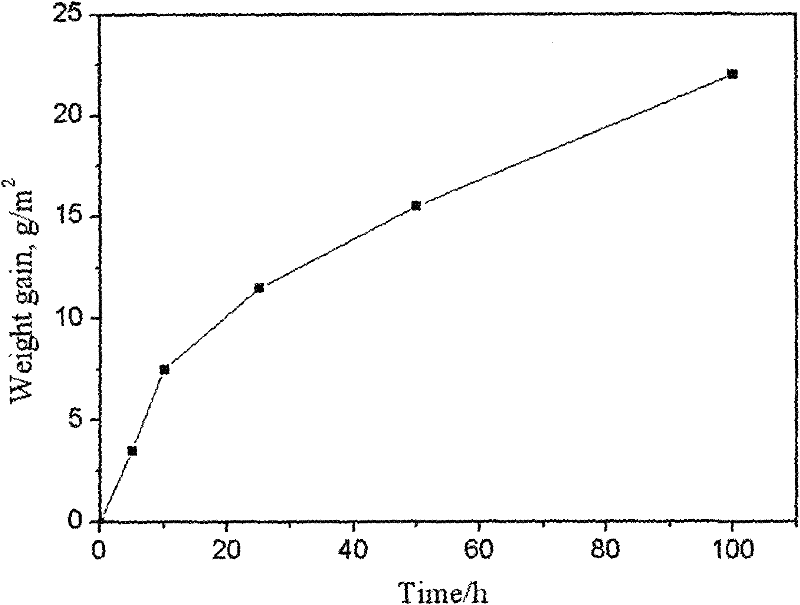

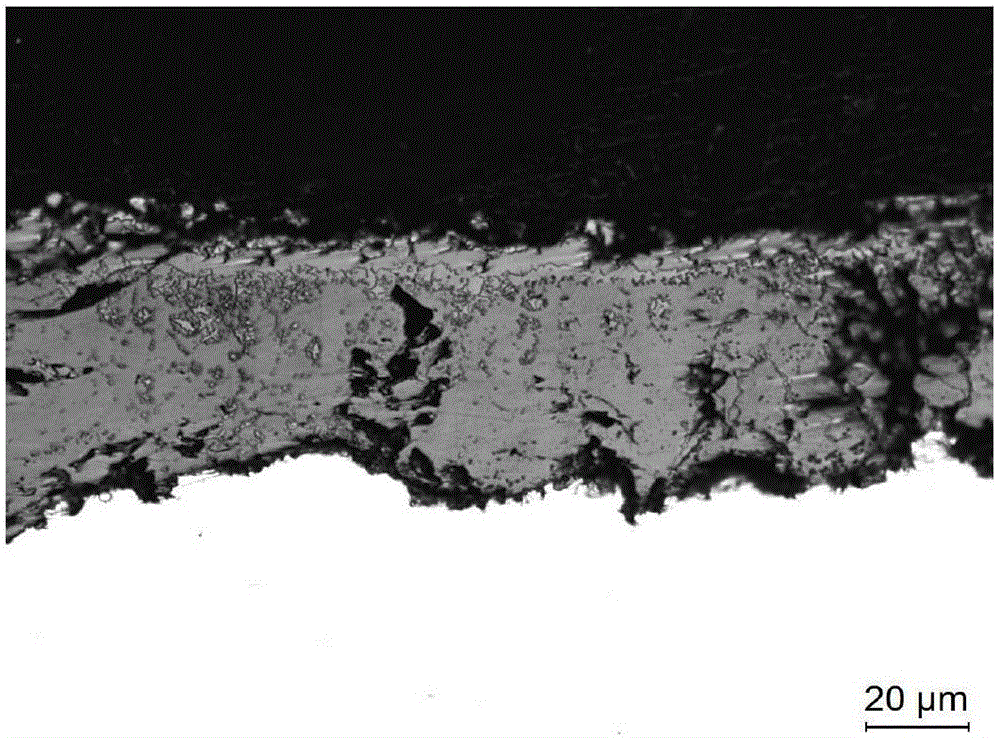

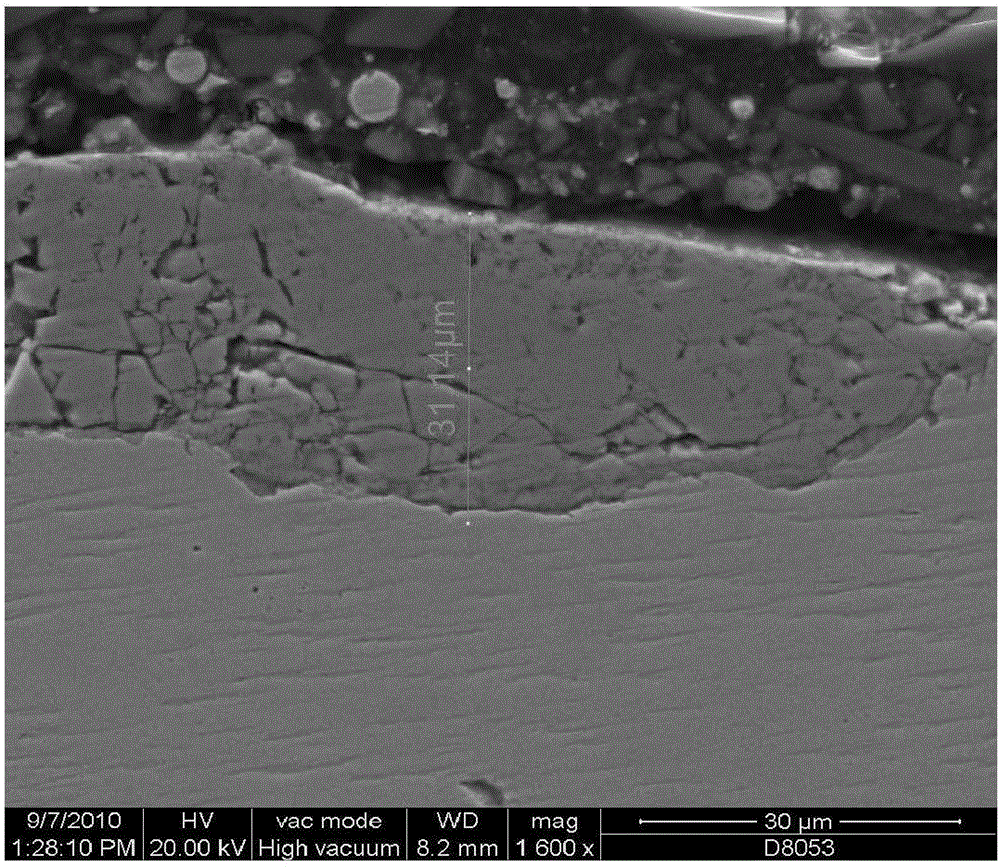

Method for prolonging service life of high-temperature coating on nickel-based alloy

InactiveCN110172703AEvenly distributedImprove controllabilitySolid state diffusion coatingAlloyThermal growth

The invention discloses a method for prolonging the service life of a high-temperature coating on a nickel-based alloy, and belongs to the field of high-temperature protection coatings. The method comprises the following steps of depositing Pt on the surface of a nickel-based high-temperature alloy by using an electroplating method; depositing an aluminide coating on the substrate by virtue of theembedding aluminizing treatment; carrying out pre-oxidation treatment on a sample coated with the modified aluminide coating; and carrying out a cyclic oxidation experiment on the pre-oxidized sampleto obtain the high-temperature coating. According to the method, the high-temperature coating comprises a Pt modified aluminide coating, a HfO2 layer and a dense thermal growth oxidation (TGO) layer,the Pt in the Pt modified coating influences outward diffusion of Hf, so that a continuous HfO2 layer is formed at the interface of the oxidation layer and the coating, the growth rate of the oxidation layer is reduced due to the existence of the continuous HfO2 layer, the bonding performance of the oxidation layer is improved, and the service life of the high-temperature protection coating is prolonged.

Owner:KUNMING UNIV OF SCI & TECH

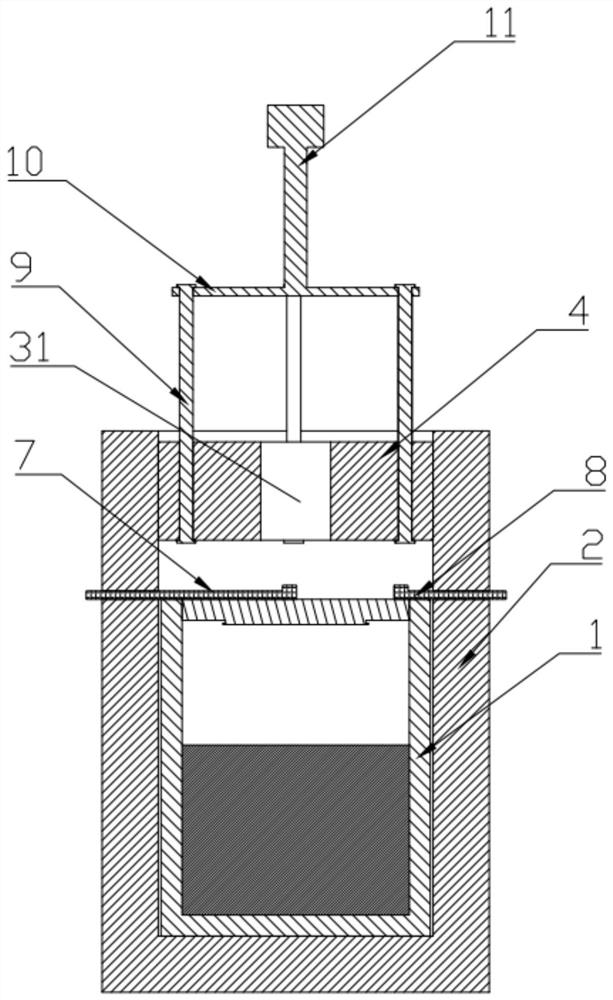

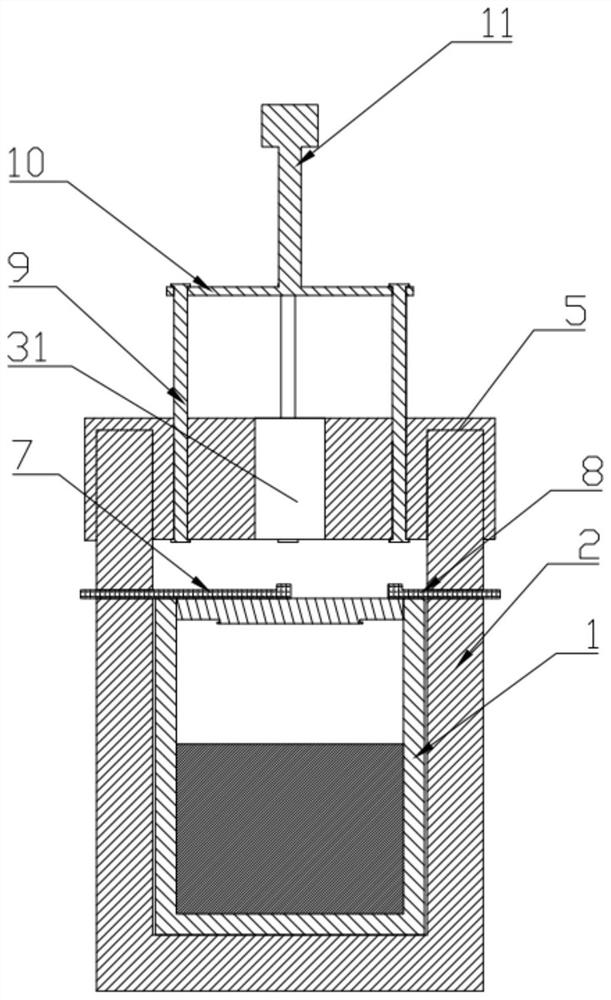

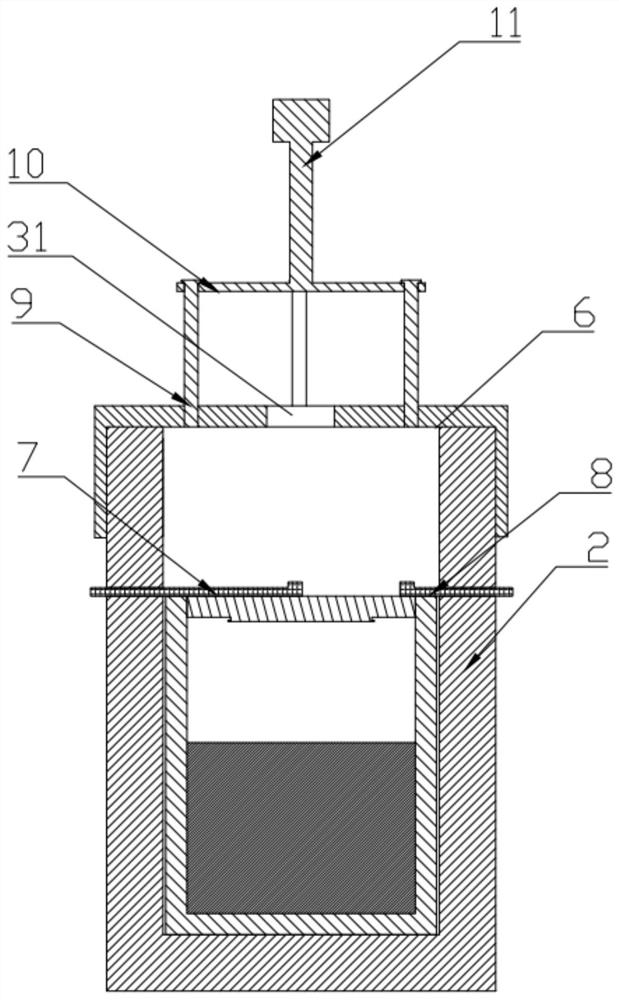

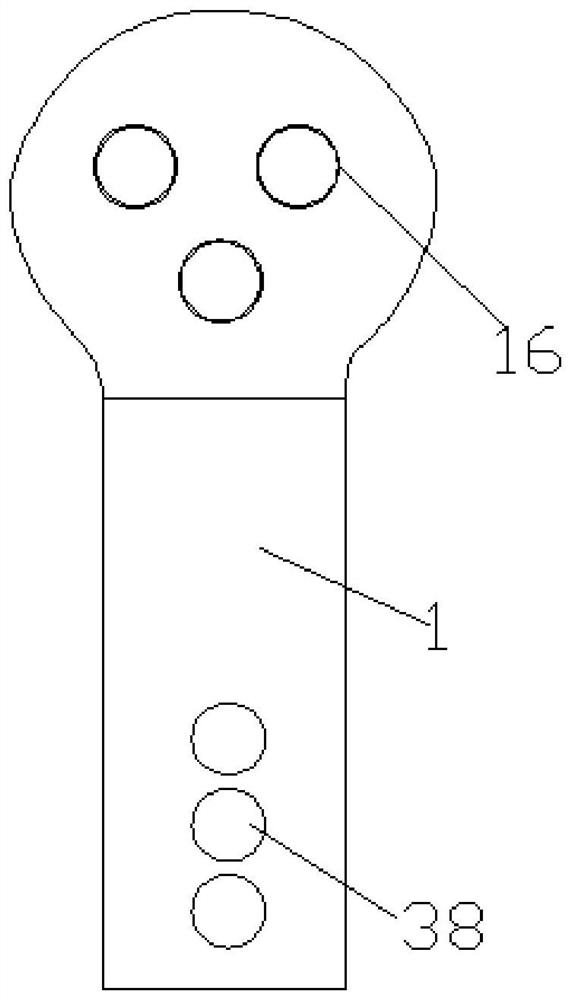

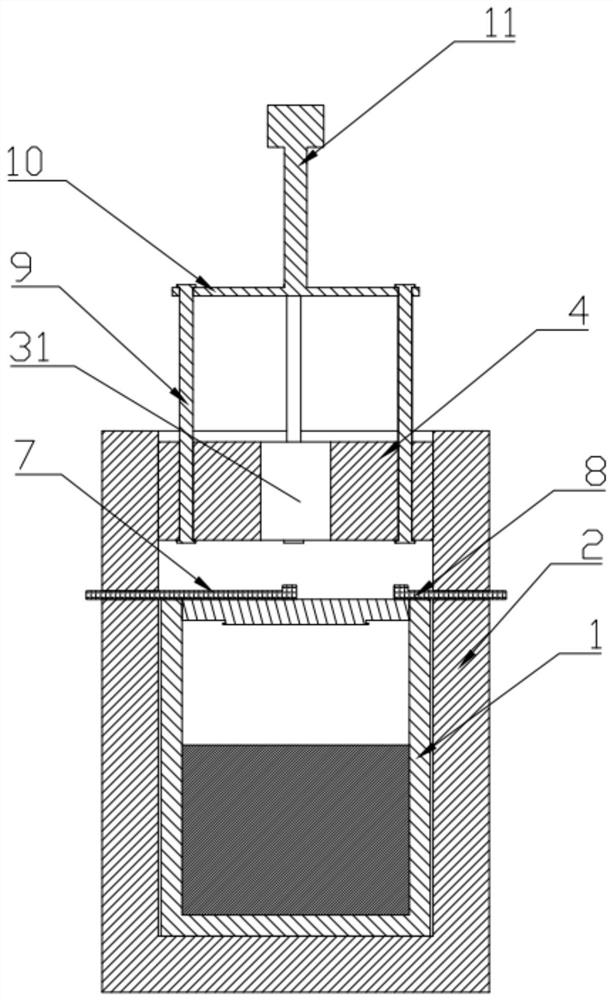

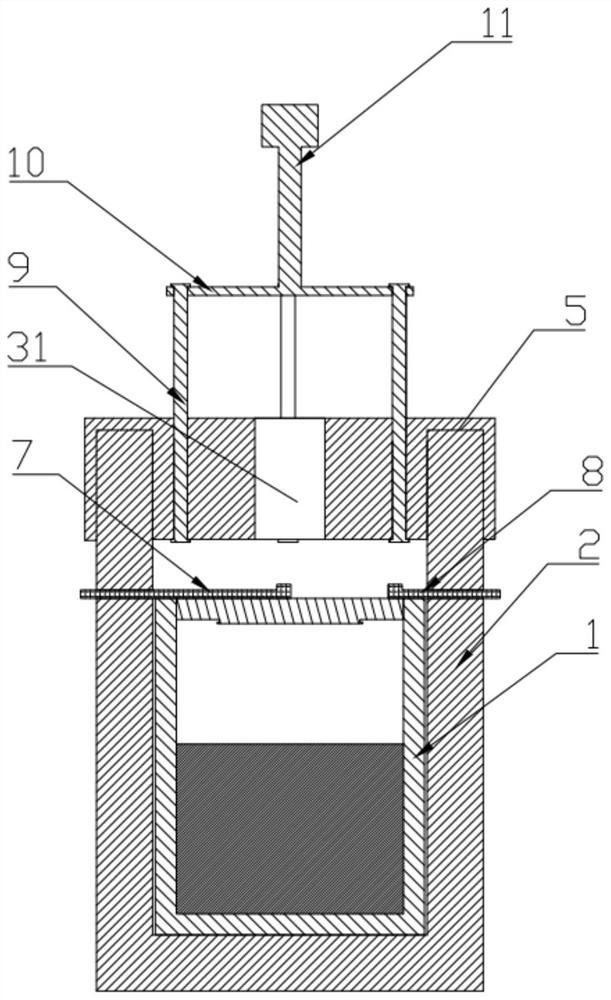

Method for growing silicon carbide crystals by PVT method and device thereof

ActiveCN112981532AReduce the difference in minimum thicknessImprove effective utilizationPolycrystalline material growthFrom condensed vaporsThermal insulationCrucible

The invention provides a method for growing silicon carbide crystals by a PVT method and a device thereof. The method comprises the following steps: (1) an assembling stage; (2) a heating stage: placing the assembled crucible in a furnace body, heating the crucible, and controlling the temperature difference between the temperature of the center of the top end of the crucible and the temperature of the edge of the top end of the crucible to be delta T1; and (3) a crystal growth stage: keeping the temperature of the center of the top end of the crucible unchanged, controlling the thermal insulation cover to move upwards along the side wall of the thermal insulation cylinder, and controlling the temperature difference between the temperature of the center of the top end of the crucible and the temperature of the edge of the top end of the crucible to be reduced to T2, so that the silicon carbide raw material is conveyed to the seed crystal for crystal growth in a gas phase manner. By controlling the heat preservation cover to move upwards, the annular temperature field is more uniform and stable, and the radial temperature gradient is gradually and slowly reduced to delta T2, so that directional quantitative adjustment of the radial temperature gradient is realized, the radial temperature gradient at the seed crystal is gradually reduced, the difference between the minimum thickness of the center and the minimum thickness of the edge of the silicon carbide crystal is reduced, and the effective utilization rate of the silicon carbide crystal with the same weight is increased.

Owner:SICC CO LTD

Ce-Y-containing A1-Ti-N multicomponent composite coating and preparation thereof

InactiveCN101353776AReduce oxidation rateReduce in quantityVacuum evaporation coatingSputtering coatingSuperhard materialOxidation resistant

The invention pertains to the technical field of ultrahard materials and provides a Al-Ti-N multielement compound coating layers containing Ce-Y and a preparation method thereof, aiming at lowering the number and size of 'bulky grain' in a coating layer, promoting the anti-strip performance and anti-oxidation temperature of the coating layer and increasing film forming speed simultaneously. The compound coating of the invention adopts that the Ce-Y is deposited at least one of coating layers of Ti-N and Al-Ti-N. Simultaneously, the preparation method of the invention adopts the technical proposal that Ti target containing 0.5 percent to 3 percent of the Ce-Y by weight percentage and Ti-Al target with atomic ratio of 1: 2 or 1: 3 are vaporized and ionized, and gas of N2 is conveyed to a vacuum chamber for carrying out sedimentation of the TiN coating layers and the Al-Ti-N coating layers both containing Ce-Y. The method of the invention greatly enhances the stiffness, the abrasive resistance and the high-temperature oxidation resistance of workpieces and obviously prolongs the service life and leads the Al-Ti-N multielement compound coating layers to be applicable to the processing fields, such as cutting, dry machining and the like, with high accuracy and high speed.

Owner:CHONGYI ZHANGYUAN TUNGSTEN +1

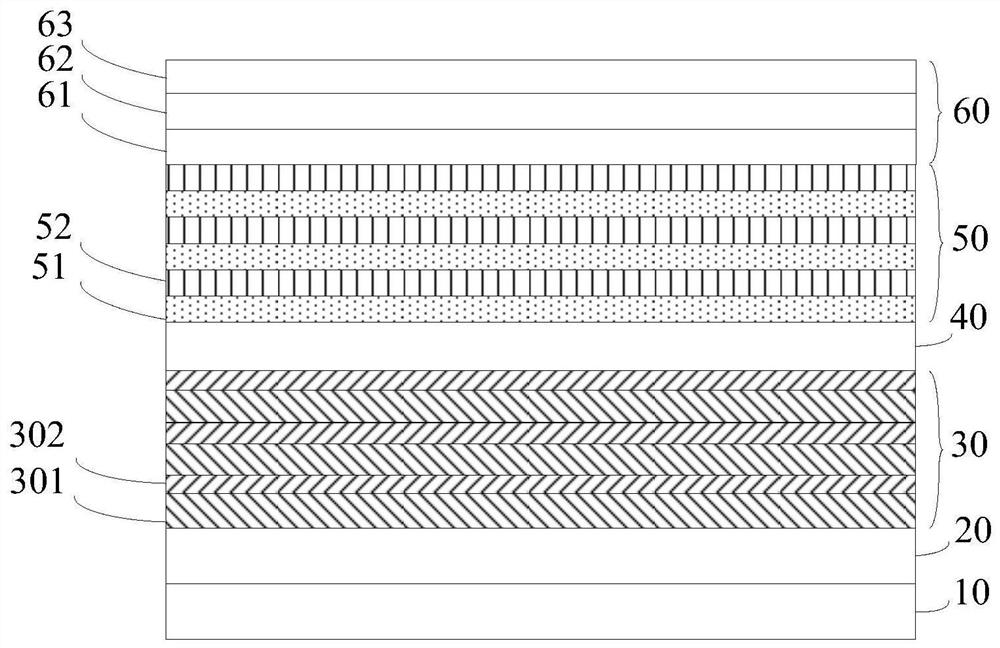

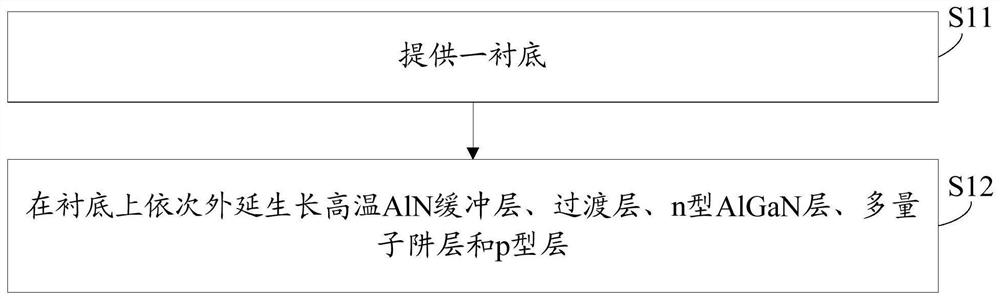

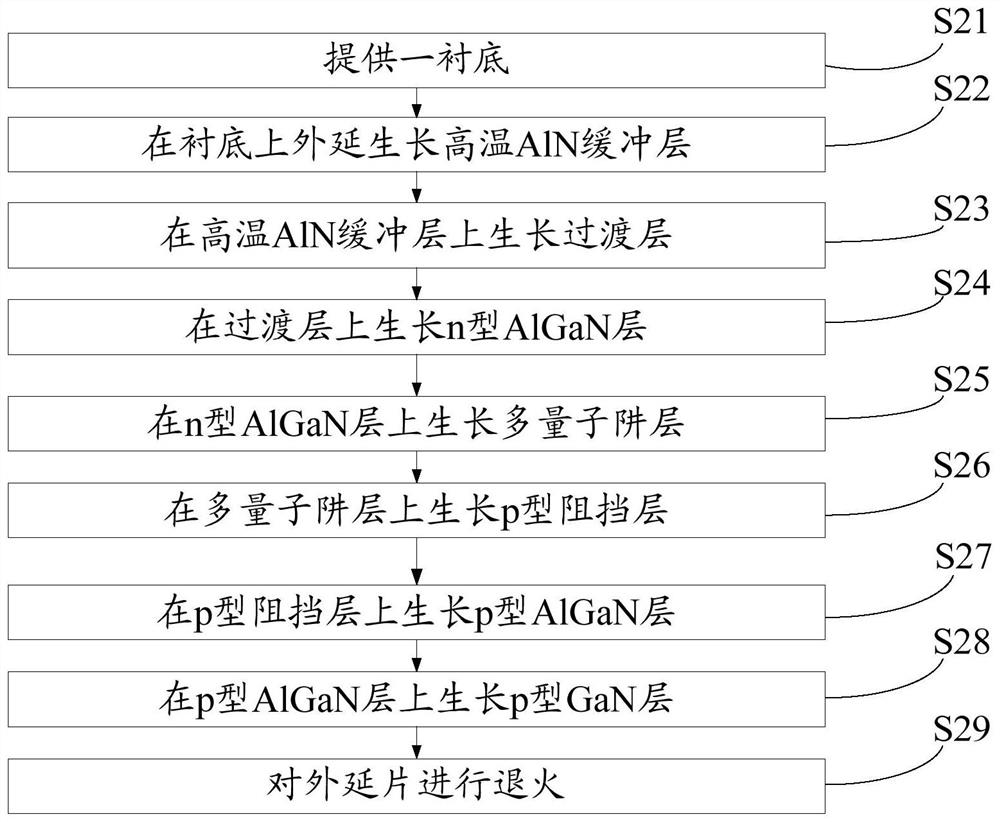

Epitaxial wafer of light emitting diode and preparation method thereof

The invention provides an epitaxial wafer of a light emitting diode and a preparation method thereof, and belongs to the technical field of photoelectron manufacturing. The preparation method comprises the following steps of: providing a substrate; and sequentially and epitaxially growing a high-temperature AlN buffer layer, a transition layer, an n-type AlGaN layer, a multi-quantum well layer and a p-type layer on the substrate, wherein the transition layer is of a periodic structure, the periodic structure comprises AlN layers and AlGaN layers which are alternately stacked, and the growth pressure of each AlGaN layer is gradually reduced in the growth direction of an epitaxial wafer. The AlN layer in the transition layer can promote dislocation defect bending extending from the high-temperature AlN buffer layer and increase the dislocation annihilation probability, so that the purpose of reducing dislocation defects is achieved, the growth pressure of the first growing AlGaN layer is high, three-dimensional island-shaped growth of the AlGaN layer is promoted, and the growth pressure of the later growing AlGaN layer is low, so that the AlGaN layer is gradually transited to two-dimensional growth from three-dimensional growth, the dislocation density is reduced and the crystal quality is improved.

Owner:HC SEMITEK ZHEJIANG CO LTD

Aluminum yttrium magnesium co-diffusion powder coating diffusion agent, preparation method and coating method thereof

InactiveCN101942635BImprove plasticityHigh bonding strengthSolid state diffusion coatingYttriumAluminum coating

The invention discloses an aluminum yttrium magnesium co-diffusion powder coating diffusion agent, a preparation method and a coating method thereof. The aluminum yttrium magnesium co-diffusion powder coating diffusion agent is a composition which comprises the following components by weight percent: 5-10% of Al powder, 2-8% of Y2O3 or YCl3, 1-5% of Mg powder, 2-5% of NH4Cl and 72-90% of Al2O3. The Y2O3 is added in the diffusion agent, thereby not only refining the structure of a coating, but also producing the obvious catalytic role and improving the thickness of an aluminized coating; and the addition of Mg element in the diffusion agent can lead the color of the surface of a co-diffusion sample to change from dark blue to grey. The adoption of the diffusion agent can conveniently carryout aluminum yttrium magnesium co-diffusion coating treatment on the surface of a nickel-based high-temperature alloy, form a diffusion type anti-oxidation nickel aluminum coating containing Y and Mgelements on the surface of the nickel-based high-temperature alloy, lead an Al2O3 film to be more compact according to oxidation process, increase the anti-stripping performance of the Al2O3 film andfurther improve the anti-oxidation performance of the coating.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for preparing platinum-aluminum coating

The invention discloses a method for preparing a platinum-aluminum coating. The method comprises the following steps of (1) platinum electroplating; (2) part surface dirt clearing; (3) pre-diffusion treatment; (4) penetrating agent preparation; (5) high-temperature gas-phase aluminizing, wherein a part and an aluminizing permeating agent are subjected to heat preservation for 5-7 hours at the temperature of 1,000-1,100 DEG C for high-temperature gas-phase aluminizing to obtain an aluminized part; and (6) sand blasting cleaning to obtain the part with the platinum-aluminum coating. The platinum-aluminum coating can be applied to a turbine part of a new-generation turboprop / turboshaft engine, so that the use temperature is increased, and the service life is prolonged; and due to modificationof the Pt element, the service temperature of the coating can be increased to 1,100 DEG C, and the coating can be used for a long time at the temperature of 950 DEG C or above.

Owner:CHINA HANGFA SOUTH IND CO LTD

Method for cooperative control of microcystis aeruginosa by using chub, bighead, silver xenocypris fish and daphnia magna

ActiveCN103880192BDecrease stockReduce growth stressBiological water/sewage treatmentEutrophicationFood chain

The invention discloses a method for cooperative control of microcystis aeruginosa by using chub, bighead, silver xenocypris fish and daphnia magna, and belongs to the technical field of water treatment. The microcystis aeruginosa in water is controlled through a food chain relationship; the chub, the bighead, the silver xenocypris fish and the daphnia magna can directly eat the microcystis aeruginosa in a filtering manner; meanwhile, the chub, the bighead and the silver xenocypris fish also can intake the daphnia magna, so as to indirectly consume the microcystis aeruginosa in water; the fish, the daphnia magna and the microcystis aeruginosa form the food chain relationship. In addition, the upper, middle and lower microcystis aeruginosa and a microcystis aeruginosa resting body at the bottom can be controlled by fully utilizing the vertical spatial distribution difference of the three fishes in the water, the content of the microcystis aeruginosa in the water can be more effectively controlled, the eutrophication level is reduced, the balance of an ecological system of the water is facilitated, and meanwhile, certain economic value can be obtained by catching the chub, the bighead, the silver xenocypris fish. The method has the advantages of low cost, no secondary pollution and the like, and is simple and feasible.

Owner:NANJING INST OF ENVIRONMENTAL SCI MINIST OF ECOLOGY & ENVIRONMENT OF THE PEOPLES REPUBLIC OF CHINA

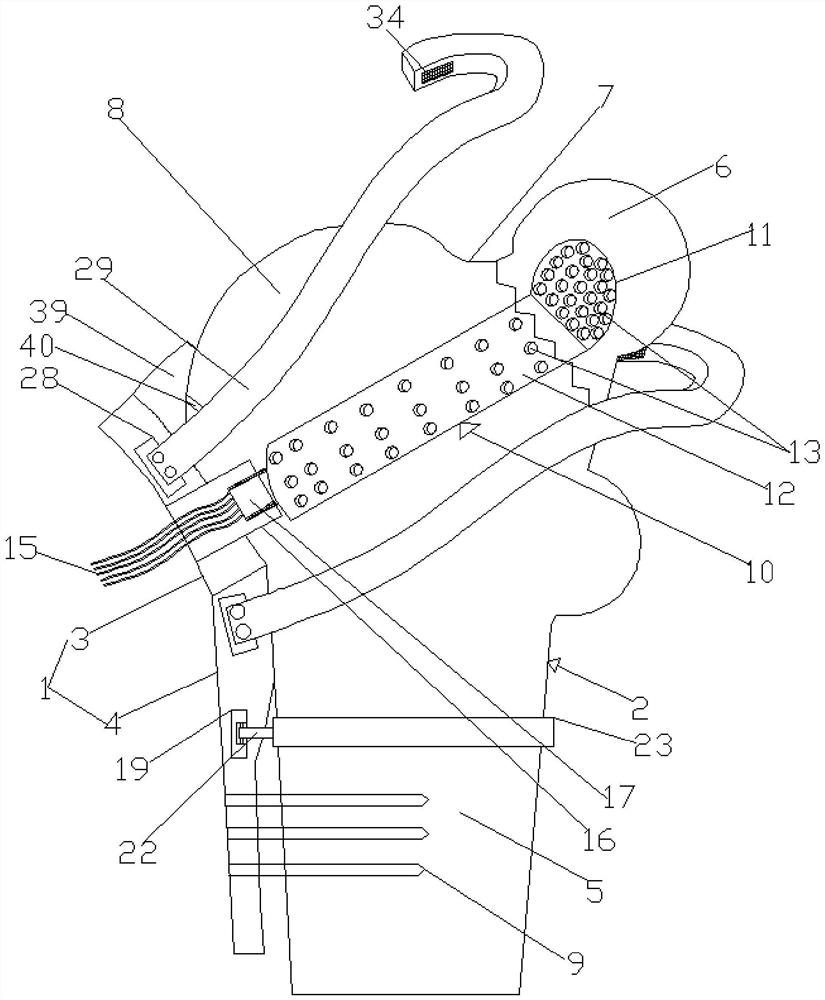

Bone fracture plate fixing device conforming to bone healing process

PendingCN114366270AImprove targetingReduce growth stressMedical devicesTherapeutic coolingFemoral boneBiomedical engineering

The bone fracture plate fixing device comprises a bone fracture plate, a thighbone and a supporting device, the bone fracture plate comprises a bone fracture plate upper portion and a bone fracture plate lower portion, the bone fracture plate upper portion is obliquely arranged at the upper end of the bone fracture plate lower portion outwards, and the bone fracture plate lower portion is obliquely arranged at the lower end of the bone fracture plate lower portion outwards. The bone fracture plate upper part and the bone fracture plate lower part are detachably connected, the femur comprises a femoral shaft, a femur head, a femoral neck and greater trochanter, a fixing screw is inserted into the bone fracture plate lower part, and the fixing screw is inserted into the femoral shaft. The knee joint self-healing device has the advantages that the containing bag makes contact with the body, then the heating wire works for heating, blood circulation can be promoted through heating, extravasated blood is prevented from being generated at the injured position, self-healing of the knee joint of a patient and recovery of the self-healing function are accelerated, the medicine bag is placed in the containing bag, generated heat is most used for the medicine bag, traditional Chinese medicine in the medicine bag is rapidly volatilized, and the effect is achieved. The cold at the painful part can be removed, so that the effect of relieving the pains is more obvious.

Owner:孔德贵

A kind of growth method of high-quality aluminum nitride single crystal

ActiveCN107955970BRelieve growth stressReduce growth stressPolycrystalline material growthFrom condensed vaporsAl powderSingle crystal

The invention discloses a method for growing a high-quality aluminum nitride single crystal. In the method, the initial deposition layer adopts a large aluminum nitride / silicon carbide mixed filler mode, and then high-purity aluminum nitride powder is used, and the temperature changes during the growth process. The aluminum nitride filler layer in the crucible is from bottom to top. The first layer is the aluminum nitride powder layer, the second layer is the sintered aluminum nitride particle layer, and the third layer is the particle mixture of aluminum nitride and silicon carbide. material, and the fourth layer is a source of particle mixture of aluminum nitride and silicon carbide. In the present invention, by doping silicon carbide powder in aluminum nitride powder, different silicon carbide: aluminum nitride ratios are used in different interlayers to relieve the growth stress between the silicon carbide substrate and the aluminum nitride single crystal, and to grow In the process, the process of variable temperature and pressure is adopted to control the heating and cooling speed. The source body is from top to bottom, and the silicon carbide composition gradually decreases. By adjusting the concentration of silicon carbide in the source, the silicon carbide in the aluminum nitride single crystal is adjusted. content, so as to reduce the growth stress of aluminum nitride single crystal.

Owner:BEIJING HUAJINCHUANGWEI ELECTRONICS CO LTD

A Control Method for Eliminating Mottling Defects in Medium and Heavy Plates

ActiveCN106216392BAchieve complete cleansing effectEasy descalingTemperature control deviceWork cooling devicesThick plateSand blasting

Owner:NORTHEASTERN UNIV LIAONING

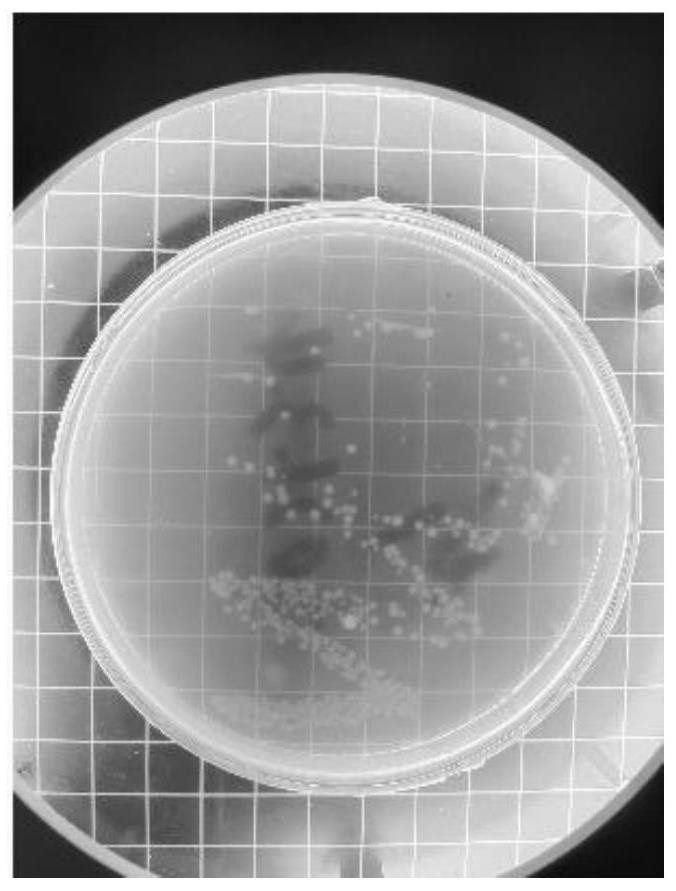

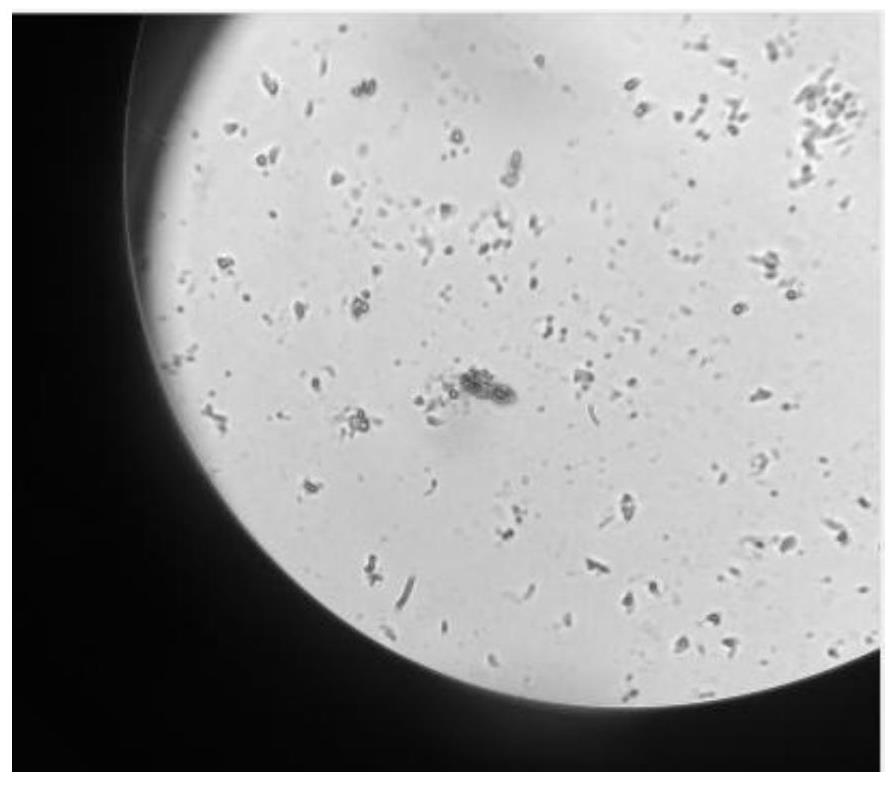

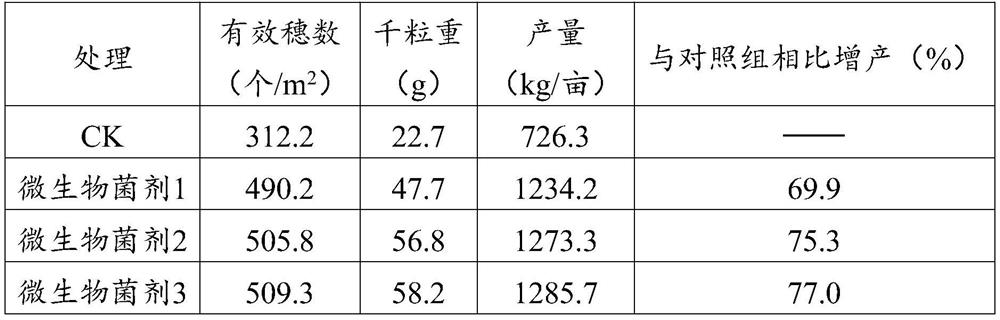

Lysobacter solani and application thereof

ActiveCN114480164AReduce growth stressReduce cadmium contentAgriculture tools and machinesBacteriaBiotechnologyMicroorganism

The invention provides lysobacter solani and application thereof, and relates to the technical field of microorganisms. The lysobacter solani provided by the invention is lysobacter solani FTB-N1, and is preserved in the General Microbiological Center of China Committee for Culture Collection of Microorganisms on September 2, 2021, and the preservation number of the lysobacter solani is CGMCC No. 23348. The bacterium has the effects of fixing nitrogen and passivating heavy metals, and can convert free nitrogen in air into nitrogen which can be absorbed by crops, so that the nitrogen utilization of the crops is improved; the method can effectively passivate exchangeable cadmium in cadmium-polluted soil, reduce the effectiveness of the exchangeable cadmium, reduce the stress effect of cadmium on crop growth, prevent cadmium from being transferred into crop plants, reduce the cadmium content of crops, and improve food safety.

Owner:FENGTIANBAO AGRI TECHOLOGY CO LTD

A kind of preparation method of low stress TIW film

ActiveCN113445005BImprove adhesionReduce thermal stressVacuum evaporation coatingSputtering coatingCrystallographyHigh density

The invention discloses a preparation method of a low-stress TiW film. The method comprises the following steps: growing a thin seed film layer at a small deposition rate and growing a main film layer under a large deposition rate on a substrate of the film to be deposited; by controlling the thickness of the growth and rate, so that the two layers of films can be optimally combined, and a low-stress TiW film can be obtained. In the invention, the TiW film is deposited on the substrate step by step, the seed film layer grown at a small deposition rate has high density, and a highly reliable interface is obtained by mutual fusion with the substrate atoms; the main film layer grown at a large deposition rate is The adhesion of the film grown on the basis of the seed layer buffer is enhanced, so that the thickness of the TiW film is stable and uniform, and the stress on the substrate is weakened and dissipated, so that the deformation amount is small, and the preparation method of the TiW film with low stress and high quality is obtained. The TiW thin film of the present invention can be prepared by common deposition methods, the obtained thin film has high stability, low film layer stress, and has good usability and popularization.

Owner:NANCHANG UNIV +1

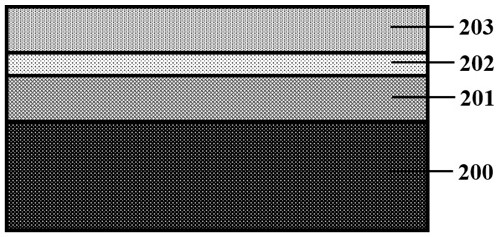

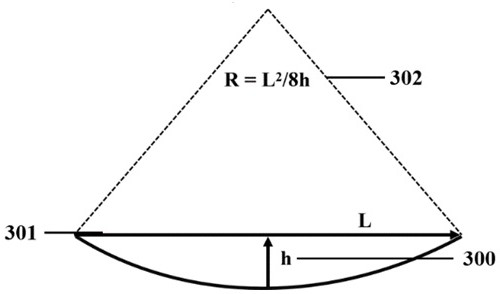

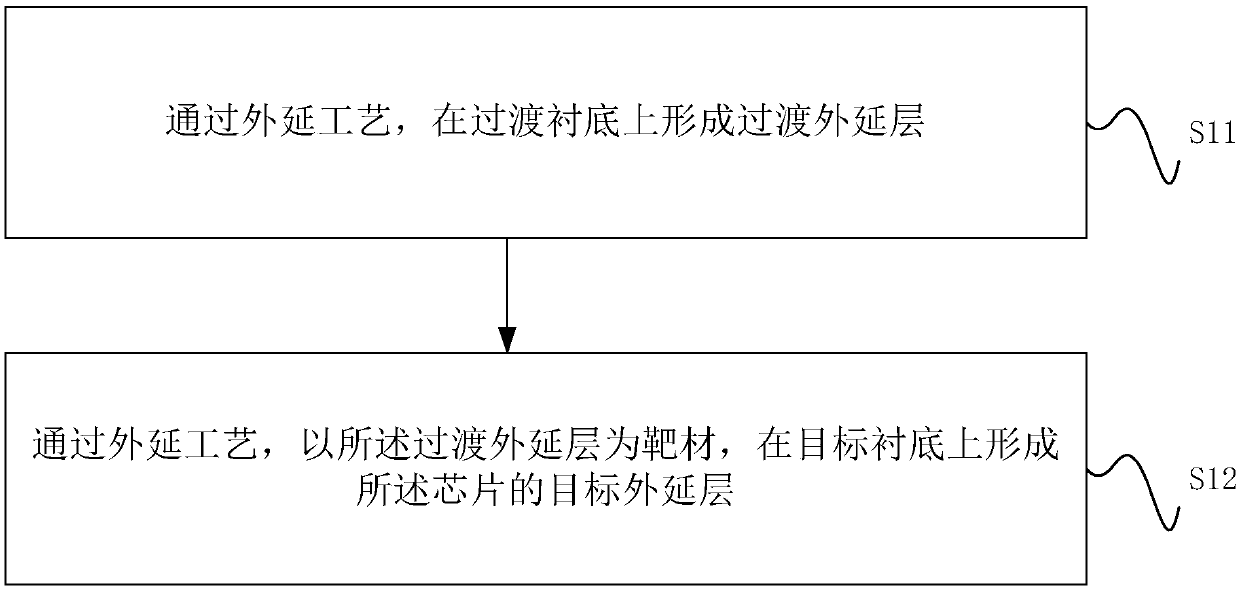

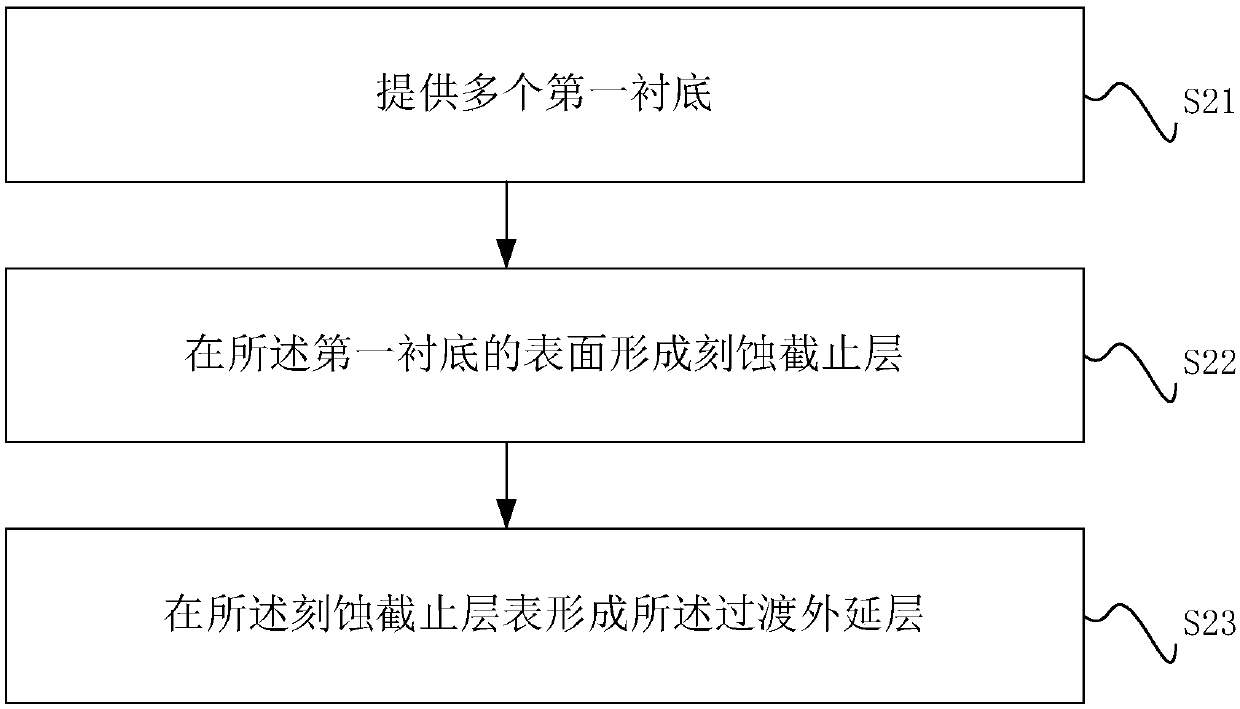

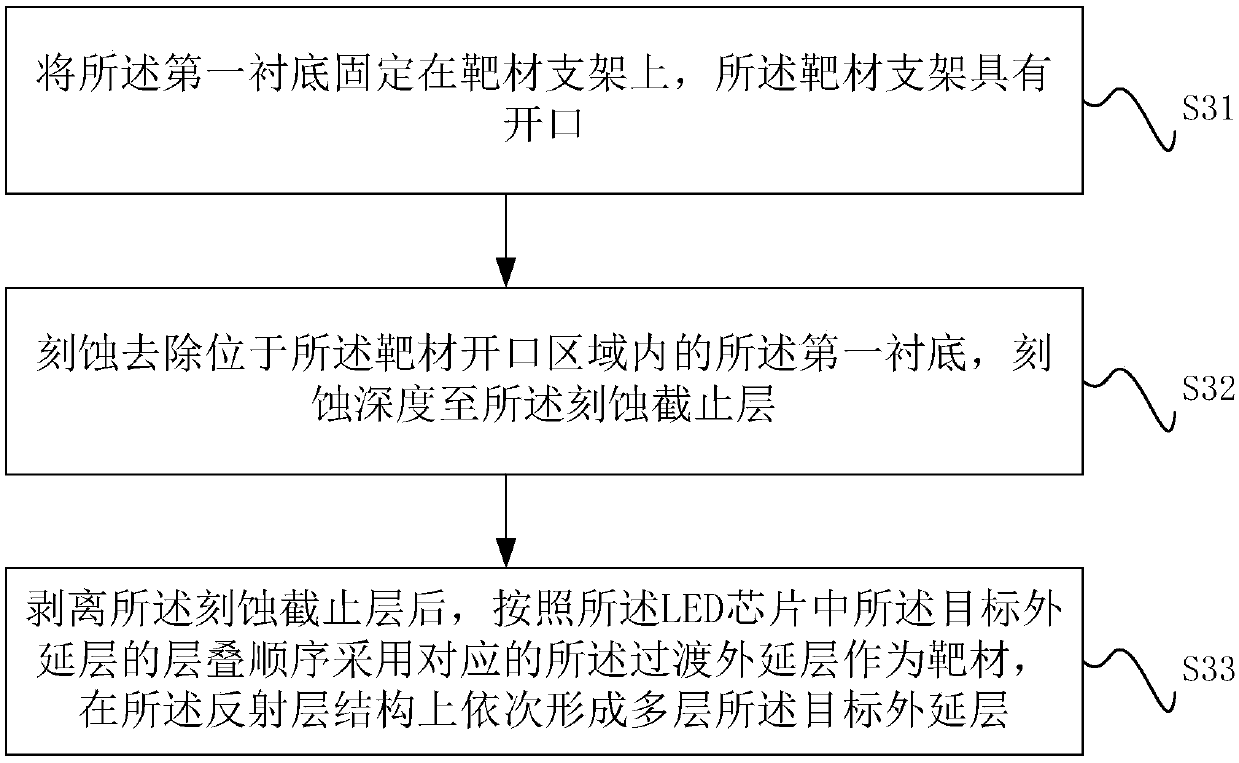

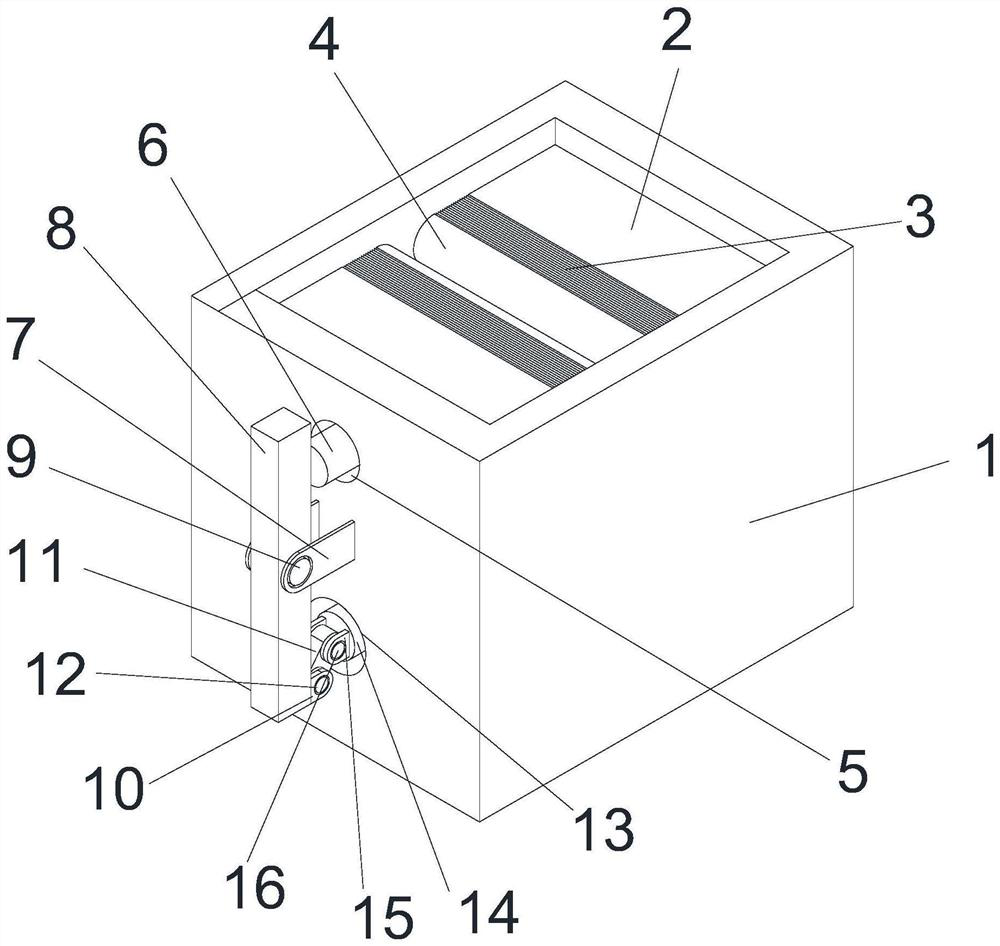

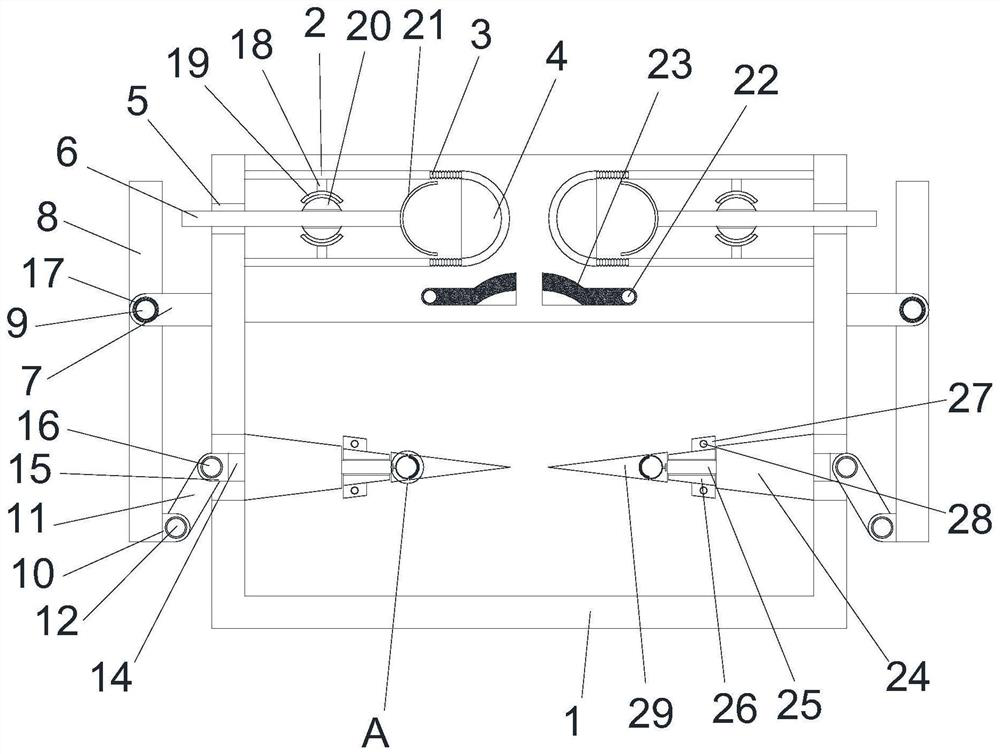

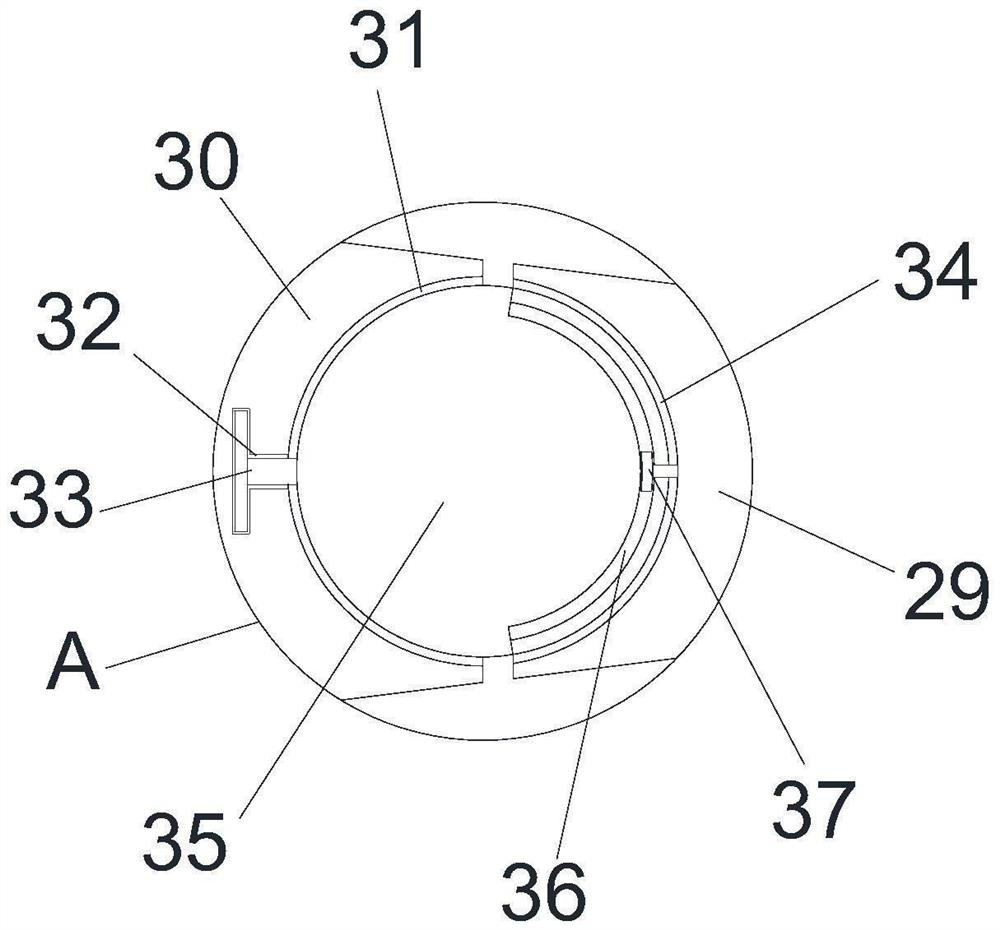

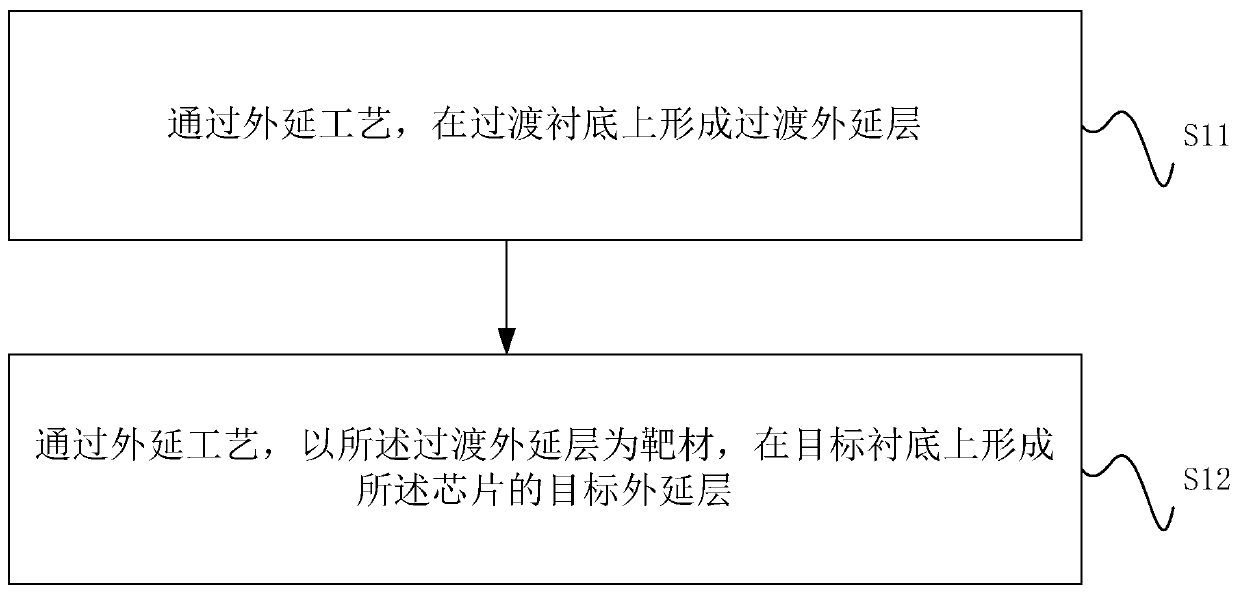

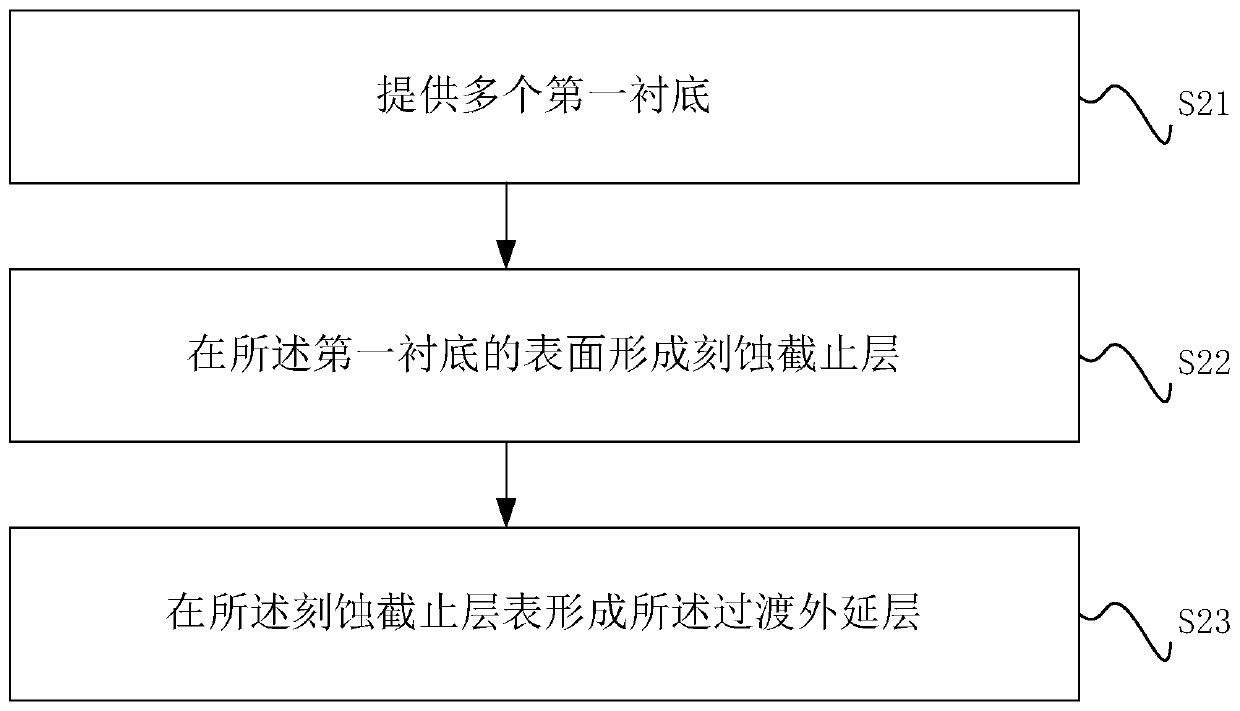

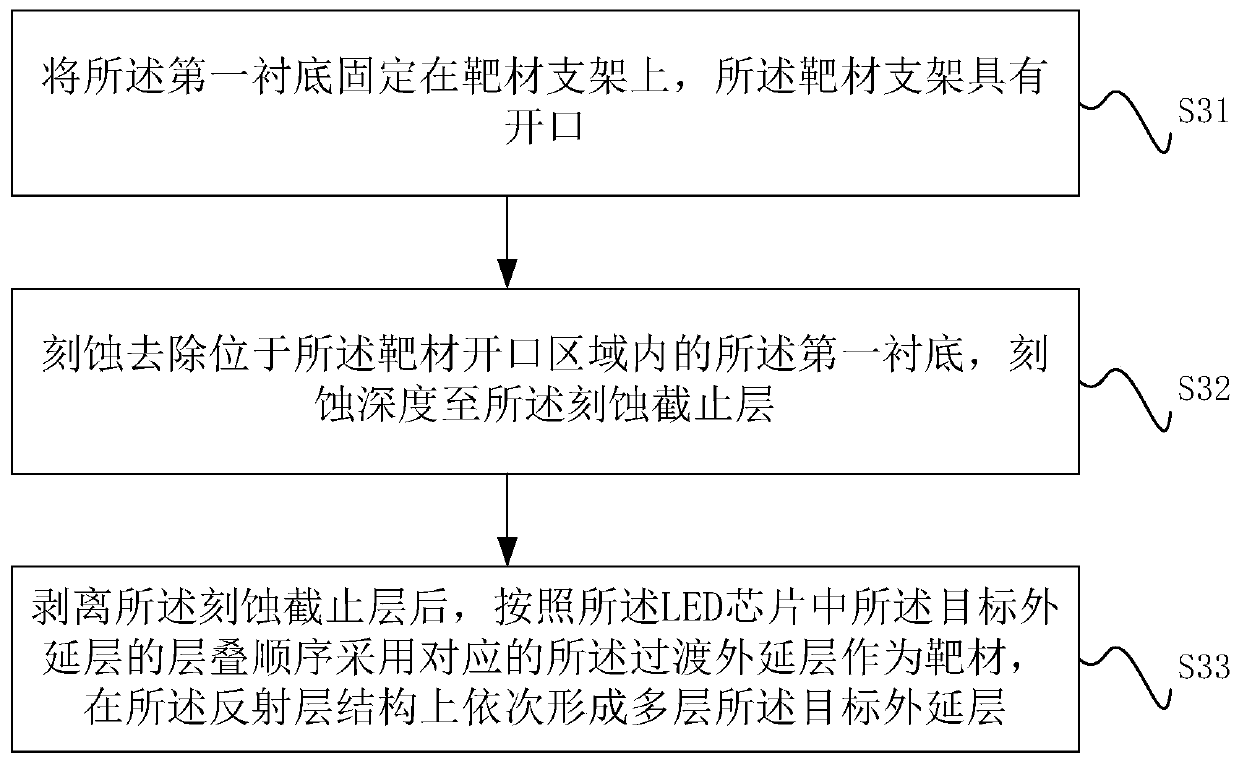

Fabrication method of chip

ActiveCN107910410AImprove reliabilityHigh thickness accuracySemiconductor devicesCrystal structureSingle crystal

The invention discloses a fabrication method of a chip. A transition substrate in lattice matching of a target epitaxial layer is employed, and a transition epitaxial layer with an integral crystal structure can be formed on a surface of the transition substrate by an epitaxial process; since the transition epitaxial layer is of the integral crystal structure, the target epitaxial layer with a single-crystal structure can be formed on a target substrate which is not in lattice matching by the epitaxial process and by taking the transition epitaxial layer as a target material; since the targetepitaxial layer is of the single-crystal structure formed by the epitaxial process, the thickness accuracy of the target epitaxial layer is relatively good, the growth stress with the target substrateis relatively small, a new substrate is not needed to be laminated so as to perform substrate transferring, the problems of relatively poor growth thickness accuracy and relatively large lamination stress and growth stress of the epitaxial layer in the prior art are solved, and the reliability of an LED chip is improved.

Owner:YANGZHOU CHANGELIGHT

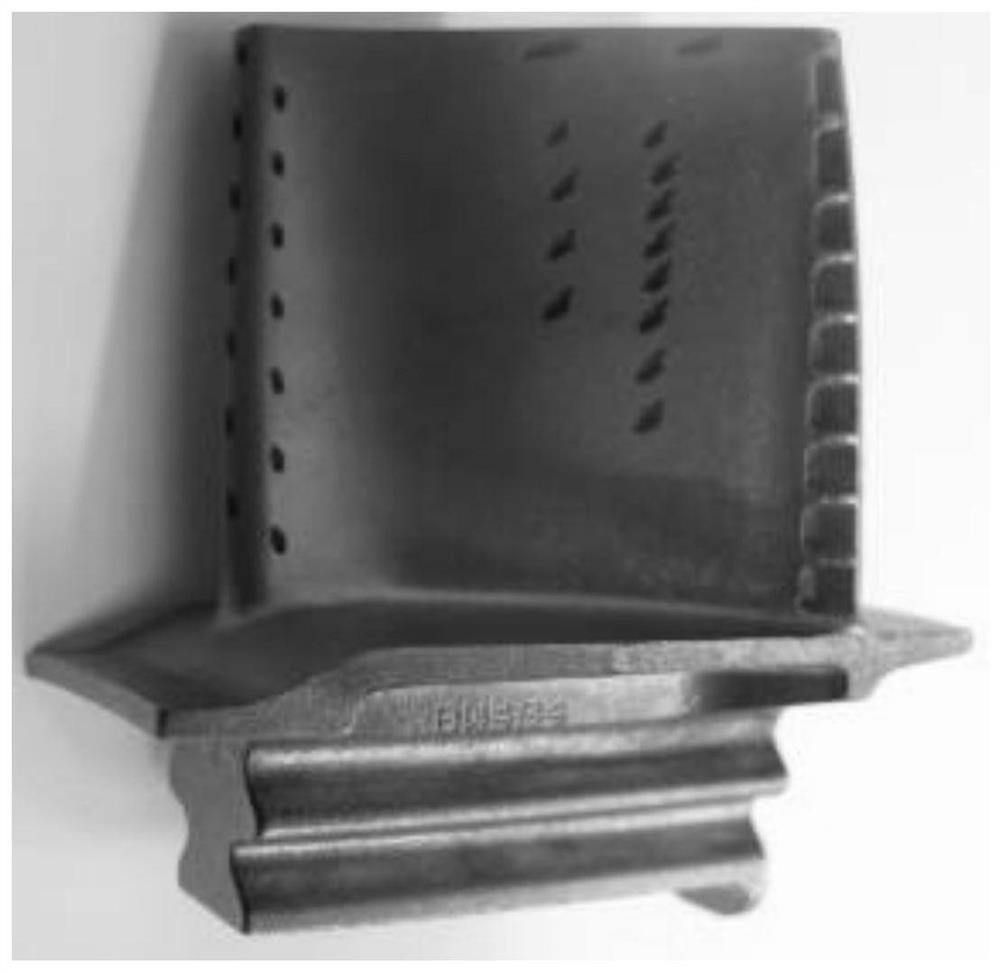

Potato planting box

InactiveCN112544283AHigh in nutrientsHigh activitySoil-working equipmentsReceptacle cultivationAgricultureEnvironmental geology

The invention discloses a potato planting box and relates to the technical field of agricultural planting. The potato planting box comprises a cultivation box, push holes are formed in a left side wall face and a right side wall face of the cultivation box, push rods are arranged in the push holes, stretching holes are formed in the left side wall face and the right side wall face of the cultivation box, base blocks are arranged in the stretching holes, the base blocks are in a cylindrical shape, and one side wall surfaces, away from auxiliary limit plates, of the base blocks are fixedly provided with loose base blocks. In the potato planting box, when soil breaking blocks just start to extrude the soil in the cultivation box, the soil breaking blocks are limited by gravity of the soil inan upper area in the cultivation box, soil breaking blocks extrude soil in the cultivation box downwards through soil breaking adjusting limiting blocks and soil breaking adjusting grooves, so that the soil at a bottom portion of an inner side of the cultivation box is compressed to form gaps, the soil on an upper portion of an interior of the cultivation box is expanded through gaps, the soil onan upper portion of the inner side of the cultivation box is loosened, and therefore, an early-stage growth pressure of potatoes is reduced.

Owner:李铁仁

A method of making a chip

ActiveCN107910410BImprove reliabilityHigh thickness accuracySemiconductor devicesCrystal structureSingle crystal

The invention discloses a fabrication method of a chip. A transition substrate in lattice matching of a target epitaxial layer is employed, and a transition epitaxial layer with an integral crystal structure can be formed on a surface of the transition substrate by an epitaxial process; since the transition epitaxial layer is of the integral crystal structure, the target epitaxial layer with a single-crystal structure can be formed on a target substrate which is not in lattice matching by the epitaxial process and by taking the transition epitaxial layer as a target material; since the targetepitaxial layer is of the single-crystal structure formed by the epitaxial process, the thickness accuracy of the target epitaxial layer is relatively good, the growth stress with the target substrateis relatively small, a new substrate is not needed to be laminated so as to perform substrate transferring, the problems of relatively poor growth thickness accuracy and relatively large lamination stress and growth stress of the epitaxial layer in the prior art are solved, and the reliability of an LED chip is improved.

Owner:YANGZHOU CHANGELIGHT

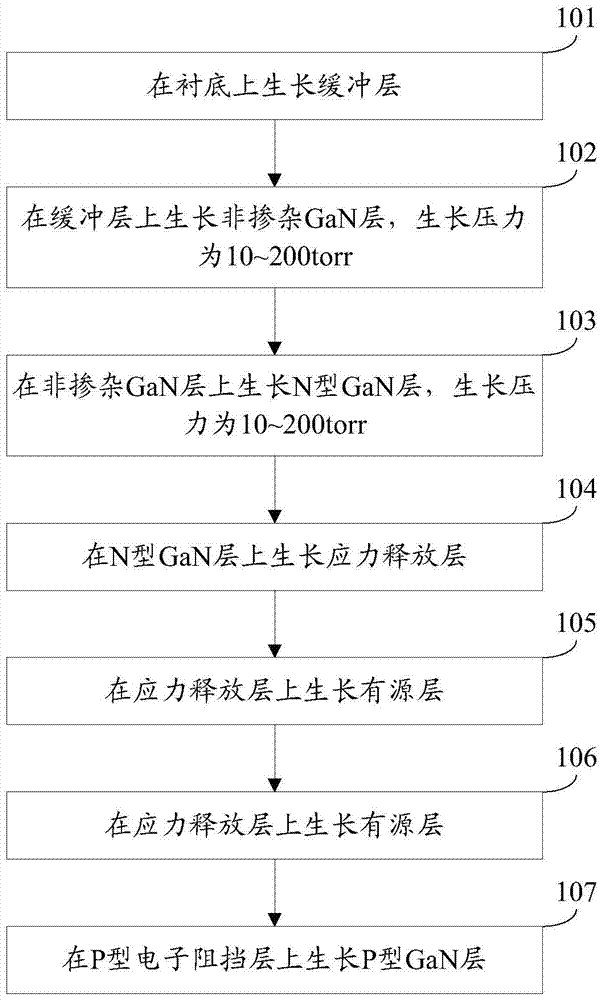

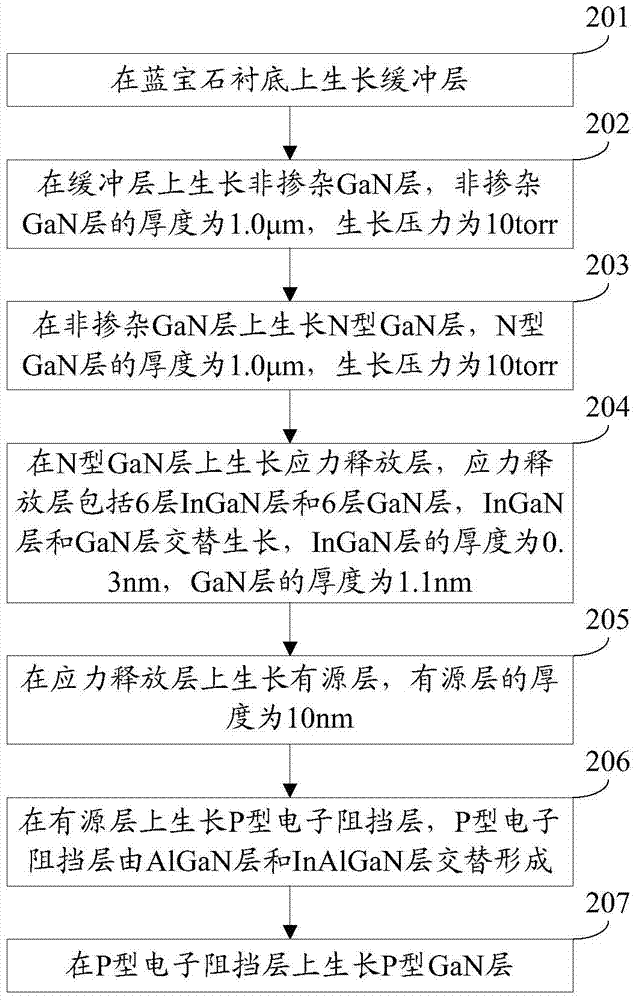

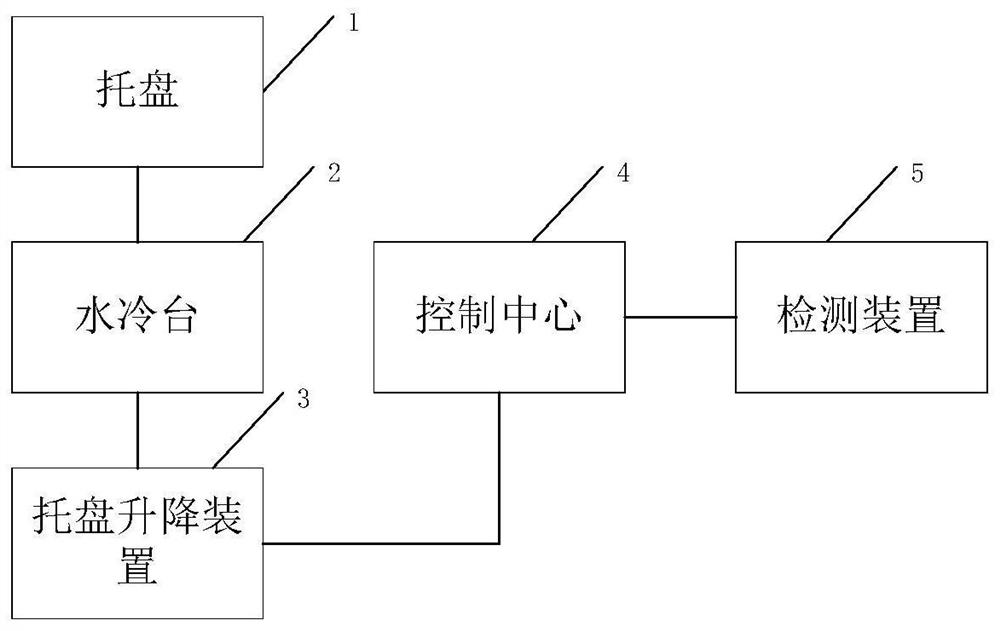

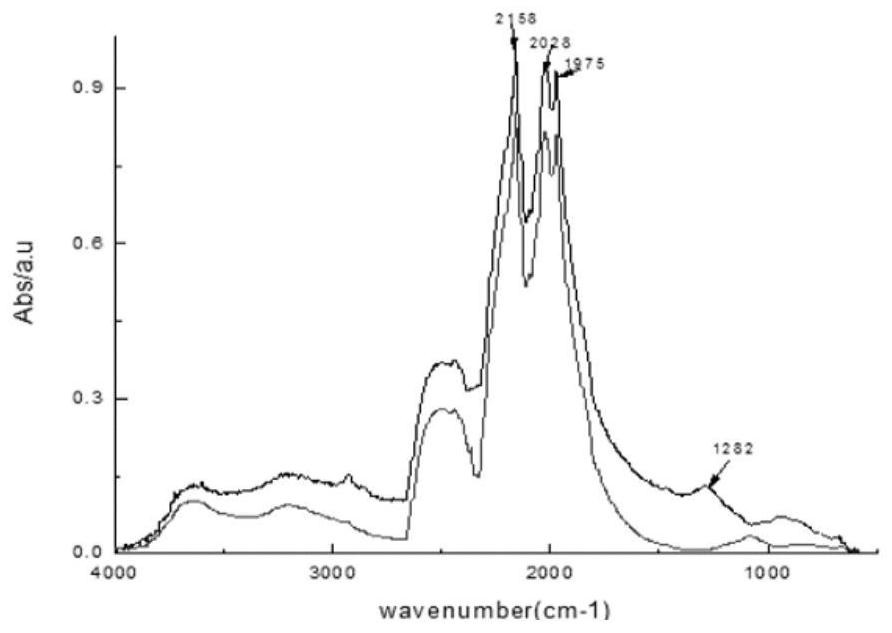

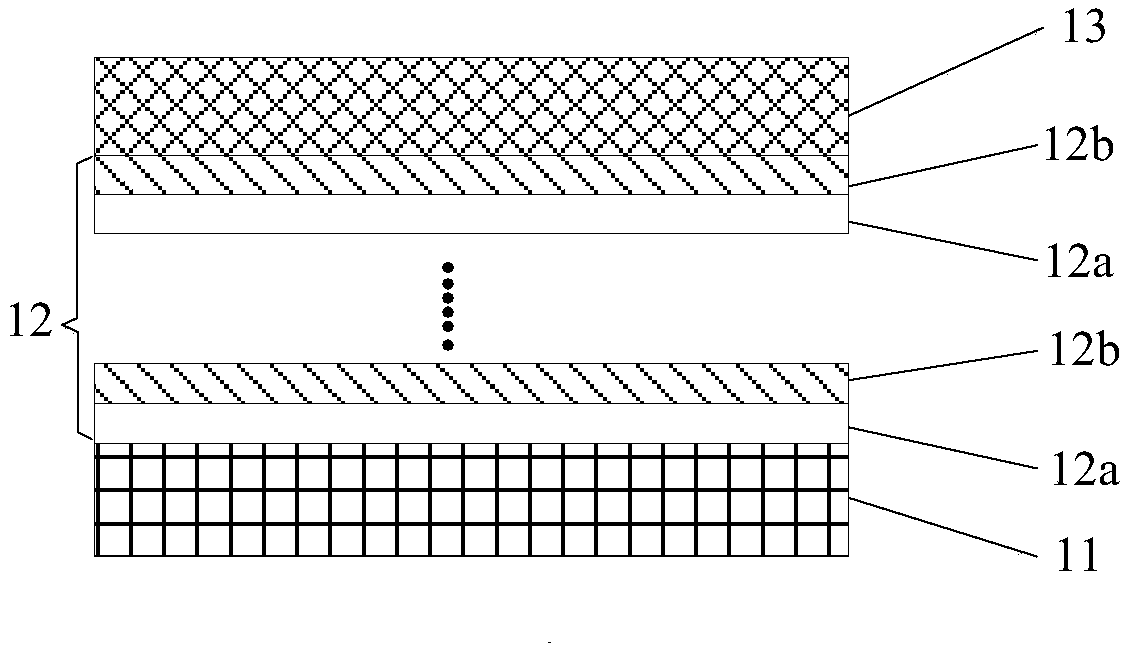

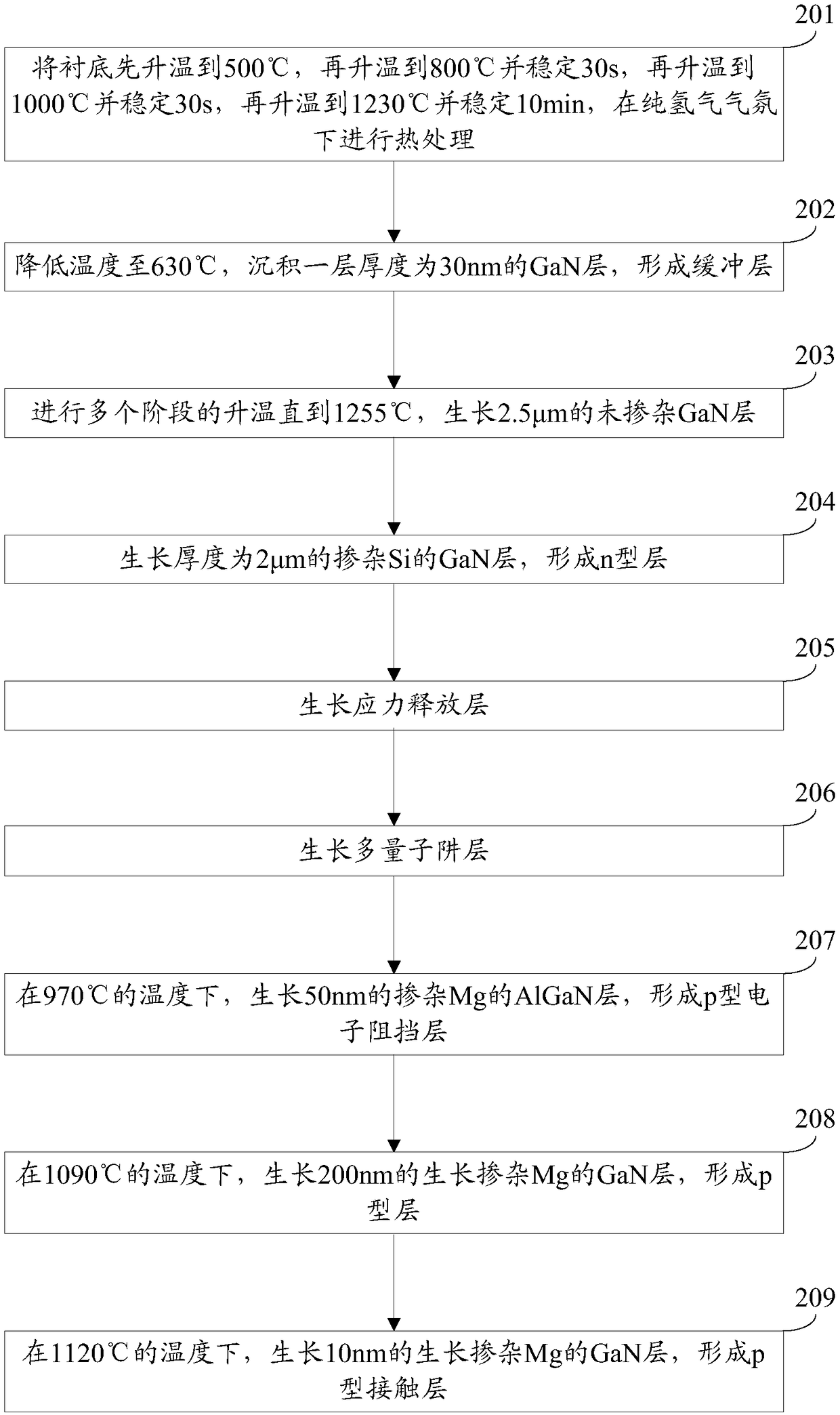

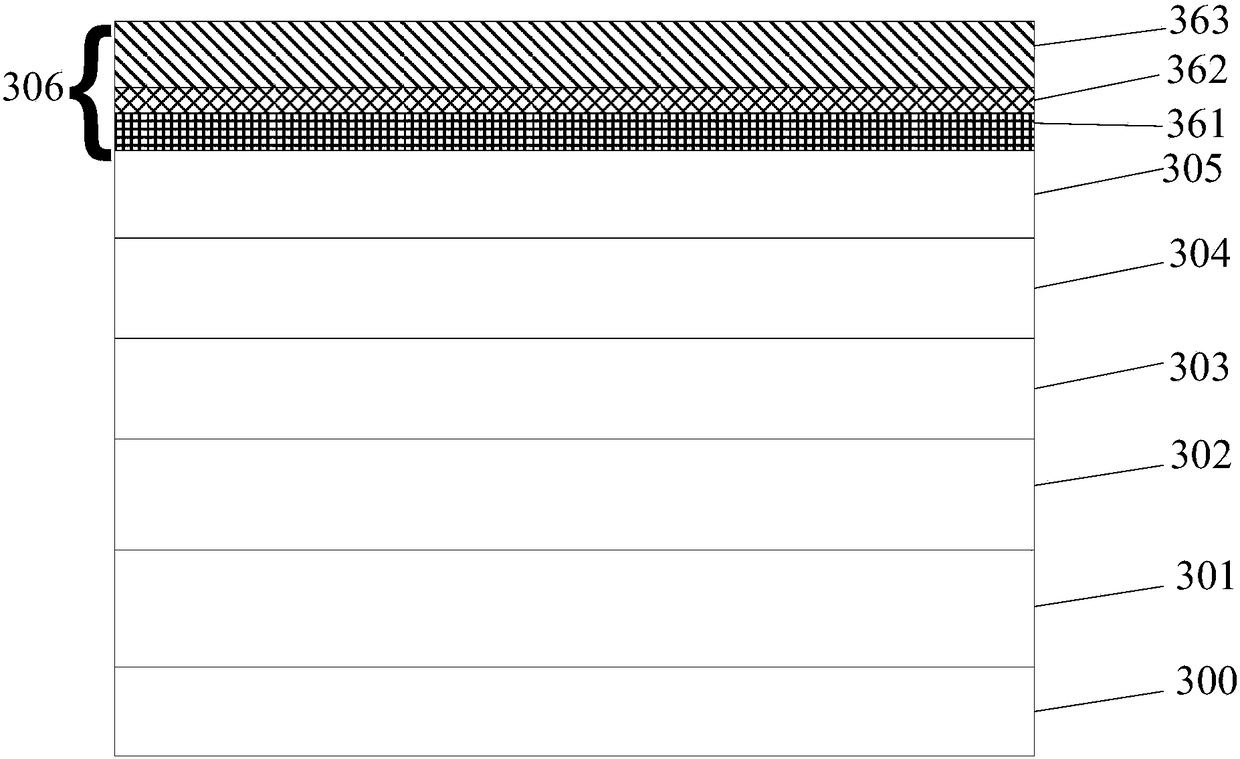

A method of manufacturing a light-emitting diode epitaxial wafer

ActiveCN104617192BReduce growth stressSmall temperature differenceSemiconductor devicesTemperature differenceElectron blocking layer

The invention discloses a manufacturing method of a light emitting diode epitaxial wafer, and belongs to the technical field of semiconductors. The manufacturing method includes: sequentially growing a buffer layer, an undoped GaN layer, an N-type GaN layer, a stress release layer, an active layer, a P-type electron barrier layer and a P-type GaN layer on a substrate, wherein the growth pressure of the undoped GaN layer and the N-type GaN layer is 10-200torr. According to the manufacturing method, the growth pressure of the undoped GaN layer and the N-type GaN layer is limited to be10-200torr, so that the growth speeds of the undoped GaN layer and the N-type GaN layer are slow, and thereby heat can be uniformly transmitted along the growth direction of the epitaxial layer by a basal disc arranged at the bottom of the substrate, temperature difference between the upper and lower surfaces of the epitaxial wafer when the undoped GaN layer and the N-type GaN layer grow is reduced, the concave deformation of the epitaxial wafer is relieved, the temperature of the periphery of the epitaxial wafer can reach required temperature, and the quality of crystals at the periphery of the epitaxial wafer is improved.

Owner:HC SEMITEK SUZHOU

A diamond growth tray and system

ActiveCN110714225BStable growth environmentQuality improvementPolycrystalline material growthFrom chemically reactive gasesEngineeringSeed crystal

Owner:CHANGSHA ADVANCED MATERIALS IND RES INST CO LTD

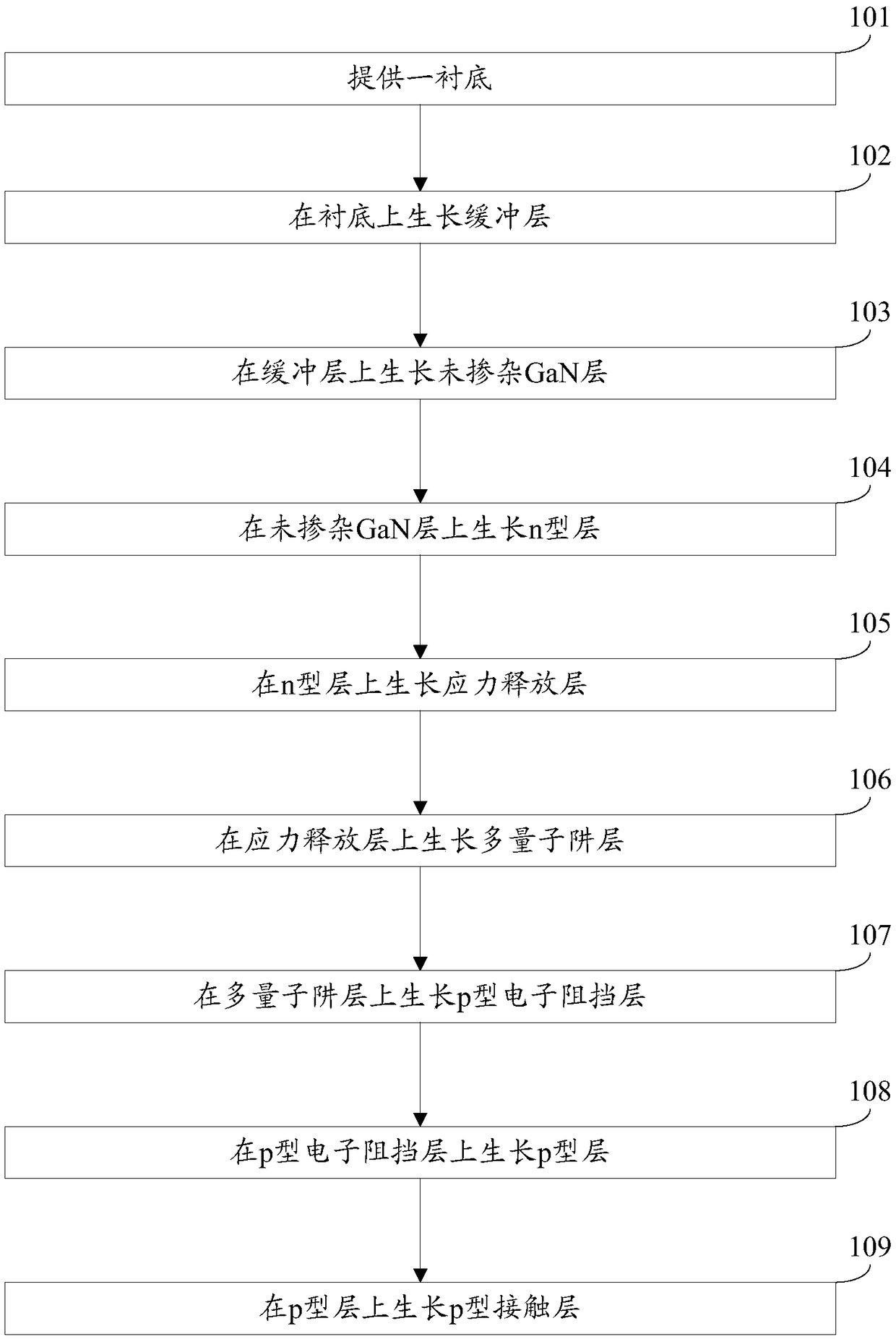

A kind of growth method of Gan-based light-emitting diode epitaxial wafer

ActiveCN106711295BReduce growth stressSmall temperature differenceSemiconductor devicesQuantum wellContact layer

The invention discloses a growing method of a GaN-based light emitting diode epitaxial wafer, and the growing method belongs to the technical field of semiconductors. The growing method comprises the steps of: providing a substrate; and successively growing a buffer layer, an un-doped GaN layer, an n-type layer, a stress release layer, a multi-quantum well layer, a p-type electron blocking layer, a p-type layer and a p-type contact layer on the substrate, wherein the stress release layer comprises a first sub-layer, a second sub-layer and a third sub-layer which are successively grown on the n-type layer, the first sub-layer is an In<x>Ga<1-x>N layer doped with Si, 0<=x<1, the second sub-layer comprises In<y>Ga<1-y>N layers and GaN layers which are laminated alternately, 0<y<1, the third sub-layer is an In<z>Ga<1-z>N layer doped with Si, 0<=z<1, the growth pressure of the second sub-layer is lower than that of the first sub-layer, and the growth pressure of the third sub-layer is lower than that of the first sub-layer. The growing method of the GaN-based light emitting diode epitaxial wafer improves the warping degree and enhances the crystal quality and the photoelectric performance.

Owner:HC SEMITEK ZHEJIANG CO LTD

Method and device for growing silicon carbide crystal by pvt method

ActiveCN112981532BReduce the difference in minimum thicknessImprove effective utilizationPolycrystalline material growthFrom condensed vaporsCarbide siliconCrucible

Owner:SICC CO LTD

Multi-ion doped large-size lanthanum bromide single crystal scintillator and preparation method thereof

ActiveCN105154973BReduce growth stressImprove yieldPolycrystalline material growthFrom frozen solutionsOptical propertyScintillation crystals

The invention relates to the field of scintillation crystal materials, a multi-ion doped large-size lanthanum bromide single crystal scintillator, characterized in that: the general chemical formula of the single crystal scintillator is (CexSryHfy)La(1-x-2y )Br3, where 0.001

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Double-layer thermal barrier/high temperature low infrared emissivity integrated coating, coated metal composite material and preparation method thereof

ActiveCN110055486BGood oxygen barrier effectStop the spreadMolten spray coatingSuperimposed coating processEmissivityThermal insulation

The invention discloses a double-layer thermal barrier / high-temperature low-infrared emissivity integrated coating. The coating is a multi-layer superimposed structure, and the multi-layer superimposed structure sequentially includes a metal bonding layer and a thermal barrier ceramic from the inside to the outside. Inner layer, thermal barrier ceramic outer layer and low infrared emissivity layer, the thermal barrier ceramic inner layer is La 2 Zr 2 o 7 ‑8YSZ mixture layer, where La 2 Zr 2 o 7 The powder accounts for no more than 45% of the mass fraction of the mixture, the outer layer of the thermal barrier ceramic is a rare earth zirconate layer, and the low infrared emissivity layer is a Bi 2 o 3 ‑Al 2 o 3 -ZrO 2 ‑CaO‑SiO 2 Department of glass coating. The invention also provides a coated metal composite material and a preparation method thereof. The integrated coating of the invention has the characteristics of heat insulation performance, low infrared emissivity at high temperature, excellent thermal shock resistance and the like.

Owner:NAT UNIV OF DEFENSE TECH

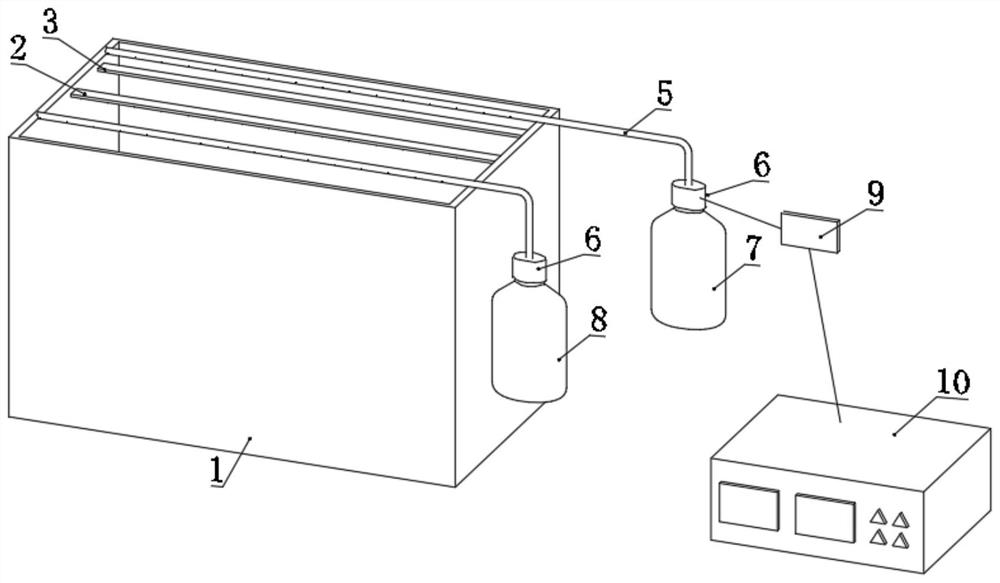

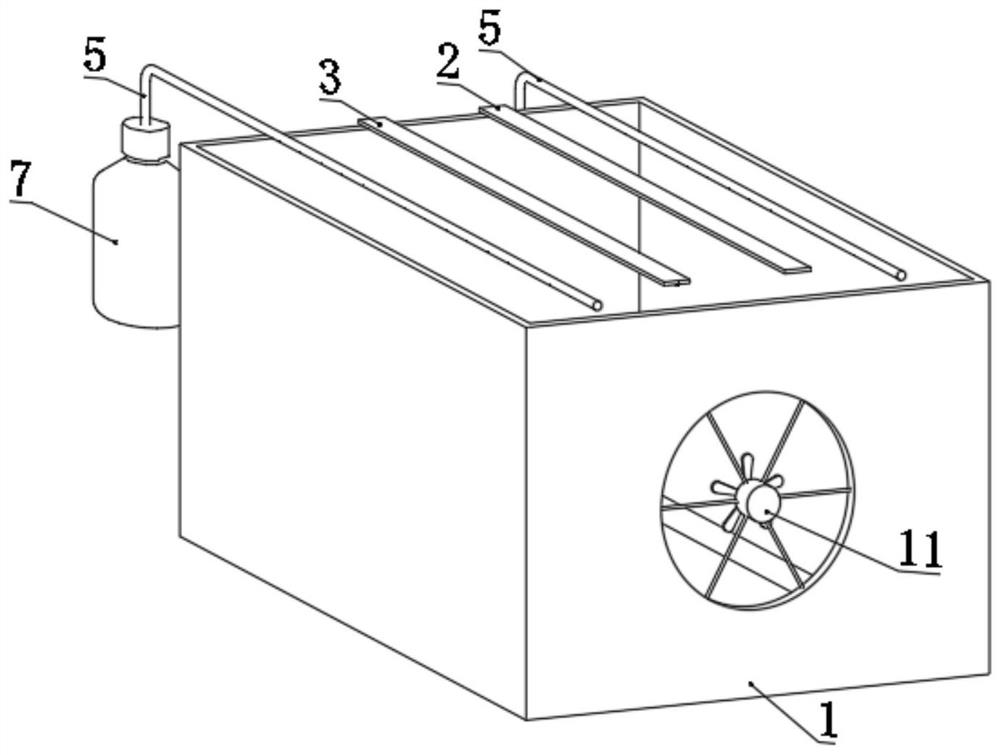

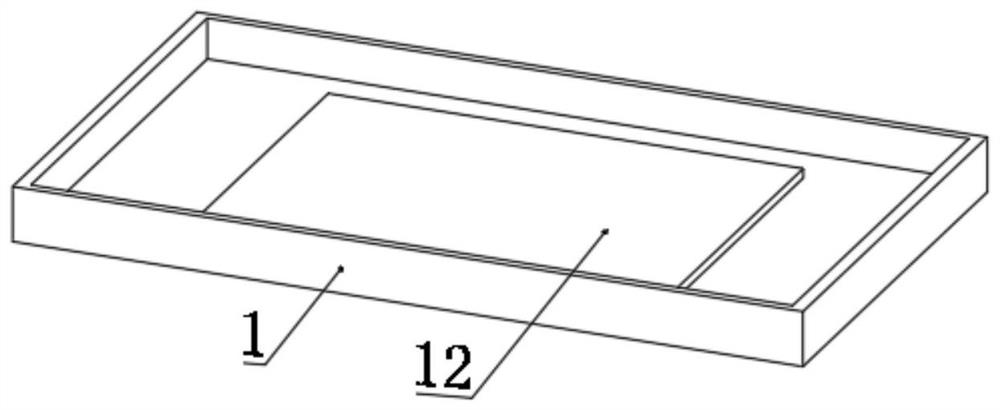

Novel multifunctional culture box

PendingCN112970573AImprove fertilizer use efficiencyReduce growth stressClimate change adaptationSaving energy measuresPhysicsEngineering

The invention discloses a novel multifunctional culture box, and belongs to the field of culture boxes. The novel multifunctional culture box comprises a box body, the upper part of the box body is provided with a first lamp body and a second lamp body, the first lamp body is a full-spectrum LED lamp tube, the second lamp body is a red-blue double-color LED lamp strip, two aerial fog conveying pipes with holes are mounted at the upper part of the box body, the two aerial fog conveying pipes with holes extend into the box body, a plurality of spraying holes are formed in the lower surfaces of the aerial fog conveying pipes with holes, the end, away from the box body, of one aerial fog conveying pipe with holes is installed on a first atomizing bottle through a connecting cover, and the end, away from the box body, of the other aerial fog conveying pipe with holes is installed on a second atomizing bottle through a connecting cover. The culture box can regulate and control environmental conditions such as temperature, humidity, illumination and nutrients, better meets the requirements of different plants for the environment in different growth and development stages, can be used for accelerating germination, seedling culture, cultivation and the like, can also be used for semi-open type cultivation, and is diversified in function and wide in application.

Owner:陈启峰

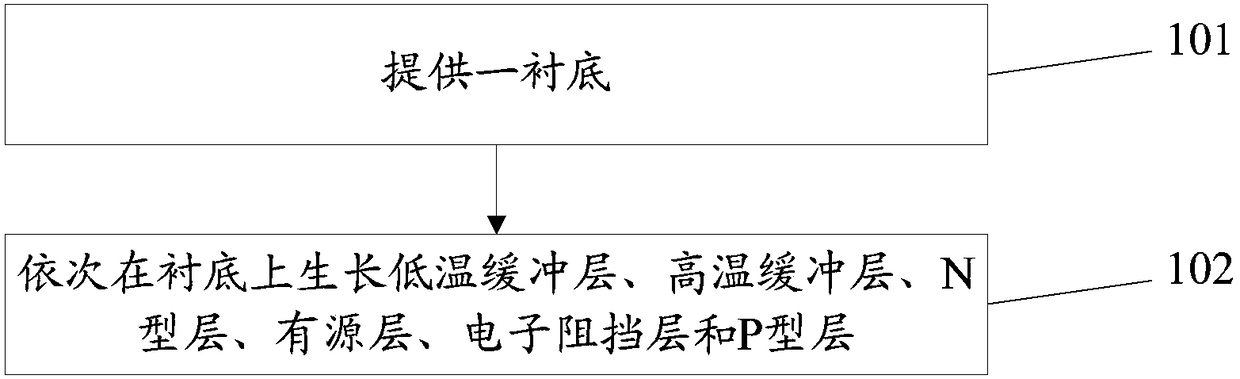

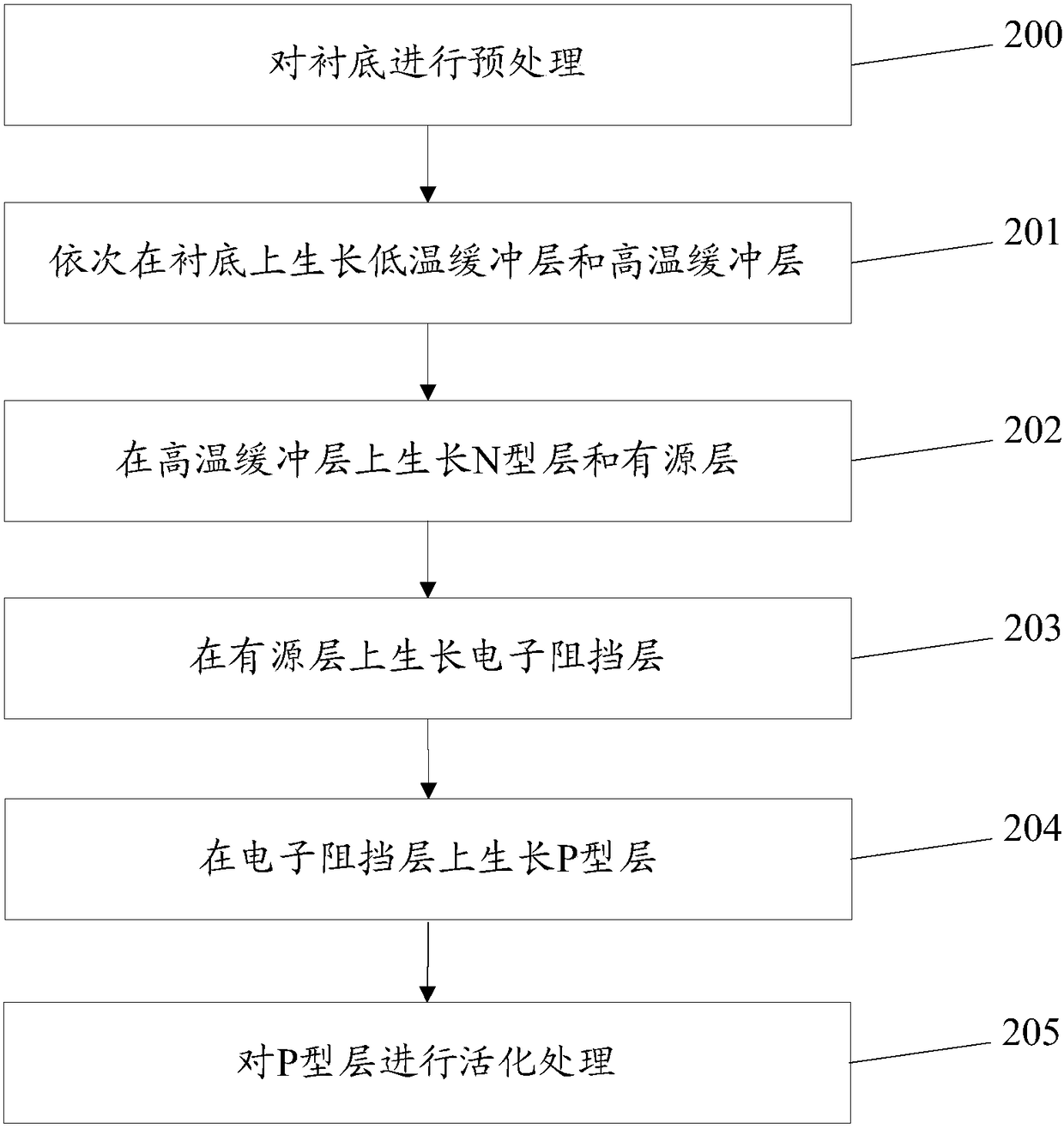

Manufacturing method of light-emitting diode epitaxial wafer and light-emitting diode epitaxial wafer

ActiveCN105679893BSlow growth ratePromote growthSemiconductor devicesElectron blocking layerActive layer

The invention discloses a manufacturing method of a light-emitting diode epitaxial wafer and the light-emitting diode epitaxial wafer, and belongs to the field of light-emitting diodes. The method comprises the steps as follows: a substrate is provided; and a low-temperature buffer layer, a high-temperature buffer layer, an N-type layer, an active layer, an electron blocking layer and a P-type layer sequentially grow on the substrate. The manufacturing method is characterized in that the P-type layer grows as follows: a first GaN sub-layer with a first thickness and a first Mg doping concentration grows on the electron blocking layer at a first growth temperature, a first growth pressure and a first growth rate; a second GaN sub-layer with a second thickness and a second Mg doping concentration grows on the first GaN sub-layer at a second growth temperature, a second growth pressure and a second growth rate; and a third GaN sub-layer with a third thickness and a third Mg doping concentration grows on the second GaN sub-layer at a third growth temperature, a third growth pressure and a third growth rate.

Owner:HC SEMITEK SUZHOU

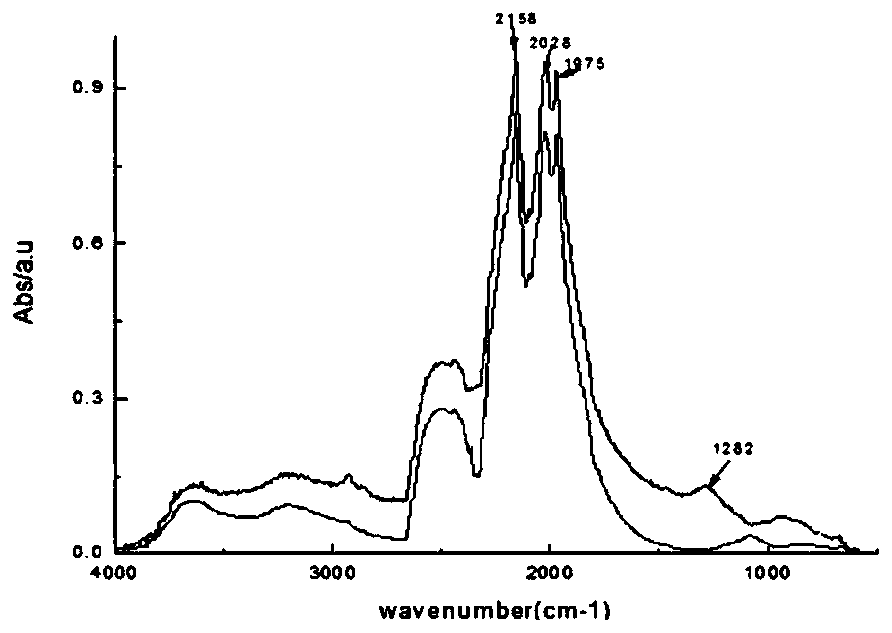

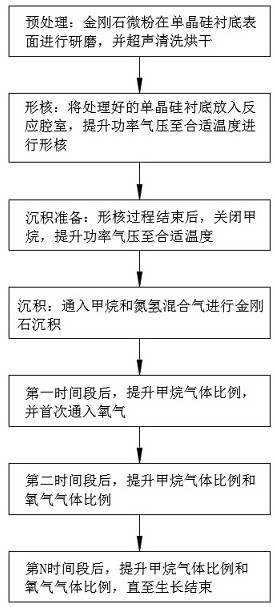

Growth method for controlling grain size of polycrystalline diamond by microwave CVD method

InactiveCN113699588AIncrease growth rateQuality improvementPolycrystalline material growthSingle crystal growth detailsPhysical chemistryPolycrystalline diamond

The invention relates to a growth method for controlling the grain size of polycrystalline diamond by a microwave CVD method, which comprises the following steps: in a deposition process, setting N groups of time periods, and continuously introducing mixed gases with different volume ratios into each group of time periods after the first group of time periods; along with the increase of the time periods, enabling the volume ratio of each gas in the mixed gas introduced after the N group of time periods to be higher than the volume ratio of the corresponding gas introduced after the (N-1) group of time periods; and after the N group of time periods, continuously introducing the mixed gas based on the volume ratio of each gas in the mixed gas until the growth is finished. According to the method, the carbon source concentration and the oxygen concentration are gradually increased in different time periods, the nucleation rate of the diamond is stepwise increased to control the grain size of the diamond, and therefore the quality of a diamond film is improved; meanwhile, the growth rate of the diamond film can be increased step by step, and lattice defects of the epitaxial layer are reduced, so that the growth stress can be reduced, and the complete crack-free diamond film can be obtained.

Owner:天津本钻科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com